admin1

June 15, 2025

Lead Tire Balancing Weights Versus Lead-Free Surprises

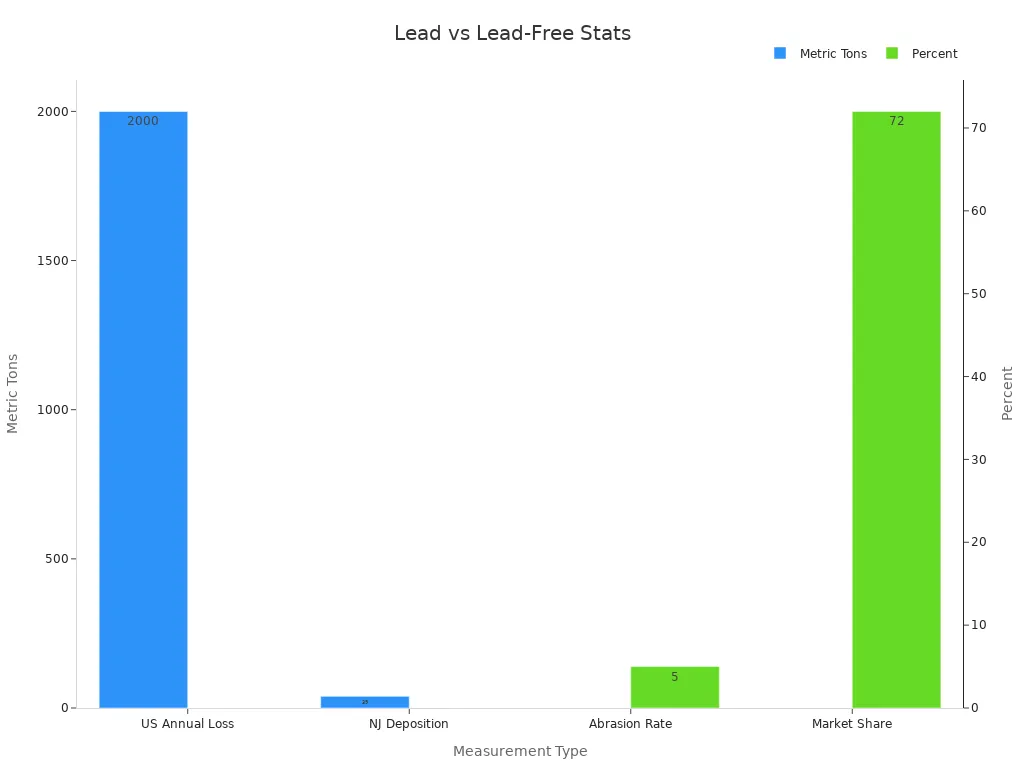

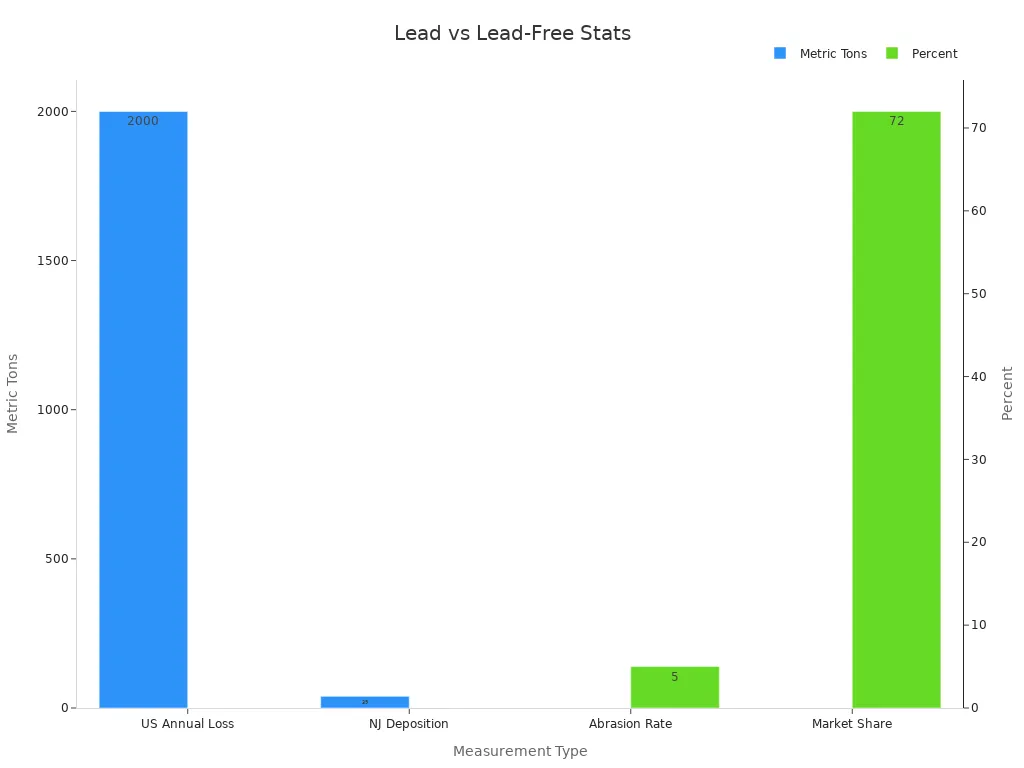

You see lead tire balancing weights on vehicles everywhere, but most drivers do not realize the environmental risks they create. Lead tire weights release about 2,000 metric tons of lead each year in the U.S. alone. This lead seeps into soil and water, raising environmental concerns and prompting new regulations. The high lead content—up to 95%—in traditional lead tire weights means even a small loss can cause major harm. New Jersey roads alone collect nearly 39 metric tons of lead annually from these weights.

Many countries now encourage transitioning to non-lead alternatives. Lead-free wheel weights, often made from steel or zinc, offer strong performance and safety. Studies show non-lead weights match or even surpass lead tire weights in durability. Regulations continue to push for non-lead options to reduce environmental impact. You help protect the environment and your community’s health by transitioning to non-lead solutions.

What Are Tire Balancing Weights?

Purpose of Tire Balancing Weights

You may not notice them, but tire balancing weights play a big role in your driving experience. These small weights attach to your wheels to keep them balanced. When your wheels are balanced, your car rides smoothly. You feel less vibration in the steering wheel and the seats. Balanced wheels also help your tires wear evenly, which means you do not have to replace them as often. You save money and enjoy a safer ride.

Unbalanced wheels can cause problems. You might notice your car shaking at certain speeds. This shaking can make driving uncomfortable. It can also lead to uneven tire wear, which shortens the life of your tires. Your car may use more fuel, and your suspension parts can wear out faster. By using tire balancing weights, you help your car perform better and last longer.

Why Material Choice Matters

You have many options when it comes to the material of your tire balancing weights. In the past, most weights contained lead. Today, many states and countries are banning lead because it harms the environment. When lead weights fall off your car, they can end up in soil and water, causing pollution.

Now, you can choose from several alternatives. Here are some common materials used in tire balancing weights:

- Zinc: A popular alternative to lead, zinc offers good density and is less harmful to the environment.

- Steel: Steel weights are strong, cost-effective, and widely used. They are smaller in size and safer for the planet.

- Polymer-coated steel: These weights combine steel with a protective coating, making them even more eco-friendly.

- Composite materials: Some weights use advanced composites for better performance and easier installation.

You also find adhesive weights made from steel or composite materials. These stick to the inside of the wheel and offer precise balance. The rise of electric vehicles has led to new alternatives designed for unique weight needs. When you pick a material, you should think about cost, durability, and how it affects the environment. Choosing the right alternative helps you meet local laws and keeps your car running smoothly.

Lead Tire Balancing Weights: Pros and Cons

Performance and Effectiveness of Lead Tire Weights

You may wonder why lead tire weights have been used for so long. Lead tire balancing weights offer a reliable way to keep your wheels balanced. They help correct both static and dynamic imbalances, which means you get a smoother ride, better fuel economy, and longer tire life. Many shops use clip-on lead wheel weights because they grip the rim tightly and stay in place over bumps and rough roads. However, lead tire weights can lose mass over time due to abrasion from the road. This loss can affect their performance and may require you to rebalance your tires more often.

| Performance Metric | Clip-On Weights | Adhesive (Stick-On) Weights |

|---|---|---|

| Weight Impact | Standard weight, generally heavier | Reduced unnecessary weight by 50-70% |

| Installation | Requires tools and more time | Easy installation with adhesive backing |

| Aesthetic Appeal | Bulky and visible on steel wheels | Sleek, hidden design for alloy wheels |

| Environmental Compliance | Often contains lead or hazardous materials | Free from harmful substances like lead |

| Bond Strength | Varies, generally less durable | Superior bond strength with adhesives |

You should know that proper installation is key. If a lead tire weight falls off, your wheel can become unbalanced, causing vibration and uneven tire wear. Regulations now encourage the use of lead-free options, which often provide better durability and environmental compliance.

Cost and Availability of Lead Tire Balancing Weights

Lead tire balancing weights have been popular because of their low cost. In the past, lead tire weights were much cheaper than lead-free options. Today, the price gap has narrowed. Now, you might pay less than $1 more for a set of four lead-free weights. Dealers do not need to carry extra stock because zinc and steel weights replace lead weights one-for-one. Most major car makers have switched to lead-free wheel weights, so you will find fewer lead tire weights in new vehicles. The industry is moving toward 100% lead-free weights, which helps reduce costs and makes it easier for shops to stock what you need.

- The cost difference between lead tire weights and lead-free alternatives is now under 25-30%.

- Lead-free weights come in full product lines, so you do not lose productivity.

- Advanced lead-free products can offer even better performance, though at a slightly higher price.

Health and Environmental Impact of Lead Tire Weights

Lead tire balancing weights raise serious public health and environmental concerns. When lead wheel weights fall off, they break down and release toxic lead into the soil and water. This contamination can harm children and wildlife. Studies show that lead contamination in playgrounds and soil can reach levels far above safe limits. For example, some playgrounds in New York City have lead levels up to 1,956 ppm, while the EPA’s safe limit for children’s play areas is only 400 ppm. Even small amounts of lead exposure can lower IQ and cause other health problems.

⚠️ The CDC says no safe blood lead level exists for children. Even a tiny amount of toxic lead can affect public health.

Although the EPA found that lead wheel weights now make up a small part of children’s overall lead exposure, the risk remains. Many states and countries have banned lead tire weights to protect public health and the environment. Lead tire weights are no longer installed on new vehicles in the U.S. because of these risks. You help reduce toxic lead contamination and protect your community by choosing safer alternatives.

Lead-Free Wheel Weights: Pros and Cons

Types of Lead-Free Wheel Weights (Steel, Zinc, Composite)

You can choose from several non-lead alternatives when you want to balance your tires. The most common lead-free wheel weights use steel, zinc, or composite materials. Steel-based weights are popular because they have high density, small size, and eco-friendly properties. Zinc weights offer good corrosion resistance and are often used in regions with strict environmental rules. Composite weights use advanced materials that resist high temperatures and provide strong environmental benefits. Each type of non-lead alternative has unique features that suit different vehicles and driving needs.

| Region | Regulation & Date | Lead Restrictions | Permitted Materials | Cost & Production Differences |

|---|---|---|---|---|

| EU | ELV Directive 2003/2013 (revised) | Lead banned in auto parts | Zinc, steel, composites | Zinc stamping requires higher precision; composites costliest |

| USA | EPA Lead Restrictions (varies by state) | 15 states ban lead weights | Primarily zinc | Zinc intermediate cost; steel used in some applications |

| China | GB Standards 2018 (updated) | Lead allowed during transition | Lead still allowed; zinc encouraged | Zinc demand up 30% (2010-2020); cost higher than lead |

| Japan | JIS D4205 2015 | Automaker supply chain requirements | Zinc, steel | Emphasis on stamping accuracy and temperature resistance |

| India | None yet | No lead ban | Lead dominant; voluntary standards | Lower adoption of lead-free materials |

Performance and Effectiveness of Lead-Free Wheel Weights

You get reliable performance from non-lead alternatives. Steel-based weights deliver strong results because they control tire wear and keep your ride comfortable. Zinc and composite weights also provide excellent performance, especially in harsh weather or high-temperature conditions. Many drivers notice that non-lead wheel weights stay in place and last as long as traditional options. Dynamic wheel balancing with these alternatives helps your tires wear evenly and improves your driving experience. You can trust lead-free wheel weights to meet or exceed the performance of older lead weights.

Note: Dynamic wheel balancing is essential for tire maintenance. Non-lead alternatives support this process and help your tires last longer.

Cost and Availability of Lead-Free Wheel Weights

You will find that non-lead alternatives are now widely available. The global market for lead-free wheel weights is growing fast, with a projected value of $750 million by 2026. Steel-based weights are cost-effective and easy to find, while zinc and composite options may cost a bit more due to higher production standards. OEM suppliers and aftermarket shops now stock a full range of non-lead wheel weights, so you can easily switch from lead to safer alternatives. Europe and Asia-Pacific regions lead the way in adopting these products, driven by strict regulations and rising consumer demand.

- Steel-based wheel weights are preferred for their eco-friendly composition and cost advantages.

- The market for steel wheel weights is growing at about 6% per year.

- OEMs are shifting to non-lead alternatives due to environmental regulations and consumer awareness.

Environmental and Safety Benefits of Lead-Free Wheel Weights

You make a big difference when you choose lead-free wheel weights for your vehicle. These weights help protect the environment in several important ways. When you use lead-free options, you prevent toxic lead from entering the soil and water. Studies show that millions of pounds of lead from old wheel weights end up in the environment every year. This pollution can harm plants, animals, and even people.

Lead-free wheel weights support eco-friendly practices. You help keep playgrounds, parks, and roadsides cleaner and safer for everyone. Many cities have seen lower lead levels in soil after switching to these weights. For example, after California banned lead wheel weights, researchers found a drop in lead pollution along highways.

You also support a sustainable solution by choosing these products. Manufacturers often use recycled steel or zinc to make lead-free weights. This process saves natural resources and reduces waste. When you pick these weights, you encourage companies to use more eco-friendly practices in their factories.

Safety matters, too. Lead-free wheel weights are safer alternatives for workers who handle them. You lower the risk of lead exposure for mechanics and anyone who comes in contact with your wheels. Children and pets who play near roads benefit from less toxic dust in the air and soil.

Tip: You can ask your tire shop if they use lead-free wheel weights. This small step helps protect your community and the environment.

Here is a quick look at the benefits:

- Reduces environmental pollution from toxic metals

- Supports eco-friendly practices in manufacturing

- Promotes a sustainable solution for future generations

- Improves safety for workers and families

- Meets strict environmental regulations in many regions

Head-to-Head Comparison: Lead Tire Balancing Weights vs. Lead-Free Wheel Weights

Effectiveness and Durability

You want your tire balancing weights to last and keep your ride smooth. When you compare lead tire weights and non-lead alternatives, you see clear differences in how they perform and how long they last. Lead tire weights have high density, which means you can use smaller pieces to balance your wheels. They also bend easily, so they fit many rim shapes. However, lead tire weights lose about 5.2% of their mass each day from abrasion on the road. This loss not only affects their durability but also releases toxic particles into the environment.

Non-lead wheel weights, such as steel and zinc, offer strong durability. Steel weights, especially those with special coatings, resist corrosion and last longer. Manufacturers test steel weights with salt-spray tests for up to 3,000 hours to make sure they stand up to harsh conditions. Zinc weights also resist corrosion and work well in wet or salty environments. Composite and hybrid weights combine steel with plastic coatings, giving you extra protection for your wheels.

Here is a quick comparison:

| Material | Advantages | Disadvantages | Best Use Cases |

|---|---|---|---|

| Steel | Durable, cost-effective, recyclable, corrosion-resistant with coating | Heavier than zinc, can rust if uncoated | Heavy-duty vehicles, budget-conscious users |

| Zinc | Corrosion resistant, eco-friendly, non-toxic | Higher cost than steel, less dense than lead | Corrosive environments, eco-friendly users |

| Lead | High density, flexible, precise | Environmental risks, regulatory limits | Older vehicles, unrestricted regions |

You can trust non-lead alternatives to provide reliable performance. Lab tests, like oven aging and rolling drum tests, show that non-lead weights hold up well over time. These tests measure how weights handle heat, pressure, and wear. Non-lead weights often match or exceed the performance of lead tire weights in these tests. You get a safer, longer-lasting solution when you choose non-lead wheel weights.

Safety and Health Risks

Your safety and health matter every time you drive. Lead tire weights pose serious risks to public health. When lead wheel weights fall off your car, they break down and release toxic lead dust. This dust can get into the soil, water, and even the air you breathe. Children and wildlife face the highest risks from lead exposure. Even small amounts of lead can cause learning problems and other health issues in kids. Mechanics and workers in auto shops also face higher risks from handling lead tire weights.

Non-lead wheel weights, like steel and zinc, do not carry these toxic risks. You lower your exposure to dangerous substances by choosing non-lead alternatives. Regulatory agencies, such as the EPA, have studied these risks and pushed for safer options. The move to non-lead weights helps protect public health and supports public health protections in your community.

- Lead is a major source of environmental contamination and health problems.

- Lead exposure can harm children, wildlife, and workers.

- Non-lead alternatives reduce toxic risks and support safer workplaces.

- Regulatory actions, like the National Lead Free Wheel Weight Initiative, encourage the use of non-lead wheel weights.

You help create a safer environment for everyone when you pick non-lead wheel weights.

Environmental Impact

You make a big difference for the environment with your choice of wheel weights. Lead tire weights cause significant environmental problems. When they fall off, they release toxic lead into the soil and water. This lead contamination harms plants, animals, and people. Lead is hard to remove from the environment and can stay in the soil for many years. Recycling rates for lead wheel weights remain low, which adds to the problem.

Non-lead wheel weights, such as steel and zinc, offer a cleaner solution. These non-lead alternatives do not release toxic substances when they fall off. Zinc weights are non-toxic and eco-friendly, though zinc losses can still pose some environmental challenges. Steel weights are easy to recycle and support eco-friendly practices. Many manufacturers use recycled materials to make non-lead wheel weights, which helps reduce waste.

- Lead-based wheel weights pollute soil and water with toxic lead.

- Non-lead wheel weights lower environmental risks and support sustainable automotive practices.

- Switching to non-lead alternatives helps protect ecosystems and public health.

- Lead-free adhesive weights make recycling easier and reduce waste.

You support a healthier planet and safer communities by choosing non-lead wheel weights. Your decision helps reduce lead contamination and supports a cleaner future for everyone.

Regulations and Legal Considerations

You need to know about the rules that affect tire balancing weights. Many countries have strict regulations about what materials you can use. These regulations protect people and the environment from harmful substances like lead. In the United States, several states have banned lead tire weights. California, Washington, and Illinois were among the first to pass these laws. Other states follow similar regulations to keep roads and communities safe.

You should always check local regulations before you buy or install tire weights. Some areas require shops to use only lead-free wheel weights. If you travel across state lines, you may notice different rules. The European Union has some of the strictest regulations in the world. The EU banned lead in automotive parts, including wheel weights, under the End-of-Life Vehicles Directive. Japan and China also have their own regulations. These rules help reduce pollution and protect public health.

Regulatory compliance is important for everyone in the automotive industry. If you own a repair shop, you must follow all regulations to avoid fines. You also need to keep records to show compliance with local laws. Many manufacturers now design products to meet global compliance standards. This helps you stay within the law, no matter where you live or work.

You may see the term “environmental regulations” when you read about tire weights. These rules focus on reducing pollution and keeping toxic materials out of the soil and water. When you choose lead-free wheel weights, you help meet these regulations and support a cleaner environment.

Tip: Always ask your tire shop if their products meet current regulations. This helps you make safe and legal choices for your vehicle.

Cost Comparison

You might wonder if switching to lead-free wheel weights will cost you more. Market research shows that the industry is moving away from lead-based weights. This shift happens because of health concerns, environmental risks, and new regulations. You will find that lead-free options, such as zinc, steel, and composite weights, are now more common.

Lead-free wheel weights offer many advantages. They last longer, resist corrosion, and are easier to recycle. These benefits make them cost-effective over time. While you may not see a big price difference at the store, you save money in the long run. You do not need to replace them as often, and you avoid fines for non-compliance with regulations.

Manufacturers focus on compliance when they design new products. They want to make sure you get a product that meets all regulatory compliance standards. This focus on compliance helps keep costs down for everyone. You do not have to worry about extra fees or legal trouble when you use approved products.

You should also think about the hidden costs of using lead weights. If you use products that do not meet regulations, you risk fines and extra expenses. You may also pay more for cleanup if lead weights pollute your property. Lead-free weights help you avoid these problems and keep your costs predictable.

Note: The market does not provide exact numbers for the cost difference between lead and lead-free weights. However, experts agree that lead-free options are more cost-effective when you consider durability, compliance, and environmental impact.

Surprising Facts and Common Misconceptions About Lead Tire Weights and Lead-Free Wheel Weights

Myths About Lead-Free Wheel Weights

You might hear that non-lead wheel weights do not work as well as lead weights. This is not true. Many drivers believe that only lead can balance tires properly. In reality, non-lead alternatives like steel, zinc, and composites offer excellent performance. Some people think non-lead weights fall off more easily, but modern designs grip the rim tightly. You may also hear that non-lead options cost much more. Today, the price difference is small, and you often save money over time because non-lead weights last longer and meet strict rules.

Tip: Non-lead wheel weights meet or exceed the standards set by car makers and safety groups.

Unexpected Benefits or Drawbacks

You may not realize how much tire balancing affects your comfort. Many drivers skip balancing because they think it takes too long or needs frequent rebalancing. Balancing usually takes just 10-15 minutes per tire and can improve your ride quality. You feel less vibration and less fatigue, especially on long trips. Fleet managers often focus on balancing only the front tires, but balancing all tires can make a big difference. Companies like Cal-Maine Foods found that balancing every axle reduced shaking and made driving smoother. The small extra weight from wheel weights is worth it for the comfort and safety you gain.

- Balancing all tires, not just the front, reduces driver fatigue.

- The added weight from non-lead alternatives is minor but brings big comfort gains.

- You may need to rebalance every 20,000 miles, but the benefits last much longer.

What Most Drivers Don’t Realize

You might not notice the impact of your choice between lead and non-lead wheel weights right away. When you choose non-lead alternatives, you help protect the environment and your health. Many drivers do not know that lead weights can break down and pollute soil and water. Transitioning to non-lead options keeps toxic metals out of your community. You also support safer workplaces for mechanics who handle your tires. Most new cars now use non-lead wheel weights because they are safer and meet legal requirements. By picking non-lead alternatives, you join a growing group of drivers who care about safety, comfort, and the planet.

| What Drivers Often Miss | Reality with Non-Lead Alternatives |

|---|---|

| Only lead weights work best | Non-lead weights match or exceed performance |

| Non-lead costs much more | Price gap is small, savings add up |

| Balancing is not important | Balancing improves comfort and safety |

How to Choose Between Lead Tire Balancing Weights and Lead-Free Wheel Weights

Consider Your Vehicle and Driving Habits

You should start by thinking about your vehicle type and how you drive. If you own a heavy-duty truck or drive long distances, you may need weights that offer strong durability. Many drivers now pick non-lead wheel weights because they work well for daily driving and high-mileage vehicles. Non-lead options, such as steel and zinc, provide reliable balance and last through tough conditions. When you use non-lead weights, you help your tires wear evenly and keep your ride smooth. Lower rolling resistance from non-lead weights can also improve your fuel economy. Tests show that tires with lower rolling resistance use less energy, which means you save money at the pump.

Check Local Laws and Regulations on Lead Tire Weights

You must check the rules in your area before choosing tire weights. Many states and countries have banned lead wheel weights to protect the environment. Some places require shops to use only non-lead weights. If you travel across state lines, you may see different laws. Always ask your tire shop about compliance with local regulations. Using non-lead weights helps you avoid fines and keeps your vehicle in compliance. Shops that follow compliance rules will have non-lead weights ready for your car. You can also look for labels or certificates that show compliance with safety and environmental standards.

Tip: Ask your mechanic if your tire weights meet compliance standards. This simple question helps you stay safe and legal.

Weigh Environmental and Health Priorities

You make a big impact when you choose between lead and non-lead wheel weights. Lead weights can break down and pollute soil and water. Non-lead weights, like steel and zinc, do not release toxic metals. Many experts use decision-making tools, such as the Analytical Hierarchy Process, to compare the importance of design, performance, durability, environment, and fuel economy. These tools show that non-lead weights often rank higher for environmental friendliness and health. When you pick non-lead weights, you help protect children, wildlife, and your community. You also support cleaner air and water. Non-lead weights align with your values if you care about the planet and public health.

- Non-lead weights reduce pollution and support a safer environment.

- Lead weights may still be allowed in some areas, but non-lead options offer better long-term benefits.

- Choosing non-lead weights shows you care about compliance, safety, and the future.

Factor in Cost and Availability

When you choose between lead and lead-free wheel weights, you need to think about both cost and availability. The tire industry is changing fast. New rules and technology shape what you find in stores and how much you pay.

You see prices change because of many reasons. Tire makers use new materials and advanced features, like Aramid fiber sidewalls and smart sensors. These upgrades make tires and wheel weights better, but they also raise costs. Companies now use recycled materials and focus on eco-friendly production. This helps the planet, but it can make products more expensive.

Supply chain issues also play a big role. Sometimes, raw materials like natural rubber or steel become hard to get. Prices go up when there are shortages or when oil prices change. Global events, such as trade policies or tariffs, can affect how much you pay for tires and wheel weights. Labor costs and research for new tire technology add to the price as well.

Here are some key trends you should know:

- The global tire market is growing because more people want sustainable and high-tech products.

- Manufacturers use advanced methods, like 3-D printing and flow-forging, to make lighter and stronger wheels.

- Environmental rules and ESG (Environmental, Social, Governance) standards push companies to use safer materials.

- Raw material prices can change quickly, making costs hard to predict.

- Classic wheel designs are still popular, but modern cars need lighter wheels for better performance.

| Factor | Impact on Cost & Availability |

|---|---|

| Raw material prices | Can cause sudden price increases |

| Advanced technology | Raises production costs |

| Environmental rules | May limit material choices |

| Supply chain issues | Affect how quickly you get products |

Tip: Ask your tire shop about current prices and stock. This helps you plan your purchase and avoid surprises.

Choosing the right wheel weight means looking at both price and how easy it is to find. By staying informed, you make a smart choice for your car and your budget.

You face an important choice when selecting tire balancing weights. Lead-free options now stand out as the smarter, safer, and more environmentally responsible path. Many drivers still see lead tire weights in shops, but new rules and growing concerns about lead pollution make lead-free weights the future. Industry reports show that zinc and steel weights help reduce lead in soil and water. Lighter materials like zinc improve fuel efficiency and vehicle control, while steel offers durability. Regular maintenance and the right weight for your vehicle keep you safe. When you choose lead-free weights, you help lower lead emissions and support cleaner air. Always check your local laws and think about your vehicle’s needs. Trust a reputable manufacturer like Fortune to provide quality products that meet strict standards.

- Lead-free wheel weights reduce lead contamination in the environment.

- Zinc weights are lighter than steel and help improve fuel efficiency.

- Steel weights offer strong durability but add more weight than zinc.

- Lighter materials support better vehicle control and longer tire life.

- Moving away from lead aligns with new regulations and industry trends.

You make a real difference by choosing lead-free wheel weights. Your decision helps protect your community from lead exposure and supports a healthier planet.

FAQ

Are lead-free wheel weights as effective as lead weights?

Yes, you get the same or better performance from lead-free wheel weights. Tests show steel and zinc weights balance tires just as well as lead. Many car makers now use only lead-free weights on new vehicles.

Do lead-free wheel weights cost more than lead weights?

You may pay a little more for lead-free wheel weights, but the price difference is small. Most shops charge less than $1 extra per set. You save money over time because lead-free weights last longer and help you avoid fines.

Are lead-free wheel weights safer for the environment?

Absolutely! Lead-free wheel weights do not release toxic metals into soil or water. Studies show that switching to non-lead weights lowers lead pollution along roads and in playgrounds. You help protect your community and wildlife by choosing lead-free options.

Can I install lead-free wheel weights on any vehicle?

You can use lead-free wheel weights on almost any car, truck, or SUV. They come in many sizes and styles to fit different wheels. Ask your tire shop for the right type for your vehicle.