admin1

July 26, 2025

Valve Stem Valve Types and Features Explained for Easy Selection

You face many options when selecting a valve stem valve. The common types of valves—such as gate, globe, ball, butterfly, and check valves—serve different needs in automotive, industrial, and water systems. Each type uses unique features to control flow and pressure, ensuring reliable performance. For example, rubber valve stems appear most often in vehicles and heavy machinery, where durability matters most. Choosing the right valve depends on matching its features to your application. The table below shows the global market share for valve stem packing types in 2024:

| Valve Stem Packing Type | Approximate Global Market Share in 2024 (%) |

|---|---|

| Braided Packing | 35 |

| Die-Formed Packing | 25 |

| Molded Packing | N/A |

| Expanded Graphite Packing | N/A |

| Carbon Fiber Packing | N/A |

What Is a Valve Stem Valve?

Basic Definition of a Valve Stem Valve

You may wonder what a valve stem valve actually is. In engineering, a valve stem valve is a device that uses a stem to connect the actuator to the valve disk. This stem positions the disk to control the flow of liquids or gases. The stem is usually forged and attaches to the disk with threads or welds. The sealing area of the stem needs a smooth finish to prevent leaks. However, the stem itself does not act as a pressure boundary.

There are two main types of valve stems you will find in valve technology. Rising stems move upward when you open the valve, making it easy to see if the valve is open or closed. Nonrising stems do not move up or down outside the valve body. Instead, the disk inside the valve moves along the stem. This design helps when you have limited space above the valve.

Valve stem valves play a key role in flow control. You use them in many control valves to start, stop, or adjust the flow of fluids. This makes them essential in both simple and advanced flow control systems.

Tip: Always check the type of stem movement when selecting a valve stem valve for your application. This helps you match the right valve to your space and operation needs.

Role of Valve Stem Valves in Tire and Fluid Control Systems

Valve stem valves serve important functions in both tire and fluid control systems. You will find them in many industries, from automotive to HVAC and industrial plants. Here is how they work in these systems:

- Valve stem extenders help you reach and operate valves in hard-to-access places. They transmit force so you can open, close, or adjust the valve easily.

- The modular design of these valves includes a hollow cylindrical body with internal threads or flanges. This ensures a secure fit and reliable operation.

- Manufacturers use materials like stainless steel, brass, carbon steel, and PVC to handle different pressures and temperatures.

- Key parts include extension bodies, sealing elements such as O-rings or gaskets, and locking mechanisms for safety.

- These valves maintain system integrity under high pressure and temperature, which keeps your system running smoothly.

- You can use valve stem valves with many types of control valves, such as ball, gate, globe, and check valves.

- In tire systems, they help you inflate, deflate, and monitor tire pressure, making them vital for vehicle safety and performance.

- When you select a valve stem valve, you need to consider size, material, and pressure rating to ensure it meets industry standards.

Valve stem valves support flow control by making it easier and safer to manage fluids and gases. They also reduce maintenance time and improve safety in your operations.

Types of Valves: Main Valve Stem Valve Types

When you look at valve technology, you find several types of valves designed for different uses. The main valve stem valve types include rubber snap-in, metal clamp-in, and high-pressure valves. Each type offers unique features for on/off control, durability, and pressure handling. You need to know these differences to choose the right valve for your application.

Rubber Snap-In Valve Stem Valves

Rubber snap-in valve stem valves are some of the most common types of valves you see on passenger cars, motorcycles, and light trucks. You push these valves into the rim hole, and the rubber body creates a tight seal. This design makes installation quick and easy. You do not need special tools for this process.

- You use rubber snap-in valves for tire inflation pressures up to 65 psi.

- These valves fit rim holes of 0.453″ or 0.625″ and come in different lengths.

- The temperature range for these valves is -40°F to 180°F, so you can rely on them in most weather conditions.

- You find these valves in tubeless tire systems, where they help you inflate, deflate, and monitor tire pressure.

Note: Rubber snap-in valves work best for standard vehicles and light-duty trailers. They are not suitable for high-speed or heavy-duty applications.

You often see these valves paired with a valve core and cap. The core lets you control air flow, while the cap protects the valve from dirt and moisture. These valves are a popular choice because they are flexible, affordable, and easy to replace.

Metal Clamp-In Valve Stem Valves

Metal clamp-in valve stem valves offer higher durability and pressure resistance than rubber snap-in types. You install these valves by inserting them through the rim hole and tightening a nut with a wrench. This process secures the valve stem and ensures a strong seal.

- You find metal clamp-in valves made from aluminum, brass, or stainless steel.

- These valves handle pressures above 65 psi, making them ideal for heavy-duty vehicles, racing cars, and high-speed driving.

- You can use them with tire pressure monitoring systems (TPMS) because they resist heat and chemicals better than rubber valves.

- Metal clamp-in valves have a lower failure rate. Many users report years of trouble-free use, even in harsh environments.

| Aspect | Metal Clamp-In Valves | Snap-In Valves |

|---|---|---|

| Installation | Requires wrench to tighten nut, securing valve stem | Simple push-in installation, no tools needed |

| Materials | Aluminum, brass, stainless steel (metal body) | Rubber |

| Durability | High resistance to heat, chemicals, pressure; durable | Flexible but prone to wear, especially under extreme conditions |

| Pressure Capacity | Handles pressures above 65 PSI, suitable for heavy-duty and high-performance vehicles | Suitable up to 65 PSI, typical for standard vehicles |

| Failure Rates | Lower failure risk due to metal construction and better environmental resistance | Higher failure risk due to rubber deterioration and environmental exposure |

Tip: Choose metal clamp-in valves if you need a valve for high-speed, heavy-duty, or TPMS-equipped vehicles. These valves give you better on/off control and last longer in tough conditions.

High-Pressure Valve Stem Valves

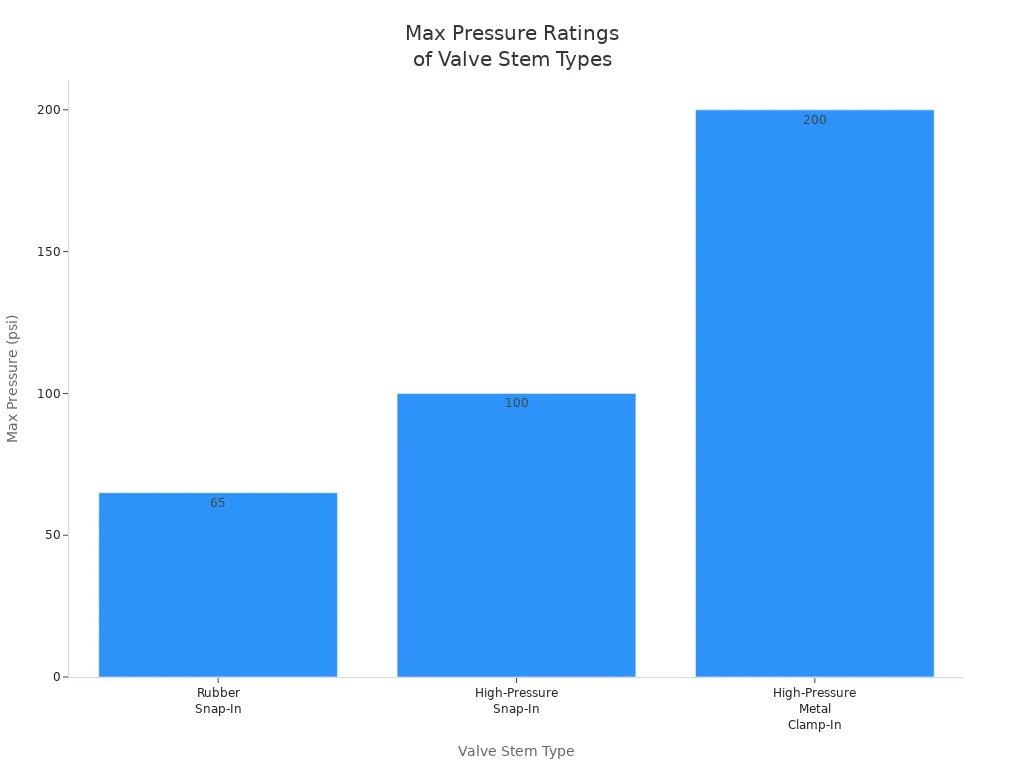

High-pressure valve stem valves are built for demanding applications. You see these valves in trucks, trailers, racing cars, and industrial equipment. They support much higher pressures than standard rubber snap-in valves.

- High-pressure snap-in valves handle 80-100 psi, depending on the rim hole size.

- High-pressure metal clamp-in valves can support up to 200 psi. You use these in racing or high-speed driving, where safety and reliability matter most.

- These valves come in straight or bent shapes and fit various rim hole sizes, such as .453″, .625″, 6mm, and 8mm.

- Manufacturers use strong materials like stainless steel or titanium to withstand high pressure and temperature.

You often find these valves in industries like oil and gas, chemical processing, and aerospace. They help you maintain safe operation under extreme conditions. The on/off function is critical in these settings, as you must control flow quickly and reliably.

Here is a chart comparing the maximum pressure ratings of different valve stem types:

Alert: Always check the pressure rating before you select a high-pressure valve. Using the wrong type can lead to leaks or failure.

When you choose a valve stem valve, think about the types of valves you need for your system. Ball valves, gate valves, and globe valves all use different stem designs. For example, a ball valve uses a stem to rotate the ball and control on/off flow. You may need a two-way ball valve for simple shut off valve tasks or a more complex design for industrial use. On/off valves like these give you precise control over your system.

You can see that the main valve types—rubber snap-in, metal clamp-in, and high-pressure—each serve a specific purpose. By understanding these types, you can match the right valve to your needs and ensure safe, reliable operation.

TPMS (Tire Pressure Monitoring System) Valve Stem Valves

You see TPMS (Tire Pressure Monitoring System) valve stem valves on almost every new vehicle today. These valves play a vital role in modern automotive safety. They help you monitor tire pressure in real time, which keeps you safe and improves fuel efficiency.

TPMS valve stem valves combine a traditional valve with a built-in sensor. This sensor measures the air pressure inside your tire. When the pressure drops below a safe level, the system sends a warning to your dashboard. You can react quickly and avoid dangerous driving conditions.

You find two main types of TPMS systems: direct and indirect. Direct TPMS uses a sensor inside each tire, usually attached to the valve stem valve. Indirect TPMS relies on the vehicle’s ABS system to detect changes in tire rotation speed. Most manufacturers use direct TPMS because it gives you more accurate readings.

The design of TPMS valve stem valves differs from standard types. You often see metal clamp-in valves used for TPMS because they offer better durability and sealing. Some TPMS valves use aluminum or brass for extra strength. The sensor attaches securely to the valve, so it stays in place even at high speeds.

You need to know that TPMS valve stem valves must meet strict standards. According to U.S. regulations, all new light motor vehicles sold after September 2007 must have TPMS installed. The European Union also requires TPMS on all new passenger cars sold from November 1, 2014. This means every new vehicle in these regions comes with TPMS valve stem valves. You can trust that these valves meet high safety and quality requirements.

You may notice that TPMS valve stem valves look different from other types. They are usually heavier because of the sensor. You must handle them with care during tire changes. Damaging the sensor can lead to costly repairs.

Here are some key features of TPMS valve stem valves:

- Built-in electronic sensor for real-time pressure monitoring

- Metal construction for strength and corrosion resistance

- Special sealing mechanisms to prevent leaks

- Compatibility with most types of valves used in modern vehicles

You can use TPMS valve stem valves on passenger cars, SUVs, trucks, and even motorcycles. They work well in both standard and high-performance vehicles. You get better safety and longer tire life when you use these valves.

Tip: Always check the compatibility of your TPMS valve stem valve with your vehicle’s system before installation. Using the wrong type can cause sensor errors or leaks.

You see that TPMS valve stem valves stand out among other valve types. They combine advanced technology with strong materials. You get reliable performance and peace of mind on the road.

Key Features of Valve Stem Valve Types

Stem Movement and Operation

When you look at valve stem valves, you notice that stem movement plays a big role in how the valve works. Some valves use a rising stem, which moves up as you open the valve. This gives you a clear sign of whether the valve is open or closed. Other valves use a non-rising stem, where the stem stays in place while the internal gate moves. This design saves space and works well in tight spots.

Here is a table that shows the main differences:

| Feature | Rising Stem Gate Valve | Non-Rising Stem Gate Valve |

|---|---|---|

| Stem Movement | Stem rises as valve opens | Stem stays still; gate moves inside |

| Visual Position | Easy to see if open or closed | Must check by hand or indicator |

| Maintenance | Easier to reach stem and packing | Harder to access |

| Space Needed | Needs more space above valve | Fits in small spaces |

| Friction/Wear | Less friction, lasts longer | More friction, wears faster |

You use rising stem valves when you want easy maintenance and a clear view of the valve’s position. Non-rising stem valves work best when you need a compact design. Both types help you control flow and improve performance in different systems.

Sealing Mechanisms and Valve Stem Seals

Sealing is one of the most important features in any valve. Good sealing keeps air, fluids, or gases from leaking out. Different valve stem valves use different sealing mechanisms based on their materials and uses.

| Valve Stem Type | Material | Sealing Mechanism | Key Features |

|---|---|---|---|

| Rubber Valve Stem | Synthetic rubber | Rubber gasket forms a tight seal | Best for low pressure, easy to install |

| Metal Valve Stem | Brass, steel | Metal stem with rubber gasket for extra sealing | Handles high pressure, resists corrosion |

| TPMS Valve Stem | Aluminum, metal | Metal with special seals and sensor integration | Maintains air, supports smart monitoring |

Rubber stems use a flexible gasket to seal the rim. Metal stems add a strong core and gasket, which helps them handle higher pressure and temperature. TPMS valves combine sealing with electronic sensors, so you get both air retention and real-time pressure data. These sealing features protect your system and boost performance.

Tip: Always check the sealing components before installation. Good seals are key components of valves and help prevent leaks.

Material Options: Rubber, Aluminum, Brass

The material you choose for your valve stem valve affects its performance, durability, and safety features. Each material has its own strengths.

- Rubber stems are flexible and cost-effective. You can install them easily, and they resist corrosion. They work well for standard vehicles and off-road use.

- Aluminum stems are lightweight and strong. They resist corrosion and look good on performance vehicles. You need to handle them with care to avoid damage.

- Brass stems are tough and reliable. They handle high pressure and heavy loads, making them perfect for trucks and industrial equipment.

Here is a quick comparison:

| Material | Advantages | Typical Applications |

|---|---|---|

| Rubber | Flexible, easy to replace, resists rust | Cars, motorcycles, bicycles |

| Aluminum | Light, durable, resists corrosion | Racing, performance vehicles, motorcycles |

| Brass | Strong, handles high pressure, reliable | Trucks, commercial, industrial |

When you select a valve, think about the key components of valves and how each material supports flow control and overall performance. The right choice helps you get the best results and long-lasting valve components.

Maintenance and Durability Considerations

You want your valve to last as long as possible and keep working at its best. Maintenance and durability play a big role in how well your valve performs over time. If you choose the right valve for your needs, you can reduce the time and money spent on repairs.

Regular inspection helps you spot problems early. You should check for cracks, corrosion, or leaks around the valve stem. Dirt and debris can build up and affect performance. Clean the valve area often to keep it working smoothly.

Different materials offer different levels of durability. Rubber valves work well for daily driving, but metal valves handle tough conditions better. Brass and aluminum valves resist rust and damage from road salt. These materials help maintain long-term sealing and high performance, even in harsh environments.

Sealing is another key factor. A good seal keeps air or fluid inside and prevents leaks. You should replace valve caps after every tire change. This small step protects the sealing surface and improves performance.

Here is a quick checklist for valve maintenance:

- Inspect the valve stem for damage or wear.

- Clean the area around the valve to remove dirt.

- Replace the valve cap after servicing.

- Check for leaks by applying soapy water and looking for bubbles.

- Use only quality valves from trusted manufacturers for best performance.

| Valve Material | Durability Level | Maintenance Needs | Typical Lifespan |

|---|---|---|---|

| Rubber | Moderate | Low | 3-5 years |

| Aluminum | High | Medium | 5-8 years |

| Brass | Very High | Low | 8+ years |

Tip: Always follow the manufacturer’s guidelines for valve care. This helps you get the best performance and safety from your system.

Pros and Cons of Each Valve Stem Valve Type

Rubber Snap-In Valve Stem Valves

You often see rubber snap-in valve stem valves on standard vehicles. These types of valves use flexible rubber as their main material. You can install them quickly without special tools. Many drivers like these valves for everyday use because they resist corrosion and cost less than other types.

| Feature | Rubber Snap-In Valve Stems | Metal Clamp-In Valve Stems |

|---|---|---|

| Material | Rubber, flexible | Metal (aluminum, brass, stainless steel) |

| Corrosion Resistance | High resistance to corrosion | More susceptible to corrosion |

| Installation | Quick, easy, no special tools needed | Requires wrench and torque for clamping nut |

| Durability | Vulnerable to drying, cracking, damage during tire servicing | More durable, withstands heat and harsh conditions |

| Pressure Capacity | Suitable up to 65 PSI (standard passenger vehicles) | Handles higher pressures (heavy-duty, high-performance) |

| Cost | Generally less expensive | Higher cost but longer-lasting |

| Suitability | Everyday driving, standard tire pressures | High-performance, heavy-duty, extreme conditions |

Advantages:

- You get easy on/off operation for tire inflation.

- You do not need special tools for installation.

- These valves resist rust and work well for standard tire pressures.

- You save money with these types.

Disadvantages:

- Rubber can dry out, crack, or harden, especially in sunlight.

- You may see slow leaks if the stem gets damaged during servicing.

- You need to replace the valve and service kits every time you remove the tire.

- These valves do not last as long under extreme heat or high pressure.

Tip: Always check the valve for cracks or leaks before you reinstall a tire.

Metal Clamp-In Valve Stem Valves

Metal clamp-in valve stem valves give you more strength and durability. You use a wrench to tighten the nut and secure the valve. These types of valves work well for high-performance and heavy-duty vehicles. You often see them paired with TPMS sensors and in applications where on/off control matters.

Pros:

- You get a strong seal and better on/off reliability.

- These valves handle higher pressures and temperatures.

- They last longer than rubber types, especially in harsh conditions.

- You can use them with advanced systems like TPMS.

Cons:

- Installation takes more time and requires a wrench.

- If you do not install the grommet correctly, leaks can happen.

- You must choose the right grommet size for a proper seal.

- Some types, like ENKEI, need tightening from inside the rim, which can be tricky.

Note: Always follow the correct steps for installing metal clamp-in valves to avoid leaks.

High-Pressure Valve Stem Valves

High-pressure valve stem valves are built for extreme conditions. You find these types in trucks, racing cars, and industrial equipment. They use strong materials like forged steel or advanced ceramics. These valves keep your system safe when you need precise on/off control.

- High-pressure valves use robust ball and diaphragm components to resist wear.

- You get better flow control and less risk of leaks.

- Advanced materials like zirconia and carbide last much longer than standard steel.

- These valves reduce maintenance and improve safety in tough environments.

Standard valves may deform or fail under constant high pressure. High-pressure types use special designs to keep the ball and other components safe from stress. You see less material fatigue and fewer leaks.

Alert: Always match the valve type to your system’s pressure needs for the best performance.

TPMS Valve Stem Valves

You see TPMS valve stem valves on many modern vehicles. These types of valves work with Tire Pressure Monitoring Systems to help you keep track of tire pressure. TPMS valve stem valves combine advanced technology with strong materials. You get both safety and performance from these types.

TPMS valve stem valves differ from standard types in several ways. You find sensors built into the valve. These sensors send real-time data to your dashboard. When tire pressure drops, you get a warning right away. This helps you avoid unsafe driving conditions.

You need to pay attention to the cost and maintenance of these types. TPMS valve stem kits usually cost between $3 and $3.50. Servicing or rebuilding these valves can cost more than standard types. Dealers often charge a fair rate for this technical work. Replacing a tire valve stem costs about $10, but TPMS types require more care and skill.

Maintenance for TPMS valve stem valves is important. Experts recommend replacing all parts of the valve stem assembly—grommet, nut, cap, and core—whenever you service the tire or sensor. This prevents leaks and keeps the system working well. You should inspect these types of valves for cracks or leaks during every tire service. Applying a soap and water mix helps you spot leaks by looking for bubbles.

Here are some tips for maintaining TPMS valve stem valves:

- Inspect for cracks and leaks during tire service.

- Replace all parts of the valve stem assembly when changing tires or sensors.

- Use plastic valve caps to prevent corrosion.

- Avoid mixing metals, such as brass caps on aluminum stems, to stop galvanic corrosion.

- Store your vehicle in a garage or use a cover to protect the valve from weather damage.

- Apply a silicone-based lubricant once a year to extend the life of the valve.

You should let professionals handle TPMS valve stem valve servicing. They have the right tools and know the correct torque settings. This ensures your TPMS system stays reliable and safe.

Note: Servicing TPMS valve stem valves takes patience and skill. Proper care helps you avoid costly repairs and keeps your tire pressure monitoring system working at its best.

Valve Selection: Typical Applications and Criteria

Industrial and Heavy-Duty Applications

You see many types of valves used in industrial and heavy-duty applications. These settings demand strong materials and reliable operation. You often find ball valves in these environments because they offer quick shut-off and precise flow control. The most common ball valve types are floating ball valves and trunnion ball valves. For gate valves, you use rising stem gate valves (outside screw and yoke, OS&Y) or non-rising stem gate valves. These designs help you handle high pressures and tough fluids.

In industrial applications, you must consider the process fluid. Slurries, viscous liquids, and scaling fluids affect your valve choice. You also need to match the valve to the pressure and temperature of your system. Sliding stem valves work well for high-pressure drops and give you better control. Rotary stem valves, like those in ball or butterfly valves, are cost-effective for many applications but have limits under extreme pressure.

Tip: Always check the material compatibility and end connections to ensure your valve fits your application.

Passenger, Commercial, and Motorcycle Uses

You use different valve stem types for passenger vehicles, commercial vehicles, and motorcycles. The table below shows the recommended types for each category:

| Vehicle Category | Valve Stem Type | Max Pressure (PSI) | Size Range (inches) | Additional Details |

|---|---|---|---|---|

| Passenger Vehicles | Rubber Valve Stem | ≤ 65 | 0.7 to 2.5 | Fits rim holes 0.453” or 0.625”; sometimes chrome sleeves. |

| Commercial Vehicles | High-Pressure Valve Stem | 80 to 100 | 1.25 to 2.0 | For medium to heavy-duty trucks with steel wheels. |

| Motorcycles | Schrader Valve (universal) | N/A | N/A | Most common valve stem on motorcycles; universal use. |

| High-Performance | High-Performance Valve Stem | 200 | 0.453” & 0.625” | For race cars; also available in smaller rim hole fittings. |

You select rubber valve stems for most passenger cars. High-pressure valve stems work best for trucks and commercial vehicles. Motorcycles use Schrader valves, which fit many applications. High-performance vehicles need special valve stems that handle higher speeds and pressures.

How to Match Valve Stem Valve Type to Application

You must match the valve stem type to your application by looking at several criteria:

- Choose the right stem movement: rising stem for easy position checks, non-rising stem for tight spaces, rotary stem for quick open/close in ball and butterfly valves.

- Check the process fluid: thick, sticky, or scaling fluids may need special valves.

- Match the valve to the pressure and temperature: high-pressure drops need sliding stem valves, while rotary valves work for moderate conditions.

- Consider your flow control needs: sliding stem valves offer precise control and handle tough conditions like cavitation or noise.

- Make sure the valve material matches your fluid and pressure requirements.

- Select the right end connections for your system size and maintenance needs.

- Always check the valve pressure rating and make sure it can handle your application.

Note: Good valve selection improves system performance and safety in all applications.

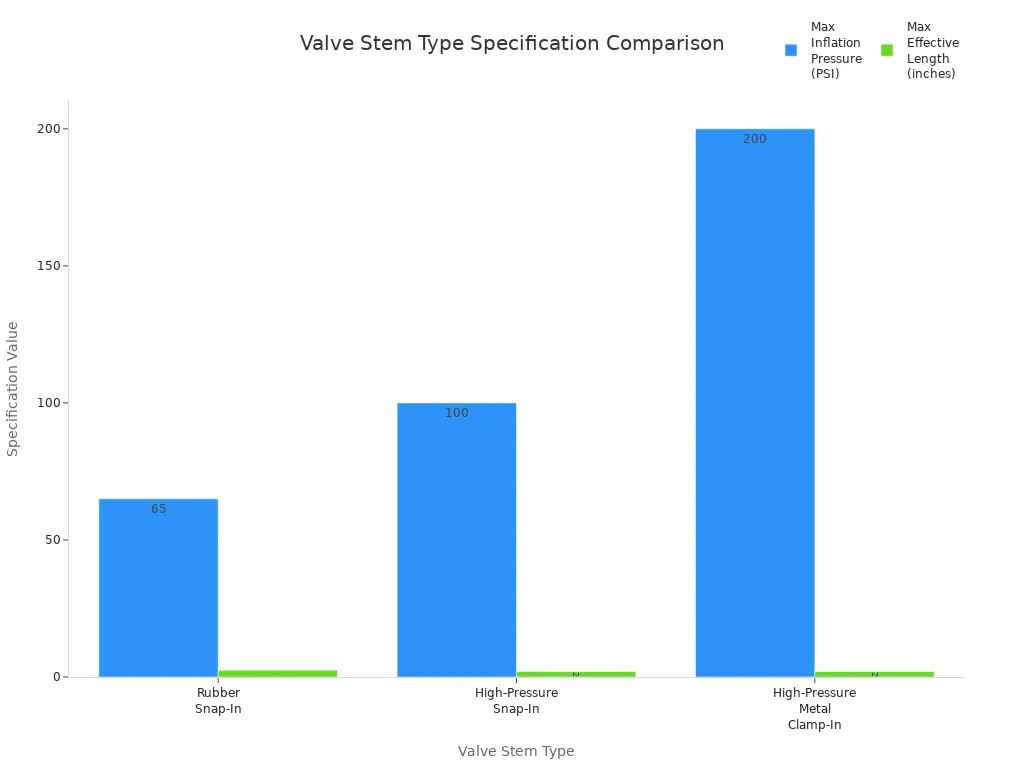

Comparison Table: Valve Stem Valve Types at a Glance

When you compare valve stem types, you see clear differences in how each one works for on/off control and ball valve applications. The right choice depends on your vehicle, wheel design, and the conditions you face. You need to look at the main types and their features side by side. This helps you pick the best valve for your needs.

Here is a table that shows the key specifications for the most common valve stem types:

| Valve Stem Type | Max Inflation Pressure (PSI) | Effective Length Range (inches) | Wheel Hole Diameter (inches) | Additional Features/Notes |

|---|---|---|---|---|

| Rubber Snap-In Valves | Up to 65 | 0.88 to 2.5 | 0.453 or 0.625 | Best for passenger cars and light trucks; easy on/off use; plastic or metal caps; lower pressure rating. |

| High-Pressure Snap-In Valves | 80 to 100 | ~1.25 to 2 | 0.453 or 0.625 | Used for trucks and trailers; thicker rubber base with metal barrel; supports higher on/off cycles. |

| High-Pressure Metal Clamp-In | Up to 200 | Flush to 2 | 0.453, 0.625, 6mm, 8mm | Metal body with rubber grommet; ideal for high-speed, racing, or track use; strong on/off performance. |

You notice that rubber snap-in valves work well for daily driving and standard ball valve setups. High-pressure snap-in types give you more strength for trucks and heavy loads. Metal clamp-in valves handle the highest pressures and offer the best on/off reliability, especially in ball valve systems.

Valve components like cores and caps also matter. You find brass or nickel-plated cores, which help prevent corrosion, especially with aluminum stems. Metal caps work better for high temperatures or racing. These valve components keep your system safe and working well.

Take a look at this chart to see how the max inflation pressure and length compare for each type:

When you choose a valve, always match the type to your on/off needs, ball valve use, and the demands of your application. This approach helps you get the best performance and safety from your valve system.

Important Valve Selection Factors

Media Compatibility and Application Environment

When you choose a valve for your applications, you must think about what kind of media will flow through it. Media compatibility is a key part of the selection criteria for valves. Different fluids, such as corrosive chemicals, abrasive slurries, or high-temperature steam, need special valve materials and designs. If you use the wrong material, the valve can wear out quickly or even fail.

- You should match the valve stem packing to the media. For example, PTFE works well with acids and alkalis because it resists chemicals. Graphite is best for high-temperature steam. Metallic packings handle toxic gases under high pressure.

- The physical state of the media—gas, liquid, or slurry—also affects your choice. Abrasive media need wear-resistant packing to keep the valve working.

- The friction and wear resistance of the packing material can change how the valve operates. Low-friction materials like PTFE make the control valve easier to move and save energy.

- If the packing does not match the media, it can swell or break down, causing leaks or other problems.

Tip: Always check the chemical resistance and temperature tolerance of your valve materials before making a choice.

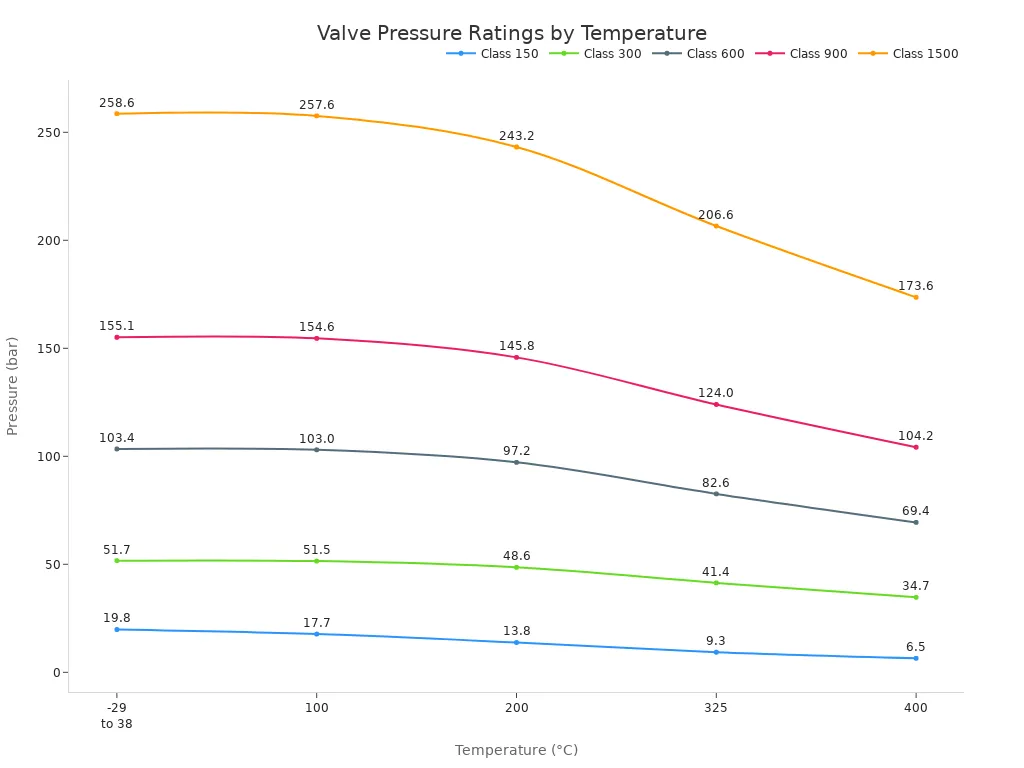

Pressure and Temperature Ratings

You must also consider the pressure and temperature ratings for your applications. Each valve type has limits for how much pressure and heat it can handle. If you exceed these limits, the valve may leak or break.

Here is a table showing standard pressure ratings for different valve classes at various temperatures:

| Temperature (°C) | Class 150 (bar) | Class 300 (bar) | Class 600 (bar) | Class 900 (bar) | Class 1500 (bar) |

|---|---|---|---|---|---|

| -29 to 38 | 19.8 | 51.7 | 103.4 | 155.1 | 258.6 |

| 100 | 17.7 | 51.5 | 103.0 | 154.6 | 257.6 |

| 200 | 13.8 | 48.6 | 97.2 | 145.8 | 243.2 |

| 325 | 9.3 | 41.4 | 82.6 | 124.0 | 206.6 |

| 400 | 6.5 | 34.7 | 69.4 | 104.2 | 173.6 |

You can see that as temperature rises, the pressure rating drops. This is important for control valves in high-temperature or high-pressure applications. Here is a chart that shows how pressure ratings change with temperature:

You should always check the valve’s rating and make sure it matches your system’s needs. This helps you avoid leaks and keeps your applications safe.

Actuation Methods and Installation Space

Valve actuation methods and installation space also play a big role in your applications. You can choose manual, pneumatic, or electric actuators for your control valves. Each method has its own space and power needs.

| Valve Stem Type | Actuation Methods | Power Source | Installation Space Requirements | Notes |

|---|---|---|---|---|

| Manual | Lever, Hand Wheel | Human | Needs space for handles | Good for small or easy-to-reach valves |

| Pneumatic | Rotary Actuator | Air | Compact, needs air supply | Works well outdoors, fast action |

| Electric | Motor Actuator | Electricity | Needs wiring and space for motor | Needs protection from weather |

Manual valves need room for handles or wheels. Pneumatic actuators use air and fit well in tight spaces. Electric actuators need wiring and protection from heat or rain. You should pick the actuation method that fits your installation space and the needs of your applications.

Note: Always check the available space and power source before you install a new valve. This helps you avoid problems and keeps your system running smoothly.

Maintenance, Serviceability, and Longevity

You want your valve stem valves to last as long as possible. Good maintenance and easy service help you get the most out of your valves. Each type of valve stem valve has its own care needs, but some steps work for all.

Key Maintenance Steps:

- Inspect the valve stem for cracks, corrosion, or leaks every time you check your tires or fluid systems.

- Clean the area around the valve stem. Dirt and debris can cause slow leaks or damage the seal.

- Replace the valve cap after every service. The cap keeps out moisture and dust.

- Use soapy water to check for leaks. Bubbles mean you need to replace the valve or its parts.

Tip: Always use quality replacement parts from trusted brands. This helps you avoid early failures.

Serviceability means how easy it is to repair or replace the valve. Rubber snap-in valves are quick to swap out. You can do this with basic tools. Metal clamp-in valves take more time. You need a wrench and must tighten the nut to the right torque. TPMS valves need special care. You should let a professional handle these to avoid damaging the sensor.

Here is a table to help you compare:

| Valve Type | Maintenance Level | Service Difficulty | Typical Lifespan |

|---|---|---|---|

| Rubber Snap-In | Low | Easy | 3-5 years |

| Metal Clamp-In | Medium | Moderate | 5-8 years |

| High-Pressure | Medium | Moderate | 5-10 years |

| TPMS | High | Advanced | 5-7 years |

You can extend the life of your valves by storing your vehicle in a garage and avoiding harsh chemicals. Regular checks and proper installation keep your valves working longer. If you follow these steps, you will save money and keep your system safe.

Note: Always follow the manufacturer’s instructions for the best results and longest valve life.

How to Choose a Valve: Step-by-Step Valve Stem Valve Selection Guide

Step-by-Step Process for Valve Selection

Choosing the right valve stem valve can seem confusing, but you can follow a clear process to make the best choice for your needs. When you know how to choose a valve, you avoid problems and keep your system safe and efficient.

Start by looking at the main factors that affect your decision. The table below shows what you should consider and why each factor matters:

| Factor | Considerations | Purpose/Reason |

|---|---|---|

| Size | Valve size and flow coefficient (Cv) matching system flow requirements | Ensures adequate flow capacity and pressure drop management |

| Temperature | Operating and ambient temperatures, temperature fluctuations affecting materials and sealing | Prevents material degradation and ensures valve integrity under temperature extremes |

| Application | Valve function needed (start/stop, regulate, direction control, overpressure protection) | Guides selection of valve type suitable for intended control function |

| Media | Compatibility of valve materials with process fluid and environmental exposure | Avoids corrosion, embrittlement, and safety risks |

| Pressure | Working and design pressure ratings, interaction with temperature | Ensures valve can safely withstand system pressures without failure |

| Ends | Type and size of end connections (fittings, threads, flanges, welds) | Guarantees leak-tight installation and system compatibility |

| Delivery | Supplier reliability, availability, and delivery timing | Maintains system operational efficiency by ensuring timely valve procurement |

You can use these steps to guide your valve selection:

- Check the required tire or system pressure. Match it with the valve stem’s pressure rating to make sure it can handle the job.

- Choose the right extension. Use metal valve extensions only with metal valve stems. Pair rubber valve stems with plastic extensions to prevent failure at high speeds.

- Before you install the valve, apply a non-petroleum-based lubricant. This protects the valve stem from damage during installation.

- Inspect the stem hole. Look for sharp edges, metal slivers, rust, or extra paint. These can stop the valve from sealing properly.

- For metal valve stems, use a torque wrench. Tighten the nut to the manufacturer’s recommended torque. This step keeps the valve safe and secure.

- If you notice air loss after installation, check the wheel’s stem hole size and shape. Make sure you selected the correct valve stem for your wheel.

- Always match the valve stem’s size, pressure rating, and material to your application. This prevents dangerous failures, especially at high speeds or heavy loads.

Tip: When you wonder how to choose a valve, always start with your application’s needs. Think about pressure, temperature, and the type of fluid or air in your system.

Common Mistakes to Avoid in Valve Selection

You can avoid many problems by watching out for common mistakes during valve selection. Industry experts see these errors often, and they can lead to leaks, failures, or even safety risks.

Here are the most frequent mistakes people make:

- Not using the correct torque when installing metal valve stems. If you tighten too much or too little, the valve can fail. Always use a torque wrench and follow the recommended settings, such as 24-45 in/lbs for TR416S stems.

- Picking a valve stem that does not fit the hole size or application. Always check the thickness and diameter of the stem hole before you choose a valve. A mismatch can cause air leaks.

- Skipping the step of checking stem specifications and compatibility. Do not assume the old stem was correct. Previous repairs may have used the wrong part.

- Ignoring safety issues like zipper ruptures in steel cord radial truck tires. Using the wrong valve stem can cause these dangerous failures.

- Forgetting to teach users how to measure tire pressure correctly. Always use the right air pressure gauge for your valve stem type.

Alert: Double-check your valve selection before installation. A small mistake can lead to big problems down the road.

You can avoid these mistakes by following the step-by-step process and paying attention to details. This approach helps you choose the right valve every time and keeps your system running safely.

You have learned about the main valve stem valve types and their features.

- Rubber snap-in valves offer easy installation for standard vehicles.

- Metal clamp-in valves provide strength for high-pressure or TPMS systems.

- High-pressure valves suit trucks and racing needs.

- TPMS valves combine safety with real-time monitoring.

For easy selection, always match valve size, material, and function to your application. Follow industry standards and inspect valves regularly. Quality manufacturers like Fortune use strict quality control and certified processes to deliver reliable, long-lasting valve solutions. This helps you keep your systems safe and efficient.

FAQ

What is the main difference between rubber snap-in and metal clamp-in valve stems?

Rubber snap-in valve stems use flexible rubber for easy installation. Metal clamp-in valve stems use metal and a nut for a stronger seal. You should choose metal clamp-in stems for higher pressure or heavy-duty use.

How often should you replace valve stem valves?

You should replace valve stem valves every time you change tires. For most vehicles, this means every 3 to 5 years. Regular inspection helps you spot cracks or leaks early.

Can you use TPMS valve stems on any vehicle?

No, you cannot use TPMS valve stems on every vehicle. TPMS valve stems work only with vehicles that have a Tire Pressure Monitoring System. Always check your vehicle’s requirements before installing.

Why does valve stem material matter?

Valve stem material affects strength, corrosion resistance, and pressure capacity. Rubber works well for standard cars. Brass and aluminum offer better durability for trucks or performance vehicles. Always match the material to your driving needs.

How do you check for valve stem leaks?

You can check for leaks by applying soapy water to the valve stem. If you see bubbles, air is escaping. Replace the valve stem if you find a leak.