admin1

July 18, 2025

TPMS Valve Stem Explained for Drivers in 2025

You rely on your tpms valve stem every time you drive. This small but vital part connects your tire to the tire pressure monitoring system, making sure you always know if your tire pressure is right. A well-maintained tpms valve stem helps protect vehicle safety, improves handling, and can even help you save fuel. If you keep your system in good shape, you lower the risk of blowouts and keep your car running smoothly.

How the Tire Pressure Monitoring System Works

The Role of the TPMS Valve Stem

You may not notice the tpms valve stem on your wheels, but it plays a crucial role in your vehicle’s safety. The tpms valve stem acts as the gateway for air entering and leaving your tire. In direct TPMS systems, the valve stem also houses the tire pressure sensor and its electronics. This setup allows the sensor to measure air pressure and temperature inside the tire. The sensor then sends this information wirelessly to your car’s onboard computer.

Valve stems come in different materials, each affecting durability and maintenance. Here’s a quick comparison:

| Material Type | Characteristics and Durability Impact |

|---|---|

| Metal Valve Stems | Made from brass, offer high durability, but can corrode over time. Require regular maintenance and special tools for installation. Can be reused and are cost-effective long-term. |

| Rubber Valve Stems | Made from synthetic rubber, resist corrosion, and are easy to install. More flexible, but degrade faster from sun and weather. Usually replaced with each tire change. |

A well-maintained tpms valve stem ensures that your tire pressure monitoring system works reliably. If you keep the valve stems in good condition, you help prevent leaks and sensor failures.

How the Tire Pressure Sensor and Valve Stems Interact

The tire pressure sensor and valve stems work together as a team. In direct TPMS, the sensor mounts directly to the valve stem inside the tire. The sensor uses advanced technology to measure air pressure and temperature. It converts these readings into digital signals. The sensor then transmits this data wirelessly to your vehicle’s control unit using radio frequency signals. Each sensor has a unique ID, so your car knows which tire is sending the information.

Here’s how the main components of a tire pressure monitoring system function together:

- Tire pressure sensors: Mounted inside each tire or on the valve stem, they measure air pressure and temperature, sending data wirelessly to the control module.

- TPMS control module: Receives sensor data, checks if tire pressure is within safe limits, and triggers alerts if needed.

- Receiver/display unit: Shows tire pressure information and warnings on your dashboard.

- Warning indicators: Lights or sounds that alert you to low tire pressure or other issues.

- Communication system: Connects all parts, allowing wireless data flow from sensors to the control module and display.

If the tire pressure sensor or valve stem gets damaged, the system may fail to send accurate data. Common causes of communication failure include low battery voltage, damage from road debris, extreme temperatures, corrosion, sensor aging, or faulty wiring. Regular checks help you catch these problems early.

Tip: If you see a TPMS warning light, check your tire pressure and inspect the valve stems for damage or corrosion.

Why Accurate Tire Pressure Matters

Keeping your tire pressure at the right level is vital for your safety and your wallet. Underinflated tires increase braking distance and reduce your car’s grip on the road. They also overheat more easily, which can lead to blowouts and shorten tire life. Overinflated tires wear out faster in the center and make your car harder to control, especially during sudden stops.

Recent research shows that even a small drop in tire pressure can hurt your fuel efficiency. For example, if your tires are at 75% of the recommended pressure, your fuel economy can drop by 2-3%. At 50% pressure, you could lose up to 10% of your gas mileage at highway speeds. Keeping your tires at optimal inflation reduces rolling resistance, saves fuel, and lowers emissions.

Note: Maintaining the correct tire pressure helps you get the best performance, safety, and value from your tires. It also means fewer trips to the gas station and longer-lasting tires.

Types of TPMS Valve Stems in 2025

Snap-In vs. Clamp-In Valve Stems

When you look at tire valve stems, you will see two main types: snap-in and clamp-in. Snap-in valve stems use rubber and fit into the wheel by pushing them through the hole. Clamp-in valve stems use metal and secure with a nut for a tighter seal. Each type has different strengths. The table below shows how they compare:

| Feature | Snap-in Valve Stems (e.g., TR413, TR415, TR600HP, TR801HP) | Clamp-in Metal Valve Stems (e.g., TR416S) |

|---|---|---|

| Maximum Inflation Pressure | Up to 65 psi for standard; up to 100 psi for high-pressure models | Up to 200 psi |

| Wheel Stem Hole Thickness | Standard snap-in limited to ≤ 0.156 inches; high-pressure up to 0.205 inches | Suitable for thicker wheels (> 0.205 inches) |

| Durability under Conditions | Prone to cracking or unseating in hot or high-pressure situations | More robust, great for off-road and rugged use |

| Use of Extensions | Only plastic extensions recommended | Metal extensions allowed but should be short |

| Maintenance and Longevity | Not serviceable; replace if damaged | Replaceable grommets and cores extend life |

| Installation Considerations | Needs lubrication; sensitive to sharp edges | Needs correct torque to prevent air loss |

| Overall Suitability | Easy to install, but less durable | Superior durability and longevity |

Snap-in valve stems work well for most daily driving. Clamp-in valve stems offer extra strength for trucks, SUVs, and vehicles that face tough conditions.

Direct vs. Indirect TPMS Systems

You will find two main types of TPMS in vehicles: direct and indirect. Direct TPMS uses sensors inside each tire valve stem to give you real-time, accurate pressure and temperature readings. This system does not need recalibration after tire rotations. It costs more and the sensors can get damaged during tire changes. Indirect TPMS uses your car’s ABS wheel speed sensors to estimate tire pressure by comparing how fast each wheel spins. This system costs less and needs less maintenance, but it is less precise and may give false warnings if tire sizes change.

| Feature | Direct TPMS | Indirect TPMS |

|---|---|---|

| Accuracy | High accuracy with precise readings | Less accurate; estimates pressure |

| Real-Time Monitoring | Works even when stopped | Needs wheels to move |

| Cost | Higher due to extra sensors | Lower; uses existing sensors |

| Maintenance | Needs sensor battery changes | Simpler; no batteries |

| Installation | More complex | Easier |

| Compatibility | Works with most vehicles | May have issues with aftermarket tires |

| Limitations | Sensors can be damaged | May miss underinflation in all tires |

Direct TPMS now appears in most new vehicles. In 2023, direct TPMS made up over 61% of new cars. This trend continues in 2025 as drivers want better safety and real-time data.

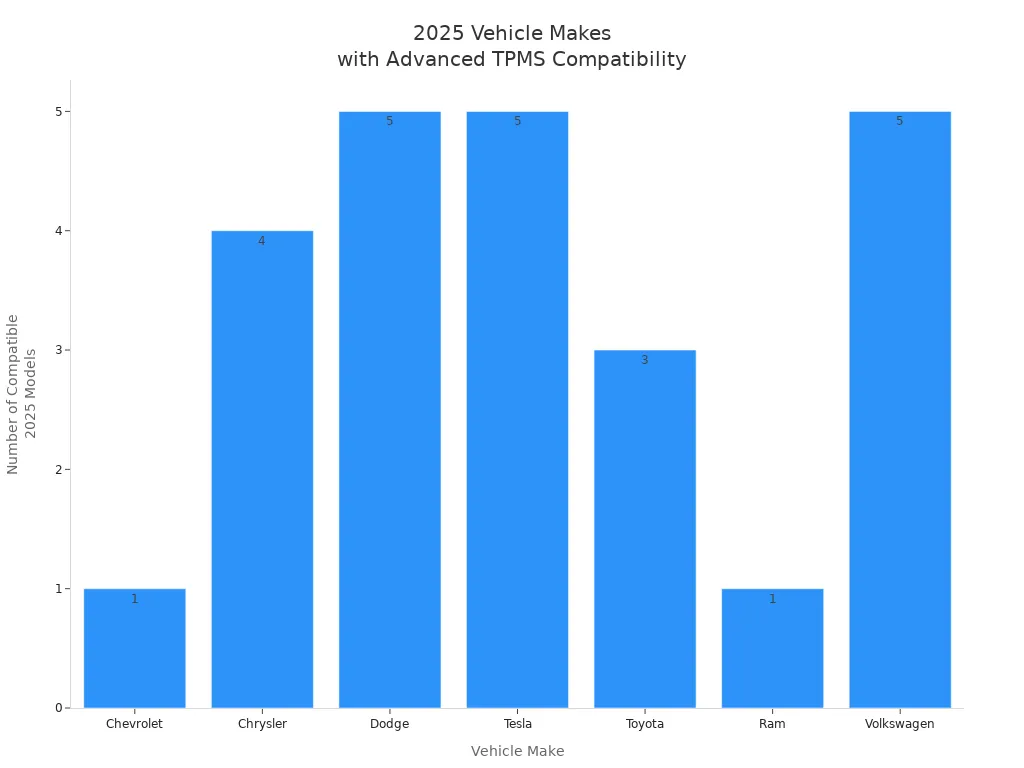

Compatibility with Modern Vehicles

Modern vehicles support advanced TPMS valve stems. For example, the 2025 Ram 1500 uses a clamp-in metal valve stem that handles up to 200 PSI and fits perfectly with its wheels. The 2025 Toyota Camry also supports advanced tire valve stems with OE-validated parts for a precise fit. Many other vehicles, like the Tesla Model 3, Chevrolet Traverse, and Volkswagen GTI, use advanced valve stem components for better performance and reliability.

| Vehicle Make | Model(s) | Compatibility Notes |

|---|---|---|

| Chevrolet | Traverse | 2025 model supported with specific TPMS sensor sets |

| Dodge | Avenger, Challenger, Caravan | 2025 models supported with metal and rubber stem options |

| Tesla | Model 3, Model S, Model X, Model Y | 2024-2025 models supported with advanced TPMS sensors |

| Toyota | Camry, Yaris, Venza | 2025 models supported with OE-validated kits |

| Ram | 1500 | 2025 model supported with clamp-in metal valve stem kits |

| Volkswagen | GTI, Beetle, CC | 2025 models supported with advanced valve stems |

Tip: Always check your vehicle’s manual or ask a tire professional to make sure you use the right TPMS valve stem for your car.

Maintenance and Replacement of TPMS Valve Stems

Signs Your Valve Stem or Tire Pressure Sensor Needs Attention

You need to watch for certain signs that your TPMS valve stem or tire pressure sensor may need maintenance or replacement. These signs help you avoid tire failure and keep your vehicle safe. Here are the most common indicators:

- The TPMS warning light turns on or flashes after you start your car. A flashing light often means a sensor problem, while a steady light points to low tire pressure.

- Your vehicle shows a warning even when your tires have the correct pressure. This can mean the sensor battery is low or the sensor is malfunctioning.

- You notice changes in how your car handles, such as swerving or a flat tire, but the TPMS does not alert you. This could signal a sensor or valve stem issue.

- You see higher fuel consumption, which sometimes happens when the system fails to detect under-inflated tires.

- The TPMS light comes on after a tire change. This may happen if the sensor was damaged during installation or if the system needs resetting.

- You use a TPMS scan tool and find battery drain or wiring problems.

- When you release air from a tire, the system does not respond. This test can reveal a defective sensor.

- Comparing a digital tire gauge with your car’s display shows different readings. This points to a possible sensor error.

Tip: If you notice any of these signs, check your tire pressure and inspect the valve stems for corrosion or damage. Early action helps prevent tire failure.

How to Maintain Your TPMS Valve Stem

Proper maintenance of your TPMS valve stem keeps your system working and helps prevent tire failure. You can follow these steps to ensure your valve stems last longer and perform well:

- Replace seals and valve stem nuts every time you reuse or replace TPMS sensors. This step ensures a tight seal and prevents leaks.

- Clean the area around the sensor and valve stem. Avoid using lubricants or sealants, as these can affect the torque and cause leaks.

- Always replace the valve core when you remove it. This prevents corrosion and keeps the valve working.

- Install the sensor in the correct position. Proper orientation avoids relearn problems and ensures the sensor sends accurate tire pressure data.

- Never reuse valve stem nuts. Old nuts can crack or leak, so always use new ones.

- Use a torque wrench to tighten the sensor nut to the manufacturer’s specifications. Over-tightening can damage the sensor or cause leaks.

- Push down on the sensor housing before tightening the nut. This helps seat the sensor correctly.

- Follow the instructions from your tire changer’s manufacturer. Careful installation prevents damage to the TPMS sensor.

You can use several tools and products to help with maintenance:

- TPMS valve core torque tools help you apply the right amount of force and protect the valve stem.

- Valve stem caps with internal seals keep out dirt and moisture, reducing corrosion.

- Replacement valve cores with Teflon seals improve durability.

- Comprehensive TPMS tool kits include tools for cleaning, installing, and maintaining valve stems.

- Grommet removal and installation tools make servicing easier.

Some drivers use a DIY TPMS valve stem repair kit. This kit lets you fix a damaged valve stem without removing the wheel or tire. It usually includes replacement stems, a drill bit, a tap, thread locker, and a torque tool. You can often finish repairs in about 20 minutes, saving time and money.

Note: Regular maintenance of your TPMS valve stems helps you avoid unexpected tire failure and keeps your tire pressure monitoring system accurate.

Replacement Process and What to Expect

When you need to replace a TPMS valve stem, you can expect a few clear steps. Most service centers follow a standard process to ensure safety and accuracy. Here is what usually happens:

- Gather the right tools. You need an air compressor, jack, jack stands, lug nut wrench, needle nose pliers, valve stem tool, bead breaker, and a ratchet strap.

- Loosen the lug nuts while your vehicle is still on the ground.

- Raise your vehicle with a jack and secure it with jack stands.

- Remove the wheel and place it with the valve stem facing up.

- Use a valve stem tool to remove the core and let the air out.

- Break the tire bead from the rim using a bead breaker or tire iron.

- Remove the old valve stem with pliers or by cutting it out.

- Lubricate the new valve stem with a soap solution. Insert it through the hole and pull it into place.

- Reseat the tire bead on the rim. A ratchet strap can help compress the tire.

- Inflate the tire to the recommended pressure. Check for leaks with soapy water.

- Reinstall the wheel, tighten the lug nuts, lower the vehicle, and secure the nuts fully.

You can also see a summary of typical costs and labor times for TPMS valve stem replacement at different service centers:

| Service Center / Scenario | Cost per Sensor (Including Installation) | Total Cost for 4 Sensors | Labor Time | Notes |

|---|---|---|---|---|

| Sam’s Club | $42 | N/A | N/A | Tests to identify bad sensor |

| Independent Shop | N/A | $300 | N/A | Replacement of all 4 sensors |

| Local Shops | N/A | $250-$350 | N/A | Varies by shop |

| Kal Tire | $15 (labor only, sensor supplied by customer) | N/A | N/A | Labor only for bead breaking and changing |

| Walmart | N/A | $120 | N/A | For all four sensors |

| Father/Son Tire Shop | N/A | $150 (for 2 sensors) | N/A | Out the door price |

| Discount Tire | $50-$60 | N/A | N/A | Vehicle specific, December pricing |

| Local Shops (Autel sensors) | $70 | N/A | N/A | Includes installation |

| Dealership | N/A | N/A | 3 hours for 4 sensors | Labor rate $160/hour, labor cost $480 |

Replacing a single tire valve stem usually costs about $10 if you do it yourself. Service centers may charge more, especially if you need to replace all four sensors. Experts recommend replacing the valve stem every time you get new tires. This step helps prevent leaks and keeps your TPMS working.

🛠️ Tip: Regular checks and timely replacement of your TPMS valve stems help you avoid costly repairs and reduce the risk of tire failure.

Tire Service and TPMS: What Drivers Should Know

TPMS Valve Stem Checks During Tire Installation

When you get new tires, tire service professionals follow careful steps to keep your TPMS valve stems working well. They start by inspecting the valve stem caps and replacing any that are missing. Properly tightened caps help keep out dirt and moisture. Technicians check for corrosion, which can happen from road salt or when different metals touch. Signs like rapid air loss or visible damage mean the valve stem needs attention.

Before installing the tire, technicians clean the area around the sensor and valve stem hole. They avoid using lubricants or sealants that could affect how tight the parts fit. If they remove the valve core, they always use a new one to prevent corrosion. The sensor gets inserted through the wheel in the correct position. New seals and nuts go on, never reusing old ones. The sensor housing must sit flush with the wheel, and the nut gets tightened with a torque wrench to the right setting. Finally, the tire is mounted carefully to avoid damaging the sensor.

Costs and Service Best Practices

You should know the typical costs for TPMS valve stem service. Here is a quick look:

| Cost Component | Typical Cost Range |

|---|---|

| Parts (Valve Stem) | $5 to $10 |

| Labor | $20 to $30 |

| Total Valve Stem Replacement | $25 to $40 |

TPMS sensor replacement usually costs $50 to $100 each, depending on your vehicle. Service kits with all the needed parts cost about $5 to $10 per wheel. Extra labor and special tools for programming can raise the total price. Experts recommend replacing all TPMS service parts—like seals, washers, nuts, and caps—every time you remove a tire. Always use new, TPMS-specific parts and follow torque specs closely. Avoid lubricants on threads and check for corrosion, especially on aluminum stems.

Dealing with TPMS Warning Lights

If you see a TPMS warning light, several things could be happening. Low tire pressure often triggers the light, especially when temperatures drop. Sometimes, a sensor malfunctions or its battery dies. After tire service, the system may need recalibration. Improper installation or not resetting the system can also cause the light to stay on.

To fix the issue, check all your tires—including the spare—with a reliable gauge. Inspect sensors and valve stems for damage or corrosion. Try resetting the system using your car’s reset button or by driving at a steady speed. If the light stays on, a scan tool may be needed for a deeper reset. Persistent problems may mean you need a new sensor or professional help. Regular checks and quick action keep your TPMS working and your drive safe.

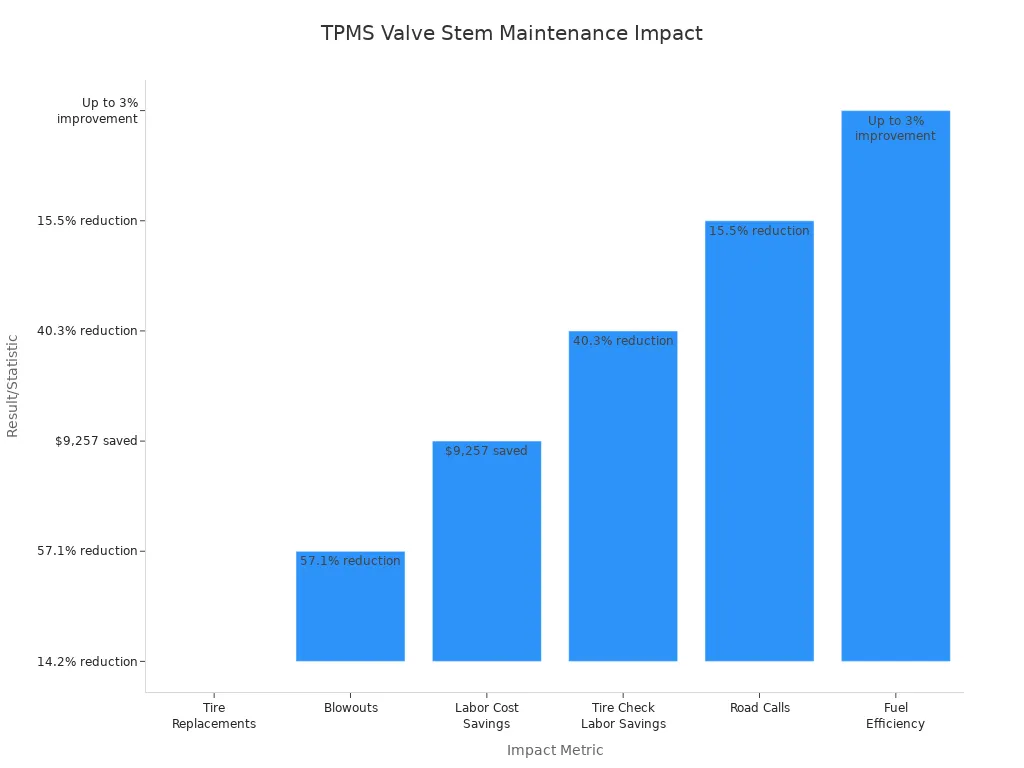

TPMS valve stems keep your tires safe and your car running well. When you care for them, you lower the risk of blowouts and save money on repairs. The table below shows how regular maintenance helps:

| Impact Metric | Result/Statistic | Benefit |

|---|---|---|

| Tire Replacements | 14.2% fewer | Longer tire life, lower costs |

| Blowouts | 57.1% fewer | Safer driving |

| Labor Cost Savings | $9,257 saved | Less money spent on repairs |

| Tire Check Labor Savings | 40.3% less | Faster, easier tire checks |

| Road Calls | 15.5% fewer | Fewer roadside emergencies |

| Fuel Efficiency Improvement | Up to 3% better | More miles per gallon |

You can extend the life of your TPMS valve stems and sensors by following these tips:

- Get professional installation with the right torque.

- Inspect and clean valve stems often.

- Replace sensor batteries when needed.

- Respond quickly to TPMS alerts.

- Keep tire pressure at the correct level.

- Handle sensors gently during tire changes.

Taking these steps helps you drive safer and spend less over time.

FAQ

What happens if you ignore a TPMS warning light?

You risk driving on underinflated or overinflated tires. This can cause poor handling, lower fuel efficiency, and even tire blowouts. Always check your tire pressure and inspect your valve stems when you see the warning.

How often should you replace TPMS valve stems?

Most experts recommend replacing TPMS valve stems every time you get new tires. If you see signs of corrosion or damage, replace them sooner. Regular checks help you avoid leaks and sensor problems.

Can you drive with a faulty TPMS sensor or valve stem?

You can drive, but you lose real-time tire pressure monitoring. This increases your risk of tire failure. Fix faulty sensors or valve stems as soon as possible to keep your vehicle safe.

Are TPMS valve stems universal for all vehicles?

No, TPMS valve stems come in different sizes and materials. Always check your vehicle’s manual or ask a tire professional to find the correct type for your car.

Tip: Using the right TPMS valve stem ensures accurate tire pressure readings and better safety.