admin1

September 12, 2025

Truck Tyre Valve Stems That Prevent Air Loss

Want to keep your truck tires in top shape? Choosing the right truck tyre valve stems makes a huge difference. High-pressure metal clamp-in stems with advanced seals stop air leaks and help you drive with confidence. You get better tire pressure, which boosts vehicle safety and performance. At Fortune, we recommend tire valve stems made from premium materials and tested for long-lasting, airtight results.

Tip: Check your valve stems often. A quick look can save you from slow leaks and costly repairs!

Key Features of Truck Tyre Valve Stems

Material Quality: Rubber vs. Metal

When you pick a valve stem for your truck, you usually choose between rubber and metal. Each type has its own strengths. Here’s a quick look:

- Brass valve stem: This is a type of metal valve stem. It is strong and lasts a long time. You often see it on heavy-duty trucks. Brass can handle high pressure, but it may corrode if you drive in wet or salty places.

- Nickel valve stem: This metal stem resists corrosion better than brass. It is a good choice if you want extra protection from rust.

- Rubber valve stem: This stem is made from synthetic rubber. It is easy to install and does not rust. However, it is not as tough as metal. You might see it more on cars or light trucks.

Tip: If you drive a heavy truck or carry big loads, high-pressure metal clamp-in valves give you the best strength and air retention.

Seal Design and Technology

You want your tire valve stems to keep air in and leaks out. That’s where seal design comes in. Some valve stems use advanced sealants like MULTI SEAL®. This sealant goes right into the valve stem and helps stop air loss from small punctures or slow leaks. It uses special fibers and fillers that block holes and keep your tires full longer. This means you spend less time fixing flats and more time on the road.

Another smart feature is the self-sealing valve stem cap. When you screw this cap on tight, it acts as a backup seal. Even if the valve core leaks a little, the cap keeps the air inside. This adds an extra layer of safety for your tires.

Pressure Ratings

Not all valve stems can handle the same amount of air pressure. You need to match the pressure rating to your truck and tire size. Here’s a table to help you see what’s right for your vehicle:

| Vehicle Type | Recommended Pressure Rating |

|---|---|

| Passenger Vehicles | Up to 65 psi |

| Heavy-Duty Trucks | Up to 200 psi |

| Motorcycles | Up to 65 psi |

| Tractors and Off-Road | Up to 100 psi or more |

If you use a valve stem with a low pressure rating on a heavy truck, you risk air loss. The valve stem is one of the main places where air can leak out. If your tire loses just 10 PSI, it can shorten tire life by 15%. If you lose 20 PSI, your tires might wear out 30% faster. Low pressure also makes your tires heat up, which can lead to blowouts.

Regular tire pressure monitoring helps you catch leaks early and keeps your tires safe and long-lasting.

Tire Valve Stem Types and Their Benefits

When you look at tire valve stem types, you’ll see that each one has its own strengths. Picking the right one helps you keep your truck tires safe and full of air. Let’s break down the main types you’ll find on the market.

Rubber Snap-In Valve Stems

Rubber snap-in valve stems are common on many vehicles. You can install them quickly, and they fit snugly into the wheel. These stems use a flexible rubber base that creates a tight seal. Here’s what you get with a rubber valve stem:

- Snap-in valve stems help minimize air leaks, so your tires keep the right pressure for longer.

- This design helps you save fuel and makes your tires last longer.

- Rubber snap-in valves do a good job holding air, but metal clamp-in valves work better for high-pressure needs.

If you drive a light truck or want something easy to replace, rubber snap-in stems are a solid choice.

High-Pressure Snap-In Valve Stems

High-pressure snap-in valves are built for trucks and trailers that need more strength. They use thicker rubber and a metal barrel for extra durability. You can see the main features in this table:

| Feature | Details |

|---|---|

| Maximum Pressure Rating | Up to 80 PSI |

| Diameter Range | .453” to .625” |

| Length Options | 1.27” to 2” |

| Design Purpose | Shorter stems reduce pressure on the valve |

You’ll find these stems on medium- and heavy-duty trucks. They work well when you need pressure above 65 psi. The tough design helps them handle big loads and rough roads.

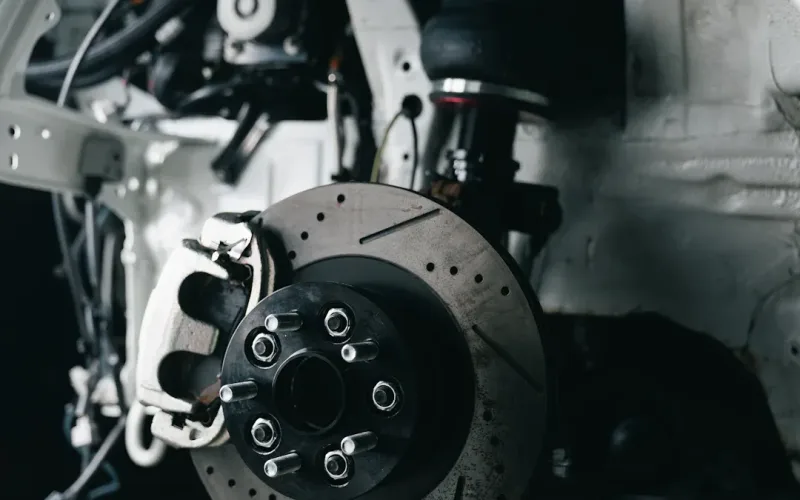

High-Pressure Metal Clamp-In Valve Stems

High-pressure metal clamp-in valves are the top choice for heavy-duty trucks. You get a stem made from strong metals like aluminum, brass, or stainless steel. These stems can handle tire pressures over 65 PSI. They stand up to heat and tough weather, so you don’t have to worry about leaks or failures. Many truck drivers trust these for long trips and heavy loads because they offer the best safety and reliability.

If you want the best performance from your truck tyre valve stems, high-pressure metal clamp-in valves give you peace of mind on every drive.

Matching Tire Valve Stems to Your Truck

Compatibility with Wheel Type

You want your truck to run smoothly, so matching the right valve stem to your wheels is key. Not every stem fits every wheel. Before you buy, check a few important things:

- Look at your truck’s specs. Think about load capacity, wheel size, and axle setup.

- Make sure the valve stem matches your wheel’s hole size and shape.

- Check the load rating. The stem must handle the weight and torque your truck carries.

If you use a rubber valve stem on a heavy-duty truck, it might not hold up under high pressure. Always pick a stem that fits your wheel and meets your truck’s needs. This helps prevent leaks and keeps your tires safe.

Tip: If you’re not sure, ask your tire shop or check your truck’s manual. The right fit makes a big difference!

Sizing and Fitment Guide

Getting the right size and fit for tire valve stems is simple when you know what to look for. Manufacturers set clear guidelines to help you choose. Here’s a handy table to guide your choice:

| Category | Specification |

|---|---|

| Angled Stems | 45-Degree for heavy-duty trucks |

| 90-Degree for motorcycles | |

| Pressure Ratings | Up to 200 psi for heavy-duty trucks |

| Up to 65 psi for passenger vehicles | |

| Rim Hole Diameters | 0.625 inches for heavy-duty trucks |

| 0.453 inches for passenger vehicles | |

| Temperature Ratings | -65°F to 250°F for heavy-duty trucks |

| -40°F to 180°F for passenger vehicles | |

| Importance of Proper Fit | Ensures air retention and tire longevity |

When you match the right size and angle, you help your truck tyres last longer. Proper fit keeps air in and stops slow leaks. Always double-check the pressure rating and rim hole size before you install new truck tyre valve stems. This way, you get the best performance and safety for your ride.

Installation and Maintenance for Tire Valve Stems

Proper Installation Steps

Getting your tire valve stems installed the right way keeps your truck tires safe and full of air. If you want to avoid leaks and keep your tire air pressure steady, follow these steps:

- Clean the wheel hole before you start. Dirt or old rubber can stop the stem from sealing tight.

- Pick the right valve stem for your wheel and tire. High-pressure snap-in valves work best for trucks that carry heavy loads.

- Push or clamp the valve stem into the wheel hole. Make sure it sits straight and snug.

- Use a valve stem tool to pull the stem through until it locks in place.

- Check the fit. The stem should not wiggle or move.

- Inflate the tire to the correct tire inflation pressure. Listen for any hissing sounds that mean air is leaking.

- Put on a valve cap. This helps keep dirt out and adds another layer of protection.

Tip: If you are replacing tire valve stems, always double-check the fit and pressure before you hit the road.

Regular Inspection and Replacement Intervals

You want your tires to last and your rides to stay safe. Regular checks and timely replacements make a big difference. Here’s what you should know:

- Replace valve stems every 4-6 years, even if they look fine.

- Always install new valve stems when you get new tires.

- Check your valve stems often, especially after driving in hot, cold, or wet weather.

- Rubber stems can crack or wear out over time. Sun, rain, and road salt speed up this process.

- Look for signs like cracks, splits, or leaks during your tire air inflation routine.

| Inspection Checklist | What to Look For |

|---|---|

| Cracks or splits | Replace the stem |

| Loose fit | Reinstall or replace |

| Air leaks | Replace right away |

| Missing or damaged cap | Add a new cap |

Regular inspections help you catch problems early. This keeps your tire air pressure steady and your truck running smoothly.

Common Mistakes When Replacing Tire Valve Stems

When you work on your truck’s tires, it’s easy to overlook small details. But even a tiny mistake can lead to big problems down the road. Let’s look at the most common mistakes people make when replacing tire valve stems and how you can avoid them.

Using Incorrect Valve Stem Type

Choosing the wrong valve stem for your truck can cause more trouble than you might think. Here’s what can happen if you use the incorrect type:

- You might see air leaking out, which drops your tire air pressure.

- Low pressure makes your truck harder to control and increases the risk of blowouts or skidding.

- Good tire pressure helps your truck grip the road, handle better, and keeps your tires lasting longer.

If you want your truck to stay safe and your tires to last, always match the valve stem type to your truck’s needs.

Overlooking Pressure Ratings

Pressure ratings matter a lot when you pick a valve stem. If you ignore them, you put your truck and yourself at risk. Check out this table to see what can go wrong:

| Consequence | Description |

|---|---|

| Tire Blowouts | Using the wrong pressure rating can cause your tire to burst while driving. |

| Loss of Control | Weak valve stems might fail, making it hard to steer, especially with heavy loads. |

| Air Leaks | Poor sealing leads to slow leaks and overheating tires. |

| Tire Failure | Unapproved stems can break down, especially in tough conditions. |

Always check the pressure rating before installing a new valve stem. This keeps your tire inflation pressure where it should be and helps you avoid dangerous situations.

Neglecting Regular Maintenance

You might think valve stems last forever, but they don’t. Skipping regular checks or using low-quality parts can lead to fast wear and sudden air loss. Here are some things that can go wrong:

- Cheap rubber stems break down quickly in bad weather or when exposed to chemicals.

- If you don’t install the stem right, weak spots can form and cause leaks.

- These problems can lead to rapid air loss or even a blowout, especially if you’re driving fast.

Tip: Make it a habit to check your valve stems every time you inspect your tires. Catching small issues early can save you from big headaches later.

Tire Pressure Monitoring System and Valve Stem Selection

Ensuring Compatibility with TPMS

When you pick new valve stems for your truck, you need to make sure they work with your tire pressure monitoring system. This system checks your tire pressure all the time and warns you if something is wrong. If you use valve stems that do not fit with your tire pressure monitoring, you might get wrong readings. That can lead to problems like tire blowouts or unsafe driving.

Most trucks today use tire pressure monitoring to keep you safe on the road. The sensors in these systems sit inside the valve stem or attach to it. If the stem does not match the sensor, the system cannot check your tire pressure the right way. Always check your truck manual or ask your tire shop before you buy new valve stems. This step helps you avoid mistakes and keeps your tire pressure monitoring working as it should.

Tip: Double-check the valve stem type before you install it. A good match means your tire pressure monitoring system will give you the right alerts every time.

Preventing Air Loss with TPMS-Ready Valve Stems

TPMS-ready valve stems do more than just fit your sensors. They help you stop air loss before it becomes a big problem. Your tire pressure monitoring system will alert you if air starts to leak from a worn or loose valve stem. This early warning lets you fix the problem fast, so you do not end up with a flat tire or a blowout.

Here’s how TPMS-ready valve stems and tire pressure monitoring work together to keep your tires safe:

- Your tire pressure monitoring system sends alerts if it finds slow leaks.

- You can fix small problems before they turn into big repairs.

- Maintenance teams can act quickly, which keeps your truck on the road longer.

You can see how often maintenance teams tighten valve stems when they use tire pressure monitoring:

| Maintenance Action | Instances |

|---|---|

| Tightening valve stems | 35 to 61 |

Under-inflated tires can cause your truck to lose grip, waste fuel, or even break down. Tire pressure monitoring gives you the data you need to keep your tires at the right pressure. When you use TPMS-ready valve stems, you make sure your system works well and your tires stay full of air.

When you pick truck tyre valve stems, go for durable materials and advanced sealing. These features help your tires last longer and save you money by cutting down on repairs. Look for self-sealing designs and strong construction. Make sure your valve stems fit your wheels and work with your TPMS. This keeps your tire pressure steady and helps you avoid accidents.

Regular checks and proper installation keep your tires safe and your truck running smoothly.

| What to Check | Why It Matters |

|---|---|

| Material & Seal Design | Stops leaks and boosts durability |

| Pressure Rating | Handles your truck’s load safely |

| TPMS Compatibility | Gives you real-time pressure alerts |

| Installation & Checks | Prevents sudden air loss |

FAQ

How often should you replace truck tire valve stems?

You should replace valve stems every time you get new tires or at least every 4-6 years. Old stems can crack or leak, which leads to air loss. Regular checks help you spot problems early.

Can you use car valve stems on a heavy-duty truck?

No, you should not use car valve stems on heavy-duty trucks. Truck tires need stems with higher pressure ratings. Using the wrong type can cause leaks or even blowouts.

What are signs that a valve stem is leaking?

Look for bubbles when you spray soapy water on the stem. You might also hear a hissing sound or notice your tire losing air faster than normal. A missing or cracked cap is another warning sign.

Do metal valve stems last longer than rubber ones?

Yes, metal valve stems usually last longer. They resist heat, weather, and high pressure better than rubber stems. Many truck drivers choose metal stems for extra durability.

Will a damaged valve stem affect your tire pressure monitoring system (TPMS)?

Yes, a damaged valve stem can cause your TPMS to give false alerts or stop working. Always use TPMS-compatible stems and check them often to keep your system accurate.