admin1

July 23, 2025

Everything You Need to Know About High Pressure Valve Stems

High pressure valve stems play a crucial role in controlling the flow of gases and liquids in many systems. They help prevent leaks and keep equipment working safely, especially in industries where failure can cause serious problems. When these valve stems break or do not seal well, dangerous situations like leaks, fires, or explosions can happen. Strong materials and careful manufacturing make high pressure valve stems reliable, even under tough conditions.

How High Pressure Valve Stems Work

Main Components and Design of High Pressure Valve Stems

High pressure valve stems rely on robust engineering to perform reliably in demanding environments. Each component serves a specific function to ensure safety and durability. The stem connects the actuator or handle to the closure mechanism. Manufacturers often reinforce this part in high-pressure valves to enhance strength and prevent bending or breaking. Stainless steel and other strong alloys are common choices for stems and bolts, providing resistance to corrosion and mechanical stress.

The valve body features thicker walls and reinforced designs. This structure supports the stem and withstands the intense forces generated by high pressure. Seats and seals use pressure-resistant materials such as EPDM, PTFE, or FKM. These materials prevent leaks and maintain integrity even when exposed to aggressive chemicals or temperature changes.

Tip: Always check the material specifications of high pressure valve stems before installation. The right material ensures long-term performance and safety.

The design of high pressure valve stems also includes features that address wear and tear. Engineers select materials and shapes that distribute stress evenly. This approach reduces the risk of failure and extends the service life of the valve stem. All these design features work together to maintain integrity and reliability under high pressure.

Pressure Control and Sealing Mechanisms

Sealing mechanisms in high pressure valve stems play a vital role in preventing leaks and ensuring system safety. The stem and packing work together to stop fluid from escaping where the stem connects to the actuator. Spring mechanisms maintain constant pressure on sealing surfaces. This design compensates for changes in pressure and temperature, keeping the seal tight at all times.

Manufacturers use several advanced sealing techniques:

- Valve stem packing seals create a very narrow gap between the stem and packing material. The packing material conforms elastically to the stem surface, forming a reliable barrier.

- Gland bolts compress the packing rings, applying the necessary sealing force. If the compression or elasticity is lost, leaks can occur.

- Live loading introduces springs into the packing assembly. These springs maintain consistent gland force over time, even as packing wears down, reducing the risk of leaks.

- Seals and O-rings fill gaps between moving parts. These components prevent leakage, especially under high pressure.

- The interaction between the ball and seat is crucial. The ball fits precisely against the seat, which is often made of a softer material that conforms over time to maintain a secure seal.

- Internal fluid pressure forces the ball tighter against the seat, enhancing the seal as pressure increases.

Material selection is critical for sealing performance. Traditional soft elastomer seals can become brittle or porous under extreme conditions. Metal-to-metal seals offer superior temperature resistance and mechanical strength. Spring-energized metal seals combine elasticity and plastic deformation, allowing them to conform to surface irregularities and maintain a tight seal during decompression cycles. Materials like Inconel and nickel are used for high temperature service, while copper is chosen for cryogenic conditions.

Proper maintenance also plays a key role. Replacing corroded gland bolts, lubricating bolts for consistent torque, and ensuring correct packing installation all help maintain seal integrity. The ideal stuffing box contains about five packing rings, which optimizes sealing and reduces friction.

High pressure valve stems often use pressure seal valves. As system pressure increases, the sealing force also increases, reducing leakage. Modern gaskets use die-formed graphite with capped edges to prevent extrusion. Live-loaded bonnet bolts maintain constant compression on the gasket, minimizing leakage caused by bolt relaxation or thermal cycling.

Note: Advances in forging, machining, and welding technologies have improved the quality and reliability of pressure seal valves, making them suitable for the most demanding applications.

These mechanical principles and design choices allow high pressure valve stems to maintain a secure seal, even under extreme pressure and temperature conditions.

Key Features of High Pressure Valve Stems

Materials and Construction for Durability

Manufacturers select materials for high pressure valve stems based on strength, corrosion resistance, and performance in extreme environments. The most common materials include low-temperature carbon steel, stainless steel, and nickel-based alloys. Each material offers unique advantages for durability and safety.

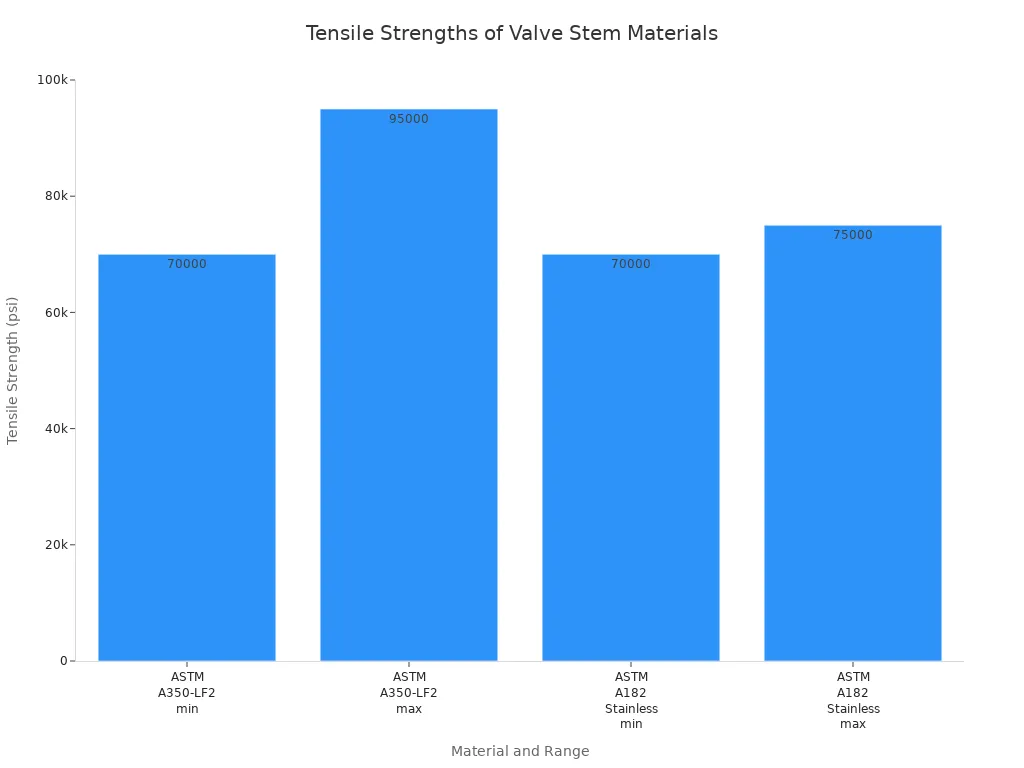

| Material (ASTM Grade) | Common Use in High-Pressure Valve Stems | Tensile Strength Range (psi) | Tensile Strength Range (MPa) |

|---|---|---|---|

| ASTM A350-LF2 | Low-temperature carbon steel, widely used for forged valve stems | 70,000 – 95,000 | 485 – 655 |

| ASTM A182 Stainless Steel (F304, F316, F321) | Stainless steel grades for high-pressure and high-temperature service | ~70,000 (approx. 485 – 515 MPa) | 485 – 515 |

| Alloy Steels (Inconel, Monel) | Nickel-based alloys used for corrosion resistance and high strength | Not explicitly stated, but known for high strength | Not explicitly stated, but high strength |

Valve stem construction methods also play a major role in durability. Welded body designs create strong, leak-resistant structures that perform well under high pressure and temperature. Forged bodies provide uniform strength and resist mechanical stress, making them ideal for demanding applications. Cast bodies allow for complex shapes but may not match the strength of forged or welded designs. Segmented and integral bodies offer benefits for maintenance and leak prevention. The right construction method helps the valve stem withstand years of mechanical stress and operational demands.

Sealing methods further impact durability. Bellows seals, made from thin metal, reduce mechanical stress and provide zero leakage, which is critical for hazardous applications. Packing seals are more affordable and adjustable, but they may leak over time. The choice of sealing method depends on the application, maintenance needs, and the required level of leak prevention.

Tip: Selecting the correct material and construction method ensures that high pressure valve stems deliver long-lasting performance, even in harsh environments.

Pressure Ratings and Industry Standards

Pressure ratings define the maximum working pressure a valve stem can safely handle. These ratings use several systems, including WSP (Working Steam Pressure), WOG (Water, Oil, Gas), PSI, and ANSI classes. Each system provides information about the valve’s pressure limits, fluid compatibility, and temperature range.

- WSP ratings show the highest steam pressure a valve can withstand at its maximum temperature.

- WOG ratings indicate the maximum pressure for water, oil, or gas applications, with common values like 400, 600, 1000, and 1500 PSI.

- ANSI classes, such as Class 150, specify pressure limits (e.g., 150 PSI or about 10 bar).

- Valve class ratings are stamped on the valve body or tag for easy identification.

Manufacturers determine these ratings through standardized testing, such as ASTM B86-99a, which measures flow capacity and pressure endurance. Industry standards like ASME B16.34, ANSI/ASME B16.34-2007, and NACE standards set the framework for design, manufacturing, inspection, and testing. These standards ensure that high pressure valve stems meet strict safety and reliability requirements.

International standards also govern manufacturing and testing. API 598 covers valve testing and inspection, including leakage rates. API 607 evaluates valve performance under fire conditions. API SPEC 6D provides guidelines for design, testing, and documentation. Testing methods include hydrostatic shell tests, seat leak tests, and backseat tests, all designed to confirm that valve stems meet or exceed pressure and sealing requirements.

Note: Adhering to these standards ensures that high pressure valve stems perform reliably in critical applications across industries.

Longevity and Quality Assurance

The lifespan of high pressure valve stems depends on material selection, construction quality, and maintenance practices. In industrial settings, ball valves—which include valve stems—typically last eight to ten years under continuous use. This service life reflects the effects of frequent operation and exposure to corrosive environments.

Quality assurance processes begin with a thorough evaluation of the application. Manufacturers test sealing systems and recommend advanced designs, such as spring-preloaded seals, to reduce wear and leakage. Material selection focuses on high-performance, regulatory-compliant options like modified PTFE with carbon filler. Regular inspections, preventive maintenance, and proper installation help extend valve life. Environmental management, such as controlling temperature and contamination, also plays a key role.

Manufacturers often partner with experienced seal suppliers to develop innovative, low-maintenance solutions. Advanced valve designs may include self-adjusting seals and wear-resistant materials. Comprehensive documentation and operator training support consistent quality and safety.

- Regular inspection protocols check for leakage, smooth operation, and seal condition.

- Preventive maintenance schedules follow manufacturer recommendations and operating conditions.

- Proper installation, including alignment and torque, prevents premature failure.

- Environmental factors, such as temperature swings and corrosive atmospheres, require protective measures.

🛠️ Consistent quality assurance and maintenance practices help high pressure valve stems achieve their full service life, ensuring safety and reliability in demanding environments.

Types of High Pressure Valve Stems

Metal Clamp-In Valve Stems

Metal clamp-in valve stems offer the highest level of durability and pressure resistance. Manufacturers design these stems with a metal body, a rubber grommet, and a retaining nut. This construction allows them to handle cold inflation pressures up to 200 psi. Technicians secure the stem to the wheel using a wrench, which creates a tight seal and prevents leaks. These stems work best for high-speed vehicles, racing cars, and heavy-duty trucks that exceed 130 mph. They come in various sizes and shapes to fit different wheel designs.

Key differences between metal clamp-in and other types of valve stems include:

- Metal clamp-in stems require tools for installation, while snap-in stems do not.

- Metal stems resist heat, chemicals, and mechanical stress better than rubber stems.

- They cost more but provide longer service life and better performance in extreme conditions.

| Feature | Metal Clamp-In Valve Stems | Snap-In Valve Stems |

|---|---|---|

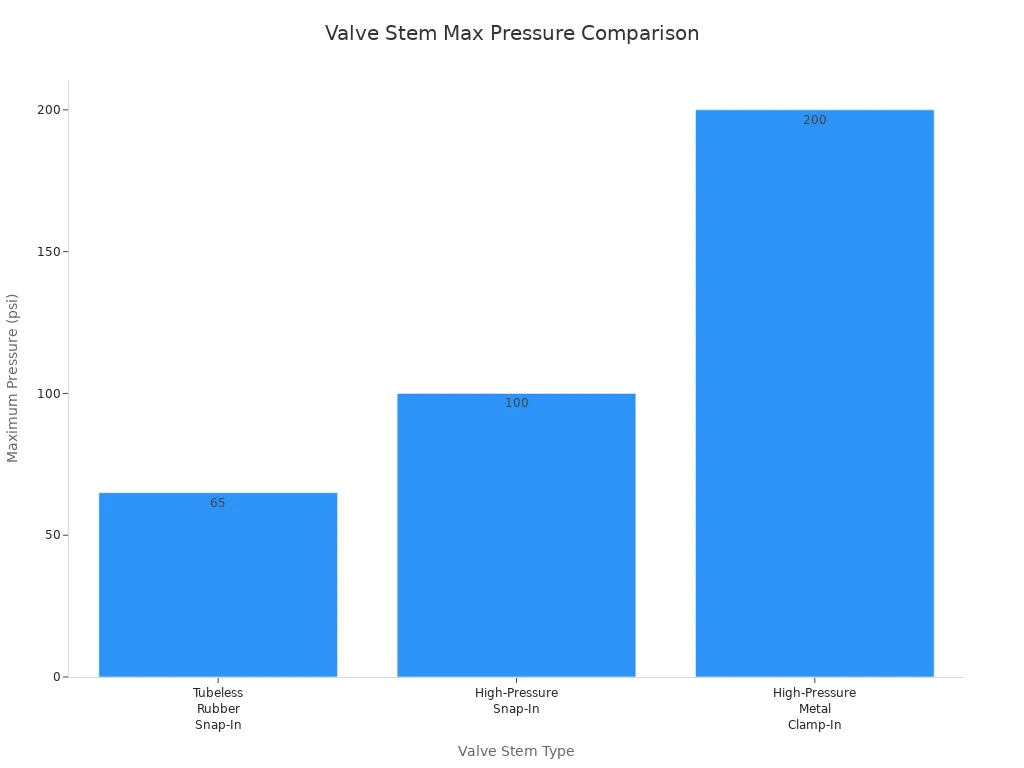

| Pressure Capacity | Up to 200 psi | Up to 65 psi (standard), 80-100 psi (high-pressure) |

| Durability | High; metal construction | Lower; rubber construction |

| Installation Method | Requires tools | Tool-free, push-in |

| Suitability | Racing, heavy-duty, high-speed | Everyday vehicles |

| Sizes & Configurations | Multiple sizes and shapes | Limited sizes |

| Valve Caps | Metal preferred | Plastic common |

Snap-In and Specialty Valve Stems

Snap-in valve stems use a rubber base and a metal barrel. These stems are easy to install by hand and do not require special tools. Standard snap-in stems handle pressures up to 65 psi, making them suitable for passenger cars, light trucks, and trailers. High-pressure snap-in stems can manage up to 100 psi, which fits the needs of medium- and heavy-duty vehicles.

Specialty snap-in stems serve unique applications, such as off-road racing or custom wheels. They offer flexibility and quick replacement. However, they do not match the durability or pressure capacity of metal clamp-in stems.

| Valve Stem Type | Maximum Pressure (psi) | Typical Applications | Key Features and Preferred Scenarios |

|---|---|---|---|

| Tubeless Rubber Snap-In Valves | Up to 65 | Passenger cars, light trailers, light trucks | Moderate pressures, easy fit, used in off-road racing |

| High-Pressure Snap-In Valves | 65 to 100 | Medium- and heavy-duty trucks and trailers | Higher pressure, metal barrel, fits larger rim holes |

| High-Pressure Metal Clamp-In Valves | Up to 200 | Track, high-speed vehicles, specialty wheels | Very high pressure, superior strength, fits various rim sizes |

Tip: Choose snap-in stems for quick installation and moderate pressure needs. Select metal clamp-in stems for demanding, high-pressure environments.

Anti-Blowout and Spring-Loaded Designs

Anti-blowout valve stems use special engineering to prevent the stem from ejecting under sudden pressure changes. These designs often include a locking mechanism or reinforced structure. Spring-loaded valve stems use an internal spring to maintain a tight seal, even if the pressure fluctuates. Both types improve safety and reliability in high pressure valve stems, especially in industrial and high-performance settings. These advanced designs help prevent leaks and reduce the risk of failure during extreme conditions.

Applications of High Pressure Valve Stems

Automotive and Heavy-Duty Vehicles

Automotive and heavy-duty vehicles rely on strong valve stems to maintain tire pressure and ensure safe operation. Trucks, buses, and performance cars often operate at higher speeds and carry heavier loads than standard vehicles. These conditions demand valve stems that can withstand increased pressure and temperature. Metal clamp-in valve stems are common in these vehicles because they resist heat and mechanical stress. Racing teams and commercial fleets choose these stems for their durability and ability to prevent leaks during long trips or high-speed driving. Technicians also prefer these stems for their secure fit and long service life. Proper valve stem selection helps prevent tire blowouts and supports vehicle stability.

Industrial and Fluid Handling Systems

Industrial systems use valve stems to control the flow of liquids and gases in pipelines, pumps, and processing equipment. These environments expose valve stems to high pressures, corrosive chemicals, and frequent temperature changes. Operators must monitor valve performance to avoid failures that can disrupt production or create safety hazards. The most common failure modes in these systems include stem failure, packing failure, and issues caused by corrosion or thermal expansion. The table below summarizes these failure modes:

| Failure Mode | Cause(s) | Effect(s) |

|---|---|---|

| Stem Failure | Excessive torque, misalignment, corrosion | Loss of flow control, safety risks, operational failures |

| Packing Failure | Incorrect packing material, overtightening, wear and tear | External leakage around the stem, reduced system efficiency, safety risks in high-pressure systems |

| Additional Issues | Corrosion, thermal expansion/contraction | Misalignment or binding of valve components |

Routine inspection and maintenance help reduce these risks. Engineers select materials and designs that resist corrosion and handle pressure changes. This approach ensures reliable operation in factories, chemical plants, and water treatment facilities.

Aerospace and High-Performance Environments

Aerospace applications require valve stems that perform under extreme conditions. Engineers use corrosion-resistant and temperature-resistant alloys and polymers to improve reliability. A major challenge involves sealing the dynamic valve stem that passes through the pressure boundary. Innovations such as magnetic valve actuation eliminate this leak path by moving the valve through a solid wall, creating a hermetic seal. This technology prevents leaks that could lead to catastrophic failures, as seen in past aerospace incidents.

Rigorous testing ensures each valve stem can withstand temperature swings and vacuum conditions. The table below highlights key adaptation aspects for aerospace use:

| Adaptation Aspect | Description |

|---|---|

| Material | Stainless steel housings and valve cores for corrosion and temperature resistance |

| Pressure Ratings | Valves rated up to 5,000 psi; connectors up to 15,000 psi |

| Safety Features | Warning system for unreleased pressure to enhance operational safety |

| Compliance | Meets MS/AN specifications; compatible with aircraft hydraulic fluids |

| Manufacturing | Precision-manufactured in the USA with rigorous testing on dedicated equipment |

| Application | Used in aerospace hydraulic and pneumatic systems requiring high reliability under extreme conditions |

Aerospace manufacturers focus on high-performance and reliability. They use agile manufacturing processes, rapid development cycles, and advanced quality control. Teams design tailored valve solutions to perform flawlessly in extreme environments. This commitment to precision and safety supports the demanding needs of aerospace and defense industries.

Choosing the Right High Pressure Valve Stem

Compatibility and Sizing Considerations

Selecting the correct valve stem starts with understanding the system’s requirements. Engineers look at several factors to ensure the valve stem fits and performs as needed:

- Size: The valve size must match the system’s flow capacity.

- Temperature: Both operating and ambient temperatures affect material choice and pressure ratings.

- Application: The valve’s function, such as flow control or shutoff, determines the type needed.

- Media: The process fluid must be compatible with valve materials to prevent corrosion or damage.

- Pressure: Both working and design pressure ratings are critical for safety.

- Ends or fittings: Proper end connections help prevent leaks and ensure compatibility.

- Delivery: Maintenance needs and delivery conditions depend on the operating environment.

Sizing errors can cause serious problems. If the actuator is too small, the valve may not open or close fully, leading to poor flow and pressure control. This can cause overheating, wear, and even hazardous situations. Oversized actuators can bend or break the valve stem and damage the valve seat. Both under-sizing and over-sizing increase repair costs and downtime. Proper sizing considers torque, safety factors, and actuator type for reliable operation.

Meeting Industry Certifications and Standards

Industry certifications help guarantee safety and performance. The table below shows some of the most recognized certifications and what they require:

| Certification Body | Certification/Standard Name | Requirements/Scope |

|---|---|---|

| ASME | BPVC Code Stamps (e.g., UV3) | Design, fabrication, inspection, testing, and operation safety for high-pressure valves |

| ASTM International | ASTM A961/A691M, ASTM B61 | Material specifications and performance testing for high-pressure service |

| Fluid Control Institute (FCI) | FCI 91-1 | Qualification and testing of valve stem seals for reliability |

| TÜV Rheinland | TA Luft, EN ISO 15848-1, API 607, API 6FA | Leakage and fire resistance tests, certificates of conformity |

Manufacturers must submit valve samples for testing. Passing these tests is necessary for market access in many regions. Certificates are issued only after successful completion of all requirements.

Maintenance, Inspection, and Replacement Tips

Regular maintenance extends the life of valve stems and keeps systems safe. Key practices include:

- Inspect valve stems for corrosion, wear, and loose connections.

- Check for rust, buildup, and stem tightness during each inspection.

- Inspect internal components annually under normal use. For severe service, inspect more often.

- Focus on stem seals, seating surfaces, bolts, and joints. Look for cracks, hardening, or misalignment.

- Replace worn or fatigued parts instead of repairing them.

- Clean and lubricate stems with manufacturer-approved products.

- Use proper tools for cleaning, such as wire brushes and swabs.

- Apply a light coat of silicone-based lubricant each year.

- Use plastic valve caps to protect against dirt and moisture.

- Perform quick monthly inspections, especially when checking tire tread.

- Keep spare parts and emergency repair procedures ready to reduce downtime.

Tip: Promptly replace any damaged valve stems to maintain system safety and performance.

High pressure valve stems deliver critical safety and performance benefits in demanding environments. Industry experts highlight their ability to withstand extreme pressure, reduce leaks, and extend service life through robust construction and precision control. When selecting valve stems, engineers should prioritize pressure rating compatibility, material durability, and reliable sealing performance. To ensure long-term reliability, teams should schedule regular inspections, replace worn components, and follow comprehensive maintenance plans. These steps help maintain safe and efficient operations across industries.

FAQ

What is the maximum pressure rating for high pressure valve stems?

Most high pressure valve stems handle up to 200 psi. Some specialized models in industrial or aerospace applications can withstand pressures up to 5,000 psi. Always check the manufacturer’s specifications for exact ratings.

How often should high pressure valve stems be inspected or replaced?

Technicians should inspect valve stems during every routine maintenance check. In heavy-duty or industrial settings, annual inspections are recommended. Replace stems immediately if signs of wear, corrosion, or leaks appear.

Which materials offer the best durability for high pressure valve stems?

Stainless steel and nickel-based alloys provide excellent strength and corrosion resistance. These materials meet industry standards for durability and safety. Manufacturers often use ASTM A182 stainless steel or Inconel for demanding environments.

Can high pressure valve stems be used in extreme temperatures?

Yes. Many high pressure valve stems use materials like PTFE, FKM, or Inconel. These materials maintain sealing performance in both high and low temperature environments. Always verify the temperature range with the product’s technical data sheet.