admin1

November 21, 2025

What Are Vehicle Wheel Lug Nuts and Why Do They Matter?

You might not think about them often, but your lug nuts are critical safety components. These specialized fasteners perform one vital job: they secure a wheel directly to your vehicle’s hub.

Did you know? The small but mighty vehicle wheel lug nuts are solely responsible for keeping your wheels attached as you drive. This makes understanding them a key part of ensuring your safety on the road.

How Do Lug Nuts Secure Your Wheels?

It might seem like magic, but simple physics keeps your wheels securely attached. The proper installation of your vehicle wheel lug nuts creates an incredibly strong connection through clamping force, correct torque, and a specific tightening pattern. Understanding this process helps you appreciate why every step is vital for your safety.

The Science of Clamping Force

Lug nuts don’t just screw on; they create immense pressure that holds everything together. This is known as clamping force. Think of the wheel stud (the bolt) as a very stiff spring. When you tighten a lug nut, you are actually stretching that stud.

This process works in a few key steps:

- You stretch the wheel stud slightly as you tighten the nut.

- This stretching creates powerful tension inside the stud.

- The tension pulls the wheel and hub together, generating a strong clamping force.

- This force creates massive friction between the wheel and the hub.

- This friction is what ultimately prevents the wheel from slipping or coming loose.

Note: Without this clamping force, the wheel would rely only on the studs to handle all the forces of driving. The friction created by proper clamping is what truly secures your wheel to the vehicle.

The Importance of Correct Torque

Torque is the measurement of rotational force you apply when tightening a fastener. Every vehicle has a specific torque specification for its lug nuts, measured in foot-pounds (ft-lbs) or Newton-meters (N-m). Applying the correct amount of torque is not just a recommendation; it is essential for safety. Applying too little or too much force can lead to dangerous situations.

What Happens if You Under-Torque? An under-tightened lug nut is a major safety risk. It will vibrate and loosen over time. This puts extra stress on the other lug nuts, causing them to loosen as well. Eventually, this can lead to complete wheel separation.

You should watch for these warning signs of loose lug nuts:

- Vibrations in your steering wheel or the vehicle’s body.

- Clicking, clunking, or rattling sounds coming from the wheel area.

- Uneven or rapid tire wear.

What Happens if You Over-Torque? You might think tighter is better, but over-tightening is just as dangerous. Excessive torque can cause severe damage to your wheel components.

- Stretched or Broken Studs: Too much force can permanently stretch the wheel studs, weakening them or causing them to snap.

- Warped Wheels: It can deform the wheel itself, preventing it from sitting flat against the hub.

- Damaged Brake Rotors: The uneven pressure can warp your brake rotors, causing a pulsing or shaking feeling when you brake.

Achieving the correct torque ensures the clamping force is exactly what the engineers designed it to be—strong enough to hold but not so strong that it causes damage.

The Star Pattern Tightening Method

The sequence you use to tighten your lug nuts is just as important as the final torque. You should always tighten them using a star or crisscross pattern. This method ensures the wheel mounts evenly against the hub.

Imagine tightening the nuts one by one in a circle. The first nut you tighten would pull that side of the wheel close to the hub, slightly tilting it. As you continue around, the wheel would be secured in a slightly crooked position. This improper seating leads to serious problems:

- Severe vibrations, especially at higher speeds.

- Uneven pressure that can warp your brake rotors.

- Lug nuts that can vibrate loose over time, even if they were torqued correctly.

Following the star pattern for the proper installation is simple. You tighten one lug nut, then move to the one most directly across from it, continuing until all are snug. This technique pulls the wheel on evenly, guaranteeing a flat, secure, and safe connection.

Are All Vehicle Wheel Lug Nuts the Same?

No, not all vehicle wheel lug nuts are the same. Using the wrong type can be extremely dangerous. You must choose a lug nut that correctly matches your vehicle and wheels. The three main differences you need to know are the seat type, size and thread pitch, and the system your car uses (lug nuts vs. lug bolts).

Matching the Seat Type to Your Wheel

The “seat” is the surface where the lug nut makes contact with the wheel. This contact point is crucial for distributing force correctly. The most common seat types are conical (tapered) and spherical (ball-shaped). You must match the lug nut’s seat to the wheel’s design. Using a conical nut on a wheel made for a spherical seat, for example, creates a dangerous mismatch. The force concentrates on a very small area, which can cause the nut to fail.

Safety Alert: An incorrect seat match is a serious safety hazard. The risks include:

- Improper seating of the wheel.

- Lug nuts that vibrate loose over time.

- Uneven force that can damage the wheel or hub.

- An increased risk of the wheel detaching while you drive.

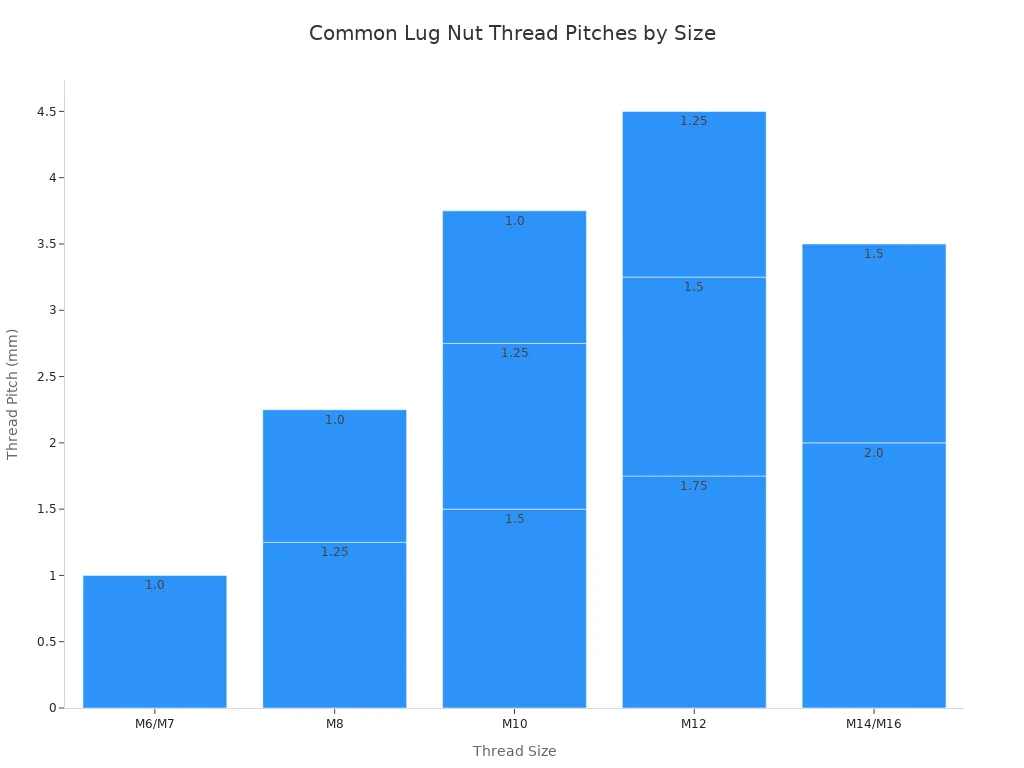

Understanding Sizes and Thread Pitch

Lug nuts also come in specific sizes. The size is defined by the diameter and thread pitch of your wheel’s studs. For example, a common size is “M12 x 1.5.” Here, “M12” means the stud has a 12-millimeter diameter, and “1.5” is the thread pitch, meaning there are 1.5 millimeters between each thread. Using the wrong size will either prevent the nut from threading on or cause it to strip the threads, ruining both the nut and the stud.

Always check your owner’s manual or consult a professional to find the correct size for your car.

The Difference Between Lug Nuts and Lug Bolts

Most vehicles use wheel studs, which are threaded posts that stick out from the hub. You secure the wheel by tightening lug nuts onto these studs. However, many European manufacturers, like BMW and Volkswagen, use lug bolts instead. With this system, you align the wheel with the hub and then insert long bolts through the wheel directly into threaded holes in the hub.

While studs make it easier to hang the wheel during a tire change, lug bolts can be more convenient if you need to use different lengths for wheel spacers. Regardless of the system, you can add a layer of security with a special locking lug nut or bolt that requires a unique key to remove.

When Should You Replace Your Lug Nuts?

Your vehicle wheel lug nuts are not designed to last forever. Regular maintenance and inspections help you know when it’s time for a replacement. Ignoring worn or damaged hardware can lead to catastrophic failure, so you should watch for a few key warning signs.

Visible Signs of Wear and Damage

You should visually inspect your lug nuts whenever you change a tire. Look for obvious signs of trouble that compromise their integrity. Rust is a common problem, as it can weaken the metal and make removal difficult. You should also check for cracks, which indicate the nut is failing. Pay close attention to the shape of the nut itself.

Spotting a Bad Nut:

- Slightly rounded corners: A socket may still fit, but it will feel loose.

- Severely rounded edges: A standard socket will no longer grip the nut.

- Stripped or damaged edges: This is a clear sign the nut is unsafe and needs replacement.

Functional Failures and Stripped Threads

Sometimes, the damage isn’t just cosmetic. A functional failure means the nut can no longer do its job. The most common issue is stripped or cross-threaded nuts. This often happens from improper installation, like starting the nut at an angle or using too much force with an impact wrench. Dirt and rust on the threads can also cause damage during tightening.

A stripped stud is a serious problem that often requires professional repair. The most dangerous functional failure is having missing lug nuts. Even one missing lug nuts puts extra stress on the others. Multiple missing lug nuts can cause your wheel to vibrate and eventually detach. Never drive with missing lug nuts. If you find missing lug nuts, replace them immediately.

When Upgrading to Aftermarket Wheels

When you buy new aftermarket wheels, you will almost always need new lug nuts. Factory nuts are designed for factory wheels, and aftermarket wheels often have a different seat type. For example, many aftermarket wheels use a conical seat, while your original wheels might have used a ball-shaped seat. Using the wrong seat type creates an unsafe connection.

You also have different material options to consider.

| Material | Strength | Cost | Best For |

|---|---|---|---|

| Steel | Very Strong | Low | Everyday driving |

| Aluminum | Less Strong | Medium | Aesthetics, light-duty use |

| Titanium | Very Strong | High | Racing, high-performance |

Choosing the right material depends on your performance needs and budget.

How to Ensure Your Lug Nuts Are Safe

Proper maintenance is the key to keeping your wheels secure. You can ensure your lug nuts are safe by using the right tools, knowing the correct specifications, and performing regular checks. This simple routine is a vital part of your vehicle’s overall safety.

Using a Torque Wrench

You must use a torque wrench to tighten your lug nuts correctly. An impact gun or a simple lug wrench cannot measure force, which often leads to over-tightening or under-tightening. A torque wrench allows you to apply the exact amount of pressure required. To ensure your tool is accurate, you should have your torque wrench calibrated regularly.

Tool Tip: Keeping Your Torque Wrench Accurate 🔧 An inaccurate torque wrench is a dangerous tool. To maintain its reliability, you should follow these general guidelines for calibration:

- Calibrate it at least once a year.

- Consider calibration after every 5,000 uses.

- Check it more often if it is used in harsh conditions or has been dropped.

Finding Your Vehicle’s Torque Specs

Every vehicle has a specific torque value recommended by the manufacturer. You can almost always find this specification in your vehicle’s owner’s manual. If you no longer have the manual, you can find the information from other reliable sources. Many professional online databases, such as the TorqueSpec Database or Mitchell1 ProDemand, provide this data for a wide range of vehicles. Always confirm the correct torque before you begin.

The Importance of Regular Inspections

Your safety checks should not end after the initial installation. It is critical to re-check the lug nut torque after driving between 50 and 100 miles. This ensures the wheels have settled properly and that nothing has come loose.

Regular tire and wheel maintenance should also include a quick visual inspection. Look for these warning signs:

- Any missing lug nuts.

- Rust streaks running from the nut, which can indicate looseness.

- Cracks or damage on the wheel rim itself.

- Rounded or stripped edges on the nuts.

Catching these issues early prevents a dangerous failure on the road.

Your vehicle wheel lug nuts are a critical safety component you should never overlook. Always inspect your lug nuts for wear during tire rotations or wheel service. Ensuring the correct torque is not just a recommendation; it is essential for safety.

A Real-World Example: Fiat-Chrysler once recalled over 500,000 Ram trucks. The issue was incorrect torque specifications in service manuals, which could damage wheel studs and cause wheels to detach.

This shows the serious risk of improper tightening. Always use the correct torque to guarantee your safety on the road.

FAQ

Can I reuse my old lug nuts?

You can reuse lug nuts if they are in excellent condition. You must replace them if you see any signs of rust, cracks, or thread damage. Rounded corners are also a clear sign that you need new lug nuts to ensure a secure fit and your safety.

How often should I check my lug nut torque?

You should always re-check your lug nut torque after driving 50 to 100 miles on newly installed wheels.

Pro Tip: It is also a great practice to inspect your lug nuts and confirm their torque during every tire rotation or oil change for continued safety.

Do I absolutely need a torque wrench?

Yes. A torque wrench is the only tool that can apply the precise amount of force your vehicle requires. Other tools like impact guns or standard lug wrenches can easily over-tighten or under-tighten your lug nuts, creating a dangerous situation on the road.

What happens if I lose the key for my locking lug nuts? 🔑

Losing your locking lug nut key can be frustrating, but you have options.

- Check your glove box or trunk for the original packaging, which may have a key code.

- Contact the lug nut manufacturer with the code to order a replacement.

- Visit a professional tire shop for assistance.