admin1

November 8, 2025

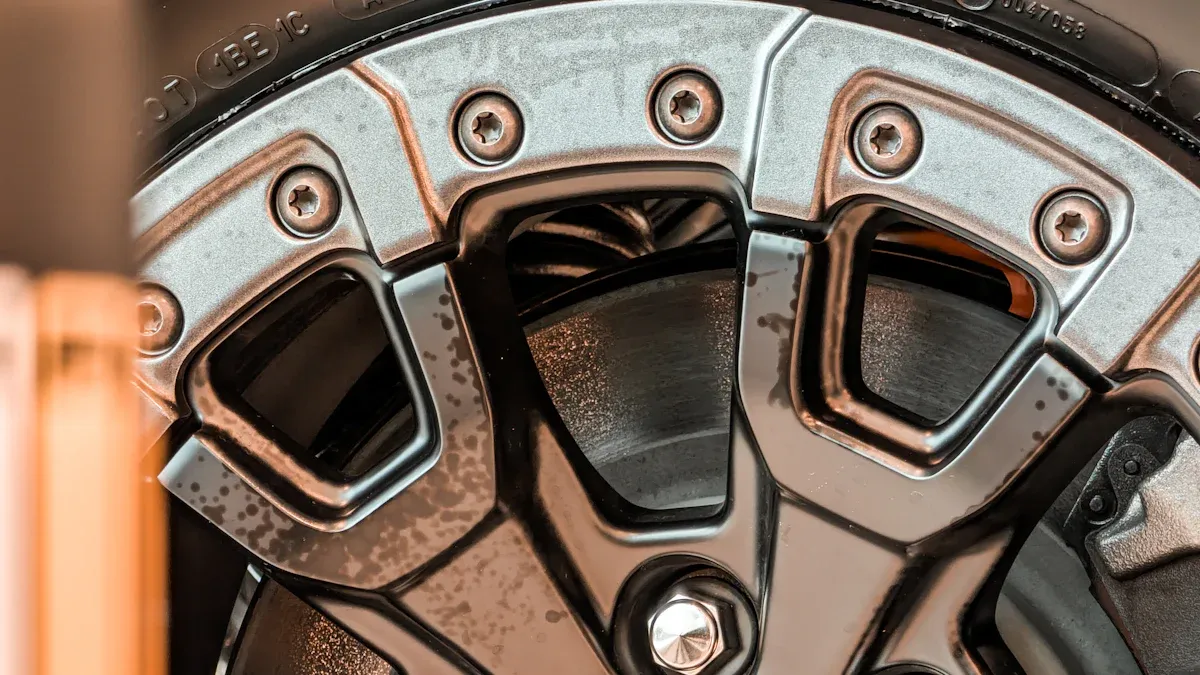

The 2025 Guide to Using Open Lug Nuts for Peak Performance

Open lug nuts are essential for peak performance in many racing applications. These open wheel nuts guarantee full connection with extended wheel studs, a key safety rule in high-stress racing. The design of open ended lug nuts is a must-have for passing safety checks.

Safety First: This design allows inspectors to instantly see that the wheel is secure. It also stops dangerous air pressure from building up due to extreme heat, which prevents the nut from getting stuck on the stud.

Why Full Thread Engagement Is a Must for Track Safety

Full thread engagement is the complete contact between the threads of a wheel stud and a lug nut. This connection is the only thing holding a wheel to the vehicle. On a racetrack, the forces involved are extreme. A weak connection guarantees failure. Therefore, ensuring every thread is properly engaged is a non-negotiable rule for safety and performance.

The Necessity of Extended Wheel Studs

Standard wheel studs are often too short for track use. Many high-performance setups use wheel spacers to widen the vehicle’s track width for better handling. These spacers push the wheel further from the hub. This reduces the length of the stud available for the lug nut. Extended wheel studs solve this problem.

Engineers manufacture these longer studs from superior materials to handle intense conditions.

- They often use premium chromoly steel for its exceptional strength over standard steel.

- This material provides a critical safety margin, especially when spacers are installed.

- Extended studs guarantee enough thread is available for the lug nut to grip securely.

Pro Tip: Choosing the Right Stud Length The length of the extended stud must match the spacer thickness. A 75mm stud, for example, can typically support a spacer up to 12mm thick. A 90mm stud might be necessary for a more aggressive 20mm spacer. Always check manufacturer specifications for your specific vehicle and wheel setup.

Preventing Catastrophic Failure Under Racing Loads

A vehicle on the track experiences immense physical forces. Hard cornering generates powerful lateral G-forces that push sideways on the wheels and tires. These forces are a major factor in stud fatigue. They cause wheel studs to wear out much faster during racing, even if the studs look fine.

The stress multiplies during combined actions, like braking hard into a turn. The car’s entire mass pushes on the wheel lugs at a sharp angle. If a lug nut is loose or not fully threaded, the remaining lugs must carry the entire load. This intense, focused force can strip threads or shear a stud completely. The result is severe wheel wobble or a wheel detaching from the car. Proper thread engagement, verified by using open lug nuts, distributes these loads evenly across all studs. This prevents overload on any single point and is essential for keeping the vehicle safe and controllable.

How Open Lug Nuts Streamline Tech Inspections

Technical inspections are a mandatory safety gate at any racing event. Officials scrutinize every part of a vehicle to ensure it meets strict safety standards before it is allowed on the track. The use of open lug nuts makes this critical process faster and more reliable, especially for wheel and tire safety checks.

The “Visual Confirmation” Rule in Racing

Most racing organizations have a simple but non-negotiable rule for wheel security. Tech inspectors must be able to see the wheel stud protruding through the end of the lug nut. This provides instant visual confirmation of full thread engagement.

Tech Inspection Mandate Official guidelines often state: “Aftermarket wheel studs must protrude through the lug nut at least the diameter of the stud. All lug nuts must be open-end; capped nuts are prohibited.”

This rule eliminates any guesswork. A capped nut hides the connection, making it impossible to know if the stud is long enough or if the nut is fully threaded. An open-end design allows an inspector to verify a secure connection with a quick glance, ensuring the setup complies with safety regulations.

Simplifying Stud and Nut Integrity Checks

A visual check goes beyond just confirming stud length. The exposed stud threads give inspectors a clear window into the health of the hardware. They can quickly spot dangerous signs of wear and tear that would otherwise be hidden.

Inspectors are trained to look for specific defects:

- Thread Damage: They check for flattened or stripped threads, which indicate cross-threading or excessive wear.

- Stud Stretching: A visible “necking” or thinning of the stud near the hub is a classic sign of metal fatigue.

- Heat Damage: Any blueish discoloration on the stud suggests it has been exposed to extreme heat, which compromises its strength.

To verify these components, inspectors may use specialized tools like a digital torque wrench to confirm proper torque or an inspection gauge to assess stud condition. This detailed examination helps prevent catastrophic failures by identifying compromised studs before they break under racing loads.

Managing Extreme Heat and Ensuring Durability

Racing pushes every vehicle component to its limit, especially the wheels. Brakes generate incredible heat that travels directly to the hubs, wheel studs, and lug nuts. Managing this heat is critical for both safety and consistent performance.

Venting Trapped Air to Prevent Pressure Lock

A closed-end, or capped, lug nut creates a sealed air chamber around the wheel stud. During a race, as brake temperatures soar, the air trapped inside this chamber heats up and expands. This expansion creates significant pressure inside the nut.

Danger: Pressure Lock The intense pressure can cause the lug nut to seize onto the stud, a phenomenon known as “pressure lock.” This makes the nut extremely difficult to remove during a pit stop. It can also damage the threads on both the nut and the stud, compromising the integrity of the entire wheel assembly.

The design of open lug nuts completely eliminates this problem. By leaving the end open, they allow the hot, expanding air to vent safely into the atmosphere. This prevents pressure buildup, ensures the nut can be removed quickly, and maintains consistent clamping force on the wheel.

The Importance of High-Quality Materials

Standard automotive hardware is not built to withstand the brutal forces of a racetrack. High-quality materials are essential for durability and safety.

Engineers make the best racing studs from superior alloys.

- Material Strength: Many top-tier studs use heat-treated 8740 chrome moly steel. This material provides a massive strength advantage over factory parts.

- Tensile Strength: These specialized studs achieve a tensile strength rating between 190,000 and 200,000 psi. This immense strength allows them to handle the extreme shock loads from acceleration and the powerful lateral forces in corners.

- Durability: Manufacturers often add a cadmium plating to these studs. The coating adds an extra layer of durability and helps resist corrosion from brake dust and moisture.

Choosing components made from these proven, high-strength materials is a non-negotiable part of building a reliable and safe race car.

A Practical Guide to Using Open Lug Nuts

Is Your Vehicle a Candidate?

A vehicle is a candidate for open lug nuts if it is used for racing or has certain modifications. Many performance setups use wheel spacers to create a wider stance for better handling. These spacers require longer wheel studs to ensure safe thread engagement. For example, a Toyota GR86 owner might use 12mm spacers for a summer wheel setup and 20mm spacers for a winter setup. Both scenarios require extended studs, making the vehicle a perfect candidate for this hardware. The open-end design guarantees the longer stud has enough room and allows for visual inspection.

Proper Installation and Torque Procedure

Proper installation is critical for safety. Technicians must always use a calibrated torque wrench to tighten lug nuts to the vehicle manufacturer’s specifications. The threads on the wheel stud and inside the nut must be clean and dry before installation.

Warning: Avoid Anti-Seize on Threads ⚠️ Applying anti-seize lubricant to wheel stud threads is dangerous. It dramatically reduces friction. This means a standard torque setting will create a much higher clamping force than intended. This can stretch the studs past their limit, damage the threads, or cause a stud to break. Always follow torque specs for clean, dry threads unless the manufacturer explicitly states otherwise.

Addressing Corrosion on Exposed Studs

The open design exposes the end of the steel wheel stud to moisture, which can cause rust. Drivers have several effective methods to prevent this corrosion. Applying a protective coating keeps the threads in good condition.

- A few drops of motor oil on the threads will coat the metal and stop rust.

- A very small amount of anti-seize compound can be used, but it must be applied sparingly to avoid affecting torque.

- Some owners spray a light coat of paint over the area after installation if appearance is not a major concern.

These simple steps protect the exposed ends of the studs, ensuring the open lug nuts can be removed easily when needed.

Open lug nuts are a mandatory component for many racing applications. They guarantee full thread engagement, simplify safety checks, and manage extreme heat.

For any serious track use, these functional and safety advantages are non-negotiable for achieving peak vehicle performance.

Drivers should choose high-quality components from trusted manufacturers like Hinuos. This ensures their performance setups meet the track’s rigorous demands.

FAQ

Are open lug nuts suitable for daily driving?

Open lug nuts are designed primarily for track vehicles. For daily driving, the exposed stud ends are vulnerable to road salt and moisture, which causes corrosion. Closed-end nuts provide better protection for standard street cars that do not need to pass a racing tech inspection.

What is the best material for open lug nuts?

Steel offers superior strength and durability for racing applications. High-strength steel lug nuts resist thread stretching and heat damage far better than aluminum. For maximum safety on the track, quality steel is the recommended choice for its reliability under extreme stress.

Do open lug nuts require a different torque setting?

No. Drivers must always tighten open lug nuts to the vehicle manufacturer’s specified torque value. Using a calibrated torque wrench on clean, dry threads ensures the correct clamping force. This prevents over-tightening, which can damage the wheel stud and compromise safety.

Torque Tip 💡 Always re-check torque values after the first heat cycle on the track, as components can settle.

Can drivers use open lug nuts with factory wheels and studs?

This combination is generally not recommended. Factory studs are often too short to protrude through an open lug nut, failing the visual confirmation rule for safety. Open lug nuts are designed to work with extended wheel studs to guarantee full and safe thread engagement.