Fortune tpms valve stem Features

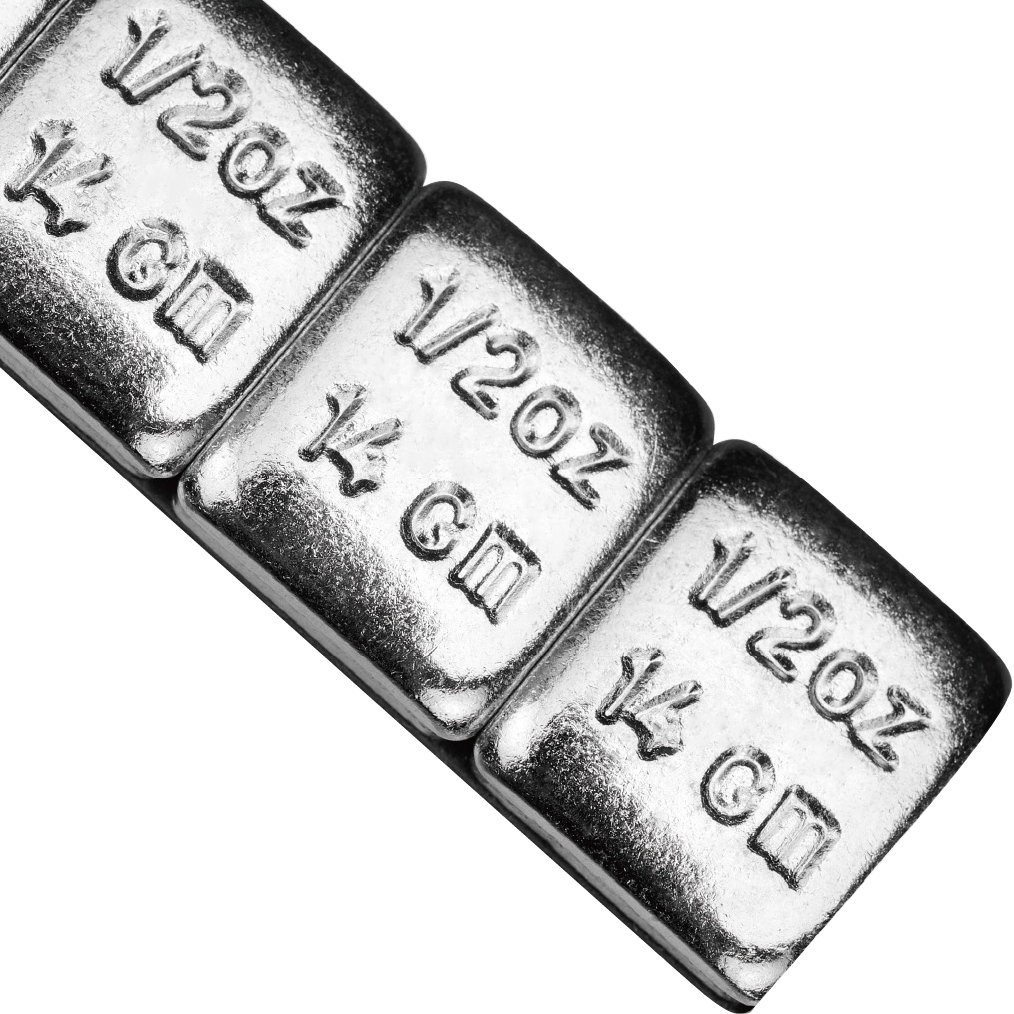

Durable material

Fortune's valve stem is made of natural rubber, a material that is structurally stable, heat resistant, hard, and abrasion resistant. It will not fade in the sunlight and has a long service life. The aluminum alloy used in the tire valve shaft makes the product resistant to oxidation and corrosion, and also makes it stronger and more reliable. Perfect for tubeless tires.

Safety Upgrade

To make driving safer, Fortune has specially designed an inductive valve that checks the pressure of your car's tires in real time. If the tire pressure is too high or too low, the overpressure release valve will automatically activate. Open or close the air vent to adjust the pressure inside the tire. It extends the life of your tires and improves driving safety.

Easy to install

Fortune was designed to ensure that it is user-friendly, so it is very easy to install. It is easy to replace the old valves without any modifications. The entire process does not require replacing any parts, cutting or drilling. The valve is designed to be sturdy and will not come off, so it will work even on bumpy roads.

Perfect Replacement

With high temperature resistant valve core and rubber box valve design, it is more flexible and convenient to carry and use. You can rely on it to help you change tires whenever and wherever you need it. Combined with advanced tire pressure sensor technology, it helps you stay on top of your tires and provides instant feedback when necessary. Ensuring you travel with confidence and safety every time.

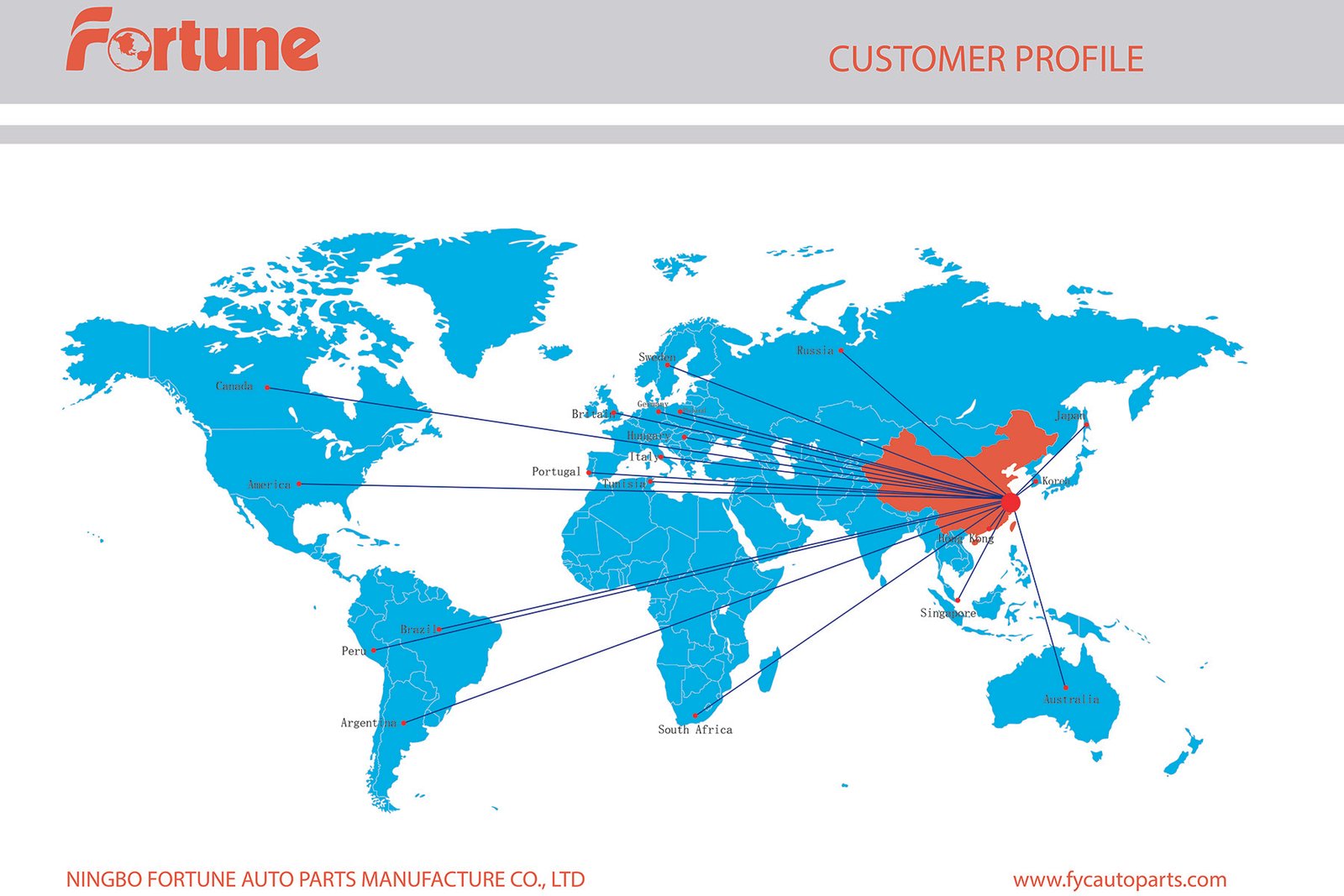

Wide range of applications

Fortune's Universal Vacuum Tire Valve Locking Valve has a standard diameter design, which means it can be used on a wide range of vehicles including, but not limited to, cars, light trucks, small trailers, wheelbarrows, lawn mowers, mountain bikes, 4x4s, scooters, off-road vehicles, and motorcycles.