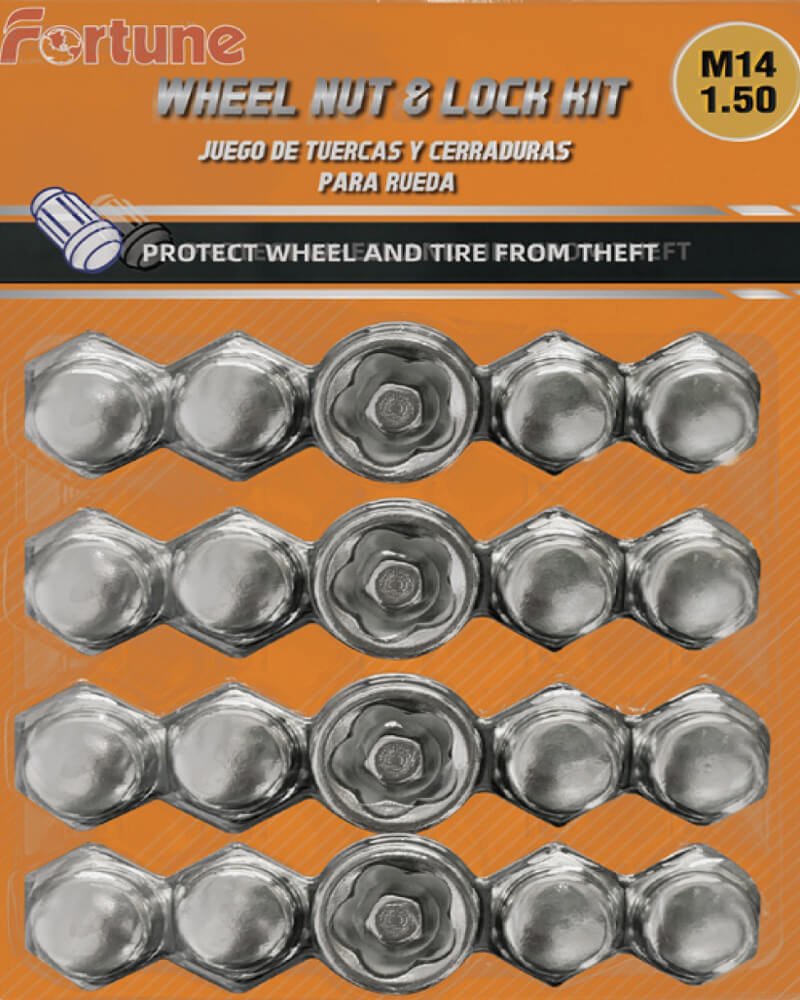

Fortune wheel lug nuts Features

safety first

Safety is always a priority in the automotive accessories industry, and Fortune's wheel lug nuts are manufactured using a precise process that ensures they will be tightened properly every time. These can stay stable in extreme conditions because they are made with strong materials. This keeps them from loosening or falling off. Whether you're traveling long distances or commuting daily, our wheel lug nuts are the best way to keep you and your family safe.

superior performance

Fortune's wheel lug nuts are designed with safety in mind, while also improving the performance of your vehicle. Reduce unwanted vibration through design and manufacturing process to improve driving stability. The use of lightweight materials reduces the weight of the car and optimizes its fuel consumption.

refined and beautiful

Appearance is very important, especially for people who want to customize their vehicle.Fortune's wheel nuts are available in a variety of colors and finishes, including chrome, matte black, and custom colors to match any vehicle style.

Superior durability

It's important to be able to handle inclement weather and rough roads. Our wheel nuts are made from high quality alloy steel and other materials that do not rust or corrode easily. This extends product life and reduces maintenance costs. Our wheel nuts work well in hot, cold or wet conditions.