admin1

May 27, 2025

Steel Wheel Weight Compared to Alloy Wheels in 2025

When you compare steel wheels to alloy wheels, one of the most noticeable differences is weight. Steel wheel weight tends to be higher, which directly affects how a vehicle performs. Lighter alloy wheels offer advantages that you can feel in handling, acceleration, and fuel efficiency. Studies show that reducing vehicle weight improves fuel consumption, especially in smaller cars, which benefit from lighter wheels. For every 100 pounds removed from a vehicle, fuel efficiency improves, but safety considerations also come into play. These differences make choosing the right wheels essential for balancing performance, efficiency, and safety.

Steel Wheel Weight vs. Alloy Wheels: Key Differences

Average Weight of Steel Wheels

Steel wheels are known for their durability and affordability, but they come with a significant trade-off: weight. On average, a steel wheel weighs approximately 78 lbs. Some models fall within the range of 65-68 lbs, depending on the size and design. Compared to alloy wheels, steel wheels can weigh 2.5 to 3 times more for the same size. This added weight makes steel wheels a practical choice for vehicles designed for rugged use, such as trucks and off-road vehicles. However, the heavier weight can impact fuel efficiency and handling, especially in smaller cars.

A study titled A Review on Fatigue Life Prediction of a Heavy Vehicle Steel Wheel highlights how manufacturing processes influence the weight and fatigue life of steel wheels. Another analysis, Failure Analysis of Steel Wheel by Using Finite Element Method, demonstrates that steel wheels experience higher stress under load, further emphasizing their heavier construction. These findings underline why steel wheels are often chosen for their strength rather than their weight-saving properties.

Average Weight of Alloy Wheels

Alloy wheels, made from materials like aluminum or magnesium, are significantly lighter than their steel counterparts. The weight of alloy wheels varies based on size and type. For example, stock 500E alloy wheels weigh around 23 lbs, while larger 17-18″ wheels weigh between 25-29 lbs. Forged alloy wheels, such as CLK forged wheels (16×7), are even lighter, weighing just 14.5 lbs. This reduced weight per corner improves overall vehicle performance.

The Automotive Forged Alloy Aluminium Wheel Market highlights the advantages of forged alloy rims, emphasizing their lightweight and strong characteristics. These wheels are particularly beneficial for high-performance and electric vehicles, where weight distribution plays a critical role in efficiency and handling. Additionally, the Alloy Rim Roundup provides detailed specifications, showing consistent weight distribution across various alloy rim types. This consistency ensures that alloy wheels deliver predictable performance, making them a popular choice for drivers seeking a balance of style and functionality.

Impact of Weight on Vehicle Performance

The weight of your wheels directly affects your vehicle’s performance. Heavier steel wheels increase the rotational mass, which can slow acceleration and reduce fuel efficiency. In contrast, lighter alloy wheels improve handling, braking, and acceleration. For instance, a study from AZoM confirms that aluminum alloy rims provide better heat dissipation, braking efficiency, and fatigue life compared to steel rims. These benefits translate to smoother rides and enhanced safety.

Another study analyzed the impact of wheel weight on vehicle performance. Factory steel wheels, weighing 68 lbs, served as the baseline. Aftermarket wheels, slightly heavier at 72 lbs, showed a minor decrease in horsepower and torque. In contrast, HRE alloy wheels, weighing just 60 lbs, increased horsepower by 8 and torque by 9 ft-lbs. This data demonstrates how reducing wheel weight can significantly enhance a vehicle’s performance.

When choosing between steel and alloy wheels, consider how weight impacts your driving experience. Steel wheels may offer durability and cost savings, but alloy wheels provide superior performance and efficiency. The right choice depends on your vehicle’s needs and your driving priorities.

Practical Considerations: Durability, Maintenance, and Cost

Durability of Steel Wheels vs. Alloy Wheels

When it comes to durability, steel wheels stand out for their strength and resistance to bending. They are less likely to crack under pressure, making them ideal for rugged terrains and heavy-duty vehicles. In contrast, alloy wheels, while lighter, are more prone to damage such as cracking or wheel corrosion. This is especially true in areas with harsh weather conditions or exposure to road salt.

| Aspect | Steel Wheels | Alloy Wheels |

|---|---|---|

| Impact Resistance | Deforms easily on impact | Less damage upon impact |

| Heat Dissipation | Higher operating temperature | Lower operating temperature |

| Longevity | Shorter lifespan due to wear | Longer lifespan due to better heat dissipation |

Steel rims also offer high ductility, allowing them to bend rather than break under extreme stress. However, alloy wheels excel in heat dissipation, which can prolong the life of tires and brakes.

Maintenance and Repair Needs

Steel wheels require minimal maintenance. Their simple design makes them easy to clean and repair. However, they are more susceptible to rust and may need repainting over time. On the other hand, alloy wheels demand more attention. You need specific cleaning solutions to protect their finishes, and they are more vulnerable to irreversible corrosion.

If you prioritize low maintenance, steel rims are a practical choice. However, if you prefer a sleek appearance and are willing to invest in upkeep, alloy wheels might suit your needs better.

Cost Comparison: Steel vs. Alloy Wheels

Steel wheels are significantly cheaper than alloy wheels. Their production involves simpler processes and less expensive materials. This affordability makes them a popular choice for replacements and budget-conscious buyers. In contrast, alloy wheels cost 40-60% more due to their complex manufacturing and premium materials.

| Feature | Steel Wheels | Alloy Wheels |

|---|---|---|

| Initial Cost | Lower initial purchase price | Higher initial purchase price |

| Ownership Costs | Lower due to durability | Higher due to maintenance needs |

Steel rims also offer long-term cost benefits. They often last the entire lifespan of a vehicle, reducing replacement expenses. If cost is a major factor for you, steel wheels provide excellent value without compromising durability.

Advancements in Wheel Technology by 2025

Innovations in Lightweight Materials

By 2025, advancements in lightweight materials are revolutionizing wheel manufacturing. Aluminum wheels remain a popular choice due to their lightweight properties and widespread use in automotive applications. Magnesium wheels are gaining traction as an alternative, offering even lighter designs for improved performance. Manufacturers are also exploring innovative techniques like 3D printing to create complex, strong, and lightweight wheel structures.

AI-assisted design methodologies are playing a pivotal role in this evolution. These techniques combine generative design with deep learning, enabling rapid exploration of optimal wheel designs. For electric vehicles (EVs), this approach is particularly beneficial. It allows manufacturers to address the unique challenges posed by battery weight while enhancing aerodynamics and overall efficiency.

| Material Type | Description |

|---|---|

| Aluminum | Widely used for its lightweight properties and commercial interest in automotive applications. |

| Magnesium | Another lightweight option that is gaining traction in the automotive industry. |

| 3D Printing | Innovative manufacturing technique that allows for complex designs and weight reduction. |

The global market for lightweight wheels is expanding rapidly. In 2023, aluminum alloy wheels accounted for 61.7% of production, while steel wheels made up 35.9%. Carbon fiber and hybrid-material wheels contributed approximately 1.1%, reflecting the growing interest in cutting-edge materials.

Enhanced Durability for Alloy Wheels

Durability improvements in alloy wheels are transforming their appeal. Advanced coatings like Steel Armor powder coat and Accu-Armor coating protect against corrosion and mechanical damage. These technologies ensure that alloy rims maintain their sleek appearance and structural integrity even under harsh conditions.

| Technology | Description |

|---|---|

| Steel Armor powder coat | Provides corrosion protection to prevent rust from forming at exposed areas of the wheel. |

| Accu-Armor coating | Encases aluminum wheels in a scuff-proof polymer to protect against mechanical damage. |

| vHub Bore Technology | Reduces hub-to-wheel contact area by up to 64%, minimizing surface area for corrosion formation. |

The manufacturing process also contributes to durability. Casting and forging techniques enhance the strength of alloy wheels while keeping them lightweight. This combination makes alloy rims a preferred choice for luxury and sports cars. Their ability to withstand wear and tear without compromising performance sets them apart from traditional steel wheels.

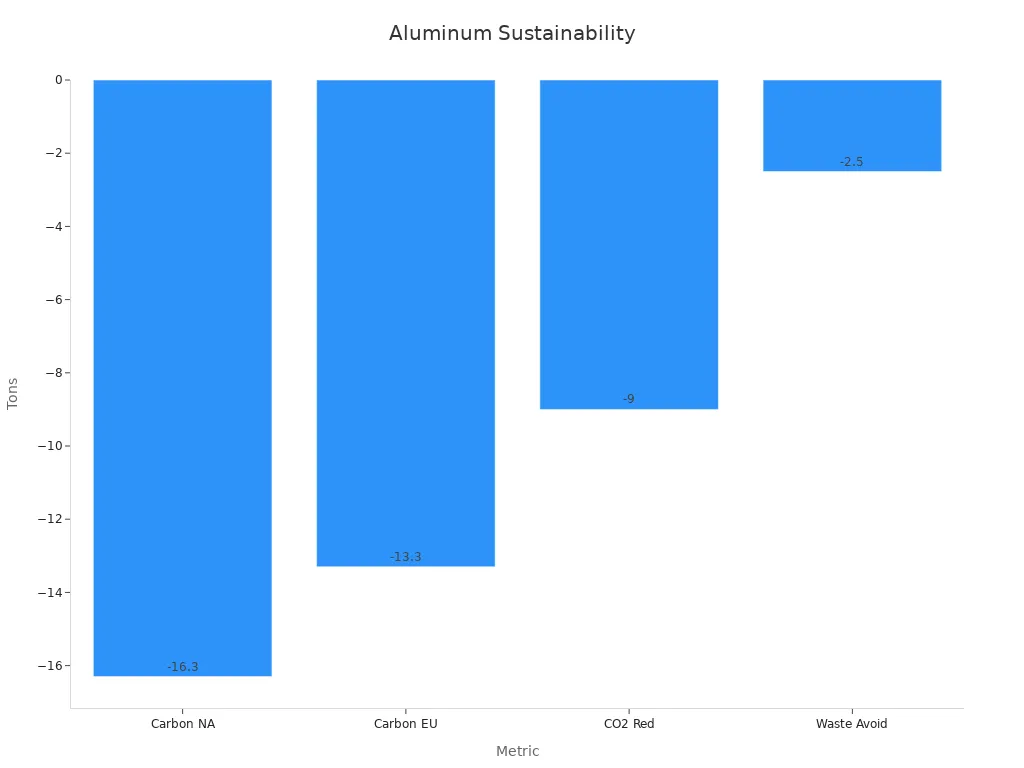

Sustainability and Eco-Friendly Manufacturing

Sustainability is becoming a cornerstone of wheel production. Manufacturers are adopting eco-friendly practices to reduce environmental impact. Aluminum wheels, for instance, are recyclable indefinitely, offering significant benefits over steel wheels, which lack recyclability.

| Metric | Steel Wheels | Alcoa® Aluminum Wheels |

|---|---|---|

| Carbon Emissions (North America) | 0 tons | -16.3 metric tons |

| Recycling Benefits | Not recyclable | Recyclable indefinitely |

| Energy Savings | N/A | 24 barrels of crude oil equivalent |

| Water Savings | N/A | 15 tons of fresh or sea water |

| CO2 Emissions Reduction | N/A | -9 tons |

| Solid Waste Avoidance | N/A | -2.5 tons |

Consumers are increasingly drawn to products made from recycled metals. This trend aligns with heightened environmental awareness and the demand for sustainable solutions. Lightweight wheels not only improve fuel efficiency but also reduce emissions, making them a key component in the shift toward greener transportation.

Predictions for Steel and Alloy Wheel Usage in 2025

The automotive industry is evolving rapidly, and by 2025, the usage of steel and alloy wheels is expected to reflect significant shifts in consumer preferences and technological advancements. These changes will influence how you choose the right wheels for your vehicle, whether you prioritize durability, performance, or cost-efficiency.

Market Trends and Growth Projections

The demand for alloy wheels is projected to grow significantly by 2025. This growth stems from advancements in lightweight materials and increasing consumer interest in high-performance designs. The automotive alloy wheel market is expected to grow at a compound annual growth rate (CAGR) of 3.0%. This trend aligns with stricter environmental regulations and the rising popularity of aerodynamic designs that improve fuel efficiency.

On the other hand, steel wheels will continue to hold a notable share of the market. Approximately 65% of commercial vehicle assemblers prefer steel wheels due to their durability and cost-effectiveness. Fleet managers also favor steel wheels, with 60% choosing them for their ability to reduce downtime and provide higher structural stability. These factors make steel wheels a practical choice for heavy-duty and commercial vehicles.

| Market Segment | Growth Projection by 2025 | Notes |

|---|---|---|

| Alloy Wheels Aftermarket | Significant growth | Driven by consumer preferences and technological advancements. |

| Steel Wheels Aftermarket | Notable share | Projected to experience significant growth in the near future. |

| Passenger Vehicles | Significant CAGR | Expected to retain position throughout the forecast period. |

Shifting Consumer Preferences

You may notice a growing preference for alloy wheels among drivers seeking lightweight and stylish options. These wheels offer better performance and aesthetic appeal, making them a popular choice for passenger vehicles and electric cars. The analysis indicates that this trend will continue to gain momentum, with alloy wheels becoming the go-to option for many consumers by 2025.

However, steel wheels will remain a staple in the commercial and heavy-duty vehicle sectors. Their unmatched durability and affordability make them indispensable for vehicles that operate in challenging conditions. If you prioritize cost savings and long-term reliability, steel wheels will likely remain a strong contender.

The Future of Wheel Technology

By 2025, advancements in wheel technology will further influence your decision-making process. Manufacturers are investing in innovative materials and production methods to enhance the performance and sustainability of both steel and alloy wheels. For instance, 3D printing and AI-assisted design are enabling the creation of lighter, stronger wheels tailored to specific vehicle needs. These innovations will likely make alloy wheels even more appealing for high-performance and electric vehicles.

At the same time, steel wheels are benefiting from technological upgrades that improve their strength and reduce their weight. These improvements ensure that steel wheels remain competitive in a market increasingly focused on efficiency and sustainability.

What This Means for You

As a consumer, your choice between steel and alloy wheels will depend on your priorities. If you value performance, fuel efficiency, and style, alloy wheels will likely meet your needs. If durability and cost-effectiveness are more important, steel wheels will continue to be a reliable option. By 2025, the advancements in wheel technology and shifting market trends will provide you with more options than ever before, ensuring that you can find the perfect wheels for your vehicle.

Steel wheels offer durability and cost-effectiveness, making them ideal for rugged use. Their heavier weight provides structural stability, especially for heavy commercial vehicles. Alloy wheels, on the other hand, improve performance and fuel efficiency due to their lightweight design. These wheels enhance handling and acceleration, making them a preferred choice for passenger vehicles and electric cars.

By 2025, advancements in wheel technology will further refine these options. Manufacturers are optimizing materials like alloy steel and stainless steel to balance strength, ductility, and corrosion resistance. For example:

| Material Type | Characteristics | Applications |

|---|---|---|

| Alloy Steel Wheels | Optimal balance of strength and ductility, appealing to mainstream applications | Passenger vehicles |

| Carbon Steel | Consistency and ease of fabrication, ideal for heavy load environments | Heavy commercial vehicles |

| Stainless Steel | Superior corrosion resistance, suitable for aggressive environmental conditions | Niche applications |

Your choice between steel rims and alloy rims depends on your priorities. If you value durability and affordability, steel rims remain a reliable option. If performance and style matter more, alloy rims will meet your needs. By 2025, these advancements will ensure you have access to wheels tailored to your vehicle and driving preferences.

FAQ

What are the main differences between steel and alloy wheels?

Steel wheels are heavier and more durable, making them ideal for rugged use. Alloy wheels are lighter, improving performance and fuel efficiency. Steel wheels cost less, while alloy wheels offer better aesthetics and handling. Your choice depends on your vehicle’s needs and driving priorities.

Are alloy wheels suitable for off-road driving?

Alloy wheels can handle off-road conditions but are more prone to cracking under extreme stress. Steel wheels perform better in rugged terrains due to their strength and ability to bend rather than break. If you frequently drive off-road, steel wheels may be a better option.

How do wheel weights affect fuel efficiency?

Heavier wheels, like steel, increase rotational mass, reducing fuel efficiency. Lighter alloy wheels lower the strain on your engine, improving mileage. Studies show that reducing vehicle weight by 100 pounds can enhance fuel efficiency by up to 2%. Choosing lighter wheels can save you money on fuel.

Can alloy wheels be repaired if damaged?

Alloy wheels can be repaired, but the process depends on the extent of the damage. Minor scratches or bends can often be fixed. However, cracks or severe damage may require replacement. Always consult a professional to assess the condition of your alloy wheels.

Which type of wheel is more eco-friendly?

Alloy wheels are more eco-friendly because they are recyclable indefinitely. Steel wheels, while durable, lack the same recyclability. Additionally, lightweight alloy wheels improve fuel efficiency, reducing carbon emissions. If sustainability matters to you, alloy wheels are the greener choice.