admin1

July 1, 2025

How to Identify the Correct Balance Weight Tire for Your Wheels

When you want your vehicle to run smoothly, you need to choose the right wheel weight for your wheels. You start by checking your tire size, the type of wheel you use, and the best method for balance. Picking the correct balance weight tire improves safety, boosts performance, and helps your tires last longer. Wheel weights keep your vehicle steady and safe on the road. Choosing the right weight also means your wheel weight matches your vehicle’s needs. Fortune uses strict quality controls to make sure every wheel weight meets high standards for balance and performance.

Understanding Balance Weight Tire and Its Importance

What Is a Balance Weight Tire?

You may notice that your vehicle feels smoother and safer when you use the right balance weight tire. A balance weight tire means your tire and wheel assembly has wheel weights attached to correct any uneven mass. These wheel weights help distribute weight evenly around the wheel’s axis. When you drive, properly balanced rims and tires prevent vibrations and keep your ride comfortable.

Wheel weights come in two main types: clip-on and adhesive. Clip-on weights fit onto the rim flange, while adhesive weights stick directly to the wheel. Both types play a key role in keeping your tires balanced. The SAE J1986 standard sets the rules for automotive wheel weights, making sure they fit well and stay in place. This standard covers both aluminum and steel wheels for cars, trucks, and multipurpose vehicles. You can trust that using balance weight tire products that meet these standards will help your vehicle perform at its best.

Why Proper Wheel Weights Matter for Your Vehicle

You need to pay attention to the importance of wheel weights for your vehicle. Balanced wheel weights improve handling, reduce vibrations, and make your drive safer. When you use proper wheel balancing, you lower the risk of steering wheel shake and floorboard vibration. Balanced wheels also help your tires wear evenly, which means you do not have to replace them as often.

Tip: Regular wheel balancing every 5,000 to 6,000 miles keeps your vehicle running smoothly and extends tire life.

Balanced wheels also improve fuel economy by reducing rolling resistance. Lighter wheels help your tires grip the road better, which boosts safety, especially in wet or sharp turns. Research shows that balanced wheels can cut whole-body vibration by up to 10% and shock by 50%. This means you get a smoother ride and better control. Automotive wheel weights also protect your suspension from extra stress, helping your vehicle last longer. If you want top vehicle performance and handling, always use balanced wheel weights and check your balance regularly.

Steps for Selecting the Right Wheel Weights

Assess Your Tire and Wheel Type

You need to start by looking at your tire and wheel type before you choose a wheel balance weight. Each tire and wheel combination has unique needs. You should check the size of your tire, the width, and the diameter of your wheel. Use a size chart to match these measurements. This step helps you avoid problems like poor fit or imbalance. If you use the wrong size, your vehicle may shake or your tires may wear out faster.

Inspect the material of your wheel. Steel wheels often work best with clip-on wheel weights. Alloy or aluminum wheels usually need adhesive weights. Look at the rim profile to see if it has a flange for clip-on weights. If not, adhesive weights are a better choice. You also need to think about the type of driving you do. High-speed driving or heavy loads may require more precise balance and stronger wheel weights.

Tip: Always use a dynamic wheel balancer to find the exact spot where you need to place the balance weight tire. This tool helps you get the best balance and handling for your vehicle.

Identify the Correct Balance Weight Type: Clip-On vs. Adhesive

You have two main types of wheel weights to choose from: clip-on and adhesive. Each type has its own strengths and best uses. Clip-on weights attach to the rim flange and work well with steel wheels. Adhesive weights stick to the inside of the wheel and are ideal for alloy or custom wheels.

Here is a comparison to help you choose a wheel balance weight that fits your needs:

| Aspect | Clip-on Weights | Adhesive Weights |

|---|---|---|

| Application | Common on steel wheels and commercial vehicles | Popular on high-performance and alloy wheels |

| Installation Ease | Quick to install with hooks or knock-on tools | Needs clean surface and strong adhesive |

| Performance | Reliable under many conditions | Offers better balance and protects wheel finish |

| Durability | Long-lasting, easy to replace | Adhesion may weaken in heat or humidity |

| Visibility | More visible on the wheel | Low profile, keeps wheels looking sleek |

| Compatibility | Best for steel wheels, may scratch alloys | Designed for alloy wheels, avoids rim damage |

You should choose a wheel balance weight that matches your wheel type and driving needs. Clip-on weights give strong attachment and are easy to replace. Adhesive weights are less visible and protect the finish of your wheels. Both types help reduce vibration and improve handling. Industry experts say that balancing all wheel positions—steer, drive, and trailer—gives the best results for your vehicle.

- Clip-on weights are durable and easy to install, making them a good choice for many vehicles.

- Adhesive weights work well for custom or high-performance wheels and keep your wheels looking clean.

Choose the Best Material: Steel, Lead, Zinc, and Alternatives

When you choose a wheel balance weight, you need to think about the material. The most common materials are steel, zinc, and lead. Many countries now ban lead because it is not safe for the environment. You should look for environmentally friendly materials like steel and zinc.

Here is a table to help you compare materials:

| Material | Benefits and Performance | Details and Testing Methods |

|---|---|---|

| Steel | Strong, durable, cost-effective, recyclable | Used in most automotive wheel weights; resists corrosion |

| Zinc | Corrosion resistant, non-toxic, easy to shape | Safer than lead; used in stamping and forming processes |

| Lead | Heavy, easy to mold, but not eco-friendly | Being phased out due to environmental rules |

| Composites | Lightweight, strong, improves fuel economy | Used in new designs; tested for strength and durability |

Steel wheel weights are popular because they last long and resist rust. Zinc wheel weights are safe and flexible, making them a good choice for many vehicles. Composites are new and offer weight savings and better performance. You should always check if your area has rules about lead. Many places require you to use lead-free wheel weights.

Note: Choosing the right weight material can extend tire life by up to 50% and improve fuel economy by 1% to 2%. Some fleets report even higher gains.

When you select a suitable wheel balance weight, you help your vehicle handle better and last longer. Automotive wheel weights made from steel or zinc meet strict quality standards. These materials also support a cleaner environment. Always choose a wheel balance weight that matches your wheel type, driving needs, and local rules. This step ensures you get the best performance, safety, and handling from your vehicle.

Determine the Right Wheel Weight Size and Placement

Getting the right wheel weight size and placing it correctly is key to keeping your vehicle safe and smooth. You need to follow a few important steps to make sure your wheels stay balanced and your ride feels comfortable.

Clean the Wheel Surface

Always start by cleaning the wheel surface. Dirt or grease can stop wheel weights from sticking or clamping well. Use a clean cloth and a mild cleaner. This step helps the wheel weight stay in place for a long time.Use Professional Balancing Equipment

You should use a wheel balancer to find out where your tire needs weight. The balancer spins the wheel and tells you the exact spot and amount for the right wheel weight. It checks three things: the size of the circle where you put the weight, the distance between the weight planes, and how fast the wheel spins. This process helps you avoid guessing and makes sure your tire gets the best balance.Choose the Correct Position for Each Weight Type

- Place adhesive wheel weights on the inner rim surface.

- Attach clip-on wheel weights to the rim edge.

The right spot depends on your wheel design. Placing the weight in the correct area helps your tire stay balanced and improves handling.

Apply Weights Properly

When you use adhesive weights, press them down firmly. Make sure there are no bubbles or wrinkles. For clip-on weights, clamp them tightly so they do not move. This step keeps the wheel weights secure, even when you drive on rough roads.Select the Right Wheel Weight Size

The balancer will tell you how much weight you need. Most times, you round the amount to the nearest quarter ounce. This prevents over-correction and keeps your tire balanced. Using the right wheel weight size means you do not have to add extra weights later.Check for Balance and Adjust if Needed

After you install the wheel weights, spin the wheel again. If you still feel vibration or shaking, adjust the weights. Sometimes, you need to rebalance if you drive long distances or hit a pothole.Inspect Wheel Weights Regularly

Look at your wheel weights after long trips or rough driving. Check for looseness, damage, or missing weights. If you find a problem, fix it right away to keep your tire balanced.

Tip: Keep your tire pressure at the right level and rotate your tires often. These habits help your wheel weights last longer and keep your wheels balanced.

| Step | What to Do | Why It Matters |

|---|---|---|

| Clean wheel surface | Remove dirt and grease | Ensures strong adhesion/clamping |

| Use balancing equipment | Find exact spot and amount for weight | Achieves precise balance |

| Place weights correctly | Adhesive inside rim, clip-on at rim edge | Matches wheel design |

| Apply weights firmly | Press adhesive, clamp clip-on | Prevents movement or detachment |

| Select correct size | Round to nearest 1/4 ounce | Avoids over-correction |

| Check and adjust | Spin again, fix if needed | Maintains smooth ride |

| Inspect regularly | Look for damage or missing weights | Keeps balance and safety |

Choosing the right weight and placing it in the correct spot helps your vehicle handle better and keeps your tires from wearing out too soon. When you follow these steps, you make sure your wheel weights do their job. You also help your car stay safe and comfortable on every drive.

Recognizing When Your Tire Needs Wheel Weights

Common Signs of Wheel Imbalance

You can spot wheel imbalance by paying attention to how your vehicle feels and sounds. When your wheels lose balance, you may notice your steering wheel vibrates, especially at certain speeds. Sometimes, your car pulls to one side or the steering feels off-center when you drive straight. You might also hear squealing from your tires or see uneven tread wear. These signs show your wheels are not balanced and need attention.

Here is a table that shows the main indicators of wheel imbalance:

| Indicator Type | Description / Sign | Quantitative Details |

|---|---|---|

| Qualitative Signs | Abnormal handling, visible tire damage, squealing tires, car pulling to one side, uneven tread wear, vibrating steering wheel | N/A |

| Vibration Analysis | Power Spectral Density (PSD) peaks at certain frequencies in x, y, z axes | At 50 km/h, PSD peaks up to 0.12; imbalance masses of 0.04 kg and 0.08 kg used as benchmarks; higher PSD means more imbalance |

| Speed Dependence | Highest accuracy at 50 km/h; accuracy drops at higher speeds | At 70 km/h, PSD peak at f0 reaches 0.23 in y-axis due to resonance |

| Manual Check | Spinning tire off the ground to check for wobbling | N/A |

You can also look for these signs:

- Vibrating steering wheel

- Uneven brake pad wear

- Vehicle pulling to one side

- Squealing tires

- Off-center steering wheel

- Visible tire damage

- Uneven tread wear

- Wobbling when you spin the tire by hand

If you notice any of these, your wheels may need new wheel weights to restore balance.

Causes of Imbalance and When to Check Your Tires

Many things can cause your wheels to lose balance. Hitting potholes, curbs, or driving on rough roads can knock wheel weights loose. Changes in tire pressure or uneven load in your vehicle can also affect balance. Even normal wear over time can lead to imbalance.

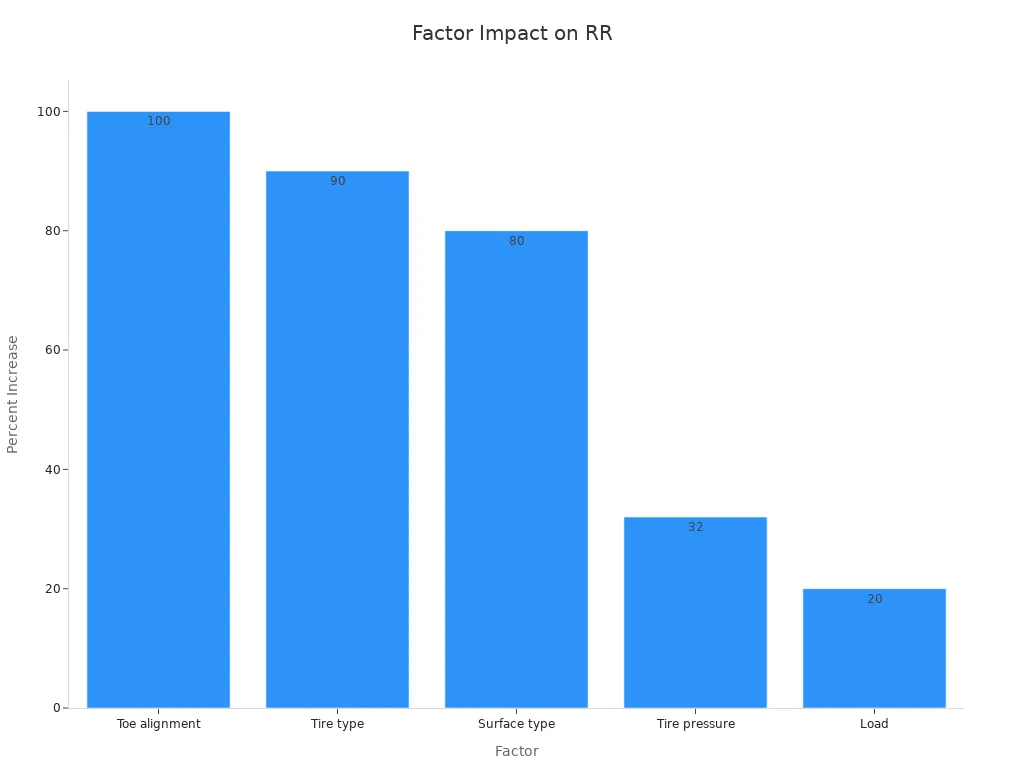

Mechanical and environmental factors play a big role. For example, poor toe alignment or using the wrong tire type can double rolling resistance. Low tire pressure can increase rolling resistance by up to 32%. Driving on rough surfaces can raise it by over 80%. These changes make your wheels lose balance faster.

You should check your tires and wheel weights if you feel vibrations, see uneven wear, or after hitting a pothole. Regular checks help keep your balanced wheels in top shape. Experts recommend checking your balance every 5,000 to 6,000 miles or whenever you notice changes in how your vehicle drives. Keeping your wheels balanced improves safety, extends tire life, and gives you a smoother ride.

Installation and Maintenance of Wheel Weights

Proper Installation Methods for Different Wheel Weights

You need to follow the right installation process to keep your vehicle balanced and safe. Wheel weights come in two main types: tape-on (adhesive) and clip-on. Each type has its own steps for easy installation.

- For tape-on weights, clean the wheel surface first. Remove all dirt and grease. Place the weight between the inboard and outboard sides to correct static imbalance. Press the weight firmly to make sure it sticks well.

- For clip-on weights, choose the correct size for your rim. Attach the weight to the rim edge. Use a tool to secure it tightly. Place clip-on weights on either side of the rim to fix static or dynamic imbalance.

You should always use a wheel balancer during installation. This tool helps you find the exact spot for each weight. When you balance both the inboard and outboard sides, you get better tire performance and a smoother ride. Environmental trends now favor zinc and steel weights over lead, so check your materials before starting the installation.

Tip: Secure installation prevents weights from falling off. Tape-on weights cannot be reused if they come loose, so press them down firmly.

Maintenance Tips for Long-Lasting Tire Balance

Regular tire maintenance keeps your wheels balanced and your vehicle running smoothly. You should check your wheel weights after long trips or rough roads. Look for loose or missing weights. Replace any that are damaged or lost.

Follow these steps for the best results:

- Inspect your tires and wheel weights every time you rotate your tires.

- Balance all tires, not just the front ones. This practice increases tire life by up to 25% for steer tires, 35% for drive tires, and over 50% for trailer tires.

- Add balancing to your preventive maintenance program. Tire wear and imbalance can develop over time, so regular checks help you catch problems early.

- Keep your tire pressure at the recommended level. Low pressure can cause imbalance and extra wear.

| Maintenance Task | How Often | Why It Matters |

|---|---|---|

| Inspect wheel weights | Every 5,000 miles | Prevents loss and keeps balance |

| Rotate and balance tires | Every 6,000 miles | Extends tire life and ride comfort |

| Check tire pressure | Monthly | Supports even wear and good balance |

Note: Neglecting balance and tire maintenance can lead to more wear, driver discomfort, and even mechanical damage. Regular installation and maintenance keep your vehicle safe and your tires lasting longer.

Choosing the right wheel weights keeps your vehicle safe and smooth. You improve driving comfort and protect your tires when you follow these steps:

- Select wheel weights that match your vehicle and wheels.

- Install weights with clean surfaces and the right tools.

- Check your wheel weights often and fix any problems quickly.

- Keep your tires balanced to avoid extra wear and damage.

Fortune always delivers high-quality wheel weights. You can trust Fortune to help your vehicle perform at its best.

FAQ

What happens if you use the wrong wheel weight?

You may feel vibrations in your steering wheel or seat. Your tires can wear unevenly. This can lower your vehicle’s safety and performance. Always use the correct size and type for your wheels.

How often should you check your wheel weights?

You should check your wheel weights every 5,000 to 6,000 miles. Inspect them after hitting potholes or curbs. Regular checks help you catch loose or missing weights early.

Can you reuse wheel weights after removal?

You should not reuse adhesive wheel weights. They lose their stickiness. Clip-on weights may bend or weaken after removal. Always use new wheel weights for the best balance and safety.

Which material is best for wheel weights?

Steel and zinc are the best choices. They resist corrosion and meet environmental rules. Lead is not safe for the environment. Many countries have banned it.

Tip: Always choose wheel weights that match your wheel type and local regulations.