admin1

October 26, 2025

A Deep Dive into Wheel Hub Bolts Materials and Designs

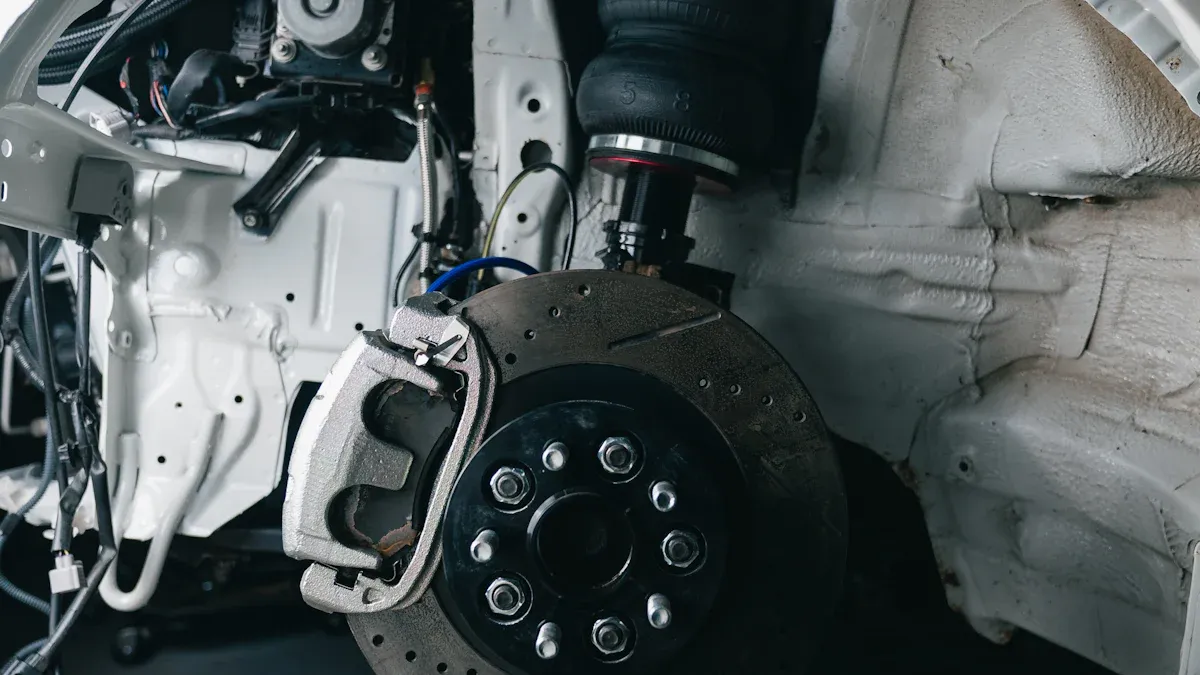

Properly secured wheels are fundamental to vehicle safety. Failures involving wheel hub bolts can have severe consequences, as statistics from the UK highlight the risks of wheel detachment.

| Statistic | Value (UK, 2010) |

|---|---|

| Estimated wheel detachments annually | 150 to 400 |

| Fatal accidents due to wheel detachment | 3 to 7 |

The design of wheel hub bolts and their material composition are primary factors in preventing these incidents. High-strength alloy steels provide the optimal balance of strength and durability for the wheel hub assembly, while features like thread type and protective coatings ensure maximum clamping force.

The Fundamental Materials for Wheel Hub Bolts

The choice of material for wheel hub bolts is a critical engineering decision. This decision balances strength, weight, corrosion resistance, and cost. Proper material selection ensures the bolts can handle the immense forces they face during vehicle operation. While several materials exist, a few have become standards for specific applications.

High-Strength Alloy Steels (e.g., 40Cr, 35CrMo)

Most wheel hub bolts are made from high-strength alloy steel. This material provides an excellent combination of strength and durability at a reasonable cost. Manufacturers often use chromium-vanadium steel because it delivers high tensile strength and resists wear and tear. These properties are essential for maintaining wheel stability under difficult road conditions.

How Alloying Elements Improve Steel Small amounts of other elements are added to iron and carbon to create alloy steels with specific traits. Each element serves a purpose:

- Chromium (Cr): Increases hardness and corrosion resistance.

- Molybdenum (Mo): Improves strength at high temperatures and enhances corrosion resistance.

- Carbon (C): The primary element for increasing hardness and strength.

- Manganese (Mn): Improves hardenability and tensile strength.

- Silicon (Si): Increases strength and resistance to oxidation.

Two common alloy steels used for wheel hub bolts are 40Cr and 35CrMo. 40Cr is a popular choice known for its solid performance. After heat treatment, it achieves impressive mechanical properties.

| 40Cr Steel Properties (Quenched & Tempered) | |

|---|---|

| Tensile Strength | 800 – 1100 MPa |

| Hardness (HRC) | 28 – 40 HRC |

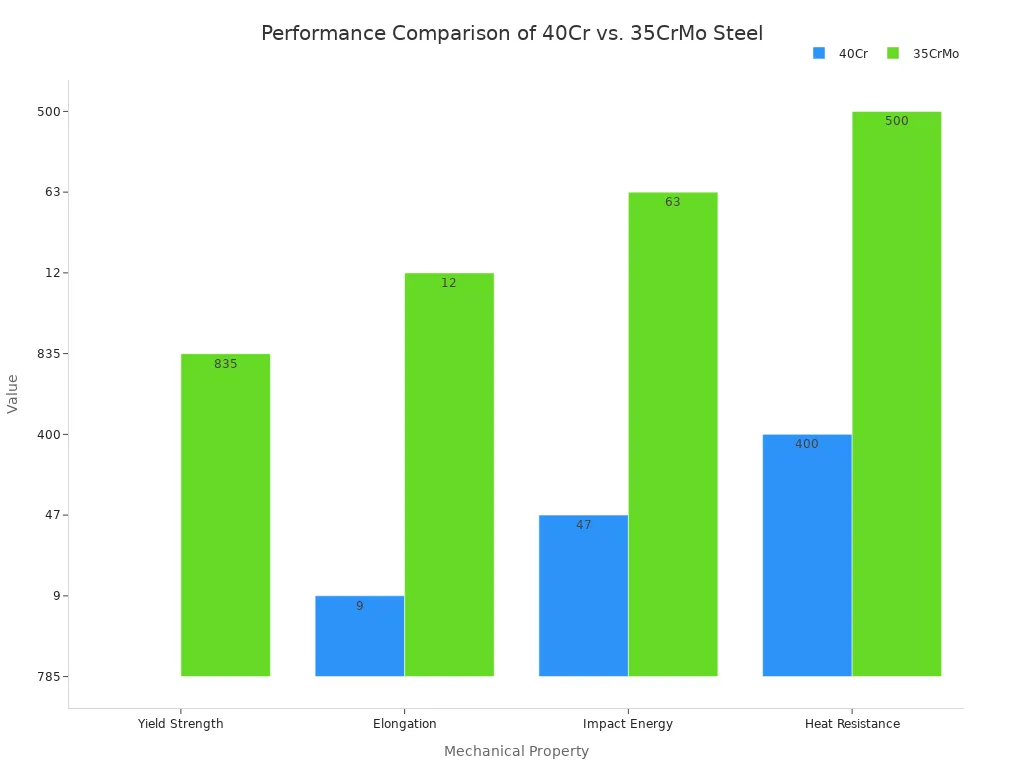

35CrMo is another medium-high strength steel. The addition of Molybdenum gives it advantages over 40Cr. It has better toughness, higher heat resistance, and greater stability after tempering. The chart below shows how 35CrMo outperforms 40Cr in several key mechanical properties.

This detailed comparison highlights why 35CrMo is often preferred for more demanding applications, such as bolts that operate at temperatures up to 500°C.

| Property Comparison | 40Cr | 35CrMo |

|---|---|---|

| Yield Strength (MPa) | 785 | 835 |

| Impact Energy (J) | ≥47 | ≥63 |

| Heat Resistance | ≤400°C | ≤500°C |

| Cost | Low | Medium |

Lightweight Titanium Alloys

Titanium alloys represent a premium material for wheel hub bolts. They are typically found in high-performance, racing, or luxury vehicles. Their main advantage is a superior strength-to-weight ratio.

Using titanium alloy bolts can reduce the weight of the fasteners by 40% to 50% compared to steel. For example, a standard M6 steel bolt may weigh 6-7 grams, while a titanium bolt of the same size weighs only 3-4 grams. This weight reduction, known as reducing “unsprung mass,” can improve a vehicle’s handling and fuel efficiency. Titanium also offers excellent corrosion resistance, making it suitable for harsh environments.

However, these benefits come at a significant cost. Titanium is far more expensive than steel, which limits its use in mass-market vehicles.

| Cost Comparison (per M10 bolt) | |

|---|---|

| High-Strength Steel | $0.30 – $0.60 |

| Titanium Alloy | $2.50 – $4.00 |

Corrosion-Resistant Stainless Steel

Stainless steel is another material option for wheel hub bolts, valued primarily for its appearance and corrosion resistance. The chromium content in stainless steel creates a passive, self-repairing layer that protects against rust. This makes it a good choice for vehicles in wet or coastal climates where salt exposure is a concern.

However, there is a significant trade-off. The following list compares the general characteristics of common bolt materials.

- Alloy Steel: High strength, good durability, but requires a protective coating to prevent rust.

- Titanium Alloy: Very high strength, lightweight, and excellent corrosion resistance, but very expensive.

- Stainless Steel: Excellent corrosion resistance, but has lower strength compared to alloy steels.

Because of its lower strength, stainless steel is generally not suitable for wheel hub bolts in heavy-duty or high-performance applications. While stainless steel is naturally rust-resistant, high-quality coated alloy steel bolts can also offer excellent protection. Some advanced coatings can withstand over 1,000 hours in a salt spray test, making them highly effective at preventing corrosion on stronger alloy steel bolts.

Critical Factors in the Design of Wheel Hub Bolts

Beyond material choice, the physical design of wheel hub bolts plays an equally important role in their performance and safety. The engineering behind a bolt’s threads, head, and coating directly impacts its ability to secure a wheel and withstand the intense forces of driving. A well-thought-out design of wheel hub bolts ensures reliability, longevity, and proper function.

Thread Engineering: Rolled vs. Cut Threads

Threads are the helical ridges on a bolt that allow it to fasten into a threaded hole, creating clamping force. The method used to create these threads significantly affects the bolt’s strength and fatigue resistance. The two primary methods are cutting and rolling.

Cut threads are made by machining away material from a bolt blank to form the thread shape. This process is like carving and, while effective, it severs the steel’s natural grain structure. These breaks in the grain flow create microscopic stress points, making the threads more susceptible to cracking under load and vibration.

Rolled threads, in contrast, are formed by compressing and shaping a bolt blank between hardened dies. This cold-forming process does not remove material. Instead, it reshapes the steel, creating a continuous grain flow that follows the contour of the thread. This method provides several key advantages:

- Superior Fatigue Life: Rolled threads can have a fatigue life 5 to 10 times longer than cut threads.

- Increased Strength: The cold-working process hardens the material, increasing thread strength by 30% to 40%. If rolling is done after heat treatment, fatigue life can improve by as much as 70% to 100%.

- Inherent Durability: Rolling creates residual compressive stress at the root of the thread. This stress helps prevent cracks from forming, making the bolt much more resistant to failure.

- Smoother Surface: The process results in a smoother, more precise thread surface without the tool marks that can act as stress risers on cut threads.

For these reasons, high-quality wheel hub bolts almost always feature rolled threads.

Fine Threads for Greater Force Wheel fasteners consistently use fine threads rather than coarse threads. This design choice offers two major benefits:

- Fine threads have a smaller thread angle, which allows them to generate a greater clamping load with the same amount of torque.

- The design increases the overall strength of the bolt, which is critical in high-vibration environments.

Head and Shank Specifications

The head and shank are fundamental parts of a bolt’s anatomy. The head allows a tool to apply torque, while the shank is the smooth, unthreaded portion that bears the shear load.

Different head designs exist to accommodate various tools and applications.

- Hexagonal Heads: This is the most common design for wheel hub bolts, easily gripped by standard wrenches and sockets.

- Socket (Allen) Heads: This internal-drive style offers more contact surfaces between the tool and the bolt, allowing for tighter fastening with less risk of stripping the head.

The shank’s diameter and length are engineered to fit precisely within the wheel and hub assembly. This precise fit ensures that the wheel is properly aligned and that the shear forces from braking and cornering are distributed correctly across all the wheel hub bolts, preventing any single bolt from bearing an excessive load.

The Role of Protective Surface Coatings

Since most wheel hub bolts are made from alloy steel, they require a protective coating to prevent corrosion. These coatings do more than just stop rust; they also influence the bolt’s performance during installation.

| Coating Type | Primary Function | Key Characteristics |

|---|---|---|

| Zinc Flake (e.g., Dacromet) | High-performance corrosion protection | A water-based mix of zinc and aluminum flakes. Offers barrier, galvanic, and self-repairing protection. Widely used by auto manufacturers. |

| Phosphate & Oil | Corrosion resistance and anti-galling | A dark gray/black pretreatment that improves paint adhesion and reduces friction. Requires an oil or top coat for effective rust prevention. |

Zinc flake coatings are a top choice in the automotive industry. These coatings, which meet standards like ISO 10683, provide cathodic protection. The zinc acts as a sacrificial layer; if the coating is scratched, the zinc corrodes first, protecting the steel bolt underneath. Advanced zinc flake systems can offer four-way protection:

- Barrier Protection: Overlapping zinc and aluminum flakes create a physical shield.

- Galvanic Action: Zinc sacrifices itself to protect the steel.

- Passivation: Metal oxides form to slow the corrosion process.

- Self-Repairing: Zinc compounds migrate to damaged areas to reseal the surface.

Phosphate coatings, often specified under standards like ASTM F1137, are typically used as a base layer. By itself, phosphate offers minimal rust protection. However, when combined with oil, it provides good corrosion resistance and acts as an anti-galling agent, preventing the threads from seizing during tightening.

Note: How Coatings Affect Torque A surface coating dramatically changes the friction between the bolt head, the threads, and the wheel surface. This is critical because approximately 50% of the torque applied during tightening is used just to overcome friction under the bolt head. A slick coating can reduce friction, while a rough one can increase it. This variability makes it challenging to achieve a precise clamping load using only a torque wrench, as the same torque value can result in different levels of tightness depending on the coating.

How Manufacturing Excellence Impacts Wheel Hub Bolt Integrity

The material and design of a wheel hub bolt set the foundation for its performance. However, the manufacturing process transforms these raw materials and blueprints into a finished product. Excellence in manufacturing is what truly guarantees a bolt’s strength, reliability, and safety on the road.

Multi-Stage Forging for Superior Grain Structure

High-quality wheel hub bolts are not simply cut from a steel bar. Instead, they are forged. Forging is a process where metal is heated and shaped under immense pressure. Top manufacturers use a multi-stage forging process. This method gradually forms the bolt’s head and shank, creating an unbroken internal grain flow. This continuous grain structure is much stronger than the severed grains found in machined parts. It significantly improves the bolt’s overall durability and fatigue resistance, making it less likely to fail under stress.

Precision Heat Treatment for Hardness and Toughness

After forging, the bolts undergo a critical heat treatment process. This usually involves two steps: quenching and tempering. First, the bolts are heated to a very high temperature and then rapidly cooled, or “quenched.” This makes the steel extremely hard. However, extreme hardness can also make the steel brittle. To fix this, the bolts are “tempered” by reheating them to a lower temperature. This process reduces brittleness and increases toughness. Precision control over these temperatures is essential. It allows manufacturers to achieve the perfect balance between hardness (to resist wear) and toughness (to resist fracture).

Rigorous Quality Control and Testing Protocols

The final step is to ensure every bolt meets strict safety standards. Reputable manufacturers implement rigorous quality control protocols. A key part of this is non-destructive testing (NDT), which finds flaws without damaging the part. Common NDT methods include:

- Liquid Penetrant Testing (PT)

- Magnetic Particle Testing (MT)

- Eddy Current Testing (ET)

- Ultrasonic Testing (UT)

Inside Look: Magnetic Particle Testing (MT) This test reveals surface and near-surface cracks that are invisible to the naked eye. The process is meticulous. Technicians clean the bolt, apply a magnetic solution, and pass an electric current through it. They then inspect the bolt under a UV light. Any cracks will disrupt the magnetic field and cause the particles in the solution to gather, glowing brightly to reveal the defect. This ensures that only flawless wheel hub bolts make it to the market.

Understanding the Design of Wheel Hubs and Bolt Compatibility

A wheel hub bolt does not work alone. Its effectiveness depends on its interaction with the wheel and the wheel hub. The design of wheel hubs and their compatibility with bolts are crucial for safety and performance. Understanding these relationships helps ensure a secure connection.

Hub-Centric vs. Lug-Centric Designs

Wheels attach to a vehicle in one of two ways: hub-centric or lug-centric. The primary function of wheel hubs is to support the vehicle’s weight, and this design choice determines how that load is managed. Hub-centric designs are the modern standard. The wheel fits snugly onto a raised lip on the wheel hub. This direct connection transfers the vehicle’s load directly to the hub, which has a high load capacity. The wheel hub bolts primarily provide clamping force, not support.

Lug-centric wheels have a larger center bore and rely on the lug nuts to center the wheel and bear the vehicle’s load. This places immense stress on the bolts.

| Feature | Hub-Centric Design | Lug-Centric Design |

|---|---|---|

| Load Bearing | The wheel hub supports the vehicle’s weight. | The lug nuts and bolts support the vehicle’s weight. |

| Vibration Risk | Low, due to precise centering. | High, if not perfectly installed. |

| Wheel Stud Stress | Reduces stress on wheel studs. | Increases stress on wheel studs. |

| Common Use | Standard on most modern vehicles. | Common on older or universal aftermarket wheels. |

Bolt Patterns and Pitch Circle Diameter (PCD)

Every wheel hub has a specific bolt pattern. This pattern includes the number of bolt holes and the Pitch Circle Diameter (PCD). PCD is the diameter of an imaginary circle running through the center of each bolt hole. Using the correct PCD is essential for a safe fit. An incorrect PCD will prevent the wheel from seating properly, creating dangerous stress on the wheel hub bolts.

How to Calculate PCD You can calculate PCD if you know the distance between adjacent studs.

Number of Studs Calculation Formula 4 Studs Stud distance ÷ 0.7071 5 Studs Stud distance ÷ 0.5878 6 Studs Stud distance ÷ 0.5

Common bolt patterns vary by vehicle size and manufacturer.

- 4-lug patterns (e.g., 4x100mm): Typical for smaller cars like the Honda Civic.

- 5-lug patterns (e.g., 5×114.3mm): Dominant on passenger cars and SUVs like the Toyota Camry.

- 6-lug patterns (e.g., 6×139.7mm): Found on trucks and large SUVs.

Material Synergy Between the Hub and Bolts

The materials of the wheel, wheel hub, and bolts must be compatible. Mismatched metals can lead to galvanic corrosion. This happens when two different metals touch in the presence of an electrolyte, like road salt and water. The less noble metal corrodes rapidly. For example, using steel wheel hub bolts on a magnesium wheel can cause the wheel to corrode around the bolt holes.

This corrosion prevents the wheel from sitting flat against the wheel hub. Even if the bolts feel tight, the uneven surface can cause them to loosen over time as the vehicle moves. This compromises the load capacity of the entire assembly. Proper material selection for all components of a wheel hub is vital for long-term safety and performance.

The Correct Application of Wheel Hub Bolts

Choosing the right wheel hub bolts depends entirely on the vehicle’s intended use. The demands on these critical fasteners vary greatly across different driving conditions. The correct application of wheel hub bolts ensures safety and optimal vehicle function.

Standard Passenger and Commercial Vehicles

Most cars and light commercial trucks operate under predictable conditions. For these standard applications of wheel hubs, manufacturers use high-strength alloy steel bolts. These bolts provide a reliable balance of strength and cost. Proper installation is just as important as the bolt itself. Technicians must follow precise torque specifications to achieve the correct clamping force without over-stressing the components.

Typical Torque Values for a Passenger Vehicle:

- Lug Nuts: 140 Foot-Pounds

- Hub to Knuckle Bolts: 133 Foot-Pounds

- Axle Shaft Nut: 188 Foot-Pounds

High-Performance and Racing Environments

Racing pushes every component to its limit. In high-performance applications of wheel hubs, every gram matters. Drivers often use wider tires or wheel spacers to improve grip and handling. These modifications require longer wheel studs or bolts to ensure proper thread engagement.

Many racers upgrade to wheel stud conversion kits. These kits replace bolts with fixed studs, making wheel changes faster and more secure. For the ultimate performance aspect, titanium kits offer a significant weight advantage over steel.

| Component Type | Total Kit Weight | Unsprung Weight Reduction |

|---|---|---|

| Titanium Stud Conversion | 1240g | ~1080g |

| Extended Steel Bolts | 2350g | N/A |

Heavy-Duty and Off-Road Scenarios

Heavy-duty trucks and off-road vehicles face extreme loads and harsh terrain. The application of wheel hub bolts in these scenarios demands maximum strength and durability. Alloy steel is the required material. It contains elements like chromium and molybdenum that provide superior tensile strength and fatigue resistance.

Carbon steel and aluminum alloy bolts are unsuitable for these tasks. They lack the strength to handle heavy loads and can fail under stress. For this reason, heavy-duty wheel hub bolts often have a high strength rating, such as grade 10.9, to prevent breakage and ensure the wheels remain securely attached.

The quality of wheel hub bolts directly impacts vehicle safety. High-strength alloy steel remains the best choice for most applications. It reliably handles a heavy load. Smart design features, like rolled threads, help these bolts withstand the operational load. Proper material selection for the wheel hub and bolts is vital.

Key Takeaway 💡 Choosing the right wheel hub bolts for the expected load ensures ultimate vehicle safety and performance.

FAQ

Why are special bolts needed for a wheel hub?

A wheel hub experiences extreme rotational and shear forces. Standard hardware lacks the required tensile strength and fatigue resistance. Engineers design specific bolts for each wheel hub to ensure safety and prevent failure under stress. The wheel hub connection is critical.

How often should I check my wheel hub bolts?

Technicians should check bolt torque during routine service, like tire rotations (every 5,000-7,500 miles). Proper maintenance and replacement schedules are vital. Always re-torque bolts about 50-100 miles after installing a new wheel hub or wheel. ⚙️

What happens if I overtighten a wheel hub bolt?

Overtightening stretches a bolt beyond its elastic limit, permanently weakening it. This condition, called “yield,” reduces clamping force and can lead to bolt fracture. It may also damage the threads on the wheel hub itself, creating a more costly repair.

Can I reuse old wheel hub bolts?

Most manufacturers advise against reusing wheel hub bolts, especially torque-to-yield types. Each tightening cycle can stretch the bolt, reducing its strength. Corrosion and thread damage also pose risks. Always use new bolts for a secure wheel hub assembly.