admin1

August 30, 2025

How Steel Valve Stems Compare to Rubber for Tire Performance

When you want reliable tire performance, the choice between steel valve stems and rubber valve stems makes a real difference. Steel valve stems give you greater durability, while rubber valve stems make installation easier. You will find that rubber options offer more flexibility, but they may dry out or crack over time. Metal stems need regular care to prevent corrosion. Picking the right valve stem helps your tires keep air longer, improves safety, and supports smooth driving.

- Metal valve stems last longer than rubber ones.

- Rubber versions are quicker to install and remove.

- Metal stems need maintenance for corrosion; rubber can crack as it ages.

- Rubber stems bend more easily, while metal stems stay rigid.

What Do Valve Stems Do?

Role in Tire Air Retention

Valve stems play a key role in keeping your tires properly inflated. You use them to add air to your tires, and they stop air from escaping when the valve cap is secure. This simple part helps you maintain the right pressure in every tire. When your tires hold the correct amount of air, your car handles better and uses less fuel. You also help your tires last longer.

If a valve stem fails, you might notice slow leaks. These leaks can cause your tire pressure to drop over time. Low pressure makes your tires wear out faster and can even affect your tire pressure monitoring system. The system alerts you when the pressure drops below a safe level. By checking your valve stems often, you can avoid problems and keep your tires in good shape.

- Valve stems allow you to add air to your tires.

- They prevent air from escaping when the cap is on.

- Proper pressure helps with handling, fuel efficiency, and tire life.

Impact on Tire Safety and Performance

You depend on valve stems for safe driving. When a valve stem works well, it keeps your tire pressure steady. This helps you avoid dangerous situations, like a blowout. A blowout can happen if your tire loses air quickly while you drive. Your tire pressure monitoring system will warn you if the pressure drops, but you need to act fast.

Valve stems also protect you from leaks that can lead to unsafe driving conditions. If you ignore slow leaks, your tires may not grip the road as they should. You might notice your car feels less stable or takes longer to stop. By keeping your valve stems in good condition, you support your tire pressure monitoring system and keep your vehicle safe.

Steel Valve Stems and Metal Valve Stems

Advantages of Steel Valve Stems for Tire Performance

You get strong performance when you choose steel valve stems. These stems resist wear and handle high pressure. Many drivers pick metal valve stems for their ability to last longer than rubber ones. You can use them on cars, trucks, and even heavy-duty vehicles. Metal valve stems help prevent damage from road debris and harsh weather. They do not crack or dry out like rubber. If you drive in tough conditions, you will notice that steel valve stems keep your tires sealed and safe.

Here is a table showing common materials used in metal valve stems:

| Material Type | Description |

|---|---|

| Metal Cap | Used in high-pressure metal clamp-in valves for sealing. |

| Rubber Grommet | Provides sealing against the wheel in metal clamp-in valves. |

| Nickel-Plated Core | Recommended for use in aluminum valve stems to prevent galvanic corrosion. |

| Brass Core | Commonly used but not recommended for aluminum valve stems due to corrosion issues. |

Metal valve stems also work well with tire pressure monitoring systems. You can trust them to keep air in your tires and help prevent damage from leaks.

Disadvantages of Steel Valve Stems

You should know that metal valve stems have some drawbacks. Tire technicians report that metal valve stems can fail more often than rubber ones. The rubber seal inside metal valve stems may leak, which can cause damage to your tires. Some drivers find that aluminum valve stems do not offer extra benefits and may not be as reliable. If you do not check your metal valve stems often, you might miss early signs of damage.

- Metal valve stems sometimes fail more than rubber stems.

- The rubber seal in metal valve stems can leak.

- Aluminum valve stems may not give you extra reliability.

You need to inspect your valve stems to prevent damage and keep your tires safe.

Metal Valve Stems for Trailer Wheels

When you use metal valve stems for trailer wheels, you get extra strength and durability. Trailers often carry heavy loads, so you need valve stems that can handle the pressure. Metal valve stems protect against damage from bumps and rough roads. You should always check the fit of the valve stem in the wheel. Make sure the grommet and washer are in place to stop leaks.

Tip: Always match the valve stem to your wheel type. Never assume the old valve stem is correct. This helps you avoid damage and keeps your trailer safe.

If you want to install metal valve stems, follow these steps:

- Gather your tools, such as an air compressor, jack, and valve stem tool.

- Loosen the lug nuts while the wheel is on the ground.

- Raise the trailer and secure it.

- Remove the wheel and set it with the valve stem facing up.

- Take out the old valve stem core to release air.

- Break the tire bead and remove the tire.

- Install the new metal valve stem from inside the wheel.

- Reseat the tire bead and inflate the tire.

- Reinstall the wheel and check for leaks.

You can use metal valve stems to help prevent damage and keep your trailer tires in top shape.

How to Install Metal Valve Stems

You can install metal valve stems at home if you have the right tools and follow each step carefully. Metal valve stems give your tires extra strength and help prevent leaks. Many drivers choose them for high-pressure or heavy-duty use. Here is a simple guide to help you install metal valve stems on your wheels.

Tools You Need:

- Valve stem puller or installer tool

- Tire bead breaker or pry bar

- Air compressor

- Soap and water solution

- Torque wrench (for aluminum clamp-in valve stems)

- Safety gloves

Step-by-Step Guide:

- Park your vehicle on a flat surface. Use wheel chocks to keep it from moving.

- Loosen the lug nuts on the wheel, then lift the vehicle with a jack.

- Remove the wheel and lay it flat with the valve stem facing up.

- Deflate the tire by removing the valve core. Use a valve core tool for this step.

- Break the tire bead away from the rim using a bead breaker. This gives you access to the valve hole.

- Pull out the old valve stem. Clean the valve hole with a cloth to remove dirt or debris.

- Insert the new metal valve stem through the hole from the inside of the rim. For aluminum clamp-in valve stems, use a torque wrench to tighten the nut to the manufacturer’s recommended setting.

- Apply a soap and water solution around the base to check for leaks after inflation.

- Reseat the tire bead and inflate the tire to the correct pressure.

- Reinstall the wheel on your vehicle and tighten the lug nuts.

Tip: Always check the instructions that come with your metal valve stems. Some types may need special torque settings or extra washers.

You can install metal valve stems to improve your tire’s durability and air retention. Regular checks help you spot leaks early and keep your tires safe.

Rubber Valve Stems

Advantages of Rubber Valve Stems

You will find that rubber valve stems offer several benefits for everyday drivers. These stems provide flexibility, which helps them fit tightly into the wheel. You can install rubber valve stems quickly, even if you do not have special tools. Many tire shops use rubber snap-in valve stems because they save time and effort during tire changes.

Rubber valve stems cost less than metal options. If you want to keep your tire maintenance budget-friendly, you will appreciate this feature. You can also replace stock rubber valve stems easily when they wear out. Most passenger cars come with rubber valve stems from the factory, so you know they work well for daily driving.

Tip: If you check your rubber valve stems often, you can spot early signs of damage and avoid sudden air loss.

Here are some reasons drivers choose rubber valve stems:

- Easy and fast installation

- Lower cost compared to metal stems

- Flexible fit for most wheels

- Commonly used in passenger vehicles

Disadvantages of Rubber Valve Stems

Rubber valve stems do have some drawbacks you should know. Over time, rubber can dry out, crack, or become brittle. This makes the valve stem more likely to leak or fail. If you drive in hot or cold weather, rubber may wear out faster. When rubber valve stems get old, they can let air escape, which leads to low tire pressure.

You may also notice that rubber valve stems can suffer damage from road debris or contact with the rim. If you use external tire pressure sensors, the extra weight can cause rubber stems to vibrate and wear out quickly. In some cases, high pressure can even cause a blowout.

Here is a table showing common problems with rubber valve stems:

| Disadvantage | Description |

|---|---|

| Faster Wear | Rubber stems will vibrate and wear at a much faster rate when the external sensors are mounted. |

| Potential Blowouts | Some drivers report that high pressure rubber valve stems can blow out within a short time. |

| Leaks | Rubber stems may start leaking where the stem meets the rim, especially as they age. |

If you see cracks or other signs of damage on your rubber valve stems, you should replace them right away. This helps prevent air loss and keeps your tires safe.

Head-to-Head Comparison: Steel vs. Rubber Valve Stems

Durability and Longevity

When you look at durability, steel and rubber valve stems show clear differences. Steel valve stems stand out for their strength. You can use them in heavy-duty trucks and off-road vehicles because they handle high pressure and tough conditions. Many drivers report that metal stems last for years without problems, even after a decade of use. This makes them a good choice if you want long-term reliability.

Rubber valve stems, on the other hand, offer flexibility. They seal well against rim imperfections, which helps prevent leaks. In cold or salty environments, rubber stems often last longer because they resist corrosion better than metal. If you drive in areas with harsh winters, you may find that rubber stems stay reliable and do not corrode as quickly.

Tip: Always inspect your valve stems after winter. Cracks or leaks can develop in both types, but regular checks help you catch problems early.

Here are some key points about durability and longevity:

- Steel valve stems can corrode in salty or wet conditions.

- Rubber valve stems flex to seal better on imperfect rims.

- Regular inspection increases the lifespan of both types.

- Rubber stems often last longer in severe climates.

Air Retention and Leak Prevention

Air retention is important for tire safety. Steel valve stems provide a strong seal, especially at high pressures. You will see them used in trucks and vehicles that need to hold more than 65 psi. Some users say they never had leaks with metal stems, even after many years. This makes steel stems a solid choice for high-pressure needs.

Rubber valve stems work well for most passenger cars and motorcycles. They seal tightly and prevent leaks at standard pressures. However, if you use rubber stems at high pressures, they may reach their limits and fail. Some drivers have switched to metal stems after experiencing leaks or blowouts with rubber ones.

- Metal valve stems work best for high-pressure tires.

- Rubber valve stems are reliable for standard vehicles.

- High pressure can cause rubber stems to fail.

- Both types need regular checks for leaks.

Installation and Maintenance

You will notice differences when you install or maintain steel and rubber valve stems. Rubber stems are easier to install. Their flexibility lets you fit them into the rim quickly, even without special tools. Most tire shops use rubber stems for this reason. You can replace them easily during routine tire changes.

Steel valve stems require more effort to install. You need special wrenches and sometimes a torque wrench to get the right fit. Metal stems are smaller in diameter, so you must handle them carefully. If you use aluminum wheels, you need to watch for corrosion and check the torque setting to avoid leaks.

Here is a table that shows the main differences:

| Feature | Metal Valve Stems | Rubber Valve Stems |

|---|---|---|

| Installation Difficulty | More challenging due to less pliability | Easier to install due to flexibility |

| Durability | Generally more durable but can corrode | Less durable but less likely to corrode |

| Size | Typically smaller in diameter | Larger diameter, easier to handle |

| Wrench Compatibility | Requires a special wrench | Can be installed/removed with a standard wrench |

| Wear | Can wear out over time | Less likely to wear out |

Note: Always match the valve stem to your wheel and driving needs. Proper installation prevents leaks and extends the life of your tires.

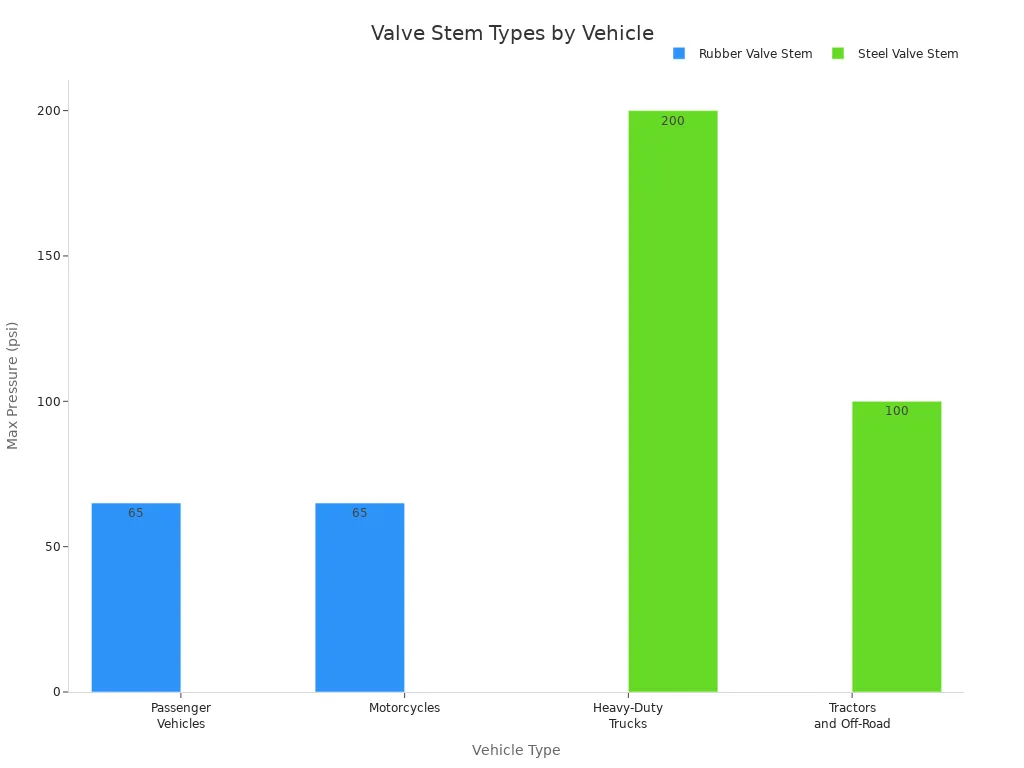

If you want to see how pressure ratings compare, check out this chart:

You can see that steel valve stems support much higher pressures. Rubber valve stems work well for most cars and motorcycles, but you should choose steel for heavy-duty or high-pressure use.

Suitability for Different Vehicles and Conditions

When you choose a valve stem, you need to think about your vehicle and where you drive. Steel and rubber valve stems work better in different situations. You can use this guide to match the right stem to your needs.

Passenger Cars 🚗

Most passenger cars use rubber valve stems. You get a flexible fit and easy installation. Rubber stems seal well at normal tire pressures. You drive on city streets and highways, so you do not need extra strength. If you check your valve stems often, you keep your tires safe.

Trucks and SUVs 🚚

Trucks and SUVs carry heavier loads. You need valve stems that handle higher pressure. Steel valve stems give you more durability. You drive on rough roads or haul cargo, so metal stems help prevent leaks. Many drivers choose steel stems for towing or off-road trips.

Trailers and RVs 🛻

Trailers and RVs need strong valve stems. You often drive long distances and carry heavy loads. Steel valve stems resist damage from bumps and vibration. You get better air retention for high-pressure tires. If you use your trailer for work or travel, metal stems keep your tires sealed.

Motorcycles 🏍️

Motorcycles use both rubber and steel valve stems. You need a stem that fits your wheel and holds air at the right pressure. Rubber stems work well for most bikes. If you ride at high speeds or use tire pressure sensors, steel stems give you extra security.

Off-Road and Heavy-Duty Vehicles 🚜

Off-road vehicles face rocks, mud, and tough terrain. You need valve stems that stand up to abuse. Steel valve stems resist impact and keep your tires sealed. You drive in extreme conditions, so metal stems last longer. Many off-road drivers pick steel stems for safety.

Weather and Road Conditions 🌦️

Weather affects your valve stem choice. In cold climates, rubber stems resist corrosion from salt and moisture. You get a good seal even in winter. In hot or dry areas, steel stems do not crack or dry out. You drive on rough roads, so metal stems protect against damage.

Tip: Always match your valve stem to your vehicle and driving environment. You get better performance and safety when you choose the right type.

Quick Reference Table

| Vehicle Type | Recommended Valve Stem | Key Reason | Typical Pressure Range |

|---|---|---|---|

| Passenger Car | Rubber | Flexibility, easy install | 32–36 psi |

| Truck/SUV | Steel | Durability, high pressure | 35–80 psi |

| Trailer/RV | Steel | Strength, vibration resistance | 65–110 psi |

| Motorcycle | Rubber or Steel | Fit, sensor compatibility | 28–42 psi |

| Off-Road/Heavy-Duty | Steel | Impact resistance | 40–100+ psi |

You can use this table to pick the best valve stem for your vehicle. If you drive in tough conditions or need high pressure, steel valve stems work best. For everyday driving, rubber valve stems give you a simple and reliable option.

Choosing the Right Valve Stem for Your Needs

Everyday Driving Needs

You want a valve stem that fits your daily routine. Rubber valve stems work well for most passenger cars. They are reliable and easy to use. You do not need to worry about changing seals or doing extra maintenance. Many drivers choose rubber stems because they snap in quickly and keep air in the tire. You can trust them for city driving, school runs, and weekend trips.

- Rubber valve stems offer a worry-free option for everyday use.

- You can install them fast without special tools.

- They fit most standard wheels and tire pressures.

When you pick a valve stem, check the size and type. Most cars use a 10mm or 12mm diameter and a standard length like 32mm. Make sure the stem matches your wheel and tire.

| Factor | Description |

|---|---|

| Material | Rubber is best for daily driving and easy maintenance. |

| Diameter | Common sizes are 10mm and 12mm for passenger vehicles. |

| Length | Standard lengths like 32mm fit most cars. |

| Compatibility | Match the valve stem to your wheel design and tire size. |

| Max Pressure | Rubber stems handle standard tire pressures up to 3 bar. |

| Valve Type | Schrader valves are common for cars. |

High-Performance and Heavy-Duty Use

If you drive a truck, trailer, or high-speed car, you need a valve stem that can handle more stress. Metal clamp-in valve stems give you extra durability. You can use them for high-pressure tires and heavy loads. These stems attach with a nut, so they resist leaks and valve failure.

- Metal valve stems withstand higher tire pressures, often over 65 PSI.

- You get better resistance to heat and tough conditions.

- Metal stems work for racing vehicles and those that go over 130 mph.

You can find metal stems in different materials like aluminum, brass, or stainless steel. They fit various rim hole sizes and lengths, such as 45mm or 60mm, for special applications.

Tip: Always check your tire’s max pressure and speed rating before choosing a metal valve stem.

Budget and Convenience Considerations

You want to save money and keep tire maintenance simple. Rubber valve stems cost less than metal ones. They are the best choice for budget-conscious drivers. You can replace them easily during routine tire changes.

- Rubber snap-in valve stems are the least expensive option.

- Metal clamp-in valve stems cost more but last longer.

Rubber stems make quick tire maintenance easy. You do not need special tools. Both steel and rubber stems let you adjust tire pressure easily, which helps your tires perform well.

Note: If you drive a standard car and want to save money, rubber valve stems offer the best mix of price and convenience. Choose metal stems for performance or heavy-duty needs.

You see clear differences between steel and rubber valve stems. Steel stems last longer and handle higher pressure, while rubber stems offer easy installation and cost savings. Your driving habits matter—if you often hit curbs or drive on rough roads, metal stems resist damage better.

| Type of Valve Stem | Application Description | Maximum Pressure (PSI) |

|---|---|---|

| Rubber Valve Stem | Passenger cars, light trucks | Up to 65 |

| High-Pressure Valve Stem | Heavy-duty trucks, rugged light trucks | Exceeds 65 |

| High-Performance Metal Stem | Sports and race cars needing durability | Up to 200 |

Consider your vehicle type, pressure needs, and maintenance routine before choosing. Select the stem that matches your driving style for safer, longer-lasting tires.

FAQ

Can you use steel valve stems on any type of wheel?

You can use steel valve stems on most wheels. Always check your wheel’s valve hole size and shape. Some aluminum wheels need special grommets or washers for a proper seal.

How often should you replace rubber valve stems?

You should replace rubber valve stems every time you change tires. Most experts recommend changing them every 4–5 years. Cracks or leaks mean you need a new stem right away.

Do steel valve stems prevent air leaks better than rubber?

Steel valve stems resist leaks at high pressures. You get better air retention for trucks and trailers. Rubber valve stems work well for standard cars but may leak if damaged or old.

Are steel valve stems harder to install than rubber ones?

Steel valve stems need more tools and careful installation. You must tighten the nut to the correct torque. Rubber valve stems snap in quickly and do not need special equipment.

Can you use tire pressure sensors with both types of valve stems?

You can use tire pressure sensors with steel and rubber valve stems. Steel stems support external sensors better because they resist vibration. Rubber stems may wear faster with heavy sensors.