admin1

September 7, 2025

Comparing Rubber Valve Stem and Metal Valve Stem for Tire Safety

You want reliable performance from your tires, and the tire valve plays a vital role in keeping them safe. The choice between a rubber valve stem and metal valve stems depends on your needs. Rubber valve stems use synthetic rubber, making them flexible and easy to install. Metal valve stems use brass, offering more durability for heavy-duty use. The valve helps maintain tire pressure, and a small leak can cause tire failures. Picking the right valves protects your tires and keeps you safe on the road.

| Feature | Rubber Valve Stem | Metal Valve Stems |

|---|---|---|

| Material | Synthetic rubber | Brass |

| Installation | Flexible, easy | Rigid, more challenging |

| Durability | Resistant to corrosion | Can corrode over time |

The Role of Valve Stems in Tire Safety

How Valve Stems Maintain Tire Pressure

You rely on valve stems every time you check or adjust your tire pressure. The valve stem acts as a gateway for air, letting you add or release air as needed. It has a body and a core that work together to keep air inside your tire. When you inflate your tires, the valve stem allows air to enter. Once you finish, the core seals tightly to prevent air from escaping. This simple mechanism helps you maintain the correct tire pressures for safe driving.

Valve stems play a critical role in keeping your tires properly inflated. If a valve stem fails, air can leak out slowly. Even a small leak can cause your tire pressure to drop below safe levels. Low tire pressure affects how your vehicle handles and can make driving dangerous. You should check your valve stems regularly to make sure they are clean and undamaged.

Tip: Always use a reliable pressure gauge to check your tire pressure. A quick inspection of the valve stem can help you spot cracks or damage before they become a problem.

Impact on Tire Performance and Longevity

Valve stem integrity directly affects how long your tires last and how well they perform. When your valve stem forms a tight seal, it prevents air loss and keeps your tire pressure steady. This helps your tires wear evenly and improves fuel efficiency. If your valve stem leaks, your tires may lose air and wear out faster. Uneven wear can lead to costly replacements and reduce your vehicle’s safety.

Advancements in valve stem materials have made them more reliable. Modern valve stems resist damage and help you maintain optimal tire pressure. This means you spend less time worrying about air leaks and more time enjoying a smooth ride. Properly maintained valve stems support your tires and keep your vehicle running safely.

- Benefits of a well-functioning valve stem:

- Maintains correct tire pressure for safe driving.

- Reduces uneven tire wear.

- Improves fuel efficiency.

- Extends tire lifespan.

You can protect your tires by checking valve stems during routine maintenance. A simple inspection helps you avoid problems and keeps your vehicle safe on the road.

Rubber Valve Stem vs. Metal Valve Stems: Key Differences

Material and Construction

When you look at the construction of a rubber valve stem and metal valve stems, you notice clear differences. Rubber valve stems use synthetic rubber, which gives them flexibility. This flexibility helps you install them easily and makes them a good choice for standard vehicles and off-road driving. Metal valve stems use brass or stainless steel. These materials make metal clamp-in valves rigid and strong.

- Rubber valve stems bend when you push them, so you can fit them into the wheel without much effort.

- Metal valve stems stay firm and do not flex. You need special tools to install metal clamp-in valves because of their rigidity.

- Metal clamp-in valves create a tighter seal, which helps you keep tire pressure steady during pressure checks.

- The strength of brass and steel in metal valve stems means they last longer and resist damage better than rubber.

You should think about how you use your vehicle. If you drive on rough roads or need easy installation, a rubber valve stem may suit you. If you want extra strength for racing or heavy-duty use, metal clamp-in valves offer better performance.

Durability and Lifespan

Durability matters when you want your tires to last. Rubber valve stems can wear out faster in harsh environments. Sunlight, heat, and cold can make rubber hard and brittle. After two years, a rubber valve stem may crack or leak, especially if you drive a truck or use your vehicle in tough conditions.

- Rubber valve stems have a higher failure rate in extreme weather. You may see cracks or dry rot if you live in a hot or cold climate.

- Metal valve stems, especially metal clamp-in valves made from brass or stainless steel, resist harsh conditions. They do not crack or rot like rubber.

- Metal clamp-in valves last longer than rubber valve stems, even when you drive in snow, rain, or heat.

If you want a valve that stands up to tough environments, metal clamp-in valves give you more reliability. You spend less time worrying about leaks and more time driving safely.

Pressure Capacity and Performance

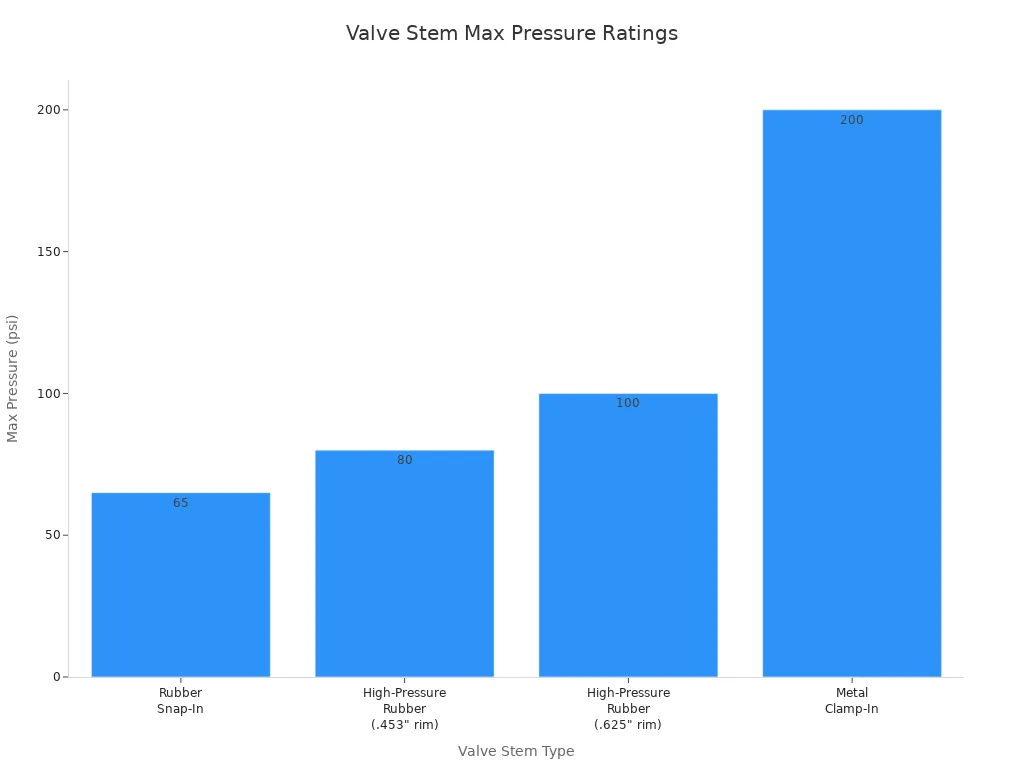

Pressure ratings show you how much air a valve can handle. Rubber valve stems work well for most cars, but they have limits. Metal clamp-in valves handle much higher pressures, making them ideal for racing, trucks, and high-speed driving.

| Valve Stem Type | Maximum Pressure Rating |

|---|---|

| Rubber Snap-In | 65 psi |

| High-Pressure Rubber | 80 psi (for .453″ rim) |

| High-Pressure Rubber | 100 psi (for .625″ rim) |

| Metal Clamp-In | 200 psi |

Metal clamp-in valves keep tire pressure stable during high-speed or high-load conditions. If you drive a performance car or use your vehicle for track activities, you need valves that resist deformation and air loss. Metal valve stems can handle speeds over 130 mph and pressures up to 200 psi. Rubber valve stems may lose air in these situations, so they are not the best choice for extreme performance.

Tip: If you want the best tire pressure retention for racing or heavy-duty work, choose metal clamp-in valves. For everyday driving, a rubber valve stem works well and is easy to install.

Installation and Maintenance

You want your tires to stay safe and last longer. The way you install and maintain valve stems makes a big difference. Rubber valve stems snap into place with a simple push. You can install them quickly, and you do not need special tools. This makes rubber valve stems a good choice if you want to replace them yourself or if you need a fast solution at a tire shop.

Metal clamp-in valves require more attention during installation. You need to use tools to secure them tightly to the wheel. Sometimes, you need professional help to make sure the seal is perfect. If you do not install metal valve stems correctly, you may see slow leaks. You must replace the seals and nuts every time you install metal clamp-in valves. This step helps prevent air loss and keeps your tires safe.

Both types of valves need regular inspections. You should check for cracks, leaks, or loose fittings. For rubber valve stems, handle them gently to avoid damage. For metal clamp-in valves, make sure the seals and nuts stay tight. If you see any problems, replace the valve stem right away. Regular maintenance keeps your tires in good shape and helps you avoid unexpected issues on the road.

Tip: Inspect your valve stems every time you check your tire pressure. Look for signs of wear or damage. Quick checks help you catch problems early and keep your tires safe.

Cost and Value

You want to get the best value for your money when you choose valve stems. Rubber valve stems usually cost less up front. You can install them easily, and you do not need extra parts. This makes them a budget-friendly choice for most drivers.

Metal valve stems and metal clamp-in valves cost more because they use stronger materials and need extra parts like rubber or vinyl gaskets. You may pay more for installation, especially if you need professional help. Every time you get new tires, experts recommend replacing all valves. This adds to the long-term cost, but it helps keep your tires safe.

Here are some important points about cost and value:

- Metal clamp-in valves need new seals and nuts during installation, which increases the total expense.

- Tire shops often replace the entire valve stem with every new tire, no matter which type you use.

- Regular replacement of valves helps prevent leaks and keeps your tires working well.

- The need for extra gaskets with metal valve stems can add to your maintenance costs over time.

You should think about how often you drive and the conditions you face. If you want a simple, low-cost solution, rubber valve stems work well. If you need extra strength and durability, metal clamp-in valves offer better performance, but you may pay more for installation and maintenance. Choosing the right valves helps you balance safety, reliability, and cost.

Advantages of Rubber Valve Stems

Flexibility and Ease of Use

You will notice that rubber valve stems offer impressive flexibility. This feature makes them easy to install and remove, even if you have little experience with tire repairs. You only need a simple valve puller tool to get the job done. The flexible design allows you to fit the stem into the wheel without much effort. You save time during installation, and you do not need special equipment. Automotive experts agree that this user-friendly approach helps you maintain your tires with less hassle.

Tip: If you want a quick and straightforward tire repair, choose rubber valve stems for their flexibility and ease of use.

Suitability for Standard and Off-Road Applications

Rubber valve stems work well for both standard vehicles and off-road adventures. Their flexibility helps you adapt to different tire pressures and changing environments. When you drive on rugged terrain, the valve stem bends and adjusts to the movement of the wheel. This adaptability protects your tire from damage and keeps air pressure stable. You benefit from cost-effective maintenance, as rubber valve stems do not require expensive tools or parts. Many off-road drivers prefer rubber valve stems because they handle pressure changes and rough conditions with ease.

Resistance to Corrosion and Cold Weather

Rubber valve stems resist corrosion better than aluminum or metal stems. You do not have to worry about rust, even if you drive in areas with salted winter roads. Metal valve stems can corrode over time, but rubber stems stay strong against moisture and chemicals. Some rubber valve stems use ozone-resistant EPDM rubber, which performs well in extreme weather. You get reliable performance in cold temperatures, and the stem remains flexible instead of becoming brittle. Regular inspections help you spot cracks early, but you will find that rubber valve stems offer dependable protection against corrosion and cold.

- Rubber valve stems resist rust and corrosion.

- EPDM rubber options perform well in harsh weather.

- Metal stems may corrode, especially in winter conditions.

You can see the advantages of rubber valve stems in their flexibility, suitability for many driving conditions, and resistance to corrosion and cold. These features make them a smart choice for everyday drivers and off-road enthusiasts.

Advantages of Metal Valve Stems

High-Pressure Capability

You need reliable tire performance, especially when you drive at high speeds or carry heavy loads. Metal clamp-in valves give you the strength to handle much higher air pressures than standard rubber options. These valves can manage up to 200 psi, making them ideal for trucks, trailers, and performance vehicles. You get peace of mind knowing your tires will not lose air, even under tough conditions. Metal valve stems stay firm and do not flex, so they keep a tight seal at all times. This feature helps you maintain the correct tire pressure, which improves safety and tire life.

Enhanced Durability for Heavy-Duty Use

When you drive in harsh environments or use your vehicle for work, you want parts that last. Metal clamp-in valves offer outstanding durability. They resist damage from heat, sunlight, and road debris. Unlike rubber, metal valve stems do not crack or become brittle over time. You can trust them to perform well in both hot and cold weather. Many drivers choose metal clamp-in valves for commercial vehicles and racing because they stand up to repeated use and rough conditions. You spend less time worrying about leaks or failures, so you can focus on the road ahead.

Compatibility with Performance and TPMS Applications

Modern vehicles often use tire pressure monitoring systems (TPMS) to keep you safe. Metal valve stems work especially well with these systems. Metal clamp-in valves have a threaded insert that holds TPMS sensors securely inside the tire. This design prevents sensor movement and ensures accurate pressure readings. You avoid problems like sensor damage or false alerts. Many customers have switched from rubber to metal valve stems to improve TPMS performance. Metal clamp-in valves are also recommended for use with TST TPMS systems.

| Valve Type | Compatibility with TPMS | Features |

|---|---|---|

| Metal Clamp-in | Yes | Threaded insert for secure sensor attachment |

| Rubber Snap-in | Yes | Standard use, less durable than metal |

You also benefit from better performance with high-speed or specialty tires. Metal valve stems hold TPMS sensors firmly and prevent issues like galvanic corrosion. This means your sensors last longer and give you more reliable data. If you want the best results from your TPMS and performance tires, metal clamp-in valves are the smart choice.

Disadvantages of Rubber Valve Stems

Wear and Tear in Harsh Environments

You may notice that rubber valve stems do not last as long when exposed to tough conditions. Sunlight, heat, and road chemicals can cause the rubber to harden or crack. If you drive on rough roads or in extreme weather, the valve stem can wear out faster. When the rubber ages, it becomes less flexible and may not seal tightly. This can lead to leaks, which lower your tire pressure and affect your safety.

Many drivers experience slow air leaks because the rubber develops tiny cracks over time. You might not see these cracks right away, but they can let air escape little by little. Regular inspections help you spot problems early. If you see any damage, you should replace the valve stem to keep your tires safe.

Note: Checking your valve stems during every tire pressure check helps you catch wear before it causes trouble.

Limited Pressure Capacity

Rubber valve stems work well for most passenger cars and motorcycles. However, they cannot handle very high air pressure. If you drive a heavy-duty truck or use tires that need more pressure, rubber valve stems may not be suitable. The pressure rating for rubber stems usually goes up to 65 psi. Metal valve stems can handle much higher pressures, up to 200 psi.

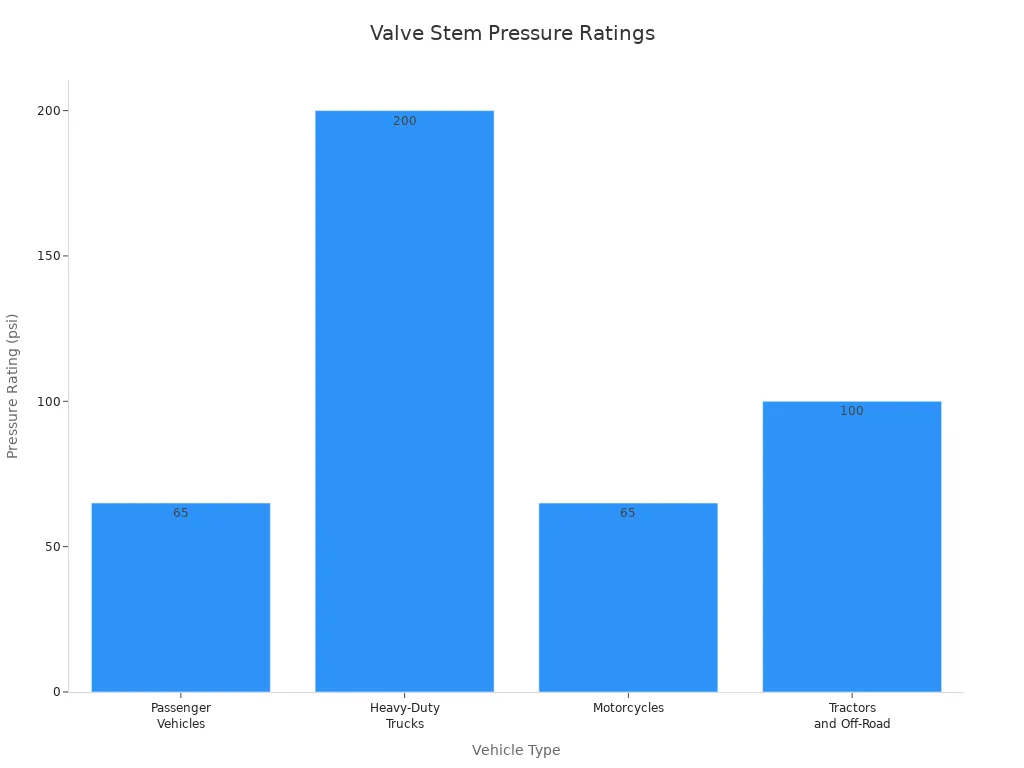

Here is a table that shows how different vehicles match with valve stem types and pressure ratings:

| Vehicle Type | Valve Stem Type | Pressure Rating |

|---|---|---|

| Passenger Vehicles | Rubber | Up to 65 psi |

| Heavy-Duty Trucks | Metal | Up to 200 psi |

| Motorcycles | Rubber | Up to 65 psi |

| Tractors and Off-Road | Metal | 100 psi or more |

If you use rubber valve stems on vehicles that need higher pressure, you risk air loss and tire damage. You should always check the pressure requirements for your vehicle before choosing a valve stem.

The disadvantages of rubber valve stems include limited pressure capacity and increased wear in harsh environments. You can avoid problems by choosing the right valve stem for your vehicle and checking for leaks often.

Disadvantages of Metal Valve Stems

Installation Complexity and Tool Requirements

You may find that installing metal valve stems takes more effort than working with rubber ones. Metal stems require special tools, such as wrenches and torque drivers, to secure them tightly to the wheel. You must follow the manufacturer’s instructions closely, or you risk leaks and sensor problems. Some service departments refuse to install metal valve stems because they worry that TPMS sensors might keep the Schrader valve open, which could cause flats. If you use TPMS, you need to make sure the sensor fits properly with the metal stem.

Mistakes during installation can lead to trouble. For example, a national tire company once put rubber grommets on the inside of the rim instead of the outside. This went against the manufacturer’s instructions and could have caused air leaks. You must check every part and step to avoid problems. Here are some challenges you might face:

- You need extra tools for installation.

- You must follow detailed instructions for each part.

- Incorrect placement of grommets or seals can cause leaks.

- TPMS sensors may not fit well with some metal stems.

Tip: Always ask your tire shop if they have experience with metal valve stems and TPMS systems before installation.

Susceptibility to Corrosion

Metal valve stems can face corrosion over time, especially in harsh environments. Corrosion weakens the stem and may cause air leaks or cracks. You should know that different types of corrosion affect metal stems in various ways. The table below shows how corrosion can impact metal valve stems:

| Corrosion Type | Rate/Impact | Environment Description |

|---|---|---|

| Pitting Corrosion | 0.12 mm/year at 60°C | Medium with 500 ppm chloride ions |

| Intergranular Corrosion | Cracks up to 50 μm wide | High-temperature acidic environments |

| Groove Corrosion | Wear of more than 200 μm annually | LNG high-pressure transmission systems |

You may drive in areas with road salt, moisture, or chemicals. These conditions speed up corrosion and reduce the lifespan of metal stems. Advancing corrosion protection technologies helps improve reliability, but current methods still have limits. You should inspect metal valve stems often and replace them if you see signs of rust or wear.

- Corrosion can cause cracks and leaks.

- High temperatures and chemicals increase corrosion risk.

- Regular inspections help you catch problems early.

You need to consider the disadvantages of metal valve stems before choosing them for your vehicle. Installation takes more time and skill, and corrosion can affect long-term reliability. Careful maintenance and proper installation help you get the best performance from metal valve stems.

Choosing Between Rubber Valve Stem and Metal Valve Stems

TPMS Compatibility and Valve Stem Selection

Ensuring Proper Fit with TPMS Sensors

You want your tire pressure monitoring system (TPMS) to work accurately. The type of valve you choose affects how well the sensors fit and function. Metal valve stems provide better durability and compatibility with most TPMS sensors. These stems hold external sensors securely and resist splitting, even under the weight of the sensor. Rubber valve stems can flex and split, especially when you use external TPMS sensors. High-pressure rubber stems are the only rubber option recommended for TPMS use.

Here is a table that shows how different valve materials interact with TPMS sensors:

| Valve Material | TPMS Compatibility | Notes |

|---|---|---|

| Standard Rubber | Not ideal for external sensors | Can flex and split under sensor weight |

| High-Pressure Rubber | Recommended for TPMS | More robust, less likely to fail |

| Metal Valve Stems | Preferred for TPMS | Best durability and sensor stability |

You should select valves that match your TPMS sensor type. Metal valve stems work best for external sensors and heavy-duty applications. If you use high-pressure rubber stems, you get better performance than standard rubber options. This choice helps prevent slow air leaks and sensor failures.

Tips for Installation and Maintenance

Proper installation and regular tire maintenance keep your TPMS working well. You need to follow best practices to avoid leaks and sensor problems. When you service your tires, always replace the valves. This step prevents old seals from causing slow air leaks. Clean the area around the sensor and valve stem before installation. Use new seals, nuts, and valve cores every time you install or reuse a TPMS sensor. Never reuse nuts, as this can lead to poor sealing.

Follow these steps for reliable TPMS and valve performance:

- Replace seals and valves during every tire repair or service.

- Clean the area around the valve stem and sensor to prevent leaks.

- Use a new valve core to avoid corrosion.

- Check torque specifications for your vehicle and avoid over-tightening.

- Inspect sensors for damage and check battery life regularly.

- Recalibrate the TPMS after any tire maintenance.

You can use tpms service kits to make this process easier. These kits include all the parts you need for proper installation. Regular inspections help you catch wear or damage early. If you notice leaks or sensor issues, address them right away. Good tire maintenance keeps your vehicle safe and your TPMS accurate.

Fortune’s Commitment to Quality in Valve Stems

Manufacturing Standards and Certifications

You want to trust the valves you use on your vehicle. Fortune follows strict manufacturing standards to make sure every product meets high expectations. The company holds ISO9001 certification, which means you get valves made under a quality management system recognized worldwide. This certification shows that Fortune controls every step, from raw material selection to final inspection.

Fortune never uses inferior materials. You receive valves made from strong, reliable components. The company tests 342% of its products before shipment. This high testing rate means you get valves that work well, whether you choose rubber or metal valve stems. Engineers at Fortune design each valve to handle real-world conditions, including high pressure and temperature changes. You can rely on these valves for daily driving, off-road trips, or even when you need to repair a tire.

Note: Fortune participates in international exhibitions every year. This keeps the company updated with the latest industry standards and technology.

Quality Control and Customer Support

You benefit from Fortune’s focus on quality control. The company checks each process during production. Experienced engineers and technicians inspect every valve for defects. They also check packaging to make sure you get the right parts in perfect condition.

If you have questions or need help, Fortune offers strong customer support. The company set up warehouses and offices in North America to serve you better. You can get fast answers and quick shipping. Fortune listens to your needs and works with you to solve any issues, including questions about metal valve stems or tpms compatibility.

A professional team of over thirty engineers keeps improving products and technology. You get valves that meet the needs of both OEM and aftermarket customers. Fortune’s commitment to quality helps you drive with confidence.

- You see clear safety differences between rubber and metal valve stems. Rubber stems work well for everyday driving, while metal valve stems offer extra strength for high-pressure needs.

- You should match your valve stem type to your vehicle and driving habits.

- Regular repair and inspection help you avoid leaks and keep your tpms working.

Choose valves from trusted brands like Fortune for every tire repair. Quality products protect you and extend tire life.

FAQ

What is the main difference between rubber and metal valve stems?

Rubber valve stems use synthetic rubber. Metal valve stems use brass or stainless steel. Rubber stems bend easily. Metal stems stay rigid and last longer. You choose based on your vehicle type and driving needs.

Can you use metal valve stems with TPMS sensors?

Yes, you can use metal valve stems with TPMS sensors. Metal stems hold sensors securely and prevent movement. You get better sensor accuracy and durability. Always check your sensor type before installation.

How often should you replace valve stems?

You should replace valve stems every time you get new tires. Experts recommend checking valve stems for cracks or leaks during regular tire maintenance. This helps you avoid slow air leaks and keeps your tires safe.

Are rubber valve stems safe for winter driving?

Rubber valve stems resist corrosion from road salt and moisture. EPDM rubber options stay flexible in cold weather. You get reliable performance in winter conditions. Inspect your valve stems for cracks before the season starts.