admin1

August 3, 2025

A Complete How-To on Metal Valve Stem Selection and Installation

You want your vehicle to stay safe and reliable, so picking the right metal valve stem makes a big difference. When you install a metal valve stem correctly, you lower the risk of air leaks and sudden tire deflation. Quality stems made from brass or stainless steel can handle rough weather and resist corrosion, giving you extra peace of mind. By maintaining proper tire pressure with a strong metal valve stem, you protect your tires and boost safety every time you drive.

Why Choose Metal Valve Stems

Benefits of Metal Valve Stems Over Rubber

When you look at metal valve stems, you see a big difference in strength and durability compared to rubber ones. Metal stems, often made from brass or stainless steel, stand up to tough conditions. They handle high tire pressures, sometimes up to 200 psi, which makes them perfect for heavy-duty trucks or high-performance cars. You do not have to worry about heat or chemicals breaking them down. Metal stems resist corrosion, so they last longer even if you drive in rain, snow, or salty roads.

Here are some reasons drivers pick metal valve stems:

- They withstand higher tire pressures, often over 65 psi.

- They resist heat and harsh chemicals better than rubber stems.

- The clamp-in design gives a secure fit, lowering the risk of air loss.

- Brass and nickel-plated stems fight off rust and corrosion.

- You can find them in different sizes and shapes for many wheel types.

Rubber stems are flexible and easy to install, but they do not last as long under extreme conditions. Metal valve stems give you peace of mind when you need extra strength and reliability.

Common Tire Problems Solved by Metal Valve Stems

Tire failures often start with small issues like cracks or leaks at the valve. Metal valve stems help you avoid these problems. They do not crack in extreme temperatures the way rubber stems can. If you drive in hot weather or on rough roads, metal stems keep their shape and seal tight.

Here are some common tire problems that metal valve stems help prevent:

- Cracks in the valve from heat or cold, which can cause air loss.

- Corrosion from road salt or moisture, leading to weak valve parts.

- Air leaks from poor sealing or worn valve cores.

- UV damage that makes rubber brittle and easy to break.

You want to keep your tires safe and avoid sudden air loss. Metal valve stems give you a strong, secure seal. They help you maintain the right tire pressure and reduce the risk of tire failures. When you choose metal stems, you protect your tires and make every drive safer.

Metal Valve Stem Selection Guide

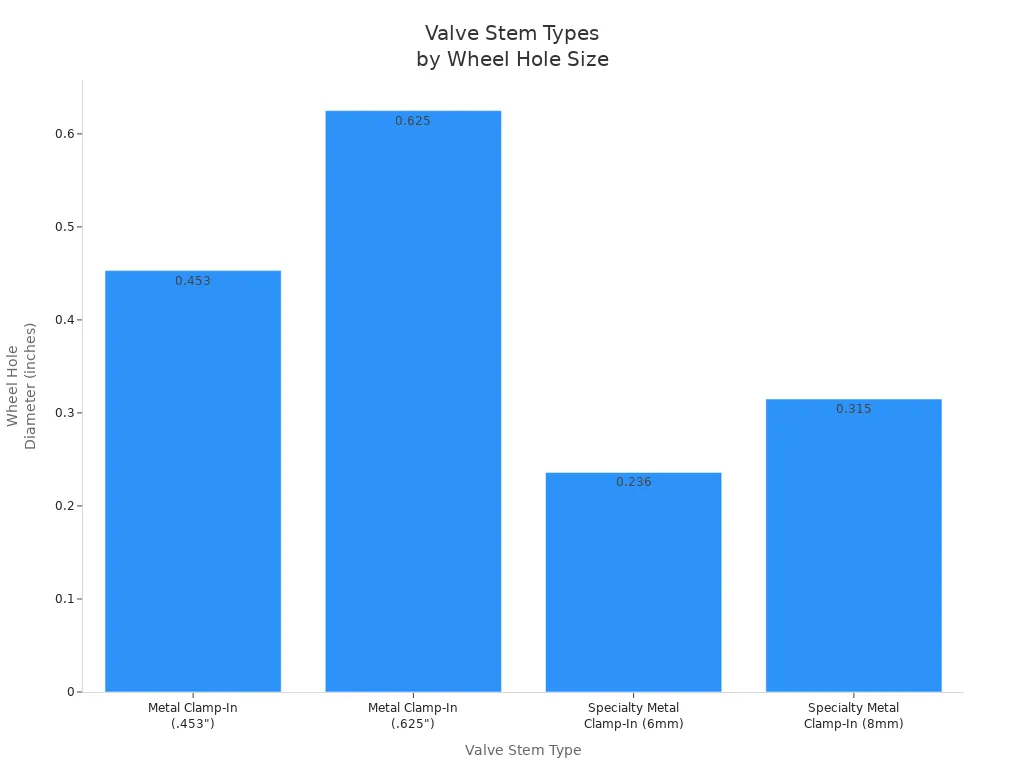

Matching Valve Stem to Wheel Hole Size and Type

When you start valve stem selection, the first thing you need to check is the size and type of the hole in your wheel. Not all wheels use the same hole diameter, so picking the right valve stem is key for a tight, leak-free fit. Most passenger vehicles use a 0.453-inch hole, but some trucks and specialty wheels use 0.625-inch or even metric sizes like 6mm or 8mm. If you drive a car with alloy wheels, you’ll often need a clamp-in style metal valve stem that uses a threaded nut for a secure hold.

The Tire & Rim Association sets the dimensional tolerances for valve stems, and the SAE 1205-1206 standard is a trusted quality benchmark. You should always look for stems that meet these standards or carry ISO9001 certification. This ensures you get a product that fits well and lasts a long time.

Here’s a quick table to help you match the right valve stem to your wheel:

| Valve Stem Type | Max Inflation Pressure (PSI) | Effective Length (Inch) | Wheel Hole Diameter (Inch) |

|---|---|---|---|

| Metal Clamp-In Valve (.453″) | Up to 200 | Flush to 2″ | 0.453 |

| Metal Clamp-In Valve (.625″) | Up to 200 | Flush to 2″ | 0.625 |

| Specialty Metal Clamp-In (6mm) | Up to 200 | Varies | 0.236 (6mm) |

| Specialty Metal Clamp-In (8mm) | Up to 200 | Varies | 0.315 (8mm) |

Tip: Always double-check your wheel’s hole size before you buy. Using the wrong size can lead to leaks or even valve failure.

You can also see how different valve stem types fit different wheel hole diameters in the chart below:

Pressure Ratings and Torque Requirements

Pressure ratings matter a lot in valve stem selection. If you drive a heavy-duty truck, you need a valve that can handle up to 200 psi. Most passenger cars and motorcycles use stems rated for up to 65 psi. Tractors and off-road vehicles may need even higher ratings. Choosing a stem with the right pressure rating keeps your tires safe and prevents blowouts.

Here’s a table to help you see which valve stem fits your vehicle type:

| Vehicle Type | Recommended Valve Stem Material | Pressure Rating (psi) |

|---|---|---|

| Heavy-Duty Trucks | Metal valve stems | Up to 200 |

| Passenger Vehicles | Standard rubber valve stems | Up to 65 |

| Motorcycles | Rubber valve stems | Up to 65 |

| Tractors/Off-Road | High-pressure metal stems | 100 or more |

When you install a metal valve stem, you also need to pay attention to torque. Each manufacturer sets a specific torque value for the base nut, usually between 25 and 80 inch-pounds. If you use too much force, you might crack the nut, especially if it’s made from softer metals like aluminum. If you don’t use enough, the stem could come loose and cause a leak. Always check the instructions that come with your valve stem or ask your supplier for the correct torque.

Note: Never guess the torque value. Using the right torque keeps your valve secure and your tires safe.

Compatibility with Tire Pressure Monitoring Systems (TPMS)

If your car has a TPMS, you need to make sure your metal valve stem works with it. Not every stem fits every sensor, so you want to pick one that matches your vehicle’s system. Many modern stems are designed to work with both factory and aftermarket TPMS sensors. Aluminum alloy stems are a popular choice because they resist corrosion and help keep the sensor working in all kinds of weather.

Here are some things to keep in mind when you choose a valve stem for TPMS:

- Make sure the stem is compatible with your TPMS sensor, whether it’s factory or aftermarket.

- Check that the material and design match your rim’s hole size and type.

- Some brands, like Mopar or BMW, use special stems for their sensors. Always check your owner’s manual or ask your parts supplier.

- Specialty stems, such as keyed or snap-in types, are available for unique sensor units.

- Steel stems are often used to match factory alloy or chrome wheels.

Pro Tip: Picking the right valve stem for your TPMS keeps your tire pressure readings accurate and helps you avoid warning lights on your dashboard.

When you follow these steps for valve stem selection, you make sure your tires stay safe, your sensors work right, and your wheels look great.

Choosing the Right Length and Angle

When you pick the right valve stem for your wheels, you need to think about both the length and the angle. These two factors can make a big difference in how easy it is to check your tire pressure, add air, and keep your tires safe.

You’ll notice that metal valve stems come in many lengths, from flush with the wheel to about 2 inches long. The length you choose should let the valve stick out enough so you can reach it with an air chuck or pressure gauge. If the stem is too short, you might struggle to add air or check pressure. If it’s too long, it could get damaged by road debris or even snap off.

The angle of the valve also matters. Some wheels work best with straight stems, while others need a bent or nearly horizontal design. Many wheel manufacturers prefer almost horizontal stems, especially if you have a tire pressure monitoring system (TPMS) mounted on the valve. This design helps the sensor fit better and makes it easier to check or adjust the pressure.

Here’s what you should look for when choosing the right length and angle:

- The valve stem must be long enough to stick out through the wheel rim hole for easy access.

- The angle should match your wheel design. A straight stem works for most wheels, but some need a bent stem to avoid rubbing or to fit around wheel covers.

- Nearly horizontal stems help with TPMS sensors and make maintenance easier.

- Vertical stems can lose pressure at high speeds because the spinning wheel pushes on the valve core. That’s why many high-performance wheels use angled stems.

- Stems with a retaining nut on the outside of the wheel let you check and adjust them without removing the tire.

Let’s look at a quick table to help you with valve stem selection:

| Wheel Type | Recommended Stem Length | Recommended Angle | Special Notes |

|---|---|---|---|

| Passenger Car Alloy Wheel | 1″ to 2″ | Straight or 15° Bent | Check for TPMS compatibility |

| Heavy-Duty Truck Wheel | 1.5″ to 2″ | 30° to 45° Bent | Use retaining nut for easy adjustment |

| Motorcycle Wheel | Flush to 1″ | 90° Bent | Short stems avoid interference with brake parts |

| Custom/Aftermarket Wheel | Varies | Match wheel design | Always measure before buying |

Tip: Always measure your wheel’s valve hole and check how much space you have around it. This helps you avoid buying a stem that’s too short, too long, or at the wrong angle.

If you want to make tire checks and air fills quick and easy, pay close attention to both the length and angle during valve stem selection. The right valve stem will fit your wheel perfectly, keep your tires sealed, and make maintenance a breeze.

Metal Valve Stem Installation Steps

Tools and Materials Needed for Installation

Before you start, gather all the tools and materials you need. Having the right equipment makes the job easier and helps you avoid mistakes. Here’s a handy list of what you should have on hand:

- Valve installers (like the Westward Common Steel Valve Installer Tool)

- Valve core extractors (for example, the Tru-Flate Valve Core Extractor)

- Valve pullers (such as the Alligator Valve Puller)

- Valve fishing tools

- Soap solution or dish detergent (for lubrication)

- Clean cloths or rags

- Tire pressure gauge

- Torque wrench (for tightening nuts to the correct value)

- Metal valve stem with removable core

- Self-sealing valve stem caps

These tools are made from steel or other metals, so they last a long time and work well for both installing and removing metal valve stems. If you use a two-piece stem with a removable core, you can fill tires with air or liquid more quickly and get a better seal.

Tip: Always use tools designed for metal stems. They help you avoid damaging the stem or the wheel during installation.

Preparing the Wheel and Valve Stem

Preparation is key for a leak-free seal and long-lasting performance. Follow these steps to get your wheel and valve ready:

- Clean the rim hole. Use a cloth to wipe away dirt, debris, or old sealant. Any leftover grime can cause leaks.

- Inspect the rim for corrosion or rough spots. If you see white residue or feel roughness, clean it off or replace the seal.

- Check the valve stem for any damage or defects. Make sure the rubber base is soft and the metal parts are smooth.

- Insert the valve stem from the inside of the wheel. The rubber base should sit flush against the rim.

- Pull the valve stem from the outside to make sure it is firmly in place.

- If you see cracks or brittleness on the stem, replace it before you install the tire.

- Always replace the valve stem when you put on new tires. This keeps your seal fresh and helps prevent leaks.

Regular inspection and cleaning help you catch problems early. You want your metal valve stem to fit perfectly and seal tight.

How to Install the Metal Valve Stem

Now you’re ready for the main event. Here’s how you can install a metal valve stem step by step:

- Remove the tire from the wheel. Lay it flat on a firm surface. Break the bead carefully so you don’t damage the rim.

- Take out the old valve stem. Use pliers or a valve puller to remove it. If it’s stuck, cut it out gently.

- Lubricate the valve stem hole and the new stem with a soap solution. This makes it easier to slide the stem in and helps create a good seal.

- Insert the new metal valve stem through the hole from the inside of the rim. Use a valve installer tool or a metal stem extender to pull it into place. Make sure the rubber grommet or washer sits on the correct side of the rim—usually the inside.

- Secure the stem by tightening the nut with a torque wrench. Follow the manufacturer’s torque specs. Don’t overtighten, or you might damage the seal.

- Double-check the placement of washers and grommets. Some people put rubber washers on both sides, but this can let the valve move even if the nut is tight. Use only one washer or grommet, and make sure it matches the rim shape. If your rim is rounded, a convex washer works best.

- Reinstall the tire on the rim. Inflate it slowly, using a hand pump at first. Watch the bead and make sure it seats properly.

- Inflate the tire to the recommended pressure. Use a tire pressure gauge to check your work.

- Add a self-sealing valve cap. This helps prevent air loss, even if the core leaks a little.

Avoid common mistakes like putting washers on the wrong side or overtightening the nut. These errors can cause leaks or let the valve move around. Always match the stem type to your wheel and follow the instructions for proper installation.

If you follow these steps, you’ll get a secure, airtight fit that keeps your tires safe and your ride smooth.

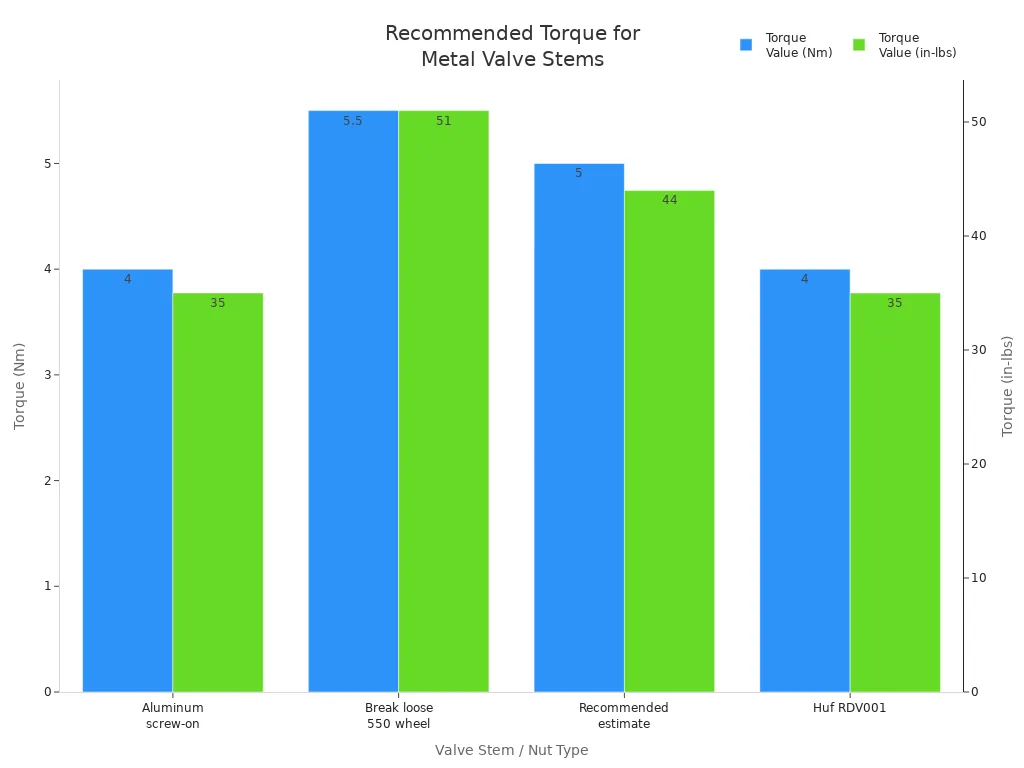

Proper Tightening and Torque Application

Getting the right torque on your metal valve stem is a big part of a successful installation. If you tighten the nut too much, you can damage the stem or the wheel. If you do not tighten it enough, you might get leaks or a loose fit. You want a proper fit every time, so always use a torque wrench for this step.

Here’s a quick look at the recommended torque values from leading manufacturers:

| Valve Stem / Nut Type | Torque Value (Nm) | Torque Value (inch-pounds) | Notes |

|---|---|---|---|

| Aluminum screw-on valve stems (general) | ~4 Nm | ~35 in-lbs | Good for most passenger vehicles |

| Break loose torque on original 550 wheel valve stems | 5.5 to 6 Nm | 49 to 53 in-lbs | Measured from long-term use |

| Recommended torque estimate | 5 Nm | 44 in-lbs | Common consensus for a secure fit |

| Huf RDV001 (Ferrari TPMS) | 4 Nm | 35 in-lbs | Manufacturer specification |

| Steel Wheel Valve Stem | — | 35 to 55 in-lbs | Standard for tubeless truck tire valve stems |

| Aluminum Wheel Valve Stem | — | 80 to 125 in-lbs | Needs careful tightening to avoid corrosion and leaks |

You want to match the torque to your valve stem type. Most passenger car stems need about 35 to 44 inch-pounds. Truck stems can go up to 55 inch-pounds. Aluminum stems on some wheels need even more, up to 125 inch-pounds. Always check the instructions that come with your valve stem for the exact number.

Tip: Use a torque wrench for every installation. This tool helps you get the correct installation and keeps your valve stem from coming loose or leaking.

When you tighten the nut, turn it slowly and watch the torque reading. Stop as soon as you hit the right number. Do not overtighten the nut. If you go past the recommended torque, you can crush the rubber grommet or strip the threads. That can ruin the proper fit and cause leaks.

A good installation means the valve stem sits snug in the wheel hole. The rubber grommet should press evenly against the rim. You should not see any gaps or movement. If you feel the stem wiggle after tightening, check the torque again and make sure you have the right parts in the right order.

Final Checks for Air Leaks and Secure Fit

After you finish the installation, you want to make sure your valve stem has a proper fit and seals tight. Checking for air leaks is easy and helps you catch problems before they turn into bigger issues.

Here are some simple steps you can follow:

- Look at the valve stem and the area around it. Check for cracks, gaps, or signs of damage.

- Spray a little soapy water around the base of the stem. If you see bubbles, you have a leak.

- Listen for any hissing sounds. Air escaping from the valve will make a soft noise.

- Use a tire pressure gauge to check the pressure. If it drops after a few minutes, you may have a slow leak.

- Put on a plastic valve cap. Plastic caps help prevent corrosion and keep dirt out. Metal caps can sometimes stick to the stem and cause leaks.

Regular inspections help you spot trouble early. If you see any leaks or movement, remove the tire and check the installation again.

Many tire shops check valve stems every time they service your tires. They look for a secure fit and replace any worn or faulty parts. If you store your vehicle in a garage or covered area, you help your valve stems last longer and keep a tight seal.

A user once shared that after installing Xtra Seal metal bolt-in valve stems, they had no leaks for over a year and a half. This shows that a careful installation and regular checks really work.

You want your valve stem to fit just right. A proper fit means no leaks, steady tire pressure, and safe driving. If you follow these steps, you can trust your installation to last.

Troubleshooting Metal Valve Stem Installation

Avoiding and Fixing Air Leaks

Air leaks can sneak up on you, but you can stop most of them before they start. The most common causes include using the wrong type of valve stem, cracks from weather, missing or damaged valve caps, and corrosion from metal caps reacting with the stem. Improper installation is another big reason leaks happen.

Here’s how you can prevent air leaks:

- Pick high-pressure metal valve stems that match your tire’s needs.

- Use black plastic valve caps instead of metal ones. Plastic caps help stop corrosion and keep dirt out.

- Check your valve stems often for cracks or weather damage. Replace them if you see any problems.

- Clean your valve stems, especially after driving on salty winter roads.

- Make sure a professional installs your valve stems and seats them properly.

If you spot a leak, try this:

- Remove the valve cap and listen for a hiss.

- Put soapy water around the stem and look for bubbles.

- Tighten the valve core with a valve core tool, but don’t overtighten.

- If the leak continues, replace the valve core or the whole stem.

Tip: Always put the cap back on after checking or filling your tires. This small step keeps out dirt and moisture.

Recognizing Improper Installation

You can spot a bad installation if you know what to look for. Signs include air leaks, a loose or wobbly valve stem, or a stem that sits crooked in the wheel. Sometimes, you might notice your tire losing pressure faster than normal.

Improper installation can lead to:

- Gradual loss of tire pressure

- Uneven tire wear

- Poor vehicle handling

- Risk of blowouts from low pressure

If you see any of these signs, check the valve stem right away. Make sure the nut is tight, the grommet is in place, and the stem sits straight.

What to Do If Problems Occur

If you find a problem, don’t panic. You can fix many issues yourself, but some need a pro’s help.

Try these steps:

- Use soapy water to find the leak.

- Tighten or replace the valve core if needed.

- Smooth any rough edges around the valve hole with a file.

- Replace the valve stem if you see cracks or damage.

- Always use rim tape to protect tubes from sharp edges.

If you can’t stop the leak or if the stem still feels loose, visit a tire shop. A professional can check the installation and replace parts if needed. Remember, keeping your valve stems in good shape helps your tires last longer and keeps you safe on the road.

Choosing the right metal valve stem and installing it with care keeps your tires in top shape and boosts safety every time you drive. You protect your wheels and get better performance when you follow each step—select the right stem, use the correct tools, and check for leaks. To keep your tires safe, make it a habit to inspect your valve stems at least once a year. Look for rust, buildup, or loose parts. If you drive in tough conditions, check them even more often.

- Check for buildup of metal, rust, or plastic.

- Make sure connections stay tight.

- Watch for signs of corrosion or wear.

- Inspect valve stems every year, or more often if you drive in harsh environments.

Regular checks help you spot problems early and keep your safety on track.

FAQ

How often should you replace metal valve stems?

You should replace metal valve stems every time you get new tires. If you drive in harsh weather or see signs of rust or damage, check them more often. Regular checks help you catch problems before they cause leaks.

Can you reuse a metal valve stem when changing tires?

You can reuse a metal valve stem if it looks clean and undamaged. Always inspect the rubber grommet and washers. If you see cracks or wear, replace the stem. New parts give you a better seal and more safety.

What torque should you use when tightening a metal valve stem?

Most metal valve stems need 35 to 44 inch-pounds of torque. Some truck or aluminum stems need up to 125 inch-pounds. Always check the instructions that come with your valve stem. Using a torque wrench helps you get it just right.

Are metal valve stems compatible with all TPMS sensors?

Most metal valve stems work with TPMS sensors, but not all. You should check your vehicle’s manual or ask your supplier. Some cars use special stems for their sensors. Using the right stem keeps your TPMS working and your dashboard free of warning lights.

See Also

Understanding The Common Page Not Found Error Message