admin1

October 21, 2025

Avoid Mistakes When Buying a Wheel Lug Nut Socket

Proper wheel maintenance begins with having the correct tools. You need a quality wheel lug nut socket for this important job. The first step is identifying the exact size for your vehicle’s lug nut. This ensures your socket fits perfectly.

Important: Using the wrong tool size can damage the wheel, making a simple task difficult and costly.

How to Find the Correct Lug Nut Socket Size for Your Vehicle

Finding the correct lug nut socket size is the most critical step. A mismatched socket can cause serious problems. These issues include damaging the lug nut or getting the socket stuck on the wheel. You have three reliable methods to find the right lug nut socket size for your vehicle.

Check Your Vehicle’s Manual

Your vehicle’s owner’s manual is the most trustworthy source of information. Car manufacturers like Ford, Toyota, and Nissan provide these details. You can often find the lug nut socket size in the ‘Specifications’ section. Some manuals list it in the section about changing a flat tire.

The manual provides more than just the size. It also gives you crucial torque specifications. Using the correct torque ensures your wheel is secure. It prevents damage from over-tightening.

Pro Tip: Your manual also shows the correct tightening pattern for your wheel. Following this star-shaped pattern ensures the wheel sits flat against the hub.

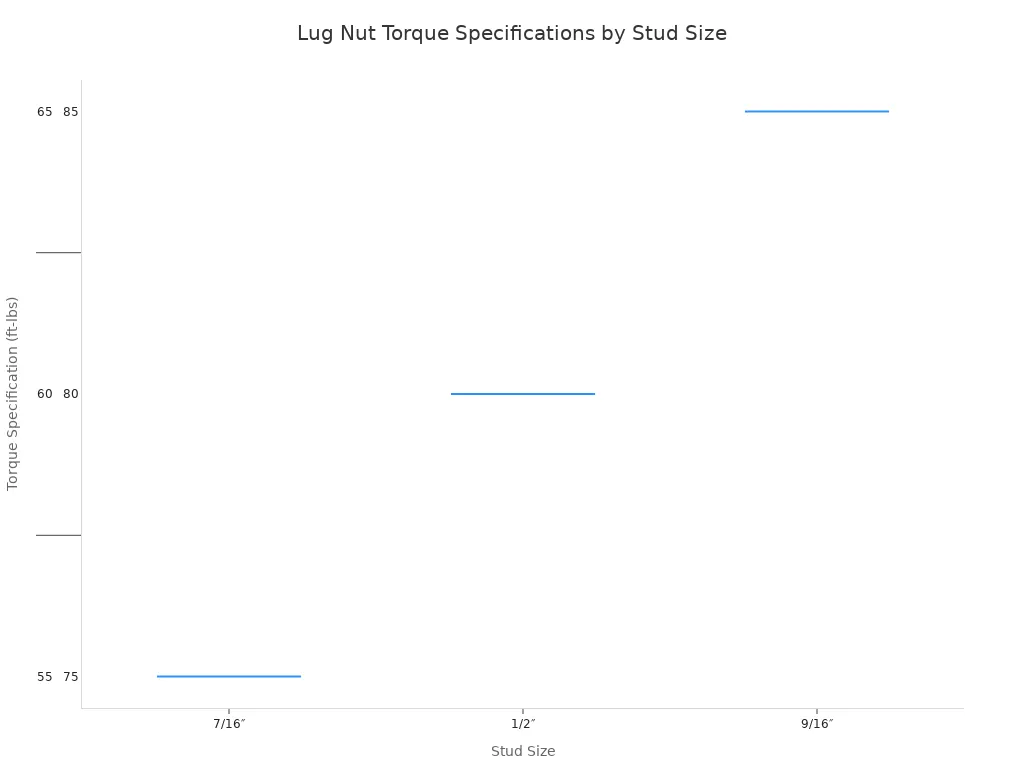

Here are some common torque specifications you might find:

| Stud Size | Torque Spec (ft.-lbs.) |

|---|---|

| 7/16″ | 55 to 65 |

| 1/2″ | 75 to 85 |

| 9/16″ | 95 to 115 |

| 5/8″ | 135 to 145 |

| 12mm | 72 to 80 |

| 14mm | 85 to 95 |

Measure the Lug Nut Manually

If you cannot find your manual, you can measure the lug nut yourself. A digital caliper is the best tool for this job. It gives you a precise measurement.

Follow these steps for an accurate reading:

- Measure the Diameter: Place the caliper’s jaws on the parallel flat sides of the lug nut. Do not measure from corner to corner. This gives you the correct size for your socket.

- Measure the Height: Place the caliper over the nut’s height from its base to its top. This helps you know if you need a deep socket.

Avoid common mistakes to get the right measurement. For example, poor lighting can make it hard to read the tool. Always work when the wheel is cool, as heat can slightly change the size. Double-check your numbers to ensure accuracy. Measuring a single lug nut is a good start, but checking a few from different spots on the wheel can account for any wear.

Use an Online Lug Nut Socket Size Chart

Using a lug nut socket size chart online is another great option. Many websites offer this tool. You can find a lug nut socket size chart on auto part retailer sites, manufacturer-specific websites, and car enthusiast forums. For example, the company McGard provides a “Vehicle Application Guide” to help you find the right parts. A good lug nut socket size chart lets you look up your vehicle’s make, model, and year.

This method is fast and convenient. However, you should be careful when using a lug nut socket size chart for older or classic cars. The information may not always be perfect.

A 21mm socket is the official size for some older Toyota models. However, some owners find a 13/16″ socket offers a tighter fit. This small difference shows why verifying the lug nut socket size is important. A slightly loose socket can work, but a snug fit is always better.

Ultimately, a lug nut socket size chart gives you a strong starting point. You can use this information to select the right wheel lug nut socket for your car. Finding the correct lug nut socket size ensures your tire changes are safe and smooth.

Choosing the Right Type of Wheel Lug Nut Socket

After you determine the correct lug nut socket size, you must select the right type of socket. The design of the socket is just as important as its size for ensuring a safe and damage-free job. You will need to consider the socket’s depth, point count, and wall thickness.

Standard vs. Deep Sockets

The most obvious difference between sockets is their length. For working on a wheel, a deep socket is almost always the best choice. Standard-depth sockets are often too short to work properly.

A standard socket can cause problems in specific situations.

- Some acorn-style lug nuts have a shape that prevents a standard socket from fully gripping the nut’s hex sides. This poor grip can round off the corners of a tight lug nut.

- A shallow socket may not provide enough clearance. Your wrench could hit and scratch the face of the wheel.

Deep sockets solve these issues and offer several key benefits. They are specifically designed for tasks like removing a stubborn lug nut.

- They are built to be stronger and more durable than regular sockets.

- Their extra length gives you better reach and leverage.

- They can handle the high torque and vibrations from power tools.

Quick Tip: Always choose a deep socket for wheel work. It provides the necessary clearance to protect your wheel and ensures a solid grip on the lug nut.

6-Point vs. 12-Point Sockets

You will also see sockets described as 6-point or 12-point. This number refers to the points inside the socket opening. For any work on your vehicle, a 6-point socket is the superior and safer option.

A 6-point socket has thicker walls and makes contact with the flat sides of a lug nut. This design distributes the turning force evenly across the nut. It greatly reduces the risk of stripping the corners, even if the nut is rusted or over-tightened. For this reason, professionals use 6-point sockets with impact tools.

A 12-point socket has more points and thinner walls. While it can be easier to place onto a nut, it has significant disadvantages for high-torque jobs.

- Using a 12-point socket is very likely to strip the corners of a lug nut.

- It is not recommended for removing tight fasteners.

- You should only use one with extreme caution if no other option is available.

For the best results and to avoid damaging your hardware, you should always use a 6-point socket for your wheel.

Thin-Wall and Non-Marring Sockets

Many modern cars have alloy wheels with very little space around the lug nuts. A standard socket may be too thick to fit into the lug nut hole without scratching the wheel. This is where thin-wall sockets become essential. A thin-wall socket has a smaller outer diameter for the same lug nut socket size, allowing it to fit into tight recesses.

For maximum protection, you can choose a non-marring socket. This is typically a thin-wall socket that includes a protective outer sleeve, usually made of nylon or another soft plastic.

| Socket Type | Best For | Key Feature |

|---|---|---|

| Thin-Wall | Wheels with tight lug nut holes | Reduced outer diameter |

| Non-Marring | Painted, chrome, or custom wheels | Protective outer sleeve to prevent scratches |

If you have expensive aftermarket or delicate factory wheels, a non-marring socket is a wise investment. It ensures you can change a tire without leaving any marks on your wheel’s finish.

Selecting the Right Material for Durability and Safety

Choosing the right material for your wheel lug nut socket is crucial for both performance and your personal safety. The material determines how a socket handles the force from your wrench. Using the wrong type can lead to broken tools, damaged parts, or serious injury.

Impact Sockets (Cr-Mo) for Impact Wrenches

If you use an impact wrench or another power tool, you must use an impact socket. These are made from Chrome Molybdenum (Cr-Mo) steel. This material offers superior impact resistance and toughness. Cr-Mo steel is designed to absorb the sudden, high-powered blows from an impact gun. The molybdenum in the steel enhances its strength and ability to handle high pressure without breaking. This makes the socket more flexible and durable for repeated use on your vehicle’s wheel.

Using an impact socket ensures you can safely apply the high torque needed to loosen stubborn lug nuts on a wheel. It is the only safe choice for power tool applications.

Safety Alert: Never use a standard chrome socket with an impact wrench. The socket is not built to handle the vibration and high torque. It can shatter under pressure, sending sharp metal fragments flying and creating a serious risk of injury.

Chrome Sockets (Cr-V) for Hand Tools

For hand tools like a lug wrench or a breaker bar, you should use a standard chrome socket. These are typically made from Chrome Vanadium (Cr-V) steel. This material is harder and more brittle than Cr-Mo. Its hardness makes it great for manual use, where the force is applied more gradually.

Chrome sockets often have thinner walls and a polished finish, making them suitable for general tasks. However, this brittleness is exactly why they are dangerous with impact tools.

- They can crack or fracture easily under the rapid force of an impact gun.

- This failure can damage the lug nut, your wheel, or the tool itself.

- Always match the socket material to your tool to follow your wheel torque specs correctly and work safely on your wheel.

Matching the Socket’s Drive Size to Your Wrench

After you select the correct lug nut socket size and type, you must match its drive size to your wrench. The drive size is the square hole on the back of the socket. It must fit the square drive on your wrench or breaker bar. A proper fit ensures you can transfer force effectively to turn the lug nuts on your wheel.

Understanding Common Drive Sizes

You will find that wrenches and sockets come in several standard drive sizes. Each size is designed for a different level of force and type of job. The three most common sizes you will encounter are 1/4-inch, 3/8-inch, and 1/2-inch. Using the right size for the task is essential for working efficiently and safely on your vehicle.

This table shows the typical applications for each common drive size:

| Drive Size | Primary Application | Typical Socket Sizes (Metric) | Typical Socket Sizes (SAE) |

|---|---|---|---|

| 1/4 inch | Precision work, small fasteners | 4mm to 15mm | 5/32 inch to 9/16 inch |

| 3/8 inch | General automotive tasks | 6mm to 24mm | 1/4 inch to 15/16 inch |

| 1/2 inch | Heavy-duty jobs, lug nuts | 8mm to 38mm | 5/16 inch to 1-1/2 inch |

Why 1/2-Inch Drive is the Standard

For working on a wheel, the 1/2-inch drive is the industry standard. Removing and tightening lug nuts requires a significant amount of force. A 1/2-inch drive socket and wrench are built to handle this high torque safely. This larger size is about 21 percent stronger than a 3/8-inch drive, giving you the strength needed to loosen stubborn nuts without breaking your tools.

Did You Know? A typical 1/2-inch drive torque wrench can handle a range from 30 to 250 ft-lbs. This capability easily covers the torque specifications for nearly every passenger car’s wheel.

Using a smaller drive, like a 3/8-inch, is risky for wheel work. You could damage the tool or fail to tighten the wheel correctly. Always choose a 1/2-inch drive for changing a tire to ensure you have the right power and durability for the job.

Choosing the right wheel lug nut socket is simple when you follow these steps. First, confirm the correct lug nut socket size for your vehicle’s wheel. Next, select the right type and material for the job. This ensures you can safely change a tire. Making the right choice protects your wheel and lug nut from damage. It also makes every tire change a smoother process. For instance, a highly-rated set like the Neiko 19-Piece 1/2-Inch Drive Master Impact Set is popular because it is built for high torque. This makes it a durable choice for removing a stubborn lug nut from a wheel. A quality socket of the correct size makes any tire job on your wheel easier. Always check your lug nut socket size and match it to the lug nut on your wheel to keep your tire and wheel safe.

FAQ

Can I use one socket for all my cars?

Probably not. Different car manufacturers use various lug nut sizes. For example, many Ford models use a 19mm socket, while some Honda and Toyota vehicles require a 21mm socket. You should always verify the correct size for each specific vehicle you own.

What happens if I use a chrome socket on an impact wrench?

You create a serious safety hazard. A chrome socket is brittle and not designed for impact forces. It can shatter under the tool’s power, sending sharp metal pieces flying. Always use a Cr-Mo impact socket with an impact wrench to prevent injury and tool damage.

Why is my socket stuck on the lug nut?

A socket can get stuck for a few reasons. You might be using the wrong size, like a 12-point socket that rounded the nut’s corners. The lug nut itself could be swollen from rust or damage. Always use a snug-fitting 6-point socket to avoid this.

Do I need a torque wrench for lug nuts?

Yes, a torque wrench is essential for proper wheel maintenance. It ensures you tighten lug nuts to the manufacturer’s exact specification. Over-tightening can damage the wheel studs, while under-tightening can cause the wheel to become loose.

Remember: Using the correct torque is just as important as using the right socket.