admin1

October 2, 2025

Understanding the Role of Wheel Lug Nuts in High-Performance Driving

You depend on wheel lug nuts to keep your wheels secure during every drive. When you push your vehicle to its limits, only the best materials and engineering can handle the stress. Manufacturers now use high-strength alloys and precise designs to meet strict safety standards. These advances help your wheel stay attached, even when you demand top performance. Reliable wheels depend on quality lug nuts, making them essential for both speed and safety.

Wheel Lug Nuts: The Foundation of High-Performance Safety

Securing Wheels Under Extreme Driving Conditions

You rely on your wheel lug nuts every time you drive, but their importance grows when you push your car to the limit. High-performance driving, like in NASCAR, puts extreme stress on your wheels. The force from sharp turns, rapid acceleration, and sudden stops can loosen wheel fasteners if they are not installed correctly. When you drive at high speeds, even a small mistake in installation can lead to a loose wheel. This risk increases during racing or track events, where every second counts and the weight of your car shifts quickly.

Properly torqued wheel fasteners keep your wheels attached to the hub, even when you face the toughest conditions. If you ignore torque specifications, you risk plastic deformation of the lug nuts. This can cause the wheel to detach from your car, which is dangerous at any speed.

You can see the importance of correct torque in real-life incidents:

- A wheel detached from a toy hauler while driving at 55 mph due to loose lug nuts. This shows how critical it is to check your wheel fasteners before high-speed driving.

- Deficient torque practices can lead to plastic deformation of lug nuts and subsequent wheel ejection. You must always use the right tools and follow the recommended torque for your wheels.

NASCAR teams use single lug designs to make pit stops faster and more reliable. These single lug systems allow for quick wheel changes without sacrificing safety. You can learn from their example by checking your wheel lug nuts before every high-performance drive.

Preventing Wheel Failure and Accidents

You want your wheels to stay secure, whether you drive on the street or the track. Wheel lug nuts play a key role in preventing accidents. If you do not use the correct torque, your wheels can become unstable. This can lead to dangerous situations, especially in high-performance cars like those used in NASCAR.

Before every race, teams check the torque of their wheel lug nuts. They often use a torque wrench and aim for a suggested torque of 85 lb-ft. This practice helps keep the wheels attached to the hub and reduces the risk of wheel failure. Good lug nut retention and a strong torque ring are crucial for wheel stability.

Here are some common causes of wheel lug nut failure and how you can prevent them:

| Cause of Failure | Mitigation Strategy |

|---|---|

| Improper installation | Adhere to proper torque specifications |

| Over-torquing | Use a torque wrench to ensure correct torque levels |

| Under-torquing | Regularly check and maintain torque on lug nuts |

| Excessive paint thickness | Ensure paint thickness does not exceed 3 mils |

You should always follow the correct installation steps for your wheels. Use a torque wrench to avoid over-torquing or under-torquing. Check your wheel fasteners regularly, especially if you drive a high-performance car or participate in motorsports like NASCAR. This simple habit can prevent wheel failure and keep you safe on the road or track.

The Science Behind Wheel Lug Nuts Design

Material Selection: Steel, Aluminum, and Titanium

When you choose wheel fasteners for your car, you need to think about the material. Each material changes how your wheels perform, especially in high-stress situations like NASCAR racing. Here is a table that shows the most common materials and their key properties:

| Material | Key Properties |

|---|---|

| Titanium Alloy | High strength, heat resistance, corrosion resistance, excellent strength-to-weight ratio |

| Stainless Steel | Outstanding corrosion resistance, wear resistance, moderate strength, self-healing oxide layer |

| Aluminum Alloy | Lightweight, good balance of weight savings and adequate strength, not suitable for heavy-duty use |

| High-Strength Alloy Steel | High tensile strength, cost-effective, suitable for various driving conditions, less corrosion resistance than others |

Steel gives you high strength, which is important for keeping your wheels secure. Aluminum weighs less than steel, so it helps reduce the weight of your car and can improve handling. Titanium stands out because it is about 43% lighter than steel but still very strong. NASCAR teams often use titanium or steel for their single lug nut systems to keep wheels safe during fast pit stops. Using advanced materials like titanium costs more, but you save money over time because your wheels and tires last longer.

Size and Shape for Optimal Wheel Performance

You need to pick the right size and shape for your wheel lug nuts. This choice affects how well your wheels stay attached, especially when you drive fast or take sharp turns. Here are some common sizes:

| Lug Nut Size | Description |

|---|---|

| 12mm x 1.25 | Common size for many vehicles |

| 12mm x 1.5 | Another standard size |

| 14mm x 1.5 | Used in larger vehicles |

| 7/16″ | Standard for some older models |

| 1/2″ | Common in heavy-duty applications |

You also need to look at the seat style. Most cars use a 60-degree tapered seat, but NASCAR wheels may use a 45-degree seat for better grip during races. The single lug design in NASCAR allows for quick wheel changes and keeps the wheel secure under pressure. If you use the wrong size or shape, you risk a loose wheel, which can be dangerous.

Corrosion Resistance and Durability in Wheels

Your wheels face tough conditions, from rain to extreme heat on the track. Wheel fasteners must resist corrosion to keep your wheels safe. Stainless steel and titanium both offer strong protection against rust. High temperatures from hard braking or long races can weaken some metals, but titanium and stainless steel hold up well. Cold weather can cause metal to shrink, which may loosen your wheel lug nuts. You should check your wheels often, especially after driving in harsh weather. NASCAR teams inspect their single lug nuts before every race to avoid problems. By choosing the right material and checking your wheels, you help prevent accidents and keep your car performing at its best.

Fastening Methods for Wheels: Mechanics and Safety

Thread Types and Their Impact on Wheel Stability

You need to pay close attention to the thread type when you select wheel fasteners for your car. Proper thread engagement keeps your wheels secure, especially during high-speed events like NASCAR races. If the thread pitch of your wheel lug nuts does not match the studs, you risk a loose wheel. This mismatch can cause instability under dynamic loads, which often leads to dangerous situations on the track or street. The right thread type ensures that your wheel fastening system works as designed. You also want to use the correct lug nut style and seat type. These choices help distribute pressure evenly across your wheels, improving retention and reducing the chance of failure. NASCAR teams rely on single lug nut systems for quick changes and maximum stability. You can learn from their approach by checking your threads and seat types before every installation.

Proper Torque Application for Wheel Lug Nuts

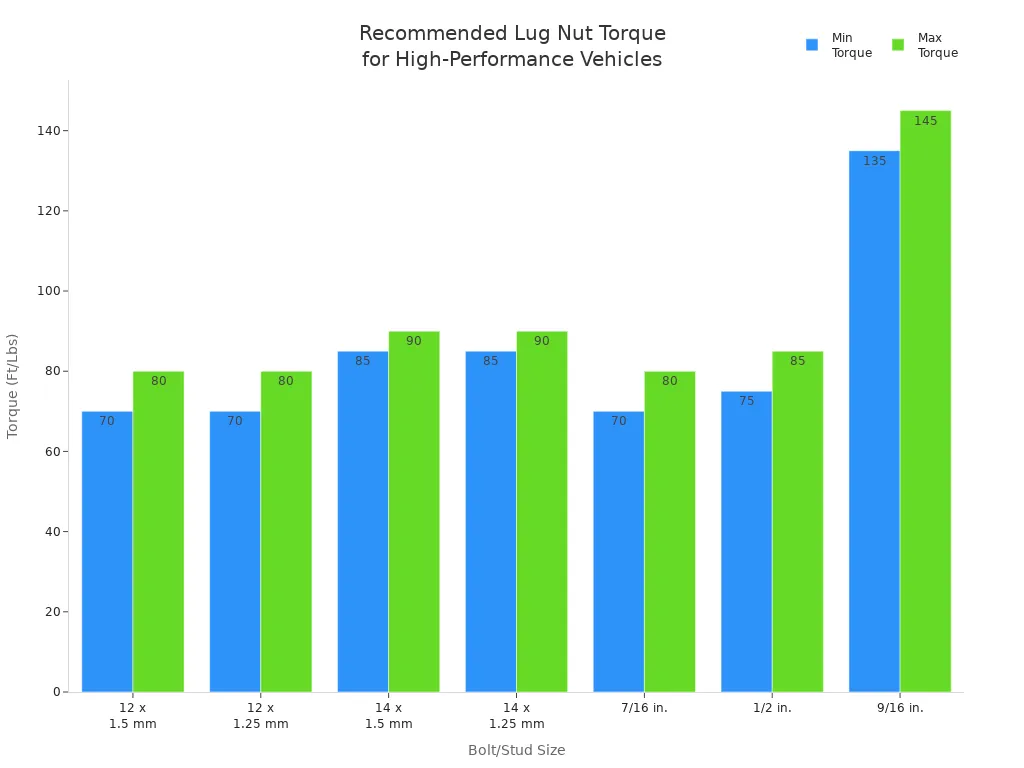

You must always use the correct torque when you tighten lug nuts. Even torque keeps your wheels attached and prevents damage. If you use too little force, your wheel fasteners can vibrate loose and cause harm to your car. Too much force can strip threads or break the fastener. NASCAR pit crews use torque wrenches to ensure every wheel gets the right amount of pressure. Here is a table with recommended torque ranges for different bolt sizes:

| Bolt/Stud Size | Torque Range (Ft/Lbs) |

|---|---|

| 12 x 1.5 mm | 70 – 80 |

| 12 x 1.25 mm | 70 – 80 |

| 14 x 1.5 mm | 85 – 90 |

| 14 x 1.25 mm | 85 – 90 |

| 7/16 in. | 70 – 80 |

| 1/2 in. | 75 – 85 |

| 9/16 in. | 135 – 145 |

Tip: Always follow the recommended torque and sequence during installation. This habit helps prevent premature wear, vibration, or even failure of your wheels.

If you want your wheels to last and your car to handle well, you must check torque regularly. NASCAR teams know that a single lug can make pit stops faster, but they never skip the torque check.

Seat Styles: Conical, Spherical, and Flat for Wheels

You need to match the seat style of your wheel lug nuts to your wheels for the best handling and safety. Different wheels require different seat types. For example:

- Honda and Acura wheels use a ball seat lug nut.

- Most aftermarket wheels use acorn or tapered lug nuts.

- The surface of your wheel determines the best lug nut seat.

You will find many types of lug nuts, such as hex nut, round seat, conelike seat, mag type with flat washer, spline drive, and flexible. The right choice depends on your wheel type and axle. NASCAR uses single lug systems for speed and reliability, but you must always check your seat style during installation. Using the wrong seat can lead to uneven pressure and a loose wheel, which affects your car’s weight distribution and handling.

Innovations in Wheel Lug Nuts Technology

Single Lug Designs for Speed and Reliability

You see big changes in motorsports, especially in NASCAR. Teams now use a single lug nut to secure each wheel. This design helps you change wheels faster and keeps your car safe at high speeds. NASCAR’s Next Gen cars use a single, center-locking lug nut. This system improves both safety and performance. You can look at the table below to see the main advancements:

| Advancement | Description |

|---|---|

| Single Lug Nut Design | NASCAR’s Next Gen cars feature a single, center-locking lug nut for better safety and performance. |

| Wheel Size Change | NASCAR moved from 15-inch steel wheels to 18-inch aluminum wheels for more durability and to match modern cars. |

| Safety and Performance | The single lug nut keeps wheels secure during high-speed racing. |

When you use a single lug, you reduce pit stop times. You also make sure your wheel stays attached during extreme racing conditions. NASCAR teams trust this system for both speed and reliability.

Lightweight Alloys and Enhanced Wheel Performance

You want your car to handle well and move quickly. Lightweight alloys help you reach these goals. When you use aluminum or titanium wheel fasteners, you lower the weight of your wheels. This change improves your car’s acceleration and braking. NASCAR teams use 18-inch aluminum wheels for better performance. These wheels also last longer under stress. You get better fuel efficiency and more control on the track. When you choose the right alloy, you make your wheel fasteners strong and light. This balance gives you the best results in both racing and daily driving.

Anti-Theft and Quick-Release Features for Wheels

You need to protect your wheels from theft. Modern wheel fasteners now include anti-theft and quick-release features. Some systems, like the Turnart wheel boot, cover part of your wheel lug nuts. This design makes it hard for thieves to remove your wheels quickly. The boot takes time to remove, so most thieves give up. You can also use Gorilla Automotive wheel locks. These locks turn your regular lug nuts into locking ones. Each set comes with a unique key, making it even harder for someone to steal your wheels. While no system is perfect, these features add strong protection and peace of mind.

Tip: Always check your wheel fasteners after installation to make sure your wheels stay secure and safe.

Real-World Outcomes: Wheels in High-Performance Scenarios

Reliability in Racing and Track Wheels

You see the true test of wheel fasteners in professional racing. When you watch a race, you notice how every wheel must perform under intense pressure. Race Star Wheels uses precision sizing and advanced manufacturing to keep each wheel secure. Forgeline designs wheels for high load ratings and aerodynamic needs, which helps your car stay stable at high speeds. Keizer Aluminum Wheels relies on aerospace-grade aluminum and CNC machining to meet strict tolerances. These features make sure your wheels handle the stress of racing without failure. In NASCAR, the switch to a single lug nut system has changed how teams approach wheel changes. You get faster pit stops, but you also face new challenges. Loose wheels can cause accidents and lead to penalties, which shows how important reliable wheel fasteners are for both performance and safety.

- Race teams use advanced wheel designs for durability.

- Precision manufacturing keeps wheels attached during high-speed events.

- Aerodynamic wheels help your car move faster and stay stable.

Safety in Daily High-Performance Wheel Use

You depend on your wheels every day, not just on the track. A loose wheel can become a safety issue for you and others on the road. When pit crews rush, mistakes happen, and wheels may come off. This risk exists in daily driving if you do not check your wheel fasteners. Experts warn that lost wheels can cause crashes and put drivers in danger. You must pay attention to every wheel on your car, especially if you drive a high-performance vehicle. The weight of your car shifts during sharp turns or sudden stops, which puts extra stress on each wheel. Regular checks help you avoid problems and keep your wheels secure.

Tip: Always inspect your wheels before long trips or after any wheel-related service to prevent safety issues.

Maintenance and Inspection Best Practices for Wheel Lug Nuts

You keep your wheels safe by following a routine. Start with a daily visual inspection to look for missing or damaged wheel fasteners. After installing new wheels or rotating tires, check the lug nuts right away. During the first 50-100 kilometers after installation, recheck each wheel to make sure it stays secure. Inspect your wheels every month or every 1,600 kilometers. Before you travel long distances or drive through rough terrain, check your wheel fasteners again. Use a torque wrench to tighten each wheel lug nut to the manufacturer’s specifications. If you drive in harsh conditions, increase your inspection frequency. After any wheel-related service, double-check the torque on every wheel.

- Snug lug nuts by hand in a star pattern to prevent cross-threading.

- Inspect the hub for cleanliness to maintain clamping force.

- Use calibrated tools for proper torque application.

- Watch for side-to-side motion during wheel rotation.

You protect your car and wheels by following these steps. Regular maintenance helps you avoid accidents and keeps your wheels performing at their best.

Fortune’s Commitment to Quality Wheel Lug Nuts

Manufacturing Standards and Certifications

You want your wheels to stay secure on every drive. Fortune follows strict manufacturing standards to help you achieve this goal. The company holds ISO9001 certification, which means you get products that meet international quality benchmarks. Every wheel lug nut goes through a detailed inspection before shipment. You can trust that each piece matches the specifications for your car and wheels. Fortune’s team of engineers checks every step in the production process. They use advanced equipment to make sure your wheel fasteners meet high-performance needs. You get peace of mind knowing your wheels have passed tough quality checks.

Tip: When you choose wheel lug nuts from a certified manufacturer, you increase the safety of your car and reduce the risk of wheel failure.

Material Integrity and Testing for Wheels

You depend on strong materials to keep your wheels attached to your car. Fortune never uses inferior materials in their wheel lug nuts. The company tests every batch for strength and durability. Engineers use advanced machines to check for cracks, corrosion, and wear. You get wheel fasteners that stand up to harsh conditions, whether you drive in rain, heat, or on the track. Fortune’s testing process includes checking the fit and finish of each wheel lug nut. You can rely on these products to keep your wheels secure during high-speed driving. Regular testing helps you avoid problems and keeps your car performing at its best.

Innovation and Customer-Centric Service

You benefit from Fortune’s focus on innovation and service. The company invests in new technology to improve wheel lug nut design. Automation equipment helps produce more precise and reliable wheel fasteners. Fortune listens to customer feedback and works to meet your needs. You see this commitment in the positive testimonials from high-performance market customers:

| Customer Name | Date | Testimonial |

|---|---|---|

| Gloria | 2022.11.08 | Wide range, good quality, reasonable prices and good service, advanced equipment, excellent talents and continuously strengthened technology forces, a nice business partner. |

| David | 2022.10.09 | Sales manager is very enthusiastic and professional, gave us great concessions and product quality is very good, thank you very much! |

| Mandy | 2022.10.06 | It is a very good, very rare business partner, looking forward to the next more perfect cooperation! |

| Melissa | 2022.01.23 | The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that’s why we chose this company. |

| Griselda | 2021.10.28 | This supplier offers high quality but low price products, it is really a nice manufacturer and business partner. |

| Isabel | 2021.08.16 | This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company. |

You see that Fortune’s customers value the quality and reliability of their wheel lug nuts. The company’s dedication to innovation and service helps you keep your wheels safe and your car ready for any challenge.

You depend on wheel lug nuts as the cornerstone of high-performance safety and reliability. When you install each wheel, you must follow these steps:

- Use a torque wrench to secure the wheel.

- Avoid over-tightening or under-tightening.

- Check every wheel for proper fastening.

| Material Type | Benefits | Performance Impact |

|---|---|---|

| ISO Grade 10 Steel | High strength, corrosion resistance | Improves safety and performance of wheels |

| Forged Aluminum | Lightweight, strong, corrosion resistant | Reduces weight, increases car acceleration |

| Anodized Aluminum | Attractive finish, good durability | Enhances the look of your wheels |

Choosing high-quality wheel lug nuts gives your car better safety, durability, and performance. Advanced materials help your wheels handle heat and stress, so your car stays reliable even in tough conditions.

FAQ

What happens if you do not torque your wheel lug nuts correctly?

If you do not torque your wheel lug nuts to the recommended level, your wheels can loosen or even fall off. This mistake can cause accidents. Always use a torque wrench and follow your vehicle’s specifications for safety.

How often should you check your wheel lug nuts?

You should check your wheel lug nuts every month or after driving 50-100 kilometers with new wheels. Inspect them before long trips and after any wheel service. Regular checks help you avoid dangerous situations.

Which material is best for high-performance wheel lug nuts?

Titanium and high-strength steel offer the best mix of strength, durability, and corrosion resistance. You get lightweight performance with titanium and cost-effective reliability with steel. Choose based on your driving needs and budget.

Can you reuse wheel lug nuts after removing them?

You can reuse wheel lug nuts if they show no signs of damage, rust, or thread wear. Always inspect each lug nut before reinstalling. Replace any that look worn or damaged to keep your wheels secure.