admin1

August 7, 2025

Schrader Valve Stem Types and How to Pick the Right One

Choosing the right Schrader valve stem helps keep your tires safe and reliable. You will find that most passenger cars use rubber snap-in valves for their tire valve needs. These rubber snap-in valves work well for daily driving and fit rim holes of either 0.453 or 0.625 inches. Trucks and heavy-duty vehicles often need a high-pressure stem because their tires can reach up to 100 PSI. If you drive a high-speed car, you may need a high-performance tire valve. Always check if your stem matches your tire and wheel. Make sure your Schrader valve stem fits your tire valve and supports your driving style.

Tire Valve Stem Types: Understanding Your Options

When you look at the different tire valve stem types, you will see that each one has a special purpose. Picking the right stem helps your tires stay safe and last longer. Let’s explore the main types of tire valve stems you might find on your vehicle.

Rubber Snap-In Schrader Valve Stems

Rubber snap-in valves are the most common type you will see on passenger cars and light trucks. You push these stems into the rim hole, and the rubber body holds them in place. Most rubber snap-in Schrader valve stems fit rim holes of either 0.453 inches or 0.625 inches. These stems can handle up to 65 psi, which works well for daily driving.

Quality rubber snap-in valves use EPDM synthetic rubber. This material stands up to heat, cold, ozone, and chemicals. It stays flexible in winter and resists cracking. You should replace these stems every time you change your tires to prevent leaks. If you use low-quality stems made from natural rubber, they may become brittle and leak after two years.

Tip: Always check the pressure rating on your tire valve stem. Using the wrong type can lead to leaks or even tire failure.

Metal Clamp-In Schrader Valve Stems

Metal clamp-in valves give you extra strength and durability. You will find these stems on high-speed cars, racing vehicles, and heavy-duty trucks. They use a metal body, a rubber grommet, and a retaining nut to clamp tightly to the wheel. This design lets them handle up to 200 psi, making them perfect for high-performance tires.

You can use metal clamp-in valves on almost any wheel, including passenger cars, trailers, and racing vehicles. They come in many sizes and shapes, such as straight, bent, or low-profile. Some versions work with tire pressure monitoring systems (TPMS). You should replace metal clamp-in valves every two years if you drive at high speeds or on tracks.

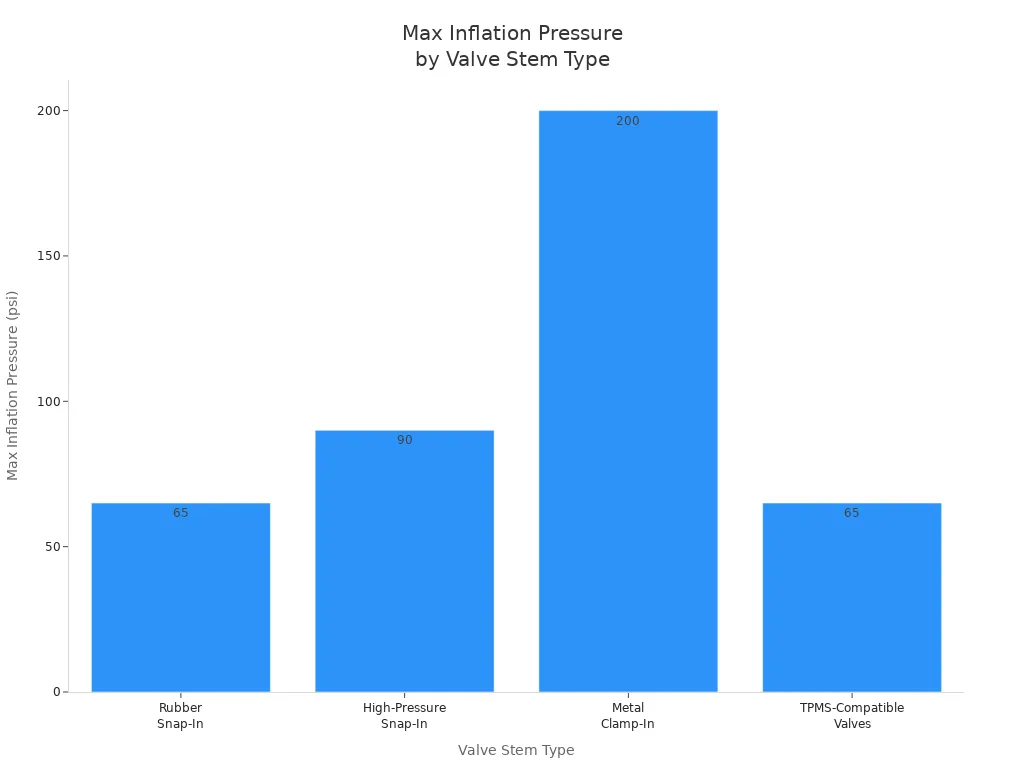

| Valve Stem Type | Construction Features | Max Inflation Pressure (psi) | Typical Applications | Additional Notes |

|---|---|---|---|---|

| Rubber Snap-In | Rubber body that snaps into rim hole | 65 | Passenger cars, light trucks, autocross | Fits .453″ or .625″ rim holes; plastic or metal caps available |

| High-Pressure Snap-In | Thicker rubber base with metal barrel | 80-100 | Medium/heavy trucks, trailers | Used in steel wheels; fits .453″ (80 psi) or .625″ (100 psi) holes |

| Metal Clamp-In | Metal valve with rubber grommet and retaining nut clamp | 200 | High-speed, track use, heavy-duty applications | Fits various hole sizes; retaining nut can be inside or outside wheel; available in straight/bent |

| TPMS-Compatible Valves | Special metal clamp-in or rubber snap-in with threaded insert | Matches base valve type | Anchoring tire pressure monitoring sensors | Designed to attach sensor/transmitter bolts |

High-Pressure and Heavy-Duty Schrader Valve Stems

High-pressure snap-in valves and heavy-duty stems are made for trucks, trailers, and vehicles that carry heavy loads. These stems use a thicker rubber base and sometimes a metal barrel. They fit steel wheels and can handle between 80 and 100 psi. You should use these stems if your tires need higher pressure for safe operation.

You will also find that some high-pressure stems are metal clamp-in valves. These offer even more strength and are best for vehicles that travel at high speeds or carry very heavy loads. Always match the stem to your tire’s pressure needs and your driving style.

Note: Using the correct types of tire valve stems helps prevent leaks and keeps your tires performing at their best.

TPMS-Compatible Schrader Valve Stems

You may notice that many modern vehicles use tire pressure monitoring systems. These systems help you stay safe by alerting you when your tire pressure drops too low. To work correctly, tire pressure monitoring systems need special valve stems. You cannot use just any valve stem if your car has this technology.

TPMS-compatible Schrader valve stems come in two main types. You will find metal clamp-in stems and rubber snap-in stems. Both types have a threaded insert or a special mounting point. This design lets you attach the sensor for the tire pressure monitoring system. The sensor sits inside the tire, connected to the valve stem. It measures the air pressure and sends the data to your dashboard.

You should always check your vehicle’s manual before choosing a TPMS-compatible valve stem. Some vehicles need a specific type or size. Using the wrong stem can cause the sensor to fail or give false readings. You may also see a warning light on your dashboard if the system does not detect the sensor.

Tip: Always replace the TPMS valve stem when you change your tires or sensors. Old stems can crack or leak, which may cause the tire pressure monitoring system to stop working.

Here is a quick comparison of TPMS-compatible valve stems:

| Type | Material | Sensor Mount | Typical Use | Notes |

|---|---|---|---|---|

| Metal Clamp-In | Metal | Threaded | Most vehicles | High durability |

| Rubber Snap-In | Rubber | Threaded | Some passenger cars | Easier to install |

You can find TPMS-compatible Schrader valves at most auto parts stores. Make sure you pick the right one for your vehicle. This choice keeps your tire pressure monitoring systems working and helps you drive safely. 🚗

How to Identify the Right Schrader Valve Stem for Your Vehicle

By Vehicle Category: Cars, Trucks, Motorcycles, and More

You need to match your tire valve stem to your vehicle type. Each category has its own requirements for size, material, and pressure. For example, cars and light trucks usually use a 10mm diameter stem with a length around 32mm. These stems often come in steel, aluminum, or composite materials. Trucks and larger vehicles need a 12mm diameter and longer stems, such as 45mm or 60mm. These vehicles face more vibration and load, so you should choose stainless steel or brass for extra durability.

Motorcycles require a different approach. Their stems often measure 17mm in diameter, and the length depends on the tire design. You may see straight or 90-degree angled stems for easier access. Specialty vehicles, like ATVs or heavy machinery, use robust stems made from high-quality materials. These stems must handle harsh environments and higher pressures.

Here is a table to help you compare the main factors for each vehicle category:

| Factor | Cars and Light Trucks | Trucks and Larger Vehicles | Motorcycles | Specialty Vehicles (ATVs, Heavy Machinery) |

|---|---|---|---|---|

| Diameter | Typically 10mm | Typically 12mm | Typically 17mm | Varies; often robust sizes to fit specific wheels |

| Length | Around 32mm | Longer stems: 45mm or 60mm | Varies depending on tire design | Longer lengths to accommodate design and access |

| Material | Steel, Aluminum, Composite, Stainless Steel | Stainless steel or brass for durability | Steel or Aluminum; depends on riding conditions | Stainless steel or brass for harsh environments |

| Max Pressure | Around 8 bar (116 psi) | Up to 12 bar (174 psi) or more | Must withstand high-speed conditions | Up to 20 bar for demanding applications |

| Thread Type | ISO or Stud threads | Stud threads for vibration resistance | Standardized for motorcycle rims | Robust thread types for secure fit |

| Compatibility | Must match wheel valve hole size | Must fit larger valve holes | Must fit tire and rim design | Designed for specific wheel and tire types |

| Maintenance & Installation | Easy installation and tool availability | Secure installation needed | Proper installation and inspection | Regular checks and proper installation |

You can see that each vehicle type needs a specific tire valve to ensure safety and performance.

By Driving Conditions: Daily, Off-Road, High-Speed, Heavy Load

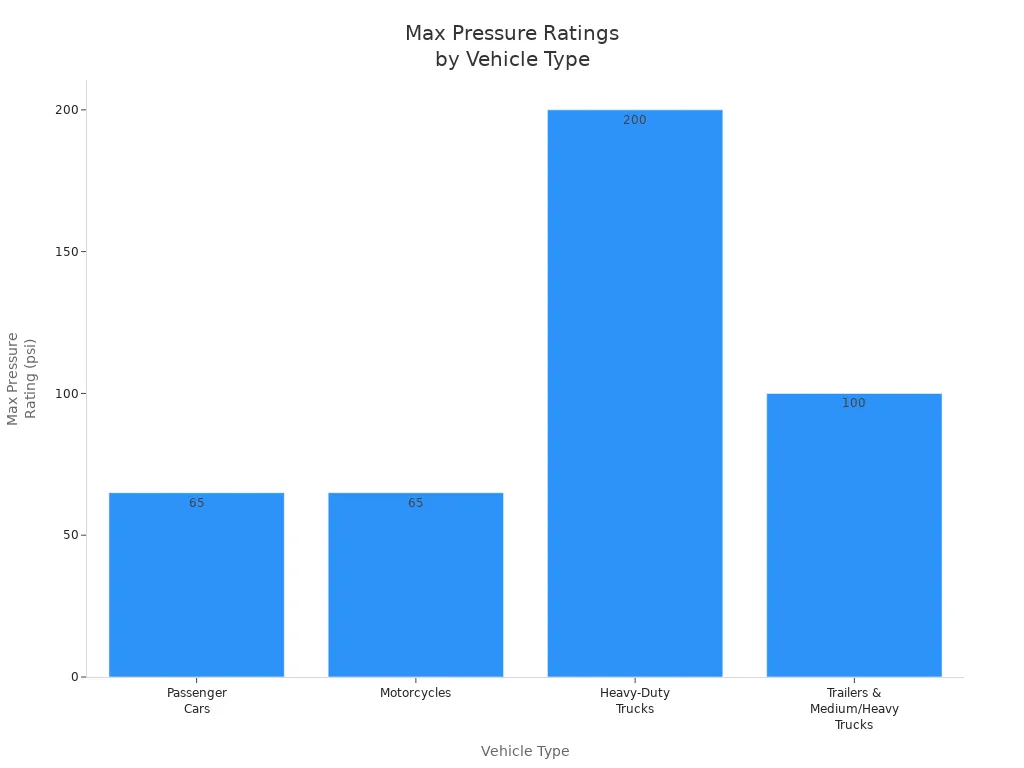

Your driving conditions play a big role in choosing the right stem. If you drive daily on city roads, a rubber snap-in tire valve works well. These stems handle up to 65 psi and fit most passenger cars and motorcycles. For off-road adventures, you need a stem that resists dirt and impact. Many off-road vehicles use tubeless valves with strong seals to keep out debris.

High-speed driving puts more stress on your tire valve. Metal clamp-in stems offer better strength and can handle up to 200 psi. Heavy-duty trucks and trailers also need high-pressure stems. These often come with 45-degree angles for easier access and fit larger rim holes. Proper fit and installation prevent air leaks and keep your tires safe.

Here is a quick list of recommended tire valve types for different vehicles and uses:

- Passenger cars and motorcycles: Rubber snap-in stems, up to 65 psi, straight or 90-degree angle.

- Heavy-duty trucks: Metal clamp-in stems, up to 200 psi, straight or 45-degree angle.

- Trailers and medium/heavy trucks: High-pressure snap-in stems, 80–100 psi, straight angle.

- Off-road vehicles: Tubeless valves with strong seals, often 90-degree angle for easy inflation.

Tip: Always match your tire valve to your driving style and environment. This helps prevent leaks and extends tire life.

By Wheel and Tire Specifications

You must also consider your wheel and tire setup. The rim hole size determines which stem fits. Most passenger car wheels use a 0.453-inch or 0.625-inch hole. Trucks and trailers often use the larger size. Motorcycles may use a smaller hole, around 0.327 inches. Always check your rim before buying a new stem.

Tubeless tires need a special seal at the valve. Many tubeless valves use a rubber grommet or wedge to create an airtight fit. Conversion kits, like Stan’s NoTubes, let you adapt standard rims for tubeless use. These kits include rim tape and a valve stem with a wide rubber seal. The quality of the rim tape and the sealing method matter most for holding air. If your tire is tubeless-ready, you can use these kits for a secure fit.

Note: Always check if your tire and rim are compatible with tubeless setups. A good seal at the valve keeps your tire inflated and safe.

When you choose a Schrader valve stem, look at the tire valve hole size, the type of tire (tubeless or with a tube), and the pressure rating. This ensures a perfect fit and reliable performance.

Pros and Cons of Different Tire Valve Stem Types

Durability and Longevity

When you choose a tire valve, you want it to last as long as possible. Rubber snap-in valve stems usually last until you change your tires, which means their lifespan matches the life of two standard tires under normal use. You should replace them every time you get new tires to keep your wheels safe. Metal clamp-in valve stems can last longer, especially if you drive in normal conditions. If you drive in high-heat or track environments, you should replace metal stems every two years. High-pressure stems do not have a set lifespan, but you should always check them for signs of wear. The quality of the valve stem material plays a big role in how long it lasts. High-quality stems resist cracking and leaks, which helps your tires stay inflated and safe.

Cost and Value

You want to get the best value for your money when picking a tire valve. The cost of Schrader valve stems usually ranges from $3 to $7 for each stem, and about $5 for a replacement core. These stems are very durable and work with most standard pumps, making them a good choice for many types of bikes and vehicles. The table below shows how Schrader valves compare to other types:

| Valve Type | Cost Range | Durability | Compatibility | Notes |

|---|---|---|---|---|

| Schrader | $3 – $7 | Very durable | Standard pumps, car compressors | Good value for mountain and hybrid bikes |

| Presta | $5 – $10 | Long-lasting | Needs special pump or adapter | Lighter, for high-pressure road bikes |

| Tubeless | $8 – $15 | Durable | Tubeless systems only | More expensive, but can be replaced alone |

Schrader valves offer a balance of low cost and high quality, especially for vehicles that do not need high-pressure inflation.

Installation and Replacement

You will find that installing and replacing a Schrader tire valve is simple. Most Schrader valves come in one standard length and use a spring-loaded poppet valve. To inflate your tire, remove the cap, attach the air chuck, and fill to the right pressure. You only need basic tools, such as an air chuck or CO2 inflator. Deflating the tire is easy—just press the center button with a pointed tool. Always replace the valve cap to keep dirt out. Presta valves need more steps and special adapters, which makes them harder to install. Tubeless valves require careful sealing to prevent leaks. If you want a quick and easy process, Schrader valves are a great choice.

Tip: Always check the quality of your tire valve before installation. A good valve keeps your tire pressure steady and your ride safe.

Maintenance and Upkeep

You need to check your Schrader valve stems regularly to keep your tires safe. Dirt, dust, and road salt can build up around the valve. This buildup can cause leaks or make the valve hard to use. You should clean the valve area with a soft brush or cloth every time you wash your car. If you see cracks or splits in the rubber, replace the valve stem right away.

Air leaks can happen if the valve core gets loose. Use a valve core tool to tighten it. If you still hear air escaping, replace the core. Always keep a valve cap on each stem. The cap keeps out dirt and moisture. Without a cap, the valve can get clogged or corroded.

Check your tire pressure at least once a month. Use a reliable gauge for the best results. Low pressure can damage your tires and make your car less safe. If you drive in extreme heat or cold, check the pressure more often. Temperature changes can cause the air inside your tires to expand or contract.

If your vehicle uses a tire pressure monitoring system (TPMS), inspect the sensor and stem during every tire change. Make sure the sensor stays tight and the stem shows no signs of damage. Replace the stem if you see rust or corrosion on metal parts.

Choose valve stems made from high-quality materials. These stems last longer and resist damage from weather and chemicals. Quality stems help you avoid leaks and keep your tires in top shape.

Tip: Keep a spare valve core and cap in your glove box. Quick repairs on the road can save you time and trouble.

Common Mistakes When Choosing a Schrader Valve Stem

When you pick a Schrader valve stem, you want to avoid common mistakes that can lead to leaks, sensor problems, or even tire damage. Paying attention to details helps you keep your tires safe and your vehicle running smoothly.

Compatibility Issues with Wheels and Tires

Many people choose the wrong tire valve size or type for their wheels. If you select a valve stem that is too large or too small, it may not fit the rim hole correctly. This can cause air leaks or even damage the rim. Schrader valves have a wider diameter than Presta valves, so they need a larger hole in the rim. Forcing a Schrader valve into a rim made for a Presta valve can weaken the rim and make it unsafe. You also need to check the length and angle of the valve stem. If the stem is too short, you may have trouble inflating the tire. If it is too long or at the wrong angle, it may not seal properly.

Tip: Always match the tire valve size and shape to your wheel and tire setup. This helps prevent leaks and rim damage.

Overlooking TPMS Requirements

Tire pressure monitoring systems are important for modern vehicles. If you ignore the needs of these systems, you may face sensor errors or warning lights on your dashboard. Some valve stems are not compatible with tire pressure monitoring systems. For example, you need to keep a small gap between the sensor and the valve stem—about 0.25mm. If you do not, the sensor may not work. Using the wrong material or not checking the O-ring seals can also cause problems. Always check your vehicle manual to make sure the valve stem works with your tire pressure monitoring systems.

Ignoring Environmental and Usage Factors

You should think about how and where you drive. If you use your vehicle for heavy loads or off-road trips, you need a strong valve stem made from metal or high-quality rubber. Using the wrong material can lead to cracks or leaks, especially in extreme weather. Not checking the pressure rating or thread type can also cause trouble. For example, if you use a valve stem with a low pressure rating on a heavy-duty tire, it may fail. Always inspect your tire valve for damage before installing it. Look for bent, cracked, or worn parts.

- Common mistakes include:

- Picking the wrong size or length for your tire valve.

- Forgetting to check for TPMS compatibility.

- Using the wrong material for your driving conditions.

- Not inspecting for damage or leaks before installation.

By avoiding these mistakes, you help your tires last longer and keep your vehicle safe.

Step-by-Step Guide to Choosing and Installing the Right Schrader Valve Stem

How to Choose the Correct Valve Stem for Your Vehicle

When choosing a tire valve, you want to make sure it matches your vehicle’s needs. Start by checking your wheel’s valve hole size. Most passenger cars use a 0.453-inch hole, while trucks and heavy-duty vehicles often use a 0.625-inch hole. Next, look at your tire’s maximum pressure. If you drive a car for daily use, a rubber snap-in valve stem works well. For trucks or vehicles that carry heavy loads, select a metal clamp-in or high-pressure snap-in stem.

You should also consider if your vehicle uses a tire pressure monitoring system (TPMS). Some stems are designed to work with TPMS sensors. Always check your owner’s manual for the correct type. If you drive in extreme temperatures or rough conditions, pick a valve stem made from corrosion-resistant materials like nickel-plated brass. This helps prevent rust and keeps your tires safe.

Tip: Properly inflated tires last longer and help you drive safely. The right valve stem makes checking tire pressure and inflating tires much easier.

How to Install a Schrader Valve Stem Safely

Installing a Schrader valve stem is simple if you follow the right steps. Use this checklist to make sure you do it safely:

- Inspect the valve hole for damage or corrosion. Clean the area before you begin.

- Choose a valve stem that fits the hole diameter, usually about 9.7 mm for most cars.

- Insert the valve stem into the hole. Apply a steady force of about 20 lbs to snap it in place.

- Check that the valve stem sits straight. The bend should be less than 5 degrees.

- Tighten the valve core to a torque of 0.2 Nm (about 5 in-lbs) to prevent leaks.

- Attach the valve cap and make sure it seals at 25 PSI.

- After driving 50 miles, check the valve core and wheel bolts for tightness.

- Inspect the valve threads and sealing surfaces for signs of wear or corrosion.

- Make sure the valve stem can handle the temperature range of -40°F to 250°F.

- Use a valve stem with a tensile strength of around 1000 PSI for durability.

Note: Regularly inspect your valve stems and caps. Clean threads and undamaged caps help prevent leaks and keep your tires in top condition.

By following these steps, you help ensure your valve stem works well and your tires stay safe.

Choosing the right Schrader valve stem keeps your tires safe and your vehicle running smoothly. You should always match the stem type to your vehicle, driving style, and wheel setup. Check for TPMS compatibility and think about your driving environment. Use this quick-reference table and checklist to help you decide:

| Valve Stem Type | Best For | Pressure Rating (PSI) | Rim Hole Size (inches) |

|---|---|---|---|

| Rubber Snap-In | Passenger cars, daily driving | Up to 65 | 0.453, 0.625 |

| High-Pressure Snap-In | Trucks, trailers, heavy loads | 80–100 | 0.453, 0.625 |

| Metal Clamp-In | Racing, high-speed, TPMS | Up to 200 | 0.453, 0.625 |

Quick-Reference Checklist:

- ✅ Check your rim hole size and pressure needs.

- ✅ Confirm TPMS compatibility.

- ✅ Pick a stem that matches your driving style and environment.

- ✅ Inspect for proper fit and quality before installation.

Tip: The right valve stem helps you drive safer and keeps your tires lasting longer.

FAQ

What is the main difference between rubber snap-in and metal clamp-in Schrader valve stems?

Rubber snap-in stems use flexible rubber and fit most passenger cars. Metal clamp-in stems use metal and a nut for a tighter seal. You should use metal stems for high-speed or heavy-duty vehicles.

How often should you replace your Schrader valve stems?

You should replace rubber snap-in stems every time you change your tires. Metal clamp-in stems last longer, but you should check them for damage or corrosion at every tire change.

Can you use any Schrader valve stem with a TPMS sensor?

No, you need a TPMS-compatible valve stem. These stems have special threads or mounts for the sensor. Always check your vehicle manual to find the correct type.

What happens if you use the wrong valve stem size?

If you use the wrong size, the stem may not seal properly. This can cause air leaks or even damage your wheel. Always match the stem size to your rim hole.

How do you know if your valve stem is leaking?

You can spray soapy water on the valve stem. If you see bubbles, air is leaking. Replace the stem or the valve core to fix the problem.