admin1

May 21, 2025

Steel Rim Wheel Weights Explained

Steel rim wheel weights play a critical role in wheel balancing, ensuring your tires rotate evenly and minimize vibrations. This process not only improves driving comfort but also protects your vehicle from uneven tire wear. Properly balanced wheels enhance safety by optimizing braking efficiency and improving handling, especially during sudden stops or on uneven surfaces.

These weights are growing in popularity due to their durability and eco-friendliness. The global market for steel wheels is projected to grow steadily, driven by the demand for fuel-efficient vehicles and the increasing preference for SUVs. Choosing steel rim wheel weights helps you achieve better performance while contributing to a sustainable future.

Types of Steel Rim Wheel Weights

Clip-On Steel Rim Wheel Weights

Clip-on weights are among the most commonly used types of wheel weights. These weights attach directly to the rim using a metal clip, ensuring a secure fit. They are ideal for steel rims due to their robust design and ability to withstand high levels of stress during driving. Over 65% of global clip-on weight usage is attributed to vehicles, with an average of 5-8 weights applied per wheel. This widespread use highlights their effectiveness in maintaining tire balance.

Clip-on weights help reduce tire wear by counteracting imbalances, which extends the lifespan of your tires and minimizes the need for frequent replacements. Balanced wheels also enhance vehicle stability and handling, providing smoother rides and better cornering. Properly balanced wheels reduce vibrations, improving traction and braking efficiency. Even when payloads are added, stopping distances increase by less than 10% due to the precise balance achieved with clip-on weights.

Adhesive Steel Rim Wheel Weights

Adhesive wheel weights offer a modern alternative to traditional clip-on weights. These weights use a strong adhesive backing to stick directly to the inner surface of the rim. This design ensures a seamless fit, making them an excellent choice for vehicles where aesthetics matter. Adhesive weights are particularly popular for alloy and custom wheels, but they also work well on steel rims.

These weights are known for their durability and corrosion resistance, making them a sustainable option compared to traditional lead weights. They maintain strong adhesion under various temperature conditions, ensuring reliable performance in extreme climates. Adhesive weights also optimize weight balancing, which enhances fuel efficiency and vehicle handling. By using lead-free materials, they reduce environmental risks, contributing to safer ecosystems.

Coated vs. Uncoated Steel Rim Wheel Weights

Steel rim wheel weights come in both coated and uncoated varieties. Coated weights feature a protective layer, often made of plastic or powder coating, which shields the steel from corrosion. This coating not only extends the lifespan of the weights but also prevents damage to the rim’s surface. Coated weights are ideal for vehicles exposed to harsh weather conditions or road salt, as they resist rust and maintain their appearance over time.

Uncoated weights, on the other hand, are more cost-effective and suitable for vehicles that operate in less demanding environments. While they lack the added protection of a coating, advancements in steel treatment processes have improved their resistance to corrosion. These improvements make uncoated weights a viable option for many applications. Both coated and uncoated weights offer the durability and performance benefits that steel rim wheel weights are known for, allowing you to choose the best option based on your specific needs.

OEM vs. Aftermarket Steel Rim Wheel Weights

When choosing steel rim wheel weights, you’ll encounter two main categories: OEM (Original Equipment Manufacturer) and aftermarket options. Understanding the differences between these two can help you make the best decision for your vehicle.

What Are OEM Steel Rim Wheel Weights?

OEM steel rim wheel weights are designed and manufactured by the same company that produces your vehicle or its original parts. These weights meet the exact specifications set by the vehicle manufacturer. They are tailored to fit your car’s rims perfectly, ensuring optimal performance and compatibility.

Advantages of OEM Wheel Weights:

- Perfect Fit: OEM weights are custom-made for your vehicle’s rims, reducing the risk of improper installation.

- Guaranteed Quality: These weights meet strict manufacturing standards, ensuring durability and reliability.

- Warranty Coverage: Many OEM parts come with a warranty, giving you peace of mind about their performance.

However, OEM weights often come at a higher price. If you prioritize precision and compatibility, they are worth the investment.

What Are Aftermarket Steel Rim Wheel Weights?

Aftermarket steel rim wheel weights are produced by third-party manufacturers. These weights are designed to fit a wide range of vehicles, offering more flexibility in terms of availability and cost. They are a popular choice for those looking for budget-friendly options without compromising on quality.

Advantages of Aftermarket Wheel Weights:

- Cost-Effective: Aftermarket weights are usually more affordable than OEM options, making them ideal for budget-conscious buyers.

- Wide Availability: You can find aftermarket weights for almost any vehicle type, including older or less common models.

- Variety of Options: Many aftermarket manufacturers offer innovative designs, such as coated weights for added corrosion resistance.

While aftermarket weights provide excellent value, you need to ensure they meet industry standards. Look for products from reputable brands to avoid issues like poor fit or reduced durability.

Key Differences Between OEM and Aftermarket Weights

| Feature | OEM Weights | Aftermarket Weights |

|---|---|---|

| Fit and Compatibility | Specifically designed for your vehicle | Universal fit for various vehicles |

| Price | Higher cost | More affordable |

| Quality Assurance | Backed by manufacturer standards | Varies by brand |

| Availability | Limited to specific models | Widely available |

Which Option Should You Choose?

Your choice between OEM and aftermarket steel rim wheel weights depends on your priorities. If you value precision and compatibility, OEM weights are the way to go. On the other hand, if you’re looking for a cost-effective solution with more variety, aftermarket weights are a great alternative.

Tip: Always check the specifications of the wheel weights before purchasing. Ensure they match your vehicle’s requirements to avoid performance issues.

By understanding the differences between OEM and aftermarket steel rim wheel weights, you can make an informed decision that suits your needs and budget.

Benefits of Steel Rim Wheel Weights

Durability and Longevity

Steel rim wheel weights are renowned for their exceptional durability. Unlike other materials, steel resists corrosion and maintains its structural integrity over time. This makes it an ideal choice for vehicles exposed to harsh weather conditions or rough terrains. With proper care, steel rims can last between 15 to 20 years, far outlasting aluminum rims, which typically endure only about 10 years. If you keep your steel rims free from rust and avoid subjecting them to excessive stress, they can last indefinitely.

Steel’s resilience also ensures that wheel weights made from this material can withstand the rigors of daily driving. Whether you’re navigating potholes or driving at high speeds, steel wheel weights maintain their performance. This longevity not only saves you money on replacements but also enhances your vehicle’s safety by ensuring consistent wheel balancing.

Fun Fact: Aluminum rims may fatigue and fail over time, but steel rims remain reliable as long as they are not subjected to more than 50% of their yield strength.

Cost-Effectiveness

Steel rim wheel weights offer a budget-friendly solution without compromising quality. Steel alloy is the most cost-effective material for wheel weight production, with an average price of $26.6 compared to magnesium alloy at $51.13. This affordability makes steel weights accessible to a wide range of vehicle owners, from everyday drivers to commercial fleet operators.

In addition to their low upfront cost, steel wheel weights provide long-term savings. Their durability reduces the need for frequent replacements, and their ability to maintain tire balance helps prevent uneven tire wear. This extends the lifespan of your tires, saving you money on replacements and improving fuel efficiency.

- Cost Comparison of Materials:

- Steel alloy: Most affordable

- Magnesium alloy: Moderately priced

- Aluminum alloy: Higher cost

By choosing steel wheel weights, you invest in a product that delivers both immediate and long-term economic benefits.

Environmental Advantages

Steel rim wheel weights contribute to a more sustainable future. Steel has the lowest CO2 footprint among primary metals, making it an eco-friendly choice for wheel balancing. Approximately 75-85% of a wheel’s carbon footprint comes from raw materials, and steel’s efficient production process minimizes this impact.

Additionally, steel’s durability reduces waste. Fewer replacements mean fewer discarded materials, which helps conserve resources. Life Cycle Assessments (LCAs) further optimize the environmental impact of steel products, ensuring they meet sustainability goals throughout their lifespan.

| Evidence Type | Description |

|---|---|

| Weight Reduction | A reduction of 3 kg per wheel can increase payload by over 40 kg, enhancing fuel efficiency. |

| CO2 Footprint | Steel has the lowest CO2 footprint among primary metals, reducing emissions. |

| Life Cycle Assessment | LCAs analyze and optimize environmental impact, leading to lower emissions. |

By choosing steel wheel weights, you not only improve your vehicle’s performance but also contribute to a cleaner, greener planet.

Enhanced Vehicle Performance

Steel rim wheel weights play a vital role in enhancing your vehicle’s overall performance. Properly balanced wheels improve handling, reduce vibrations, and ensure a smoother driving experience. When your wheels are balanced, your tires make consistent contact with the road, which boosts traction and stability. This is especially important during sharp turns or sudden stops.

Balanced wheels also help you optimize performance by improving fuel efficiency. Uneven tire rotation increases rolling resistance, forcing your engine to work harder and consume more fuel. By using wheel weights to maintain balance, you reduce this resistance and save on fuel costs. Studies show that balanced wheels can improve fuel efficiency by up to 3%, which adds up over time.

Another benefit of steel rim wheel weights is their ability to enhance braking efficiency. Balanced wheels distribute weight evenly across the tires, allowing your brakes to perform at their best. This is crucial for safety, especially in emergency situations. For example, vehicles with balanced wheels experience shorter stopping distances, which can make a significant difference in avoiding accidents.

Steel rim wheel weights also contribute to better tire longevity. Imbalanced wheels cause uneven tire wear, which reduces the lifespan of your tires. By maintaining balance, you ensure that your tires wear evenly, extending their life and saving you money on replacements. This is particularly beneficial for vehicles that carry heavy loads, as balanced wheels minimize stress on the tires.

Tip: Regularly check your wheel weights during tire maintenance to ensure they remain securely attached. This simple step can prevent imbalances and keep your vehicle performing at its best.

In addition to these practical benefits, steel rim wheel weights improve ride comfort. Vibrations caused by imbalanced wheels can make driving unpleasant, especially on long trips. Balanced wheels eliminate these vibrations, providing a smoother and quieter ride. Whether you’re driving on highways or rough terrains, steel rim wheel weights ensure a more enjoyable experience.

By choosing steel rim wheel weights, you invest in a solution that enhances every aspect of your vehicle’s performance. From fuel efficiency to braking and ride comfort, these weights deliver measurable improvements that make driving safer and more efficient.

Applications of Steel Rim Wheel Weights

Passenger Cars and SUVs

Steel rim wheel weights are essential for passenger cars and SUVs. They ensure your tires remain balanced, which improves handling and reduces vibrations. Balanced tires also prevent uneven wear, extending their lifespan and saving you money on replacements. For SUVs, which often carry heavier loads, steel weights provide the durability needed to maintain performance under stress.

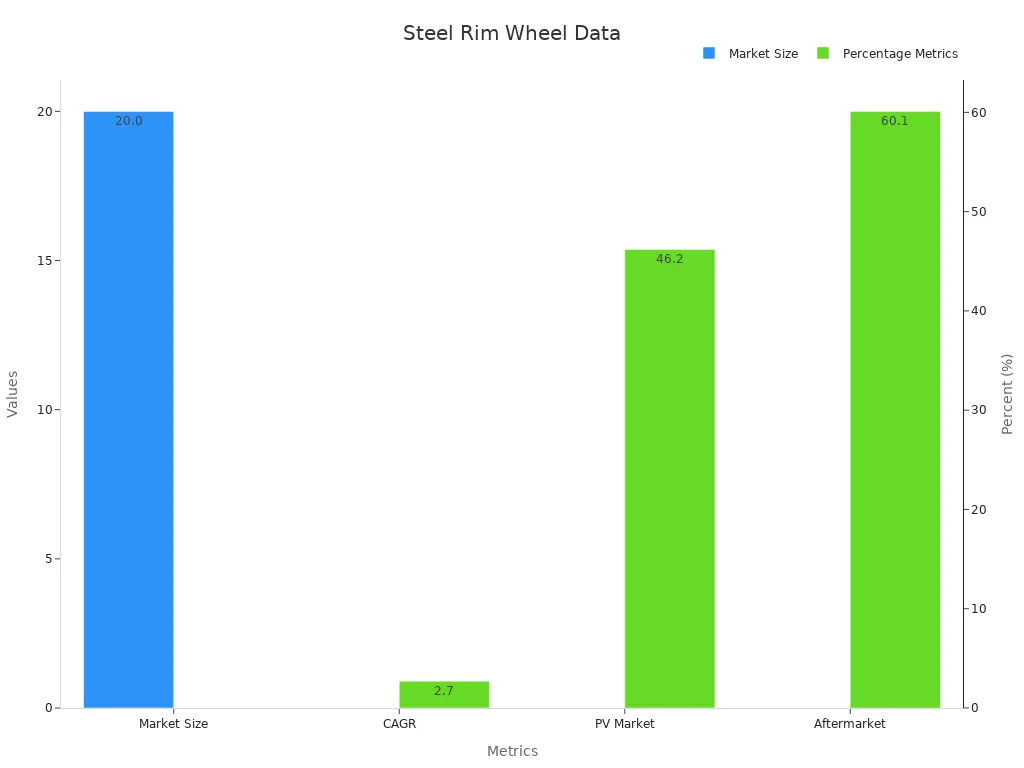

The automotive industry heavily relies on steel rim wheel weights for passenger vehicles. By 2024, passenger vehicles are expected to account for 46.2% of the market share, driven by high production volumes and global demand. The aftermarket segment will hold 60.1% of the share, reflecting the growing need for durable replacement wheels.

| Aspect | Details |

|---|---|

| Market Size Projection | USD 20.0 billion by 2034 |

| CAGR | 2.7% |

| Passenger Vehicle Market Share | 46.2% in 2024, driven by high production volumes and global demand |

| Aftermarket Segment Share | 60.1% in 2024, due to demand for durable replacement wheels |

Steel rim wheel weights are a reliable choice for passenger cars and SUVs. Their durability ensures consistent performance, even in extreme weather conditions. Whether you drive a compact car or a family SUV, these weights enhance safety and comfort.

Commercial and Heavy-Duty Vehicles

Steel rim wheel weights play a critical role in commercial and heavy-duty vehicles. These vehicles often operate under demanding conditions, carrying heavy loads and traveling long distances. Balanced wheels reduce the risk of understeering or oversteering, ensuring stability and safety during operation.

Steel rims paired with zinc weights offer a cost-effective solution for heavy-duty vehicles. They resist corrosion and maintain their performance over time. Balanced tires also optimize fuel efficiency, saving you money on fuel costs. Properly balanced wheels extend tire lifespan, reducing maintenance expenses.

| Evidence Description | Benefit |

|---|---|

| Steel rims paired with zinc weights offer a cost-effective and long-lasting solution for heavy-duty vehicles. | Cost-effectiveness and durability in performance. |

| Balanced tires extend their lifespan and optimize fuel efficiency. | Improved longevity and fuel savings. |

| Properly balanced wheels reduce the risk of understeering or oversteering. | Enhanced vehicle stability and safety. |

Steel rim wheel weights ensure your commercial vehicle performs efficiently, even under heavy loads. They improve handling, reduce vibrations, and enhance braking efficiency. For fleet operators, these benefits translate into lower operational costs and safer driving conditions.

Off-Road and Specialty Vehicles

Off-road and specialty vehicles demand robust solutions to handle challenging terrains. Steel rim wheel weights provide the durability needed for these applications. They maintain tire balance, ensuring your vehicle performs well on uneven surfaces. Balanced wheels improve traction, which is crucial for off-road adventures.

Specialty vehicles, such as construction equipment and agricultural machinery, benefit from steel weights due to their ability to withstand harsh environments. These weights resist corrosion and maintain their structural integrity, even in muddy or wet conditions. For off-road enthusiasts, steel rim wheel weights enhance safety by reducing vibrations and improving handling during extreme maneuvers.

Steel rim wheel weights are a versatile choice for off-road and specialty vehicles. They ensure your tires remain balanced, providing a smoother ride and better control. Whether you’re navigating rocky trails or working on a construction site, these weights deliver reliable performance.

Seasonal Tire Maintenance

Seasonal tire maintenance is essential for keeping your vehicle safe and performing at its best throughout the year. Different seasons bring unique challenges for your tires, and steel rim wheel weights play a crucial role in ensuring your wheels remain balanced during these transitions.

Why Seasonal Maintenance Matters

Temperature changes can significantly impact your tires. In colder months, the air inside your tires contracts, reducing tire pressure. This can lead to imbalances that affect handling and fuel efficiency. During warmer months, higher temperatures cause tire pressure to increase, which may result in uneven wear. Regularly checking and balancing your wheels helps you avoid these issues.

Tip: Always check your tire pressure when the seasons change. Properly inflated tires improve safety and extend their lifespan.

How Steel Rim Wheel Weights Help

Steel rim wheel weights ensure your tires stay balanced, regardless of seasonal changes. Balanced wheels reduce vibrations, improve traction, and enhance braking efficiency. This is especially important during winter when icy roads demand maximum stability. In summer, balanced wheels prevent excessive heat buildup, which can damage your tires.

Seasonal Maintenance Checklist

Here’s a quick checklist to keep your wheels in top shape year-round:

- Inspect Tire Pressure: Adjust pressure according to seasonal recommendations.

- Check for Imbalances: Look for signs like uneven tire wear or vibrations.

- Replace Worn Weights: Ensure your steel rim wheel weights are securely attached and free from corrosion.

- Rotate Tires: Rotate your tires every 5,000 to 7,500 miles to promote even wear.

| Season | Key Maintenance Task |

|---|---|

| Winter | Check for ice buildup and low pressure. |

| Summer | Inspect for heat damage and overpressure. |

| Spring/Fall | Rotate tires and inspect wheel weights. |

By following these steps, you can maximize the lifespan of your tires and maintain a smooth, safe driving experience. Steel rim wheel weights are a reliable partner in seasonal tire care, ensuring your vehicle performs optimally in any weather.

How to Choose and Use Steel Rim Wheel Weights

Factors to Consider When Choosing Wheel Weights

Selecting the right steel rim wheel weights depends on several factors. You need to consider durability, performance, and how the weights align with your vehicle’s needs. For example, if you frequently drive on rough terrain, choose weights that can handle high-stress conditions without compromising their integrity.

Lightweight options can improve your vehicle’s suspension performance and steering precision. Heavier weights, while durable, may slightly affect acceleration and braking efficiency. Consulting a professional can help you make the best choice based on your driving habits and vehicle type.

| Factor | Description |

|---|---|

| Durability | Wheels must withstand high-stress conditions, especially during demanding maneuvers or rough terrain. |

| Performance | Heavier wheels may sacrifice performance, affecting acceleration, braking, and steering efficiency. |

| Lightweight Benefits | Reduces unsprung and rotational weight, improving suspension performance and steering precision. |

| Professional Guidance | Experts can recommend wheels that align with driving habits, vehicle type, and performance goals. |

By evaluating these factors, you can ensure your wheel weights meet your performance and durability needs.

Installation Techniques for Clip-On and Adhesive Weights

Proper installation of steel rim wheel weights is crucial for maintaining tire balance. Clip-on and adhesive weights require different techniques to ensure they stay securely attached.

For adhesive weights, clean the rim surface thoroughly before installation. A clean and flat surface ensures the adhesive bonds properly, providing long-lasting performance. Clip-on weights, on the other hand, need a secure clamp. Prepare the rim surface by removing dirt and debris, then attach the weight firmly to prevent detachment.

- Adhesive Weight Mounting Method: Clean and prepare the surface for optimal adhesion, ensuring a strong bond.

- Clip-On Weight Mounting Technique: Requires thorough rim surface preparation and regular inspections to maintain balance.

Follow these steps for effective installation:

- Adhesive Method: Ensure a clean and flat surface for peak adhesion.

- Clip-On Method: Clean the rim surface and clamp securely for maximum stability.

- Regular Inspections: Check for wear or detachment to maintain balance.

These techniques not only improve tire life but also enhance driving comfort by reducing vibrations.

Avoiding Common Mistakes

Avoiding common mistakes during installation and maintenance can save you time and money. One frequent error is neglecting to clean the rim surface before attaching weights. Dirt and debris can weaken the bond, causing the weights to detach. Another mistake is using the wrong type of weight for your vehicle, which can lead to imbalances and reduced performance.

Regular maintenance is equally important. Inspect your wheel weights periodically to ensure they remain securely attached. Pay attention to signs of wear or corrosion, as these can affect their effectiveness. Proper maintenance practices, such as following flange climb derailment criteria and using accurate measurement techniques, can prevent issues and extend the lifespan of your weights.

Tip: Always consult your vehicle’s manual or a professional to ensure you’re using the correct weights and installation methods.

By avoiding these mistakes, you can maintain optimal tire balance and ensure a smoother, safer driving experience.

Maintenance Tips for Longevity

Proper maintenance ensures your steel rim wheel weights last longer and perform effectively. Follow these tips to keep your wheel weights in excellent condition:

1. Inspect Regularly

Check your wheel weights during routine tire maintenance. Look for signs of wear, corrosion, or detachment. Loose weights can cause imbalances, leading to uneven tire wear and reduced vehicle performance. If you notice any issues, replace the weights immediately.

Tip: Perform inspections every time you rotate your tires or change them seasonally. This helps you catch problems early.

2. Clean the Rims

Dirt and debris can weaken the bond between adhesive weights and the rim. Use a soft cloth and mild cleaner to remove grime from the rim surface. For clip-on weights, ensure the rim edges are free of rust or buildup. Clean rims improve the adhesion and stability of your weights.

3. Avoid Harsh Chemicals

Some cleaning products can damage the protective coating on coated steel weights. Use cleaners specifically designed for automotive rims. This prevents corrosion and extends the lifespan of your weights.

4. Monitor Tire Pressure

Imbalanced tires often result from incorrect tire pressure. Check your tire pressure monthly and adjust it to the recommended levels. Proper pressure reduces stress on your wheel weights and ensures even tire rotation.

| Maintenance Task | Frequency | Benefit |

|---|---|---|

| Inspect wheel weights | Every tire rotation | Prevents detachment and wear |

| Clean rims | Monthly | Improves adhesion and stability |

| Check tire pressure | Monthly | Reduces stress on weights |

5. Replace Damaged Weights

Damaged weights compromise tire balance. Replace weights showing signs of rust, cracks, or deformation. Always choose high-quality steel rim weights to ensure durability and performance.

Note: Using inferior weights can lead to frequent replacements and reduced vehicle safety.

By following these maintenance tips, you can maximize the lifespan of your steel rim wheel weights and maintain optimal tire balance. Regular care not only saves you money but also enhances your driving experience.

Steel rim wheel weights are essential for maintaining proper wheel balancing, which directly impacts your vehicle’s safety and performance. They minimize vibrations, improve handling, and prevent uneven tire wear, ensuring a smoother and more stable ride. These benefits not only enhance driving comfort but also extend the lifespan of your tires, saving you money in the long run.

The growing importance of steel rim wheel weights is reflected in market trends.

| Metric | Value |

|---|---|

| Current Market Size | US$ 727.8 million (2024) |

| Projected Market Size | US$ 1.35 billion (2034) |

| CAGR | 6.4% |

By choosing steel rim wheel weights, you also contribute to a sustainable future. Their durability reduces waste, and their eco-friendly production process minimizes environmental impact. Whether you drive a passenger car, SUV, or heavy-duty vehicle, these weights ensure optimal performance across all terrains and conditions.

Tip: Consider steel rim wheel weights during your next tire maintenance to experience their durability, cost-effectiveness, and eco-friendliness firsthand.

FAQ

What are steel rim wheel weights used for?

Steel rim wheel weights balance your tires. They reduce vibrations, improve handling, and prevent uneven tire wear. Balanced tires enhance safety and extend their lifespan, saving you money on replacements.

How do I know if my wheels need balancing?

Look for signs like vibrations in the steering wheel, uneven tire wear, or reduced fuel efficiency. These issues indicate imbalanced wheels. Regular inspections help you catch these problems early.

Can I install steel rim wheel weights myself?

You can install adhesive weights by cleaning the rim and applying them securely. Clip-on weights require proper clamping. If unsure, consult a professional to ensure accurate installation.

Are steel rim wheel weights eco-friendly?

Steel weights are eco-friendly due to their durability and low CO2 footprint. They reduce waste by lasting longer and minimizing replacements. Choosing steel weights supports sustainability.

How often should I check my wheel weights?

Inspect your wheel weights during tire rotations or seasonal maintenance. Check for signs of wear, corrosion, or detachment. Regular inspections ensure your wheels stay balanced and perform optimally.