admin1

May 10, 2025

A Complete Guide to Selecting Steel Rim Wheel Weights

Choosing the right steel rim wheel weights is essential for your vehicle’s performance and safety. Proper wheel balancing weights ensure a smoother ride by reducing vibrations, which can enhance driving comfort and minimize tire wear. Studies show that balanced tires can improve fuel economy by up to 2%, thanks to reduced rolling resistance. Material selection also plays a key role. For instance, steel rim wheel weights provide durability and reliability, which are crucial for long-term safety. By considering factors like compatibility, environmental impact, and quality, you can achieve optimal balance and performance for your wheels.

Understanding Steel Rim Wheel Weights

What Are Steel Rim Wheel Weights?

Steel rim wheel weights are small, precisely engineered components designed to correct imbalances in your vehicle’s wheels. These weights are attached to the rim to ensure dynamic balance during rotation. Imbalances can occur due to uneven weight distribution in the wheel assembly, which leads to vibrations and reduced performance. Steel rim wheel weights counteract these issues by redistributing weight evenly across the wheel.

The global automotive industry has increasingly shifted toward steel-based wheel weights due to their cost efficiency and environmental benefits. Regulatory changes and heightened awareness of vehicle maintenance have further accelerated this trend. Steel rim wheel weights are durable, corrosion-resistant, and compatible with high-performance wheels, making them a preferred choice for modern vehicles.

Why Are Steel Rim Wheel Weights Essential?

Steel rim wheel weights play a critical role in maintaining your vehicle’s safety and performance. Properly balanced wheels reduce vibrations, which improves driving comfort and minimizes wear on tires. Balanced wheels also enhance fuel efficiency by reducing rolling resistance. This contributes to a smoother ride and lower operating costs.

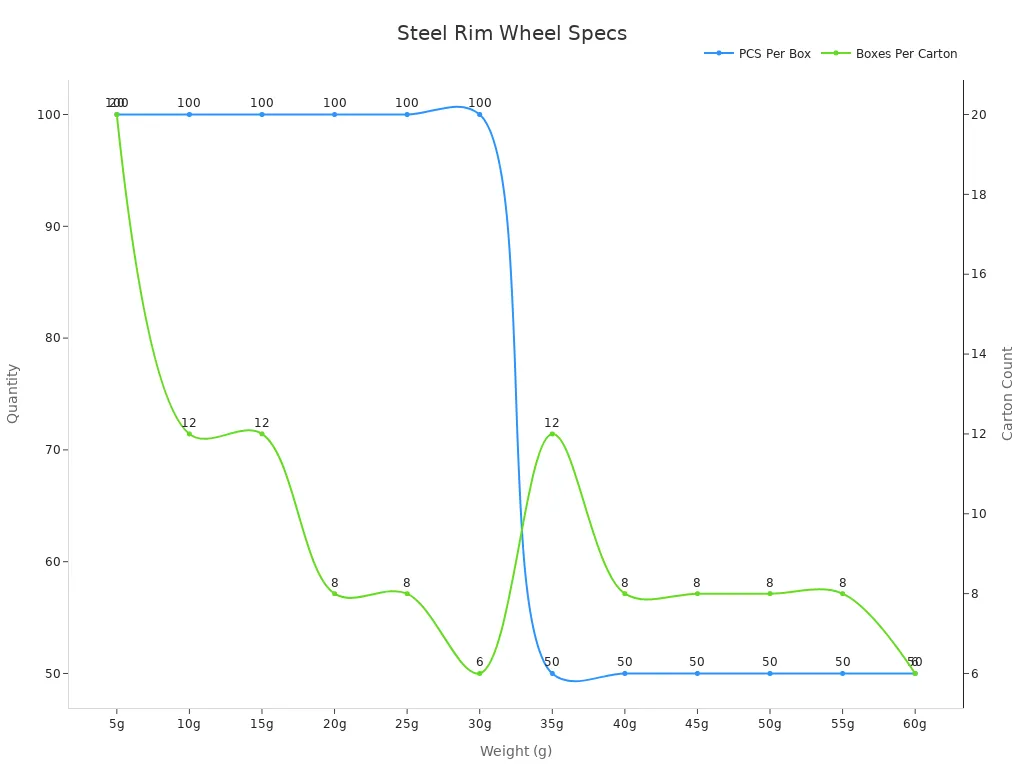

The technical specifications of steel rim wheel weights highlight their versatility. For example, they come in various sizes and packaging configurations to suit different wheel types. Below is a table showcasing common specifications:

| Weight (g) | PCS/BX | BX/CTN | Box Size (mm) | CTN Size (mm) |

|---|---|---|---|---|

| 5g | 100 | 20 | 115x75x60 | 420x250x130 |

| 10g | 100 | 12 | 135x115x70 | 420x250x150 |

| 15g | 100 | 12 | 135x115x70 | 420x250x150 |

| 20g | 100 | 8 | 195x115x60 | 420x250x130 |

| 25g | 100 | 8 | 195x115x60 | 420x250x130 |

| 30g | 100 | 6 | 225x130x70 | 420x250x150 |

Steel rim wheel weights also contribute to improved braking, steering, and suspension performance. Lighter wheels require less energy to change speed, enhancing braking capabilities. Reduced unsprung weight improves handling and cornering, while allowing the suspension system to operate more effectively. This extends the lifespan of critical automotive components.

By ensuring dynamic balance, steel rim wheel weights help you achieve optimal performance for your vehicle. Whether you’re driving on highways or navigating city streets, balanced wheels provide stability and control, making them essential for safe and efficient driving.

Types of Wheel Weights

Clip-On Weights for Steel Rims

Clip-on weights are a popular choice for steel rims due to their durability and ease of use. These wheel weights are designed to attach securely to the rim’s edge using a strong clip. This ensures they stay in place even under challenging driving conditions. Clip-on wheel weights are particularly effective for vehicles with steel rims, as the pronounced lip of the rim provides a secure area for attachment.

Manufacturers like BADA have developed clip-on wheel weights with precise measurements and rust-resistant coatings. These features make them suitable for all weather conditions. Their robust design ensures long-lasting performance, even in extreme environments. By balancing all wheel positions, including trailer tires, you can improve fuel economy by up to 2%. This makes clip-on weights an excellent choice for drivers seeking both reliability and efficiency.

Adhesive Wheel Weights for Custom Wheels

Adhesive wheel weights, also known as stick-on wheel weights, are ideal for modern alloy and custom wheels. These weights use strong adhesive properties to stick directly to the wheel’s surface. This design allows for precise placement, which is crucial for achieving optimal balance in high-performance applications. Diagnostic wheel balancers often recommend adhesive weights for their accuracy.

One of the main advantages of adhesive wheel weights is their aesthetic appeal. They can be discreetly placed behind the spokes of custom wheels, preserving the wheel’s appearance while maintaining balance. The growing popularity of lightweight alloy wheels has increased the demand for adhesive weights. These wheels enhance fuel efficiency and reduce emissions, making adhesive weights a practical and eco-friendly option.

Applications of Different Wheel Weight Types

The choice between clip-on and adhesive wheel weights depends on your vehicle’s wheels and your preferences. Clip-on weights work best for steel rims with a defined lip, offering durability and ease of adjustment. On the other hand, adhesive weights are better suited for alloy or custom wheels, where aesthetics and precise balance are priorities.

For vehicles used in rugged conditions, clip-on weights provide a secure and reliable solution. If you prioritize style and performance, adhesive weights offer a sleek and effective alternative. Both types of wheel weights play a crucial role in maintaining balance, improving performance, and ensuring a smooth driving experience.

Material Considerations for Wheel Weights

Comparing Steel and Zinc Wheel Weights

When choosing wheel weights, understanding the differences between steel and zinc materials can help you make an informed decision. Steel wheel weights are known for their strength, durability, and cost-effectiveness. They are also highly recyclable, making them an environmentally friendly option. On the other hand, zinc weights offer excellent corrosion resistance and flexibility, which makes them suitable for regions with strict environmental regulations.

Both materials perform well under different conditions. Steel clip-on weights, for example, resist heat and moisture, ensuring long-term reliability. Zinc weights, however, excel in scratch resistance and are easier to install. These qualities make zinc weights a strong competitor to steel in terms of longevity and effectiveness.

| Material | Advantages | Market Trends |

|---|---|---|

| Steel | Strength, durability, recyclability | Popular in heavy-duty and sustainable applications |

| Zinc | Corrosion resistance, flexibility | Preferred in regulated markets for easy installation |

Steel vs. Lead Wheel Weights

The transition from lead weights to steel has been driven by environmental concerns. Lead weights, once common, are now being phased out due to their toxicity. Steel has emerged as a safer alternative, offering similar performance without the environmental risks. Zinc weights also serve as a viable replacement for lead, thanks to their density and plasticity, which allow them to perform comparably.

Steel weights are particularly valued for their recyclability and compliance with global regulations. For instance, General Motors switched to steel wheel weights for vehicles in North America to meet EU export standards. This shift highlights the growing preference for eco-friendly materials in the automotive industry.

Benefits of Steel Wheel Weights

Steel wheel weights offer several advantages that make them a top choice for vehicle owners. Their durability ensures they can withstand harsh environmental conditions, such as extreme heat and moisture. This reliability translates to consistent performance over time. Additionally, steel weights are cost-effective, making them an economical option for maintaining wheel balance.

Another key benefit is their compatibility with steel rims and other wheel types. Steel weights provide a secure fit, ensuring proper balance and reducing vibrations. This improves driving comfort and extends the lifespan of your tires. With their recyclability and lower environmental impact, steel weights are a sustainable choice for modern vehicles.

Key Factors When Choosing Steel Rim Wheel Weights

Compatibility with Steel Rims

Selecting the right wheel weights for steel rims requires careful consideration of compatibility. Steel rims are heavier than alloy or forged wheels, which means the wheel weights must provide sufficient balance without compromising performance. Clip-on wheel weights are often the best choice for steel rims due to their secure fit along the rim’s edge. These weights ensure stability during high-speed driving and rough road conditions.

The design of your wheels also impacts compatibility. Steel rims with a pronounced lip allow clip-on weights to attach firmly, while adhesive weights may not adhere as effectively. The table below compares different wheel types and their compatibility with wheel weights:

| Wheel Type | Weight | Cost | Fuel Efficiency | Handling | Summary |

|---|---|---|---|---|---|

| Steel | Heavy | Low | Lower | Standard | Durable and cost-effective, but heavier, affecting fuel efficiency and acceleration. |

| Alloy | Lighter | High | Higher | Improved | Offers better handling and fuel efficiency due to reduced weight, but at a higher cost. |

| Forged | Lightest | Highest | Highest | Best | Superior in performance and handling, though at a premium price. |

| Modular | Variable | Highest | Variable | Customizable | Provides customization options with a significant price, weight varies by design. |

Understanding these differences helps you choose the most compatible wheel weights for your steel rims, ensuring optimal balance and performance.

Durability and Longevity of Wheel Weights

Durability is a critical factor when selecting wheel weights. Steel wheel weights are known for their strength and resistance to wear, making them ideal for vehicles exposed to harsh environments. Whether you drive in extreme heat, rain, or snow, steel weights maintain their integrity over time. This durability reduces the need for frequent replacements, saving you money in the long run.

Longevity also depends on the type of wheel weight you choose. Clip-on weights for steel rims offer excellent durability due to their robust design. Adhesive weights, while effective for custom wheels, may lose their stickiness over time if exposed to moisture or dirt. By prioritizing durable materials and designs, you can ensure your wheel weights provide consistent balance and performance throughout their lifecycle.

Environmental Impact and Regulations

Environmental considerations play a growing role in the selection of wheel weights. Steel wheel weights are highly recyclable, making them an eco-friendly choice. Unlike lead weights, which have been banned in many regions due to their toxicity, steel weights comply with global environmental regulations. This shift toward sustainable materials reflects the automotive industry’s commitment to reducing its ecological footprint.

When choosing wheel weights, consider the environmental impact of the materials and manufacturing processes. Steel weights not only meet regulatory standards but also contribute to a cleaner environment by reducing waste. By opting for steel wheel weights, you align with sustainable practices while ensuring your vehicle remains balanced and efficient.

Tip: Always check local regulations regarding wheel weights to ensure compliance with environmental standards.

Cost-Effectiveness of Steel Rim Wheel Weights

Steel rim wheel weights offer an excellent balance between performance and affordability. When you choose steel weights, you invest in a product that delivers long-term value. Their high density ensures precise weight distribution, which improves balance accuracy. Unlike lower-density materials like zinc, steel weights maintain their effectiveness without requiring larger sizes. This makes them a cost-effective solution for maintaining your vehicle’s performance.

The durability of steel wheel weights further enhances their value. These weights resist wear and tear, even in harsh conditions. Whether you drive through rain, snow, or extreme heat, steel weights retain their integrity. This reduces the need for frequent replacements, saving you money over time. Their robust design also minimizes the risk of balance issues, ensuring consistent performance.

Steel weights are also recognized as an industry standard for health and safety. They contain no harmful substances, unlike lead weights, which have been banned in many regions. By choosing steel, you comply with environmental regulations while avoiding potential health risks. Their recyclability adds another layer of cost-effectiveness, as they contribute to sustainable practices.

Adhesive steel weights provide additional benefits for custom wheels. Their strong adhesive backing ensures a secure fit, even on high-performance vehicles. This eliminates the need for frequent adjustments, reducing maintenance costs. Adhesive weights also preserve the aesthetic appeal of your wheels, making them a practical choice for modern vehicles.

Practical Tips for Selecting the Best Wheel Weights

Checking for Quality and Certifications

When selecting wheel weights, always prioritize quality. High-quality wheel weights ensure durability and consistent performance. Look for products that meet industry standards and certifications, such as ISO9001. These certifications indicate that the manufacturer adheres to strict quality control processes. Certified wheel weights are less likely to fail during use, providing you with peace of mind.

You should also inspect the materials used in the wheel weights. Steel wheel weights, for example, are known for their strength and resistance to wear. Avoid products made from inferior materials, as they may compromise the balance of your wheels. Reputable manufacturers often provide detailed product specifications, which can help you verify the quality before making a purchase.

Ensuring Proper Fit and Balance

Proper fit and balance are crucial for the effective performance of wheel balancing weights. A poorly fitted wheel weight can lead to vibrations, uneven tire wear, and reduced fuel efficiency. To ensure a proper fit, choose weights specifically designed for your vehicle’s wheels. Clip-on weights work well for steel rims, while adhesive weights are ideal for custom or alloy wheels.

Independent studies have shown that improper installation can negate the benefits of wheel weights. The table below highlights findings from balance and fit tests:

| Evidence Type | Findings |

|---|---|

| Wheel Balance Claims | The applicant did not provide adequate data to substantiate claims of improved wheel balance compared to conventional methods. |

| Fuel Economy Claims | Data submitted were insufficient; multiple vehicles were not tested under controlled conditions. |

| Safety Claims | The applicant’s statement on safety was unclear, and the EPA could not confirm any safety improvements. |

These findings emphasize the importance of proper installation and fit. Always follow the manufacturer’s guidelines to achieve optimal balance. If you’re unsure, consult a professional to ensure the wheel weights are installed correctly.

Ease of Installation for Wheel Weights

Ease of installation is another factor to consider when choosing wheel weights. Clip-on weights are straightforward to attach to steel rims, making them a convenient option for many vehicles. Their design allows for quick and secure placement along the rim’s edge. This reduces the time and effort required for installation.

Adhesive weights, on the other hand, require a clean and dry surface for proper adhesion. Before applying adhesive weights, clean the wheel thoroughly to remove dirt and grease. This ensures the adhesive sticks firmly, preventing the weights from detaching during use. While adhesive weights may take slightly longer to install, they offer a sleek appearance and precise balance for custom wheels.

For DIY enthusiasts, selecting wheel weights with clear instructions can simplify the installation process. Some manufacturers include step-by-step guides or video tutorials to assist you. If you prefer professional assistance, many auto repair shops offer wheel weight installation services. Proper installation not only enhances the performance of your vehicle but also extends the lifespan of your tires.

Consulting Professionals or Manufacturers

When selecting steel rim wheel weights, consulting professionals or manufacturers can save you time and ensure you make the right choice. These experts have the knowledge and experience to guide you through the process, helping you avoid common mistakes. Whether you are unsure about compatibility, installation, or material options, their advice can be invaluable.

Why Consult Professionals?

Professionals, such as mechanics or tire specialists, work with wheel weights daily. They understand the specific needs of different vehicles and can recommend the best type for your steel rims. For example, if you are deciding between clip-on and adhesive weights, they can explain which option suits your driving conditions and wheel type. Their expertise ensures that your wheels remain balanced, improving your vehicle’s performance and safety.

Additionally, professionals use advanced tools to test and install wheel weights. They can identify imbalances that may not be visible to the naked eye. By addressing these issues, they help you avoid uneven tire wear and vibrations. This not only enhances your driving experience but also extends the lifespan of your tires.

Benefits of Consulting Manufacturers

Manufacturers are another excellent resource when choosing wheel weights. Reputable companies, like Ningbo Fortune Auto Parts Manufacture Co., Ltd., provide detailed product information and technical support. They can answer questions about the durability, environmental impact, and cost-effectiveness of their products. Many manufacturers also offer guides or videos to help you understand the installation process.

When you consult a manufacturer, you gain access to high-quality products that meet industry standards. For instance, certified manufacturers often produce wheel weights that comply with ISO9001 standards. These certifications guarantee that the products have undergone rigorous testing for quality and safety. By choosing certified weights, you reduce the risk of purchasing inferior materials that may fail over time.

How to Approach Professionals or Manufacturers

To get the most out of your consultation, prepare a list of questions. Ask about the differences between clip-on and adhesive weights, the best materials for your vehicle, and the expected lifespan of the weights. If you are consulting a manufacturer, inquire about their certifications and the environmental impact of their products. Providing details about your vehicle, such as the type of wheels and driving conditions, will help them give tailored recommendations.

You can also request demonstrations or samples to better understand the products. Many manufacturers and professionals are happy to showcase their offerings, giving you confidence in your decision. If possible, visit their facilities or workshops to see the products in action. This hands-on approach can clarify any doubts you may have.

The Value of Expert Guidance

Relying on expert guidance ensures that you choose the right wheel weights for your needs. Professionals and manufacturers can help you avoid costly mistakes, such as selecting weights that are incompatible with your wheels. Their advice also saves you time by narrowing down your options to the most suitable choices. By consulting experts, you invest in the long-term performance and safety of your vehicle.

Tip: Always verify the credentials of the professionals or manufacturers you consult. Look for reviews, certifications, and a proven track record of quality service.

Choosing the right steel rim wheel weights is vital for your vehicle’s safety and performance. Properly balanced wheels reduce vibrations, improve fuel efficiency, and extend tire life. Steel and zinc weights stand out for their durability and eco-friendliness, offering corrosion resistance and strong adhesive properties.

Key findings emphasize the importance of accurate material selection and design considerations:

- Wheel rims are safety-critical components designed under strict international codes.

- Steel weights provide reliable balance and comply with industry standards.

- Corrosion-resistant materials ensure long-term performance.

By considering compatibility, material quality, and environmental impact, you can make informed decisions. Following practical tips, such as consulting professionals and ensuring proper installation, guarantees optimal wheel balance and driving comfort.

FAQ

What is the purpose of steel rim wheel weights?

Steel rim wheel weights balance your vehicle’s wheels. They reduce vibrations, improve tire wear, and enhance fuel efficiency. Balanced wheels also provide smoother handling and better braking performance. These weights ensure your vehicle operates safely and efficiently, whether on highways or rugged terrains.

How do I know which type of wheel weight to choose?

Choose clip-on weights for steel rims with a pronounced lip. Use adhesive weights for alloy or custom wheels where aesthetics matter. Consider your driving conditions and wheel type. If unsure, consult a professional or manufacturer for tailored recommendations.

Are steel wheel weights environmentally friendly?

Steel wheel weights are recyclable and comply with global environmental regulations. Unlike lead weights, they pose no toxicity risks. Their durability reduces waste, making them a sustainable choice for eco-conscious drivers.

Can I install wheel weights myself?

Yes, you can install wheel weights yourself. Clip-on weights are easy to attach to steel rims. Adhesive weights require a clean, dry surface for proper adhesion. Follow the manufacturer’s instructions or watch tutorials for guidance. For precise installation, consult a professional.

Why should I consult a manufacturer before buying wheel weights?

Manufacturers provide detailed product specifications and certifications like ISO9001. They ensure you choose high-quality, compatible weights for your vehicle. Their expertise helps you avoid costly mistakes and guarantees optimal performance and safety.