admin1

November 9, 2025

Pro Picks Top 5 Open Lug Nuts for Car Lovers

You are looking for the best open lug nuts for your aftermarket wheels in 2025. The automotive accessory market is growing fast. You can see its projected value and growth below.

| Report Attribute | Details |

|---|---|

| Market Size Value In 2025 | $42.64 billion |

| Growth Rate | CAGR of 7.5% from 2025 to 2034 |

This growth brings many great options. We have picked the top 5 open lug nuts for you:

- Project Kics R40 Iconix

- Muteki SR48

- Gorilla Forged Steel Racing Lug Nuts

- Mishimoto 7075-T6 Aluminum Racing Lug Nuts

- Volk Racing Formula Lug Nuts

Our detailed reviews will help you choose the perfect set for your ride.

Detailed Reviews: The 5 Best Open Lug Nuts of 2025

Choosing the right lug nuts is crucial for your vehicle’s safety and appearance. You need a set that secures your wheels properly and complements their style. This section breaks down our top three picks, giving you the details to make a confident choice.

1. Project Kics R40 Iconix: Ultimate Security & Premium Build

You want the best in security and craftsmanship. The Project Kics R40 Iconix, manufactured in Japan, represents the peak of lug nut engineering. These are an excellent investment for high-end wheel setups where protection is a top priority.

The R40 Iconix uses a unique two-piece construction. The main body is a strong lug nut, while the bottom is a separate, rotating seat. This “floating” seat design is a major benefit. It spins freely during installation. This action prevents the lug nut from scratching your valuable wheels. It also ensures a precise and even clamp, improving the connection to the hub.

Key features make the R40 Iconix stand out:

- Premium Material: They are made from high-strength Chromoly Steel 435. This material provides exceptional durability for both street and performance use.

- Advanced Security: Each set includes four special locking nuts. This adds a powerful layer of theft protection for your wheels.

- Two-Piece Design: The top of the lug nut spins independently from the tapered centering ring. This allows for a tighter hold and protects your wheel’s finish.

Pro Tip: The two-piece design of the R40 Iconix is especially useful for expensive or delicate wheel finishes. You can torque them down without worrying about marring the lug seat area.

2. Muteki SR48: Best for Track Days & Performance

You are a performance enthusiast looking for a reliable track-day option. The Muteki SR48 is a favorite in the car community for its strength, style, and value. These steel open lug nuts are built to handle the extreme forces of performance driving.

The SR48 is known for its durability. Made from cold-forged steel, it resists the stripping and stretching that can happen with repeated high-torque applications. Its 48mm length works perfectly with extended wheel studs, a common modification for track cars.

Some users have noted a “clicking” sound during hard cornering on the track. This can happen when the lug nut’s seat size is smaller than the wheel’s seat. This slight mismatch may allow for tiny movements under heavy load.

Note: This issue is not a defect but a compatibility point. You should always check that the lug nut seat matches your specific aftermarket wheels. For most wheel and driver combinations, the SR48 performs flawlessly.

3. Gorilla Forged Steel Racing Lug Nuts: Top Durability & Value

You need a tough, no-nonsense lug nut that will not break the bank. Gorilla has built a reputation for producing incredibly strong and affordable wheel accessories. Their Forged Steel Racing Lug Nuts deliver exceptional durability and peace of mind for any daily driver or weekend warrior.

These lug nuts are all about strength. Gorilla uses forged and heat-treated steel to create a product that resists wear and impact. Their simple, effective design focuses on one thing: keeping your wheels securely attached.

| Feature | Benefit |

|---|---|

| Forged Steel Construction | Offers maximum strength and resistance to stripping. |

| Triple Chrome Plating | Provides a durable finish that resists rust and corrosion. |

| Oversized 60-Degree Seat | Ensures better contact with the wheel for a secure fit. |

| External Pattern Design | Provides more gripping points for the socket, reducing slip risk. |

If you are looking for a fit-and-forget solution that prioritizes strength and safety over flashy features, the Gorilla Forged Steel Racing Lug Nuts are an unbeatable choice. They offer professional-grade durability at a price accessible to every car lover.

4. Mishimoto Aluminum Racing Lug Nuts: For Weight Reduction & Show Cars

You want to reduce your car’s weight and add a splash of color. The Mishimoto Aluminum Racing Lug Nuts are an excellent choice for this. They are perfect for show cars or daily drivers where every ounce matters. These nuts help you achieve a performance edge and a custom look.

The main benefit is significant weight savings. Mishimoto crafts these nuts from a single piece of 7075-T6 aluminum. This material is incredibly light yet strong. Each Mishimoto 7075-T6 Aluminum Racing Lug Nut weighs just 0.8 oz (22.68 g). This small number adds up, reducing the unsprung mass at each corner of your vehicle. Lighter wheels can improve your car’s handling and acceleration.

Mishimoto also offers these lug nuts in a variety of vibrant, anodized colors.

- Blue

- Black

- Red

- Neo Chrome

This allows you to perfectly match your lug nuts to your wheels, brake calipers, or overall car theme. They provide a clean, stylish finish that stands out at any car show.

Important Note: Aluminum is softer than steel. You must always install and remove these lug nuts with a hand wrench. Using an impact gun can easily damage the finish or the threads. They are best suited for street driving and show purposes rather than intense, repetitive track use.

5. Volk Racing Formula Lug Nuts: Iconic JDM Style & High-End Builds

You are building a top-tier vehicle and demand authentic, legendary parts. The Volk Racing Formula Lug Nuts are more than just hardware; they are a statement. These are the definitive choice for high-end builds, especially those with a Japanese Domestic Market (JDM) influence.

Volk Racing is a pillar of JDM car culture. The brand’s reputation for quality and style is unmatched. Owning their parts connects your build to a rich history of performance and design.

Brands like Pandem/Rocket Bunny and Volk Racing have become synonymous with the look [JDM aesthetics: wide-body kits, deep-dish wheels, and functional aero that doubles as art].

These open lug nuts feature a sophisticated two-piece design. A steel body provides strength, while a floating aluminum seat protects your expensive wheels during installation. This ensures a perfect torque setting without scratching the wheel surface. The materials used are a testament to their quality.

- Body Material: High-strength Chromoly Steel (28BCrvM)

- Seat Material: Free-spinning A7075 aluminum collar

This combination offers the best of both worlds: the durability of steel and the protective qualities of a soft aluminum seat. Each set also includes a special keyed socket, providing excellent security against wheel theft. Choosing Volk Racing Formula Lug Nuts is the perfect finishing touch for a build that values heritage and uncompromising quality.

How to Choose the Right Open Lug Nuts for You

Selecting the right hardware is just as important as picking your wheels. You need to consider the material, seat type, and your primary use. This guide helps you understand these key factors to make the best choice.

Quick Comparison: The Top 5 at a Glance

You can use this table for a quick overview of our top picks. It highlights the main features of each lug nut.

| Lug Nut | Material | Best For | Key Feature |

|---|---|---|---|

| Project Kics R40 | Chromoly Steel | Security & High-End Wheels | Two-piece floating seat |

| Muteki SR48 | Cold-Forged Steel | Track Days & Performance | Extended 48mm length |

| Gorilla Forged | Forged Steel | Daily Driving & Durability | Excellent value and strength |

| Mishimoto | 7075-T6 Aluminum | Show Cars & Weight Savings | Lightweight and colorful |

| Volk Racing Formula | Chromoly Steel | JDM Builds & Prestige | Iconic brand, two-piece design |

Match the Seat Type to Your Wheel

You must match the lug nut seat to your wheel. The seat is the area where the lug nut touches the wheel. Most aftermarket wheels use a 60-degree conical seat, also called a taper or acorn seat. Using the wrong seat type is dangerous.

Safety First: Always confirm your wheel’s required seat type before buying lug nuts. A mismatch can lead to serious problems.

Using the wrong seat can cause:

- Improper torque readings

- Wheel misalignment and vibration

- Damage to your wheels or vehicle studs

Material Matters: Steel vs. Aluminum vs. Titanium

The material of your open lug nuts affects their strength, weight, and durability. Steel is strong and affordable, making it great for daily and track use. Aluminum is very light but softer, so you should use it for show cars or street driving. Titanium offers a balance of high strength and low weight, but it is the most expensive option.

The table below compares common materials.

| Material | Tensile Strength | Approx. Weight | Weight vs. Steel |

|---|---|---|---|

| 7075-T6 Aluminum | ≥ 572 MPa | 25g – 28g | ~60% lighter |

| Steel | Varies | 60g – 65g | Reference point |

| Grade 5 Titanium | ≥ 950 MPa | 30g – 35g | ~50% lighter |

You should choose the material that best fits your budget and how you drive.

Understanding Thread Pitch and Size

You must get the correct thread pitch and size for your lug nuts. This detail is essential for safety. The wrong size can prevent the lug nut from tightening correctly. This could cause a wheel to come loose.

Thread size is the diameter of your car’s wheel stud. Thread pitch measures the distance between the threads. These two measurements create a specific code, like M12x1.5. Getting this code right ensures a perfect fit.

Pro Tip: The easiest way to find your car’s thread pitch is to check your owner’s manual or search online. You can also take an old lug nut to an auto parts store, where they can measure it for you.

Different car manufacturers use different sizes. You will commonly find these thread patterns on passenger cars and light trucks:

- Metric Sizes:

- M12x1.25 (Common on Nissan, Subaru, Infiniti)

- M12x1.5 (Common on Honda, Acura, Toyota, Lexus, BMW)

- M14x1.5 (Common on newer domestic trucks, VW, Audi)

- SAE / US Standard Sizes:

- 1/2″-20 (Common on older domestic cars, Jeep)

- 9/16″-18 (Common on heavy-duty Ford and Dodge trucks)

If you need to measure the studs yourself, you will need two tools: a caliper and a thread pitch gauge.

- Measure the Diameter: Use a caliper to measure the outside diameter of the wheel stud’s threads. This gives you the thread size, like 12mm (M12) or 14mm (M14).

- Measure the Pitch: Use a thread pitch gauge. Find the leaf on the gauge that fits perfectly into the stud’s threads with no gaps. This tells you the pitch, such as 1.5 or 1.25 for metric studs.

Matching these measurements exactly ensures your new open lug nuts will keep you safe on the road.

Installation and Safety Best Practices

You have your new lug nuts. Now, you need to install them correctly. Proper installation is the most important step for your safety. Following these best practices ensures your wheels stay securely attached to your vehicle.

The Importance of Hand-Torquing

You should always use a torque wrench to tighten your lug nuts. An impact wrench is great for removal, but it is too powerful for installation. Using an impact gun can cause serious damage.

- It can over-tighten and damage the threads on your lug nuts.

- It can damage the wheel hub, especially on delicate alloy wheels.

- Using the wrong size socket with an impact wrench can round off and ruin your new lug nuts.

A torque wrench lets you apply the exact amount of force needed. This force, or torque, is specific to your vehicle. You can find this specification in your owner’s manual. Using the correct torque ensures your wheels are secure without over-stressing the studs.

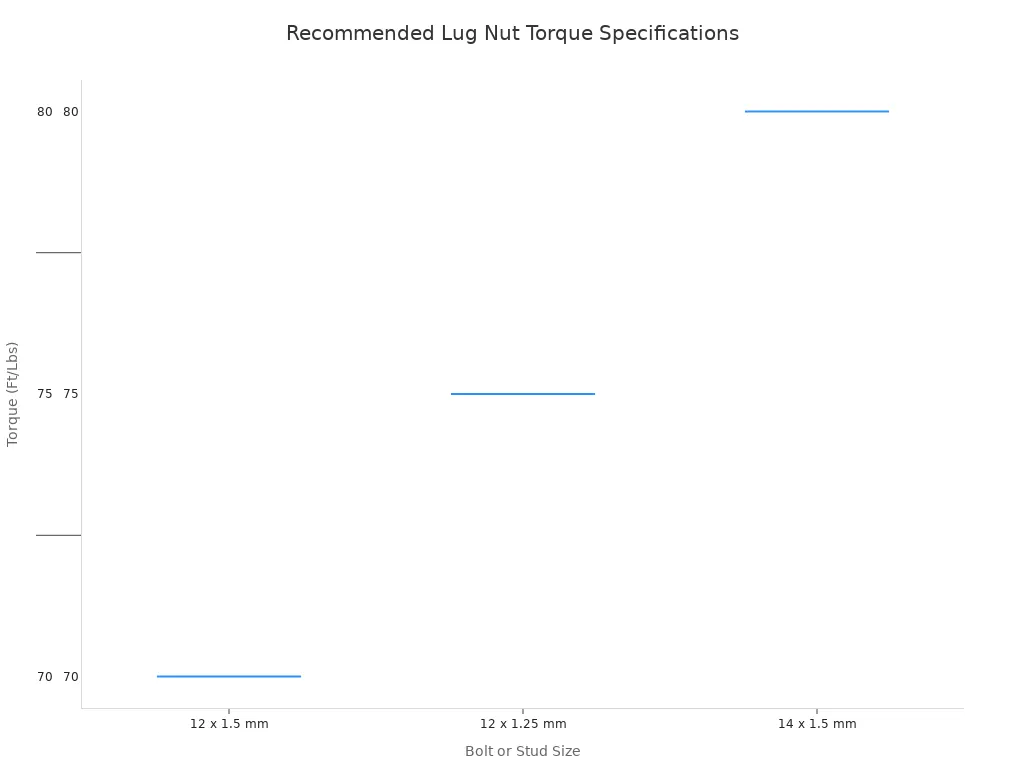

| Hardware Bolt or Stud Size | Typical Torque Range in Ft/Lbs |

|---|---|

| 12 x 1.5 mm | 70 – 80 |

| 12 x 1.25 mm | 70 – 80 |

| 14 x 1.5 mm | 85 – 90 |

| 7/16 in. | 70 – 80 |

| 1/2 in. | 75 – 85 |

How to Avoid Cross-Threading

Cross-threading happens when a lug nut’s threads do not align with the wheel stud’s threads. Forcing it on will damage both parts. You can easily avoid this.

Always start threading your lug nuts by hand. 🖐️ You should be able to turn the nut for several full rotations with just your fingers. If you feel resistance right away, stop. The nut is likely crooked. Back it off and try again. If you see any of these signs, you may have a cross-threaded stud:

- The lug nut is difficult to turn.

- The nut appears crooked or misaligned.

- You see metal shavings around the stud.

Proper Use of Anti-Seize Lubricant

You might think about using anti-seize lubricant on your wheel studs. This compound can prevent rust and stop the nut from getting stuck. However, you must be very careful.

Warning: Most vehicle and wheel manufacturers recommend installing lug nuts on clean, dry threads. Lubricants like anti-seize dramatically reduce friction.

This reduction in friction means that your torque wrench’s setting is no longer accurate. Applying the standard dry torque value to a lubricated stud can create much more clamping force. This can stretch or even break the wheel stud, creating a dangerous situation. If you must use anti-seize, you need to reduce the torque value significantly, often by 10% or more. This requires careful calculation and is best left to professionals. For most car lovers, clean and dry is the safest way to go.

Regular Inspection and Re-Torquing Schedule

You have installed your new open lug nuts. Your work is not done yet. You must perform regular checks to ensure your wheels remain secure. This simple habit is one of the most important safety routines for any car owner.

Your wheels and lug nuts go through a “settling-in” period after installation. You need to re-check the torque to account for any minor shifts. Forgetting this step can lead to loose wheels. You should follow a specific re-torquing schedule.

- You must re-torque your lug nuts after driving the first 50 to 100 miles.

- Some drivers are extra cautious. They check at 25 miles and again at 100 miles, often finding a few lug nuts that need a slight adjustment.

Ignoring this check is extremely dangerous. A loose wheel can cause a chain reaction of failures. It puts immense stress on your vehicle’s studs, brakes, and suspension components.

The nightmare scenario is complete wheel separation. If lug nuts continue to back out, the studs can snap, and the wheel can detach from your vehicle while you are driving. This can cause a total loss of control and lead to major accidents.

Your car will often give you warning signs that your lug nuts are loose. Pay attention to these clues:

- Wheel Vibration or Wobble: You may feel a new vibration through the steering wheel or the whole car.

- Uneven Stress: A single loose or missing nut puts more strain on the others, causing them to loosen faster.

- Tire and Wheel Damage: You might notice unusual wear on your tires or damage around the wheel’s bolt holes.

Make it a habit to check your lug nut torque. A quick check during every oil change or tire rotation provides lasting peace of mind. This small effort ensures your safety on every drive. 🚗

Why Choose Open-Ended Lug Nuts?

You might wonder why some car lovers prefer open-ended lug nuts over the more common closed-ended style. These nuts offer specific functional and aesthetic benefits, especially for performance-oriented vehicles. They solve problems that standard lug nuts cannot, making them a smart upgrade for many builds.

Accommodating Extended Wheel Studs

You may need to install extended wheel studs on your car. This is common when you add wheel spacers or use wheels with a thick mounting pad. A standard closed-ended lug nut can “bottom out” on a long stud. This means the nut tightens against the tip of the stud before it properly clamps the wheel to the hub, creating a very dangerous situation. Open-ended designs solve this problem completely.

The open design allows the stud to pass through the nut. This ensures you achieve proper clamping force and thread engagement. For safety, you must have enough thread contact.

Pro Tip: Experts and racing organizations have clear rules for safe thread engagement.

- A good general rule is that the engaged thread length should be at least equal to the stud’s diameter (e.g., 12mm of engagement for an M12 stud).

- Many racing rulebooks require the stud to stick out at least 1.5 threads past the nut.

- Performance expert Carroll Smith advised an engaged thread distance of 1.5 times the stud’s diameter for maximum security.

Heat Dissipation for Performance Driving

You push your car hard on the track or during spirited driving. Your brakes generate immense heat. This heat travels from the rotors and hubs directly into your wheel studs and lug nuts. Closed-ended nuts trap this hot air.

Open lug nuts provide a path for that heat to escape. This airflow helps cool the entire wheel and brake assembly. Keeping these components cooler reduces the risk of brake fade and protects your hardware from the stress of extreme temperatures. This small detail can make a big difference in performance and safety during a track session.

Motorsport-Inspired Aesthetics

You want your car to look the part. The appearance of open-ended lug nuts is directly inspired by professional motorsports. On race cars, function dictates form, and the open design is a necessity for long studs and quick inspections. 🏁

This functional origin gives your vehicle an aggressive, track-ready look. The sight of extended studs passing through the nuts tells others that your car is built for performance. It is a subtle but powerful styling cue that completes the look of many high-end and JDM-style builds.

You may seek the best all-around balance of performance, security, and value. The Muteki SR48 stands out as an excellent choice for these goals. However, your specific needs might point you to another one of our top picks. You could prioritize weight reduction for a show car, ultimate security for expensive wheels, or a strict budget. Choose the lug nut that best fits your wheels and driving style. This decision ensures your safety, performance, and peace of mind on the road or track.

FAQ

Can I use an impact wrench to install my new lug nuts?

You should never use an impact wrench for installation. It can easily damage the threads or overtighten the nut. Always use a hand-held torque wrench to tighten your lug nuts to the correct specification. This ensures both safety and the longevity of your hardware.

Will my open-ended lug nuts rust?

Rust depends on the material. Steel nuts can rust if their protective coating wears off. Quality finishes like triple chrome plating offer excellent protection. Aluminum and titanium nuts will not rust. You can keep your lug nuts clean to prevent corrosion and maintain their look.

Can I use these lug nuts on my factory (OEM) wheels?

You probably cannot. Most aftermarket lug nuts use a 60-degree conical seat. Many factory wheels require a different “ball” or “flat” seat. Using the wrong seat type is extremely dangerous. You must always match the lug nut seat to your specific wheel’s requirement.

Safety Tip: Check your wheel’s specifications before buying lug nuts. A mismatch can cause the wheel to loosen while you are driving. ⚠️

What does a “two-piece” or “floating seat” lug nut do?

This design features a separate, rotating collar at the base. The collar stays still against your wheel as you tighten the nut. This smart design prevents scratches on your wheel’s finish and helps provide a more accurate and secure clamp onto the hub.