ADHESIVE WHEEL WEIGHTS

home > steel ADHESIVE WHEEL WEIGHTS

STEEL ADHESIVE WHEEL WEIGHTS (GRAM)

| FSF01-A | |

|---|---|

| WEIGHT SIZE | (5g+10g)x4, 60G, 6.00kgs/box |

| SURFACE | Zinc plated or Plastic coated |

| PACKAGE | 100strips/box, 4boxes/case |

ZINC PLATED

POWDER COATED

CUSTOMIZED COLOR

| FSF01-B | |

|---|---|

| WEIGHT SIZE | (5g+10g)*4, 60G, 6.000kgs/box |

| SURFACE | Zinc plated or Plastic coated |

| PACKAGE | 100strips/box, 4boxes/case |

ZINC PLATED

POWDER COATED

CUSTOMIZED COLOR

| FSF02-A | |

|---|---|

| WEIGHT SIZE | 5g*12, 60G, 6.000kgs/box |

| SURFACE | Zinc plated or Plastic coated |

| PACKAGE | 100strips/box, 4boxes/case |

ZINC PLATED

POWDER COATED

CUSTOMIZED COLOR

| FSF02-B | |

|---|---|

| WEIGHT SIZE | 5g*12, 60G, 6.000kgs/box |

| SURFACE | Zinc plated or Plastic coated |

| PACKAGE | 100strips/box, 4boxes/case |

ZINC PLATED

POWDER COATED

CUSTOMIZED COLOR

| FSF03-A | |

|---|---|

| WEIGHT SIZE | 2.5g*12, 30G, 3.000kgs/box |

| SURFACE | Zinc plated or Plastic coated |

| PACKAGE | 100strips/box, 4boxes/case |

ZINC PLATED

POWDER COATED

CUSTOMIZED COLOR

| FSF02-C | |

|---|---|

| WEIGHT SIZE | 5g*12, 60G, 6.000kgs/box |

| SURFACE | Zinc plated or Plastic coated |

| PACKAGE | 100strips/box, 4boxes/case |

ZINC PLATED

POWDER COATED

CUSTOMIZED COLOR

STEEL ADHESIVE WHEEL WEIGHTS (OUNCE)

| FSF025-3S | |

|---|---|

| WEIGHT SIZE | 1/4ozx12, 3oz, 4.368kgs/box |

| SURFACE | Zinc plated or Plastic coated |

| PACKAGE | 52strips/box, 4boxes/case |

ZINC PLATED

POWDER COATED

CUSTOMIZED COLOR

| FSF025G-4S | |

|---|---|

| WEIGHT SIZE | 1/4ozx12, 3oz, 4.032kgs/box |

| SURFACE | Zinc plated or Plastic coated |

| PACKAGE | 48strips/box, 4boxes/case |

ZINC PLATED

POWDER COATED

CUSTOMIZED COLOR

| FSF025-3R | |

|---|---|

| WEIGHT SIZE | 1/4ozx12, 3oz, 4.368kgs/box |

| SURFACE | Zinc plated or Plastic coated |

| PACKAGE | 52strips/box, 4boxes/case |

ZINC PLATED

POWDER COATED

CUSTOMIZED COLOR

| FSF050-3R | |

|---|---|

| WEIGHT SIZE | 1/2ozx6, 3oz, 4.032kgs/box |

| SURFACE | Zinc plated or Plastic coated |

| PACKAGE | 48strips/box, 4boxes/case |

ZINC PLATED

POWDER COATED

CUSTOMIZED COLOR

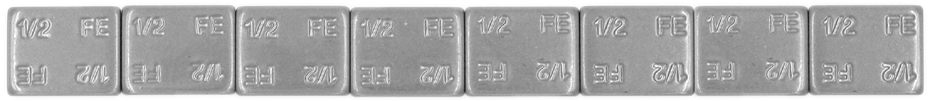

| FSF050-4S | |

|---|---|

| WEIGHT SIZE | 1/2ozx8, 4oz, 3.360kgs/box |

| SURFACE | Zinc plated or Plastic coated |

| PACKAGE | 30strips/box, 4boxes/case |

ZINC PLATED

POWDER COATED

CUSTOMIZED COLOR

| FSF050-4R | |

|---|---|

| WEIGHT SIZE | 1/2ozx8, 4oz, 3.360kgs/box |

| SURFACE | Zinc plated or Plastic coated |

| PACKAGE | 30strips/box, 4boxes/case |

ZINC PLATED

POWDER COATED

CUSTOMIZED COLOR

| FSF050-6R | |

|---|---|

| WEIGHT SIZE | 1/2ozx12, 6oz, 5.040kgs/box |

| SURFACE | Zinc plated or Plastic coated |

| PACKAGE | 30strips/box, 4boxes/case |

ZINC PLATED

POWDER COATED

CUSTOMIZED COLOR

| FSF100-4S | |

|---|---|

| WEIGHT SIZE | 1ozx4, 4oz, 4.032kgs/box |

| SURFACE | Zinc plated or Plastic coated |

| PACKAGE | 36strips/box, 4boxes/case |

ZINC PLATED

POWDER COATED

CUSTOMIZED COLOR

| FSF100-6R | |

|---|---|

| WEIGHT SIZE | 1ozx6, 6oz, 5.040kgs/box |

| SURFACE | Zinc plated or Plastic coated |

| PACKAGE | 32strips/box, 4boxes/case |

ZINC PLATED

POWDER COATED

CUSTOMIZED COLOR

| FSF200-8R | |

|---|---|

| WEIGHT SIZE | 2ozx3, 6oz, 3.024kgs/box |

| SURFACE | Zinc plated or Plastic coated |

| PACKAGE | 18strips/box, 4boxes/case |

ZINC PLATED

POWDER COATED

CUSTOMIZED COLOR

STEEL TRAPEZIUM ADHESIVE WHEEL WEIGHTS

| FSFT025-A | |

|---|---|

| WEIGHT SIZE | 1/4ozx12, 3oz, 4.368kgs/box |

| SURFACE | Zinc plated or Plastic coated |

| PACKAGE | 52strips/box, 4boxes/case |

ZINC PLATED

POWDER COATED

CUSTOMIZED COLOR

| FSFT025-B | |

|---|---|

| WEIGHT SIZE | 1/4ozx12, 3oz, 4.368kgs/box |

| SURFACE | Zinc plated or Plastic coated |

| PACKAGE | 52strips/box, 4boxes/case |

ZINC PLATED

POWDER COATED

CUSTOMIZED COLOR

| FSFT050-A | |

|---|---|

| WEIGHT SIZE | 1/2ozx12, 6oz, 5.040kgs/box |

| SURFACE | Zinc plated or Plastic coated |

| PACKAGE | 30strips/box, 4boxes/case |

ZINC PLATED

POWDER COATED

CUSTOMIZED COLOR

| FSFT050-B | |

|---|---|

| WEIGHT SIZE | 1/2ozx12, 3oz, 4.368kgs/box |

| SURFACE | Zinc plated or Plastic coated |

| PACKAGE | 30strips/box, 4boxes/case |

ZINC PLATED

POWDER COATED

CUSTOMIZED COLOR

application of adhesive weights

//

preparatory work

Rotate the tyre and determine the wheel imbalance in both planes. Ensure that the weight, rim and ambient temperature have at least 15°C.

//

clean the mounting area

Use pre-cleaning wipe to clean oil and dust on mounting area, Then wipe with a dry cloth to make sure the wheel surface is dry and clean. Be sure to test the cleaning agent on a small area to ensure it will not damage the wheel’s finish.

//

tear the segments

Once the imbalance point is located and the proper amount of segmented weights have been chosen,according to the properties of the tape of the adhesive wheel weight, use scissors or tear it by hand to cut off the required number of balance weights.

//

peel off the protective backing

Peel off the protective backing without touching the adhesive surface. Be sure to not contaminate the adhesive tape with dirt or oils once the protective backing has been removed. Otherwise, it will affect the adhesion of the tape.

//

set up the weight

Stick the weight and press the weight from the middle towards the outer edges to match the rim perfectly. The pressure should be at least 100 kPa.

//

final check

After applying the weight and ensuring the appropriate pressure has been exerted, it is essential to verify that the weight is securely adhered before reinstalling the assembly on the vehicle. To confirm proper fitment, gently grasp the sides of the weight with your fingers and give it a slight pull. If the weight stays firmly in place without any movement, the setup process has been successfully initiated.

tape options and feature

tapes also available in easy peel tapes

| foam color | liner color/liner material | foam | re-positionable | initial tack | adherence after 24h | resistance to high low temperature | |

| 3M RED | grey | plastic with 3m logo | Acrylic (high temperature resistant) | yes | fair | excellent | excellent |

| NORTON BLUE | black | plastic | acrylic (high temperature resistant) | yes | fair | excellent | excellent |

| LOHMANN | white black | easy release paper | polyethylene | no | excellent | excellent | excellent |

| US WHITE/BLACK | white black | easy release paper | polyethylene | no | excellent | fair | fair/good |

| FST | white black | easy release paper | polyethylene | no | excellent | excellent | fair |

| CHINA BLUE | black | plastic | polyethylene | no | excellent | good | fair/good |

steel adhesive wheel weights:

the ultimate solution for tire balancing

What is Steel adhesive Wheel Weight?

An adhesive wheel weight is mounted on the wheel hub to balance the weight of the tire and wheel assembly. Because when the tire is mounted on the wheel, it may not be balanced due to manufacturing tolerances, uneven wear, or other components. This imbalance can cause vibration and uneven tire wear, affecting the vehicle’s handling and safety.

Fortune Steel adhesive Wheel Weights are made of high-quality products with a strong adhesive backing that can be easily adhered to the inside of the wheel rim. Unlike traditional clip-on wheel weights that require a specific rim design to hold it in place, adhesive wheel weights can evaluate various types of wheels and are a versatile choice for tire balancing.

Why steel adhesive wheel blocks are a better choice

You often ask which material is better when purchasing. Lead is the traditional material for adhesive wheel blocks, but it is toxic. Manufacturers often consider steel and zinc instead. Of these, steel is popular for its effectiveness and ease of use. As a leading steel sticky wheel balancing block adhesive wheel weights manufacturer, Fortune knows that high-quality steel is a good choice for manufacturing it.

Advantages of Steel adhesive Wheel Weights

You often ask which material is better when purchasing? Lead is the traditional material for adhesive wheel blocks, but it is toxic. Manufacturers often consider steel and zinc instead. Of these, steel is popular for its effectiveness and ease of use. As a leading steel sticky wheel balancing block adhesive wheel weights manufacturer, Fortune knows that high-quality steel is a good choice for manufacturing it.

Strength

Steel is a strong and durable material that ensures wheel weights are strong even at high speeds and in harsh conditions. As a responsible steel adhesive wheel weight supplier, Fortune uses the highest grade of steel to manufacture our products.

Environmentally friendly

Lead is a well-known toxic substance and there are increasing restrictions on its use in wheel weights due to environmental concerns. Steel is even about 10% denser than zinc.

Corrosion resistant

Fortune's steel adhesive wheel weights are usually coated with a protective layer that offers excellent corrosion resistance. This is great for resisting dust and moisture, and will not rust or corrode.

Recyclability

Steel products are easily recyclable and more sustainable in terms of their life cycle and disposal.

Cost-effectiveness

The service life and durability of steel wheel weights offer long-term cost savings. The wide availability of steel also means that the cost is competitive. In addition, the durability of steel makes it extremely low maintenance during use.

Factors affecting the selection of sticking wheel balance weights

Each of these factors below will help you choose the best sticky wheel weight for your vehicle.

Weight range

Different vehicles require different weights for proper balancing. Sticky weights come in various sizes, usually ranging from 0.25 ounces to 2 ounces.

Adhesive Quality

The quality of the adhesive backing is critical to ensure that the weights stay in place during operation. A high-quality adhesive will withstand the heat generated by the brakes and the forces applied to the wheels while traveling. Choose weights with a strong, durable adhesive that can withstand various weather conditions and temperatures.

Ease of use

Weights that are easy to affix save time and effort, especially for the inexperienced. Some come with pre-cut strips, while others need to be cut to size.

Compatibility with Wheel Types

Not all adhesive wheel weights are compatible with all types of wheels. Always make sure that the weights you choose are suitable for your particular wheel type, whether it be alloy, steel or another material. Some weights are designed for specific wheels, so check the manufacturer’s recommendations before purchasing.

Aesthetic considerations

Stick-on wheel weight blocks are less noticeable than traditional clip-on weights, but some are designed to be more discreet. If aesthetics are important to you, look for weight blocks that blend in with the wheel or match the color of the wheel surface.

Cost

Cost is always a consideration when making a purchase. Depending on the material, brand, and quality, the price of a sticky wheel weight block can vary greatly. Investing in higher quality blocks will reduce the need for replacement and ensure better performance.

Environmental Impact

As environmental awareness grows, many consumers are looking for eco-friendly products. Choosing a sticky wheel weight block made from steel, a non-toxic material, can help reduce your environmental impact. The packaging and manufacturing process of your chosen product should also be considered.

Can you drive without wheel weights?

Unbalanced wheels can also affect your vehicle’s handling. You may notice the vehicle shifting to one side, or the steering may feel loose or unresponsive. This is especially dangerous at high speeds or during emergency maneuvers.

Although it is technically possible to drive short distances without wheel weights, this is not recommended and it is best to limit driving. If you must, keep your speed low and avoid sharp turns or hard braking. However, this is only a temporary solution and you should have your wheels balanced as soon as possible.

Customized, Reliable Steel adhesive Single wheel Solutions

Fortune’s commitment goes beyond production, we are committed to providing solutions that meet your specific needs. As China’s leading supplier of steel adhesive wheel weights, our products are manufactured to the most stringent industry standards to ensure you get the best performance and durability.

We provide more than just parts. Our team of engineers collaborate with you from design to delivery. We understand your rim specifications and create a weight that is right for you. Whether it’s a specialty project that requires a small batch, or a large-scale production run, we can handle it.

Partner with Fortune for your steel adhesive wheel weight manufacturing needs. Contact us today for more information.

Why Choose Fortune’s steel adhesive wheel weights?

Fortune offers steel automotive wheel weights that are known for their ruggedness and durability. These weights are built to withstand the harshest road conditions while providing excellent balance for confident and comfortable driving.

Our state-of-the-art facility is not only a production center, but also a center of innovation. Our facility is equipped with state-of-the-art machinery and staffed with highly trained technicians to ensure that every steel wheel weight is crafted with care.

Quality is the foundation. Fortune’s steel wheel weights are rigorously tested to meet standards such as ISO 9001:2015. We provide excellent quality assurance for every part that passes our testing procedures.

We are committed to your success. Whether it’s our environmentally friendly steel selection, competitive pricing, or responsive support, we will do our best.

Fortune provides more than just products, but also reliability, collaboration, and peace of mind. Fortune is a manufacturer you can trust

Frequently asked questions about clip-on wheel weight blocks

Are adhesive wheel weights better?

Adhesive wheel weights are easier to use, don’t require a hammer, and won’t damage the wheel surface like clip-on weights. They also offer precise placement and a neater aesthetic.

However, they may not be as durable as clip-on weights in extreme conditions, depending on the quality of the adhesive.

Are adhesive weights only suitable for steel wheels?

No, they can be used on both steel and alloy wheels. Especially to avoid scratches when a smooth surface is required or where clip-on weights won’t fit.

Are adhesive wheel weights only for steel wheels?

No, adhesive wheel weights are not limited to steel wheels. They are commonly used on steel wheels and are equally effective on aluminum wheels. The choice between adhesive wheel weights and traditional clip-on weights depends on aesthetic considerations and the specific requirements of the wheel.

The effectiveness of bonded weights is largely dependent on proper application. The wheel surface must be clean and free of debris or grease to ensure a secure bond. Fortune uses specialized equipment to determine the precise location of weight placement.