admin1

August 8, 2025

Are Rubber Valve Stems Better Than Metal Valve Stems for Tire Safety in 2025

When you think about tire safety, rubber valve stems stand out in 2025. You get better protection from corrosion because rubber does not rust or weaken like metal. If you bump a curb or hit debris, the rubber can flex without breaking. Many drivers find that rubber valve stems make it easier to keep tires in top shape. You can trust rubber to hold air and keep your ride safe every day.

Rubber Valve Stems vs. Metal Valve Stems: Safety Features

Durability and Lifespan

When you look at how long valve stems last, you notice some clear differences. Rubber valve stems give you flexibility and are easy to install. Most drivers find that rubber stems last as long as their tires. You can expect them to hold up well for regular street driving. Over time, though, rubber can dry out, crack, or harden, especially if you drive in hot or sunny places. This slow wear usually takes years, often longer than the life of your tires.

Metal valve stems, especially those made from brass or aluminum, offer more strength and can last up to ten years or more if you take care of them. These stems work well for heavy-duty vehicles and high-performance cars. They resist heat and pressure better than rubber. However, you need to check them for corrosion, especially if you drive in wet or salty conditions. If you keep them clean and dry, metal stems can outlast rubber ones. Still, both types need replacement after years of use or if you spot any damage.

- Rubber valve stems: Flexible, easy to install, usually last as long as your tires.

- Metal valve stems: Strong, long-lasting, best for heavy-duty or high-performance use, but need regular checks for corrosion.

Resistance to Corrosion and Weather

You want your valve stems to stand up to all kinds of weather. Rubber snap-in valve stems do not rust, so you do not have to worry about corrosion from rain, snow, or salty roads. This makes them a great choice if you live in a place with lots of moisture or road salt. Many car makers now use rubber snap-in stems instead of aluminum clamp-in valve stems because rubber handles harsh weather better.

Aluminum clamp-in valve stems can corrode over time, especially if you drive where salt or sand is common. Corrosion can cause the stem to stick to the wheel rim, which may lead to slow leaks or broken parts. Aluminum stems need more care and regular service kits to keep them working right. Even though rubber does not corrode, it can still suffer from sun and heat. UV rays can make rubber brittle and cause cracks, so you should check your stems if you park outside a lot.

Tip: Always replace the service kit when you change your tires. This helps prevent leaks and keeps both rubber and aluminum stems working well.

Vulnerability to Damage and Leaks

Both rubber and metal valve stems can develop leaks, but the reasons are different. Rubber stems often crack from extreme temperatures or get damaged if the valve cap is missing. Dirt and moisture can get inside, leading to slow leaks or even sudden air loss. If you see cracks or feel that the rubber is stiff, it is time to replace the stem.

Metal valve stems, including those made from aluminum, can leak if they corrode. Sometimes, the metal valve cap reacts with the stem, causing it to break or stick. This is a bigger risk if you use metal caps instead of plastic ones. Metal stems are also less flexible, so a hard hit from a curb or debris can cause damage. If you use a tire pressure monitoring system (tpms), metal stems are often preferred because they handle the sensors better and resist deflection.

- Common problems for rubber: Cracks, missing caps, air leaks from aging.

- Common problems for metal: Corrosion, broken parts from metal cap reactions, leaks from improper installation.

A driver once shared that after a few hours of driving, a rubber valve stem started leaking due to flexing. Switching to a metal valve stem solved the problem, especially when using tpms sensors.

No matter which type you choose, regular inspection and using plastic valve caps can help prevent most leaks. If you spot any damage, replace the valve stem right away to keep your tires safe.

Maintenance and Common Issues with Rubber Valve Stems and Metal Valve Stems

Maintenance Needs for Rubber Valve Stems

You want your tires to stay safe, so checking your rubber valve stems should be part of your routine. Manufacturers suggest inspecting rubber stems about once a month, especially when you check your tire tread or rotate your tires. If you spot cracks or discoloration, that’s a sign the stem needs attention. You can clean the stems with a damp cloth to remove dirt. Using plastic valve caps helps keep out moisture and dust, which can cause slow air leaks. Once a year, you might apply a light coat of silicone-based lubricant to extend the life of the rubber. If you park outside, sunlight and weather can wear down the rubber faster, so storing your car in a garage or under a cover helps. When you buy new tires, ask the shop to inspect and replace the valve stems if needed.

Tip: Handle valve stems gently when checking tire pressure. Avoid pushing sideways, which can damage the rubber and lead to leaks.

Maintenance Needs for Metal Valve Stems

Metal valve stems need a different kind of care. You should inspect them regularly for cracks, corrosion, or damage, especially if you drive in wet or salty conditions. Always use plastic valve caps because metal caps can stick to the stem and cause corrosion. When you change tires, have a professional check the sealing components like grommets or O-rings. Proper installation is key—using the right torque keeps the stem sealed and prevents slow air leaks. If you own a truck or SUV, make sure the valve cores are rated for high temperatures. Lubricating the threads and O-rings with anti-corrosive compounds helps protect against rust. Never use pliers or grips that can crimp the stem during installation.

Common Problems and Tire Safety Impact

Both rubber and metal valve stems can develop problems that affect your safety. Rubber stems often crack from heat, sunlight, or age, which leads to slow air leaks or even sudden deflation. Metal stems are tough but can corrode, especially in winter when road salt is everywhere. If a valve cap is missing, dirt and moisture can get inside, causing leaks and making it hard to inflate your tires. Sometimes, metal caps fuse with the stem, which complicates air checks. Improper installation can also cause poor sealing and slow air leaks. If a stem breaks off, you can’t fill the tire with air, which puts you at risk for a flat or blowout. Regular inspections and timely replacement keep your tires safe and help you avoid these issues.

How Valve Stem Choice Affects Tire Performance and Longevity

Air Retention and Pressure Stability

You want your tires to keep the right amount of air. The material of your valve stem plays a big role in this. Rubber valve stems use flexible seals that fit tightly, but they can wear out over time, especially in hot or cold weather. If the rubber dries out or cracks, you might notice slow leaks. Metal valve stems, on the other hand, resist heat and pressure better. They use nickel-plated valve cores, which help prevent corrosion and keep a strong seal. This means you lose less air over time.

If you use a tire pressure monitoring system (tpms), metal valve stems are often the best choice. They work well with sensors and help keep your tire pressure steady. When you replace your tires, ask for new rubber seals and grommets. Old seals can lose their “memory” and let air escape. Keeping your valve stems in good shape helps your tires last longer and keeps you safe on the road.

Tip: Check your tire pressure every month. If you see a drop, inspect your valve stems for cracks or corrosion.

Effects on Tire Wear and Performance

Valve stems do more than just hold air. They affect how your tires wear and how your car handles. If your valve stem leaks, your tire loses pressure. Low pressure makes your tire wear out faster and can cause uneven tread. You might feel your car pull to one side or notice poor grip on wet roads.

Here are some differences you should know:

- Rubber valve stems work well for normal driving and keep costs low. They handle tire pressures up to 65 PSI, which is perfect for most cars and light trucks.

- Metal valve stems are stronger and last longer. They handle higher pressures, so they are great for trucks, motorhomes, and sports cars. You get better performance and less risk of valve failure.

- If you drive in extreme heat or cold, metal stems resist damage better. Rubber stems may crack or harden, leading to leaks.

Keeping the right valve stem on your tires helps you avoid problems and keeps your car running smoothly.

Suitability for Different Driving Conditions

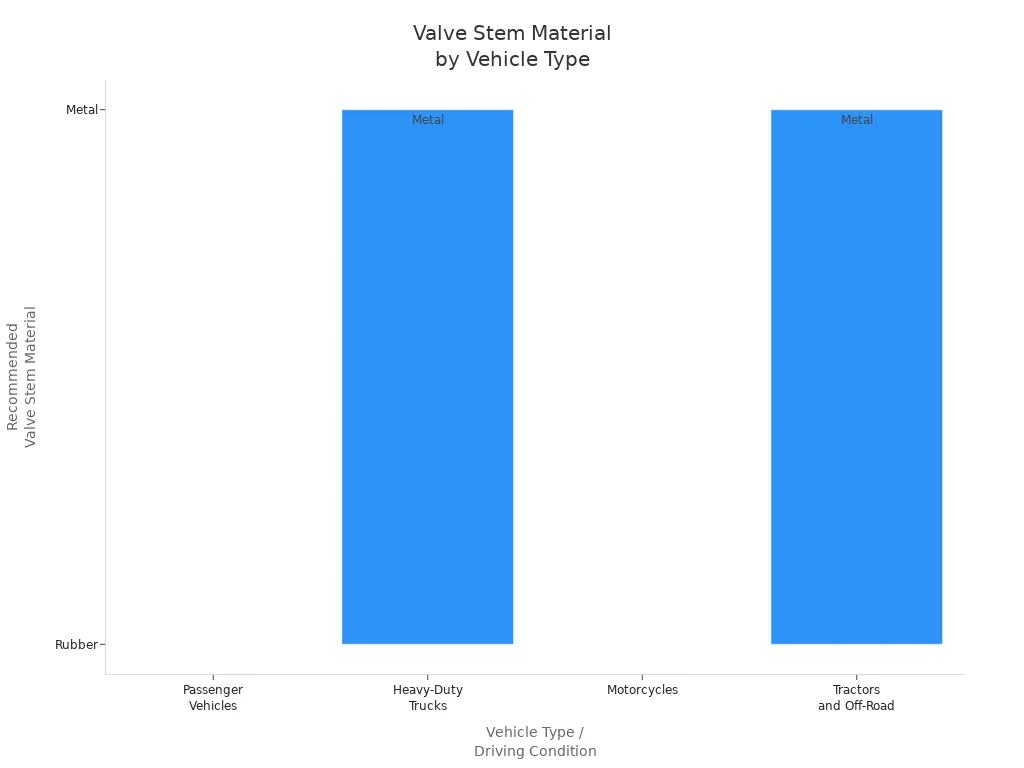

Not every valve stem fits every driving style. You need to match your valve stem to your vehicle and where you drive. Take a look at this table to see which type works best:

| Driving Condition / Vehicle Type | Recommended Valve Stem Material | Pressure Rating | Temperature Rating |

|---|---|---|---|

| Passenger Vehicles | Rubber valve stems | Up to 65 psi | -40°F to 180°F |

| Heavy-Duty Trucks | Metal valve stems | Up to 200 psi | -65°F to 250°F |

| Motorcycles | Rubber valve stems | Up to 65 psi | -40°F to 180°F |

| Tractors and Off-Road Vehicles | Metal valve stems | 100+ psi | Suitable for extreme temperatures |

You can also see how valve stem choice changes with driving conditions in this chart:

- Metal valve stems work best for high-speed driving, off-road adventures, and heavy-duty trucks. They stand up to rough roads and extreme temperatures.

- Rubber valve stems are perfect for everyday driving in passenger cars and motorcycles. They are flexible and easy to replace.

If you drive a sports car or a truck, you should choose metal valve stems for extra safety and durability. For city driving or short trips, rubber valve stems give you good performance at a lower cost.

Choosing the Right Valve Stem for Your Vehicle and Driving Needs

Passenger Cars vs. Trucks and SUVs

You might wonder if your car needs a different valve stem than a truck or SUV. The answer is yes! Each vehicle type has its own needs. Here’s a quick look:

| Aspect | Passenger Cars | Trucks and SUVs (Light/Heavy Duty) |

|---|---|---|

| Valve Stem Material | Rubber (flexible, affordable) | High-pressure snap-in or metal clamp-in |

| Pressure Rating | Up to 65 psi | Up to 95 psi or 200 psi (metal stems) |

| Rim Hole Diameter | 0.453 and 0.625 inches | Same, but thicker rims need metal stems |

| Temperature Rating | -40°F to 180°F | -65°F to 250°F |

| Durability Considerations | Good for normal use | Built for rugged roads, heavy loads, and extreme temps |

| Installation Notes | Easy to install | Needs special tools for secure fit |

Passenger cars usually use rubber valve stems. These work well for daily driving and normal tire pressures. Trucks and SUVs often need metal or high-pressure rubber stems. These handle bigger loads, higher pressures, and tough conditions. If you drive a heavy-duty truck, you’ll want a metal or aluminum stem for extra strength.

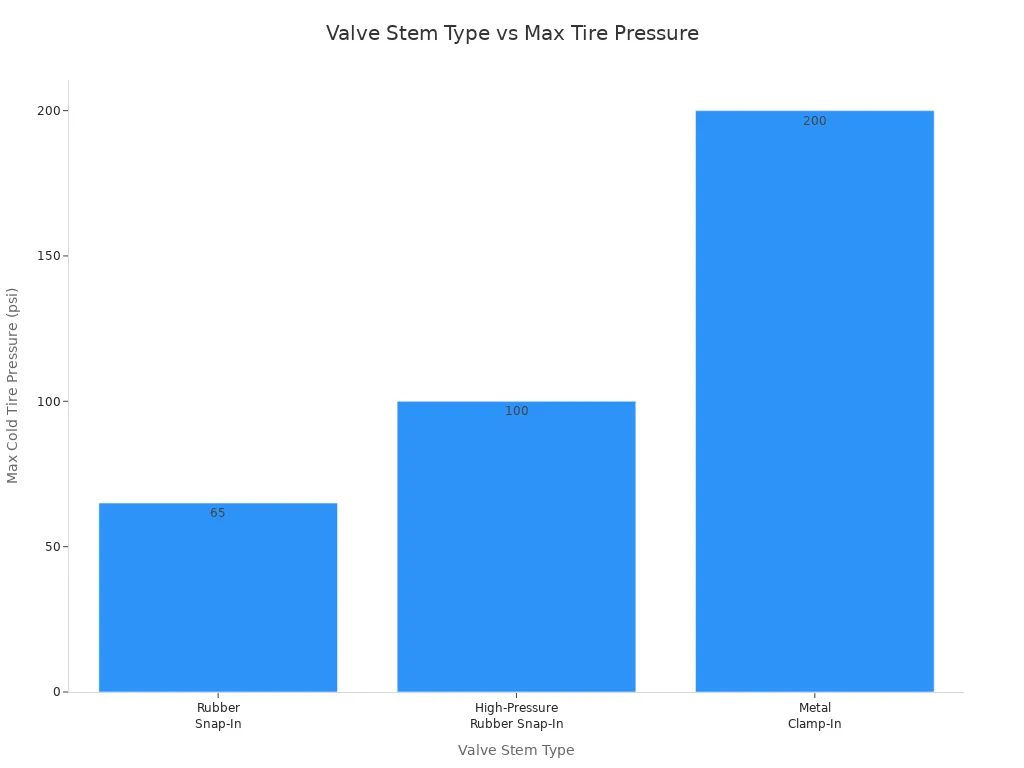

Everyday Driving vs. High-Performance Use

Your driving style matters, too. If you stick to city streets or highways, rubber valve stems do the job. They’re flexible and easy to replace. For high-performance or racing, you need something stronger. Metal clamp-in stems, often made from brass or aluminum, can handle speeds over 130 mph and pressures up to 200 psi. They last longer and keep your tires safe during hard driving.

| Valve Stem Type | Maximum Cold Tire Pressure | Typical Use | Key Features |

|---|---|---|---|

| Rubber Snap-In | Up to 65 psi | Everyday cars, light trucks | Easy, affordable, flexible |

| High-Pressure Rubber | 65 to 100 psi | Medium/heavy trucks, trailers | Thicker, combines rubber and metal |

| Metal Clamp-In | Up to 200 psi | Racing, high-performance vehicles | Durable, needs proper installation |

Tip: If you drive fast or carry heavy loads, choose a metal or aluminum valve stem for better safety.

Climate and Environmental Considerations

Where you live and drive affects your valve stem choice. Hot weather can make rubber dry out and crack. Cold weather makes rubber brittle. High humidity causes metal stems to corrode, especially if they’re not stainless steel or aluminum. Dry air can also make rubber age faster.

- Excessive heat speeds up rubber aging.

- Extreme cold makes rubber stiff and likely to crack.

- Humidity can cause corrosion in metal stems and degrade rubber.

- Dry conditions dry out rubber, leading to cracks.

If you live in a place with lots of rain or road salt, consider a metal or aluminum valve stem. These resist corrosion better. For dry, sunny places, check your rubber stems often for cracks. Always pick a valve stem that matches your local climate for the best tire safety.

Practical Recommendations for 2025: Rubber Valve Stems or Metal Valve Stems?

When to Choose Rubber Valve Stems

You want a simple, reliable choice for most cars? Rubber valve stems work great for everyday driving. They are easier to install and cost less than metal ones. If you drive a passenger car or a motorcycle, you will find rubber valve stems flexible and safe. They handle normal tire pressures and work well with most tpms sensors. Rubber also resists corrosion, so you do not have to worry about rust from rain or salty roads. If you replace your tires often, rubber valve stems make the process quick and easy.

Tip: Always check your rubber valve stems for cracks or dryness, especially if you park outside in the sun.

When to Choose Metal Valve Stems

Metal valve stems shine when you need extra strength. If you drive a heavy-duty truck, SUV, or a high-performance car, metal stems are the way to go. They handle higher tire pressures and extreme temperatures. You should pick metal stems if you use metal valve extensions or drive at high speeds. Metal stems also work best with tpms, especially when you need tpms service kits for sensor changes. Tire safety experts recommend using metal stems with proper torque to prevent leaks and keep your tires safe. Always match the valve stem’s pressure rating to your tire’s needs.

Here’s a quick look at new industry standards for valve parts in 2025:

| Valve Part | Recommended Material | Key Property / Requirement |

|---|---|---|

| Valve body/cover | Duplex Steel 2507 | Passed hydrogen embrittlement test at 150℃/100 bar H₂ |

| Sealing surface | Stellite 6B | Very low hydrogen permeability |

| Bolt | Inconel 718 | High tensile strength for tough environments |

Tips for Ensuring Valve Stem Safety

You can keep your tires safe by following a few simple steps:

- Always check the tire’s required pressure and use a valve stem that matches.

- For high-pressure tires, choose high-pressure snap-in or metal clamp-in stems.

- Never use metal extensions with rubber valve stems, as this can cause failure.

- Inspect the wheel’s stem hole for sharp edges, rust, or paint before installing a new stem.

- Use a non-petroleum-based lubricant when installing valve stems to prevent damage.

- Check your tpms sensors and replace tpms service kits as needed.

- Teach yourself and others how to use a tire pressure gauge with all valve stem types.

Note: Regular inspections and proper installation help prevent air leaks and keep your tires performing at their best.

When you pick between rubber and metal valve stems, you want to look at what matters most for your safety. Here’s a quick table to help you decide:

| Factor | Rubber Valve Stems | Metal Valve Stems |

|---|---|---|

| Durability | Good for daily driving | Best for heavy-duty use |

| Installation | Easy | Needs special tools |

| Corrosion Resistance | High | Also high, but check often |

| Pressure/Temp Rating | Standard | Handles higher levels |

| Ease of Use | Simple | More precise |

To keep your tires safe, follow these steps:

- Check valve stems and caps for cracks or damage.

- Make sure caps stay tight to block dirt and water.

- Replace worn stems right away to stop leaks.

- Keep stems in good shape for steady tire pressure.

- Good pressure means safer rides and longer tire life.

Stay alert and check your valve stems often. You help your tires last longer and keep your drive safe.

FAQ

Can I mix rubber and metal valve stems on my car?

You can use both types on one vehicle, but it’s best to match them for balance and safety. If you drive a heavy-duty truck, stick with metal stems. For most cars, rubber stems work well.

How often should I replace my valve stems?

You should replace valve stems every time you get new tires. If you see cracks, rust, or leaks, change them right away. Most rubber stems last as long as your tires, while metal stems can last longer with good care.

Do valve stems affect tire pressure sensors (TPMS)?

Yes, they do. Metal valve stems often work better with TPMS sensors because they handle the sensors’ weight and pressure. Rubber stems also work, but always check your car’s manual for the best match.

What’s the main cause of valve stem leaks?

The most common reasons are cracks in rubber, corrosion on metal, or missing valve caps. Dirt and moisture can sneak in and cause slow leaks. Always keep valve caps tight to protect your stems.

Tip: Check your valve stems when you check tire pressure. Catching problems early keeps your tires safe!