admin1

September 27, 2025

Trailer Valve Stem Guide for Safer Road Trips

When you prepare for a long road trip, choosing the right trailer valve stem can make a big difference in your safety. Metal stems offer more strength and last longer than rubber stems. You can see the difference in reliability below:

| Valve Stem Type | Reliability | Failure Rate |

|---|---|---|

| Rubber | Prone to leaks | Higher |

| Metal | Generally reliable | Lower |

Users often report leaks with rubber stems, while metal stems rarely have issues. For most trailers, a metal valve gives you peace of mind and helps prevent blowouts.

Quick Comparison: Rubber vs. Metal Trailer Valve Stem

Safety

You want your trailer to stay safe on every trip. The type of valve stem you choose can affect your safety. A rubber valve stem may work for light loads, but it can crack or leak more easily. Cold weather makes rubber brittle, and UV rays from the sun break it down over time. If you store your trailer outside, you should use white tire covers to protect the rubber from sunlight and cold. Indoor storage helps prevent damage, but outdoor storage needs barriers to keep moisture away and stop freeze-thaw cycles.

A metal valve stem gives you stronger protection. Metal resists most impacts and handles higher pressure. You will find that metal stems rarely leak, which lowers the risk of a blowout. You should inspect metal stems for corrosion, especially if you drive in wet or salty conditions. Regular checks keep your trailer safe.

Durability

Durability matters when you travel long distances. You want a valve stem that lasts. Take a look at the average lifespan and durability of each type:

| Type of Valve Stem | Average Lifespan | Durability | Corrosion Susceptibility |

|---|---|---|---|

| Metal | ~10 years | More durable | Susceptible to corrosion |

| Rubber | Not specified | Less durable | Less likely to corrode |

Rubber can wear out faster, especially if exposed to harsh weather. You may need to replace a rubber valve stem every 4-6 years. Metal valve stems last longer, sometimes up to 10 years, but you should check for rust. If you maintain your metal valve stem, you can save money and avoid frequent replacements.

Tip: Always inspect your valve stems before a road trip. Replace any stem that shows cracks, leaks, or corrosion.

Cost

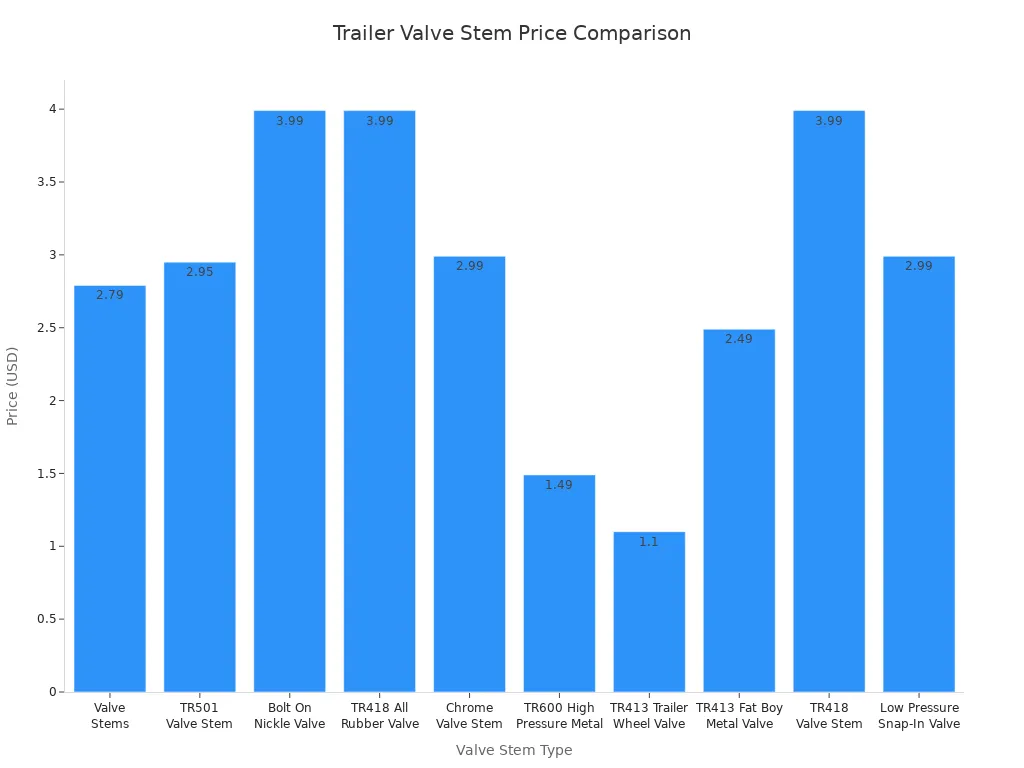

Cost is important when you choose a trailer valve stem. You will see a range of prices for both rubber and metal options. Here is a table showing typical prices:

| Product Description | Price |

|---|---|

| Valve Stems | $2.79 |

| TR501 Valve Stem | $2.95 |

| Bolt On Nickle Valve Stem | $3.99 |

| TR418 All Rubber Valve Stem | $3.99 |

| Chrome Valve Stem | $2.99 |

| TR600 High Pressure Metal Valve Stem | $1.49 |

| TR413 Trailer Wheel Valve Stem | $1.10 |

| TR413 Fat Boy Metal Valve Stem | $2.49 |

| TR418 Valve Stem | $3.99 |

| Low Pressure Snap-In Valve Stem | $2.99 |

You may notice that metal valve stems sometimes cost more at first. However, you will save money over time because metal lasts longer. Rubber valve stems need replacement every few years, which adds up. If you maintain your metal valve stem, you lower your long-term costs.

Note: The initial price of a metal valve stem is higher, but its durability means fewer replacements and less risk of failure.

Compatibility

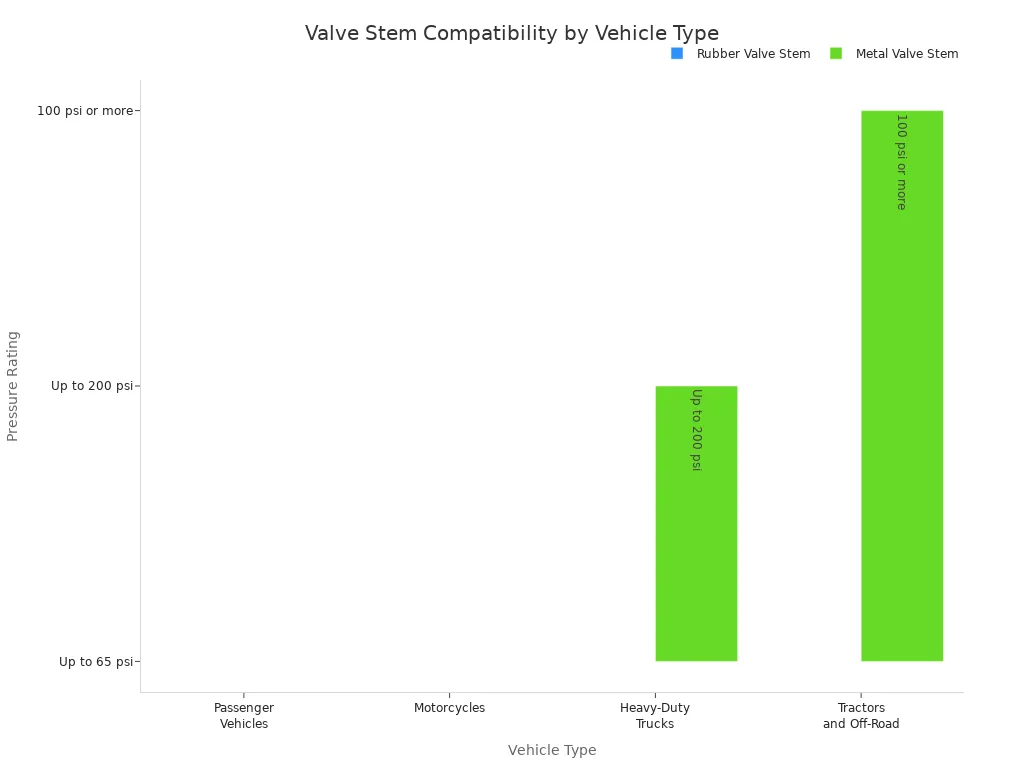

When you choose a valve stem for your trailer, you need to make sure it matches your wheel type and tire pressure needs. Not every valve stem fits every trailer. Manufacturers design rubber and metal valve stems for different vehicles and conditions. You can see how compatibility changes based on vehicle type, pressure rating, rim hole diameter, and temperature rating.

| Vehicle Type | Valve Stem Type | Pressure Rating | Rim Hole Diameter | Temperature Rating |

|---|---|---|---|---|

| Passenger Vehicles | Rubber | Up to 65 psi | 0.453″ – 0.625″ | -40°F to 180°F |

| Heavy-Duty Trucks | Metal | Up to 200 psi | ~0.625″ | -65°F to 250°F |

| Motorcycles | Rubber | Up to 65 psi | ~0.327″ | -40°F to 180°F |

| Tractors and Off-Road | Metal | 100 psi or more | ~0.625″ | Extreme conditions |

You can use rubber valve stems for passenger vehicles and motorcycles. These stems work well at lower pressures and moderate temperatures. Metal valve stems fit heavy-duty trucks, tractors, and off-road trailers. Metal handles higher pressure and extreme temperatures. If your trailer carries heavy loads or travels long distances, you should use metal valve stems.

You may notice that rim hole diameter matters. Most trailer wheels use a 0.625-inch hole, which fits metal valve stems. Passenger cars and motorcycles often use smaller holes, so rubber stems work better.

Tip: Always check your trailer’s manual or wheel specifications before buying valve stems. Using the wrong type can lead to leaks or blowouts.

Some users have shared their experiences with metal valve stems. You can learn from their feedback:

- Some users saw failures with metal valve stems in high temperatures. This suggests that certain brands or conditions may affect compatibility.

- A technician noticed more failures with metal stems compared to rubber ones. This points to possible issues with specific tire brands or extreme conditions.

- Many users have used metal valve stems for years without problems. This shows that compatibility depends on your trailer, tire brand, and how you use your trailer.

If you want the safest option for heavy loads and long trips, metal valve stems are usually the best choice. You should always match the valve stem to your trailer’s needs and check for any special requirements from your tire manufacturer. This helps you avoid problems and keeps your trailer safe on the road.

Key Factors When Choosing a Trailer Valve Stem

Tire Pressure Requirements

You need to match the valve stem to your tire pressure needs. If your trailer uses tires that require high pressure, you should select a valve stem that can handle it. Most metal valve stems support pressures up to 200 psi. Rubber stems usually work for tires with pressure up to 65 psi. You can check your tire’s sidewall for the recommended tire pressure. If you use a valve stem that cannot handle the pressure, you risk leaks or blowouts. Always choose a valve that matches or exceeds your tire’s pressure rating.

Tip: Use a tire pressure gauge before every trip. This helps you spot problems early and keeps your trailer safe.

Trailer Type and Load

Your trailer type and the load you carry affect your valve stem choice. Heavy-duty trailers need strong valve stems. Metal stems work best for trailers that haul large loads or travel long distances. If you use a small utility trailer with light cargo, rubber valve stems may be enough. You should think about how much weight your trailer carries. Overloading your trailer puts extra stress on the valve and tire. You can use this table to see which valve stem fits your trailer:

| Trailer Type | Recommended Valve Stem | Load Capacity |

|---|---|---|

| Utility (Light) | Rubber | Up to 1,500 lbs |

| Cargo (Medium) | Metal | 1,500–5,000 lbs |

| Heavy-Duty | Metal | Over 5,000 lbs |

Road Conditions and Trip Length

Road conditions and trip length also matter when you choose a trailer valve stem. If you drive on rough roads, your valve stem faces more vibration and impact. Metal valve stems resist damage from bumps and potholes. Rubber stems may crack or leak if you travel on uneven surfaces. Long trips increase wear on your valve and tire. You should inspect your valve stem before each journey. If you plan to travel in extreme temperatures, metal stems offer better performance. Always consider your route and how far you will go.

Note: Regular inspection helps you catch problems early. Replace any valve stem that shows signs of damage.

Pros and Cons of Each Valve Stem Type

Rubber Valve Stem Advantages

You may find several advantages of rubber valve stems when choosing parts for your trailer. Many users prefer rubber snap-in valve stems because they are easy to install and remove. You do not need a torque tool—just a valve puller tool will do the job. This simple process helps you avoid damage during removal. Rubber stems also have fewer parts, which means less can go wrong during installation. If you worry about corrosion, rubber offers more resistance than aluminum clamp-in valve stems. You can use rubber stems with confidence in wet or salty conditions. Many experts recommend replacing rubber stems each time you remove a tire. This habit helps prevent slow air leaks and keeps your tires safe.

- Rubber stems resist corrosion better than aluminum clamp-in valve stems.

- You can install and remove them easily with a valve puller tool.

- Fewer parts mean less risk of installation errors.

- Regular replacement helps prevent air leaks.

Rubber Valve Stem Disadvantages

You should also know the disadvantages of rubber valve stems. Some users report that valves made in China may crack or split sooner than expected. If the rubber does not have enough ozone protection, it can break down quickly. Many people have seen flat tires or even blowouts within 8 to 14 months of use. Premature cracking often leads to air loss, which can cause serious accidents. You may not notice a defective valve stem until you remove the tire, making it hard to spot problems early. The weight and force from tire pressure monitoring systems (TPMS) can also stress the base of the stem. Sometimes, a split stem may seem fine when parked but fail while driving.

- Cracking and splitting can happen if rubber lacks ozone protection.

- Flat tires and blowouts may occur within a year of use.

- Defective valve stems are hard to detect without removing the tire.

- TPMS sensors can cause the base of the stem to fail.

Metal Valve Stem Advantages

You gain many advantages when you choose a metal valve stem for your trailer. Metal stems work well for high-speed travel and heavy loads. Professional mechanics recommend them for speeds over 130 mph and for high-pressure applications up to 200 psi. You can check and adjust the retaining nut without removing the tire, which makes maintenance easier. Metal stems last longer than rubber alternatives and handle tough road conditions. Regular inspection of your valve stem helps prevent air loss and keeps your trailer safe. If you use a tire pressure monitoring system, you can catch pressure drops early and avoid slow leaks. The advantages of metal valve stems make them a top choice for safety and durability.

| Benefit | Description |

|---|---|

| High-speed suitability | Works well for speeds over 130 mph and track activities |

| Ease of maintenance | You can check and adjust the retaining nut without removing the tire |

| Durability | Handles high pressure (up to 200 psi) and lasts longer than rubber stems |

Tip: Always inspect your metal valve stem for signs of corrosion or wear before a long trip.

Metal Valve Stem Disadvantages

When you choose a metal valve stem for your trailer, you gain many benefits. However, you should also know about the disadvantages of metal valve stems. Understanding these disadvantages helps you make the best decision for your safety and budget.

Metal valve stems can corrode over time, especially if you drive in areas with a lot of moisture or road salt. Corrosion may weaken the stem and cause leaks. You need to check your valve stem for rust before each trip. If you see any signs of corrosion, you should replace the stem right away.

You may notice that metal valve stems cost more than rubber stems. The higher price can affect your budget, especially if you have several trailers. While metal stems last longer, the initial cost is something you need to consider.

Maintenance can be a challenge with metal valve stems. You do not need to replace them often, but you must pay attention to the rubber seals. These seals can wear out before the metal part does. If the seal fails, air can leak from the valve. Always inspect the seal when you check your tires.

Tip: Use a flashlight to look for cracks or damage on the rubber seal. Replace the seal if you see any problems.

Some users find that metal valve stems are harder to install than rubber stems. You may need special tools to tighten the retaining nut. If you do not install the stem correctly, it can leak or loosen while you drive.

Here are some common maintenance challenges with metal valve stems:

- You must check for corrosion and rust.

- The rubber seals may fail before the metal stem does.

- Installation requires careful tightening of the retaining nut.

- You need to inspect the valve for leaks after installation.

You should compare these disadvantages with the disadvantages of rubber valve stems. Rubber stems may crack or split, but metal stems need careful inspection for rust and seal failure. Knowing the disadvantages of each type helps you choose the right valve stem for your trailer.

How to Choose the Right Trailer Valve Stem

Step-by-Step Decision Guide

Selecting the best trailer valve stem for your needs keeps your road trips safe and worry-free. You want to match the valve stem to your trailer type, tire pressure, and travel conditions. Follow these steps to make the right choice:

Check your trailer type and load

Look at your trailer’s weight and how much cargo you carry. Heavy-duty trailers need strong metal valve stems. Light utility trailers can use rubber stems, but only for lighter loads.Review tire pressure requirements

Read the tire sidewall for the recommended pressure. If your tires need high pressure (over 65 psi), choose a metal valve stem. Metal stems like TR75A, TR77A, TR78A, TR175A, TR177A, and TR179A work well for split ring medium truck and industrial applications. These stems bend about 85 degrees after rising .94 inches out of the tube, which helps with installation and maintenance.Consider the valve stem design

Some metal stems, such as TR440, TR441, TR442, TR443, TR444, and TR445, also bend 85 degrees but do not have a washer or plate at the base. This design fits certain wheels and tires better. Always match the stem to your rim hole diameter and tire type.Think about road conditions and trip length

If you travel on rough roads or take long trips, metal valve stems resist vibration and impact better than rubber stems. You lower the risk of leaks and blowouts.Inspect for compatibility with tire pressure monitoring systems (TPMS)

If your trailer uses TPMS, make sure the valve stem supports the sensors. Metal stems often work better with TPMS because they handle extra weight and force.

Tip: Always check your trailer manual or ask a professional before choosing the right valve stem. Matching the stem to your trailer and tire keeps you safe.

Common Mistakes to Avoid

Many trailer owners make mistakes when choosing a valve stem. You can avoid these problems by learning what to watch for:

- You inflate tires to the same PSI no matter the load. This can cause under-inflation or over-inflation, which leads to tire failure.

- You ignore tire speed and load ratings. This mistake causes dangerous heat buildup and can damage your tires.

- You use the maximum PSI listed on the tire for daily driving. This is not always the best setting and may shorten tire life.

- You install low-cost rubber valve stems meant for passenger cars. These stems can fail from vibration on trailers. Switching to bolt-in metal stems prevents this issue.

- You forget to adjust tire pressure for different loads. Not changing the pressure can cause blowouts or flats.

Note: Always use a tire pressure gauge and adjust the pressure for your trailer’s load. Choose a valve stem designed for your trailer type and travel needs.

You keep your trailer safe by avoiding these mistakes. Choosing the right valve stem and checking your tires before each trip helps prevent accidents and costly repairs.

Installation and Maintenance Tips for Valve Stems

Proper Installation

You want your trailer to stay safe on every trip, so installing your valve stem correctly is important. Start by choosing a new valve stem from a trusted source. Open the package and remove the cap and the valve inside. Spray the whole stem with soapy water. This step makes the rubber slippery and helps you fit it into the rim easily.

Follow these steps for a secure fit:

- Hold the base of the valve stem with long pliers.

- Use your other hand to hold the valve stem pull tool.

- Guide the stem through the rim’s valve hole.

- Screw the pull tool onto the stem from the outside.

- Pull gently but firmly until the stem pops into place.

If you use a metal stem, apply a small amount of anti-seize thread lubricant. This prevents corrosion between different metals. You can find anti-seize lubricant at most auto parts stores. Using it helps your valve last longer, especially if you drive in wet or salty areas.

Tip: Always check that the valve stem sits straight and snug in the rim before inflating your tire.

Regular Inspection and Replacement

You should inspect your valve stems every time you check your tires. Look for cracks, splits, or signs of wear, especially on rubber stems. If you see any damage, replace the stem right away. Regular checks help you catch problems before they cause a flat tire or a blowout.

Set reminders for periodic maintenance. Professional inspections every few months can spot issues you might miss. This habit keeps your trailer safe and your trips worry-free.

Note: Replace your valve stem whenever you change your tire. This simple step adds another layer of safety.

Fortune’s Commitment to Quality in Trailer Valve Stem Manufacturing

Quality Assurance and Certifications

You want your trailer to stay safe on every trip. Fortune takes quality seriously when making each valve stem. The company follows strict standards to make sure every product meets your needs. You can trust Fortune because they hold important certifications. These certifications show that Fortune keeps high standards in every step of production.

- ISO/TS16949 certification by TUV management services

- Careful inspection of every valve stem before shipment

- Use of premium materials, including aluminum and other metals

Fortune tests each valve stem to make sure it works well under pressure. The company never uses inferior materials. You get a product that lasts longer and performs better. Fortune’s engineers check every detail, from design to packaging. You can feel confident that your valve stem will help keep your trailer safe.

Tip: Look for the ISO/TS16949 mark when you buy trailer parts. This mark means the product meets global quality standards.

Customer Support and Global Service

You need support when you buy trailer parts. Fortune gives you help wherever you are. The company has offices and warehouses in North America. You get fast shipping and easy access to customer service. Fortune’s team answers your questions and helps you choose the right valve for your trailer.

You can reach Fortune’s support team by phone or email. The company works with customers in the Americas, Europe, Japan, Asia, and Oceania. Fortune’s engineers keep improving products and technology. You get new solutions and better service every year.

- Offices and warehouses in North America

- Fast response to customer questions

- Service for OEM and aftermarket customers worldwide

Fortune’s commitment to quality and service helps you travel with peace of mind. You know your trailer has reliable parts and strong support.

You keep your trailer safe when you choose a metal trailer valve stem. Metal stems help prevent valve stem failure and lower the risk of tire blowouts. Regular inspection of each valve and tire protects you from unexpected problems. Investing in high-quality valve stems leads to fewer breakdowns and lower maintenance costs. A regional fleet switched to better repairs and saw a 40% drop in breakdowns. You avoid issues with rubber stems and improve your peace of mind on every trip.

- Metal valve stems reduce tire failure.

- High-quality valve stems lower maintenance costs.

- Regular checks prevent valve stem failure.

FAQ

What is the main difference between rubber and metal valve stems?

You will find that metal valve stems last longer and handle higher pressure. Rubber valve stems work well for light loads and lower pressure. Metal stems resist damage from rough roads. Rubber stems cost less but need more frequent replacement.

How often should you replace trailer valve stems?

You should check your valve stems every time you inspect your tires. Replace rubber valve stems every 4–6 years. Metal valve stems can last up to 10 years with regular inspection.

Tip: Replace your valve stem whenever you change your tire for extra safety.

Can you use metal valve stems with tire pressure monitoring systems (TPMS)?

Yes, you can use metal valve stems with most TPMS sensors. Metal stems support the extra weight and force from TPMS better than rubber stems. Always check your TPMS manual for compatibility before installing new valve stems.

What signs show a valve stem needs replacement?

Look for cracks, splits, leaks, or rust on your valve stem. If you see any damage, replace the stem right away.

- Cracks or splits

- Air leaks

- Rust or corrosion

- Loose fit in the rim

Do all trailers need metal valve stems?

Not all trailers need metal valve stems. Light-duty trailers with low tire pressure can use rubber stems. Heavy-duty trailers, long trips, or high-pressure tires need metal valve stems for safety and durability.

Note: Always check your trailer manual for the recommended valve stem type.