admin1

June 21, 2025

Wheel Tire Weight Explained for Safer and Smoother Rides

Wheel tire weight plays a crucial role in your driving safety and how your car feels on the road. When you use the right wheel weights and balance your tires, you get a smoother ride and better control. Studies show that lighter and well-distributed wheel tire weight can lower whole-body vibration by up to 10% and reduce shock by 50%, making every trip more comfortable. Proper tire weight distribution also improves lateral stability, lowering the risk of rollover and helping you stay safe, especially with new tires. The importance of wheel weights goes beyond comfort—they keep your vehicle stable and responsive in every situation.

How Wheel Tire Weight Affects Safety and Ride Quality

The Role of Wheel Balancing in Tires

Wheel balancing plays a key role in how your car handles and how safe your ride feels. When you balance your wheels, you add small wheel weights to the rim. These weights help spread the weight of the tire and wheel evenly around the whole circle. You use a tire balancing machine to spin the wheel and find any heavy or light spots. The machine tells you where to put the wheel balancing weights.

When you have proper wheel balancing, your tires roll smoothly. You do not feel shaking in the steering wheel or floor. Your tires wear down evenly, so they last longer. You also get improved fuel economy because your tires do not drag or bounce. Wheel balancing reduces stress on your car’s suspension, which helps your car parts last longer. You should balance your wheels every 5,000 to 6,000 miles, after you get new tires, or if you feel vibrations while driving.

Tip: Regular tire balancing keeps your ride smooth and helps you avoid costly repairs.

Common Problems from Improper Wheel Tire Weight

If you do not use proper wheel weight or skip balancing, you can face many problems. Here are some common issues:

- Vibrations in the steering wheel, seat, or floorboard

- Uneven tire wear, which means you need new tires sooner

- Noises from the tires or wheels while driving

- Poor handling, making it harder to steer or stop

- Extra strain on your car’s suspension and axles

- Reduced traction, especially on wet or rough roads

In commercial vehicles, improper wheel tire weight can cause even more trouble. You might see increased tire wear, vehicle instability, and mechanical strain. Overloading or uneven cargo can make handling worse and increase the risk of rollovers. Underinflated tires can also lead to heat buildup and faster tire damage.

Safety Risks and Ride Quality Concerns

Wheel tire weight affects your driving safety every time you get behind the wheel. Imbalanced wheels can make your car shake, especially at higher speeds. This shaking can make it hard to control your car, especially in bad weather. You might notice your car pulling to one side or taking longer to stop. These problems can increase your risk of accidents.

Balanced wheels give you enhanced handling and stability. You get better traction and control, which helps you stay safe on the road. Proper wheel weight and wheel balancing weights also help your brakes work better, especially when roads are wet or bumpy. When you use the right wheel weights and keep your tires balanced, you protect yourself and your passengers.

Note: Professional installation and regular checks of your wheel weights and tire balancing can prevent most safety risks and keep your ride comfortable.

Types of Wheel Weights for Tires

When you want a smooth and safe ride, you need to choose the right type of wheel weights for your vehicle. Each type of wheel weight has its own features, benefits, and best uses. Let’s look at the main options you will find in the market.

Clip-On Wheel Weights

Clip-on wheel weights have been around since the 1930s. You attach them by clamping them onto the wheel’s flange, which is the lip or edge of the wheel. These wheel weights work best on steel wheels or any wheel with a clear lip. You often see them on trucks and older vehicles. Clip-on wheel weights are known for their strength and durability. They stay in place even when you drive on rough roads or in harsh weather.

Here is a quick comparison between clip-on and stick-on wheel weights:

| Feature/Aspect | Clip-On Wheel Weights | Stick-On Wheel Weights |

|---|---|---|

| Introduction Era | Patented in the 1930s | Introduced in the 1970s |

| Application | Used on wheels with flanges (lip edge) | Used on wheels without flanges (e.g., alloy wheels) |

| Attachment Method | Clamped firmly onto wheel flange | Adhesive applied to inside of wheel hub |

| Material | Lead, iron, zinc, etc. | Lead, iron, zinc, etc. |

| Durability | More durable, withstands harsh driving conditions | Less durable compared to clip-on weights |

| Aesthetics | More visible, less preferred for stylized wheels | Less visible, preferred for aesthetic appeal |

| Precision & Flexibility | Easier to adjust and move for balancing | Allows more precise placement and wider weight selection |

| Compatibility | Suitable for wheels with a lip or edge | Suitable for modern alloy wheels without lip |

| Performance Impact | Provides sturdy, reliable balance under tough conditions | Offers precise balance and better aesthetics |

| Use Case Preference | Harsh driving conditions, traditional wheels | Modern, stylized wheels, aesthetic preference |

Tip: If you drive in tough conditions or use traditional wheels, clip-on wheel weights give you reliable performance.

Stick-On (Adhesive) Wheel Weights

Stick-on wheel weights, also called adhesive wheel weights, became popular in the 1970s. You use these on wheels without a lip, such as many modern alloy wheels. You attach them to the inside of the wheel hub using strong adhesive. Stick-on wheel weights are less visible, so they look better on stylish wheels.

Laboratory tests show that lead stick-on wheel weights keep their mass better than zinc ones. Lead weights lose as little as 0.11% to 0.13% of their weight, while zinc weights can lose up to 1.02%. This means lead stick-on wheel weights last longer and resist wear from road conditions. Peel and fatigue tests also show that stick-on wheel weights stay attached even after repeated stress. High-strength adhesives help them grip the wheel in rain, heat, and at high speeds. These wheel weights come in many sizes, so you can match them to your wheel’s needs.

- Stick-on wheel weights work well in cities and on smooth roads.

- They bond securely to alloy wheels and do not damage the finish.

- You can choose from a wide range of sizes for precise balancing.

Balancing Beads and Innovative Solutions

Balancing beads offer a new way to balance your tires. You pour these small beads inside the tire. As you drive, the beads move and spread out to balance the wheel automatically. This method works well for pickup trucks and vehicles with large tires. Balancing beads help reduce vibrations and improve stability. You get a smoother ride, longer tire life, and better fuel efficiency.

Research shows that balancing beads use centrifugal force to move inside the tire. The beads settle opposite any heavy spot, so they balance the wheel as you drive. Unlike traditional wheel balancing weights, beads adjust themselves every time you hit the road. You do not need to worry about placement or sizes. Installation is simple, and the beads work with many tire types. Many drivers report better comfort and handling after switching to balancing beads.

Note: Balancing beads may not work as well with low-profile tires or racing cars, but they offer a smart solution for most everyday vehicles.

Wheel Weight Materials and Their Impact

Lead Wheel Weights

You may notice that lead wheel weights have a long history in the automotive world. Since the 1930s, people have used lead for wheel weight because it is dense and easy to shape. This high density lets you use smaller weights to balance your tires, which helps reduce vibrations and keeps your ride smooth. Lead wheel weights are cost-effective and durable, making them a popular choice for many years.

However, lead has some serious drawbacks. It can corrode over time, which lowers its durability. More importantly, lead is toxic. When lead wheel weights fall off or break down, they release harmful particles into the soil and water. This pollution can hurt plants, animals, and even people, especially children. Many places now ban or regulate lead wheel weights to protect the environment and public health. The market for wheel weight materials is changing as more drivers and manufacturers look for safer options.

| Aspect | Details |

|---|---|

| Historical Use | Used since the 1930s for high density and malleability. |

| Effectiveness | Small, compact weights balance tires and reduce vibrations. |

| Advantages | Cost-effective, durable, easy to shape. |

| Limitations | Toxicity, corrosion, and regulatory bans in many regions. |

| Environmental Impact | Lead contamination harms soil, water, and health. |

Steel Wheel Weights

Steel wheel weights give you a strong and reliable way to balance your tires. Steel is fully recyclable, which means you help the environment when you choose this material. Advanced high-strength steels make these weights lighter and stronger, so your car uses less fuel and creates less pollution. Steel wheel weights also resist rust and last a long time, even in tough driving conditions.

You can trust steel wheel weights for their durability and cost-effectiveness. Recycling steel saves energy and reduces carbon dioxide emissions. Many drivers and shops now prefer steel because it meets strict safety and environmental standards. If you want a wheel weight that performs well and supports a cleaner planet, steel is a smart choice.

Zinc and Eco-Friendly Alternatives

You have more choices than ever when it comes to eco-friendly wheel weight options. Zinc wheel weights stand out because they do not contain lead and resist corrosion. Zinc forms a protective layer that keeps it strong in wet or salty environments. These weights also use less energy to produce, which helps lower pollution.

Here are some benefits of zinc and other eco-friendly wheel weights:

- Zinc and steel weights do not release toxic particles, so they protect soil and water.

- Both materials are recyclable, which reduces waste and saves resources.

- Zinc offers good strength and toughness for high-stress driving.

- Steel provides long-lasting performance and supports global efforts to cut pollution.

Switching to zinc or steel wheel weights helps you avoid the health risks linked to lead. You also support a safer, cleaner ecosystem for everyone.

Choosing the Right Wheel Tire Weight for Your Vehicle

Matching Wheel Weights to Wheel Design and Size

When you select wheel weights, you need to match them to your wheel’s design and size. Each wheel has unique features that affect how you balance it. Rim width and rim diameter are two main measurements. Rim width, measured in inches, changes how your tires fit and how your car handles. Rim diameter, also in inches, helps you find the right tire and wheel combination.

Tire width and tire aspect ratio also play a big role. Tire width, measured in millimeters, tells you how wide your tire is when inflated. The aspect ratio shows the height of the tire’s sidewall compared to its width. These numbers affect how your car grips the road and how much weight you need to balance the wheel.

You also need to check the load index and speed rating. The load index shows how much weight each tire can safely carry. The speed rating tells you the top speed your tires can handle. Both ratings help you choose the right tires and wheel weights for your driving needs.

Here is a step-by-step list to help you match wheel weights to your wheel design and size:

- Measure the rim width and rim diameter in inches.

- Check the tire width and aspect ratio on the tire sidewall.

- Find the load index and speed rating for your tires.

- Choose wheel weights that fit your wheel’s design—clip-on for wheels with a lip, stick-on for smooth alloy wheels.

- Make sure the weight matches the size and type of your wheel and tire.

Tip: Always check your car’s manual or ask a professional if you are unsure how to read tire sizes or ratings.

Considering Vehicle Type, Tire Size, and Driving Habits

Your vehicle type and how you drive affect your choice of wheel weights. Passenger cars, trucks, SUVs, and performance vehicles all have different needs. For example, a sedan uses smaller wheel weights, while a heavy-duty truck needs larger, stronger weights. The size of your tires and the load index also matter. Larger tires with higher load index numbers need more weight for proper balance.

Driving habits play a big part, too. If you drive fast or take sharp turns, you need precise balancing. Off-road vehicles need heavier weights to handle rough terrain. Commercial vehicles that carry heavy loads need dynamic balancing and strong wheel weights to keep the ride safe.

A study shows that improper load distribution can cause axle overload and reduce stability. Even if you do not exceed the total weight limit, poor placement can make your car less safe. The research also found that load distribution affects acceleration and handling. You need to use the right wheel weights for your vehicle type and driving style to stay safe and get the best performance.

| Vehicle Type | Wheel Weight Considerations | Driving Habits Impact | Benefits of Proper Wheel Weight Selection |

|---|---|---|---|

| Passenger Vehicles (Sedans, SUVs, Hatchbacks) | Use standard, smaller weights (0.25 to 1 oz); static balancing; consider tire size | Everyday driving conditions | Smoother ride, improved fuel economy, increased tire lifespan |

| Performance and Sports Cars | Use lighter, precision weights (<0.25 oz); dynamic balancing; lightweight materials (alloys, carbon fiber) | High-speed driving, rapid acceleration/deceleration | Enhanced handling, stability, cornering response, reduced tire wear |

| Off-Road Vehicles (4x4s, Trucks) | Heavier weights (1-2+ oz); static balancing preferred; larger, stronger wheels | Rough terrain, variable speeds | Improved off-road traction, reduced suspension wear, smoother handling |

| Heavy-Duty Trucks and Commercial Vehicles | Heavier weights (2-3+ oz); dynamic balancing; focus on load distribution | Long hours, heavy loads, highway speeds | Increased stability, reduced fuel consumption, longer tire and suspension life |

| Electric and Hybrid Vehicles | Lightweight weights (<1 oz); dynamic balancing; focus on energy efficiency | Smooth, quiet rides, variable speeds | Improved energy efficiency, longer driving range, reduced tire wear |

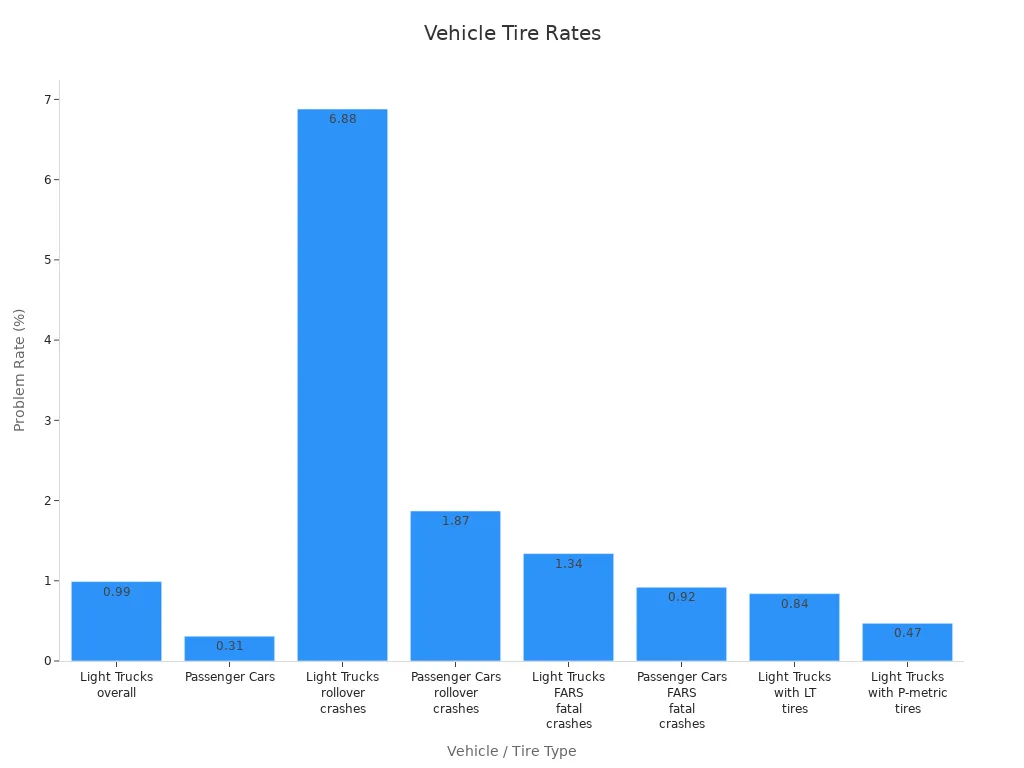

You can see that choosing the right tires and wheel weights depends on your vehicle and how you use it. For example, light trucks with LT tires have a higher tire problem rate than passenger cars. The chart below shows how tire problem rates change with vehicle and tire type:

Sizing, Placement, and Selecting the Right Wheel Weights

Sizing and placement are key steps in selecting the right wheel weights. You need to know the exact size and weight of your wheels and tires. Use professional wheel balancing equipment to find any unbalanced spots. Clean the wheel surface well before you attach any weights. Dirt or grease can stop the weights from sticking.

Place adhesive wheel weights on the inner side of the rim. Clip-on weights go on the edge of the rim. Make sure you press adhesive weights firmly so there are no bubbles or wrinkles. Clip-on weights must clamp tightly to avoid falling off. Always use the right size and type of weight for your wheel and tire.

Here is a checklist for best practices in sizing and placement:

- Clean the wheel surface to remove dirt, grease, and rust.

- Use a wheel balancing machine to find unbalanced spots.

- Select the correct installation position—inside rim for adhesive, edge for clip-on.

- Attach the weights securely and check for a firm fit.

- Double-check the load index and tire size to ensure you use the proper wheel weight.

You should also consider the material of the wheel weights. Lead, zinc, and steel each have different densities and strengths. The right material helps you get the best balance and durability. Always choose high-quality automotive wheel weights for safety and long life.

Proper wheel weight selection and placement improve dynamic balance, reduce vibration, and make your ride smoother. You also lower the risk of tire problems and accidents. When you follow these steps, you protect your car and get the most out of your new tires.

Installation and Maintenance of Wheel Weights

Step-by-Step Guide to Installing Wheel Weights

You can achieve a smooth ride and safe handling by following a careful installation process for wheel weights. Start by removing any old weights and cleaning the wheel surface with a degreaser. Dirt or leftover adhesive can stop new weights from sticking, especially at high speeds. Next, use a wheel balancer to check for imbalance. Identify your rim type so you can choose between clip-on or adhesive weights. Test fit the weight to make sure it matches the rim. For clip-on weights, use a soft tip hammer to avoid damaging the rim. For adhesive weights, press them firmly onto the clean surface. After weight installation, spin the wheel again to confirm balance.

Tip: Always match the weight profile to the rim flange and use manufacturer charts for accuracy.

Best Practices for Longevity and Performance

You can extend the life of your wheel weights and improve wheel balancing by following a few best practices:

- Inspect wheel weights regularly for movement or corrosion.

- Remove rust from nuts and studs, and lubricate them with engine oil.

- Use a calibrated torque wrench and follow the recommended torque (450-500 foot-pounds).

- Replace bearings as matched sets from the same manufacturer.

- Keep tire pressure at the correct level and use bead lubricants for secure mounting.

- Walk around your vehicle to check for signs of vibration, abnormal tire wear, or hot hub caps.

Modern monitoring systems and mounted wheel programs can help you maintain optimal performance and safety.

Common Mistakes to Avoid with Wheel Tire Weight

Avoid these mistakes to ensure proper installation and safe driving:

- Skipping the cleaning step before applying adhesive weights.

- Using the wrong type or size of weight for your rim.

- Over-tightening or under-tightening wheel fasteners.

- Ignoring regular inspections for loose or corroded weights.

- Failing to align weights with the imbalance point during wheel balancing.

Note: Proper installation and regular checks help prevent wheel tire weight issues and keep your ride smooth.

Environmental and Regulatory Considerations for Wheel Weights

Lead-Free Wheel Weights and Compliance with Local Laws

You help protect the environment when you choose lead-free wheel weights. Many states now require you to use safer alternatives. Lead can harm soil, water, and living things. Because of this, lawmakers have set strict rules for wheel weights.

Here is a table that shows how some states handle lead wheel weights:

| Jurisdiction | Regulation Reference | Effective Date | Lead Content Limit | Compliance Requirements | Penalties |

|---|---|---|---|---|---|

| California | Health and Safety Code Sections 25215.6-25215.7 | January 1, 2010 | >0.1% lead | No sale, manufacture, or installation of lead wheel weights on any vehicle | $2,500 per day per violation |

| Washington State | RCW 70A.435.030 | January 1, 2011 | N/A | Must replace lead weights with safer options; must recycle removed lead weights | Penalties as per RCW 70A.435.050 |

If you live in California, you cannot buy, sell, or install lead wheel weights. The law covers both new and used vehicles. In Washington State, you must replace old lead weights with safer ones and recycle the old weights. Fines can reach $2,500 per day in California if you do not follow the rules.

Tip: Always check your local laws before you buy or install wheel weights. Using lead-free options keeps you safe from fines and helps the planet.

Proper Disposal and Recycling of Wheel Weights

You should never throw old wheel weights in the trash. Lead and other metals can pollute landfills and water. Recycling helps keep harmful materials out of the environment.

Follow these steps for safe disposal and recycling:

- Collect old wheel weights in a sealed container.

- Take them to a certified recycling center or ask your tire shop for help.

- Never burn or bury wheel weights.

Many recycling centers accept both lead and non-lead wheel weights. When you recycle, you help save resources and reduce pollution. Some states, like Washington, require you to recycle removed lead weights by law.

Recycling wheel weights is a simple way to protect your community and the environment. Always choose the responsible path when you replace or remove wheel weights.

When to Consult a Professional for Wheel Tire Weight

Signs You Need Expert Help with Tires and Wheel Weights

You may notice signs that tell you it is time to see a professional for your wheel tire weight. These signs help you keep your car safe and your ride smooth. Watch for these common indicators:

- Vibrations in the steering wheel, seat, or floorboard when you drive at steady speeds.

- Uneven or fast tire wear that makes your tires look worn out before their time.

- Your car pulls to one side or feels hard to control.

- You hear strange noises from your wheels.

- You recently hit a curb or pothole.

- You replaced or repaired your tires.

You should also check your tires every 5,000 to 7,000 miles or with every other tire rotation. If you see any of these signs, do not wait. Ignoring them can lead to dangerous handling, higher fuel use, and more tire problems. Regular inspections by a professional help you find issues early and keep your car running well.

Benefits of Professional Wheel Balancing and Installation

A professional uses special tools and skills to balance your wheels and install weights the right way. You get many benefits when you trust an expert:

- Accurate balancing with advanced machines.

- Correct placement of wheel weights for your specific wheels and tires.

- Early detection of problems like bent rims or worn suspension parts.

- Longer tire life and better fuel efficiency.

- Safer driving with less vibration and better control.

Professionals know how to spot issues that you might miss. They follow the right steps and use the best equipment. You save money in the long run because your tires last longer and your car stays safe. Regular visits to a tire shop or service center give you peace of mind on every trip.

You play a key role in keeping your ride safe and smooth by choosing the right wheel tire weight. Regular checks and proper installation help you avoid problems like vibration or uneven tire wear.

- Check your wheel weights often.

- Install and maintain them with care.

For expert advice and top-quality products, trust a professional or a reliable manufacturer like Fortune. Your attention to wheel tire weight leads to safer, more comfortable drives every day.

FAQ

What happens if you drive with unbalanced wheels?

You may feel vibrations in your steering wheel or seat. Your tires can wear out faster. Unbalanced wheels can also damage your suspension. You might notice your car does not handle well. Regular balancing helps you avoid these problems.

How often should you check or replace wheel weights?

You should check your wheel weights every 5,000 to 7,000 miles. Inspect them after hitting a pothole or curb. Replace any missing or damaged weights right away. Regular checks keep your ride safe and smooth.

Can you mix different types of wheel weights on one wheel?

You should not mix different types of wheel weights on the same wheel. Using only one type, like clip-on or adhesive, ensures proper balance. Mixing types can cause uneven weight distribution and lead to vibration or tire wear.

Are lead wheel weights still legal everywhere?

No, some states like California and Washington ban lead wheel weights. These laws protect the environment and public health. Always check your local rules before buying or installing wheel weights.

Why do some vehicles need heavier wheel weights?

Larger vehicles, such as trucks or SUVs, have bigger tires and wheels. These need heavier wheel weights to balance properly. Heavy-duty vehicles also carry more weight, so they require stronger and larger weights for safe driving.