metal tpms valves

home > metal tpms valves

metal tpms valves

| TPMS-11 | |

|---|---|

| PACKAGE | 100 pcs/bag, 10 bags/case |

| TPMS-12 | |

|---|---|

| PACKAGE | 100 pcs/bag, 10 bags/case |

| TPMS-13 | |

|---|---|

| PACKAGE | 100 pcs/bag, 10 bags/case |

| TPMS-14 | |

|---|---|

| PACKAGE | 100 pcs/bag, 10 bags/case |

| TPMS-15 | |

|---|---|

| PACKAGE | 100 pcs/bag, 10 bags/case |

| TPMS-16 | |

|---|---|

| PACKAGE | 100 pcs/bag, 10 bags/case |

| TPMS-17 | |

|---|---|

| PACKAGE | 100 pcs/bag, 10 bags/case |

| TPMS-18 | |

|---|---|

| PACKAGE | 100 pcs/bag, 10 bags/case |

| TPMS-19 | |

|---|---|

| PACKAGE | 100 pcs/bag, 10 bags/case |

| TPMS-20 | |

|---|---|

| PACKAGE | 100 pcs/bag, 10 bags/case |

| TPMS-21 | |

|---|---|

| PACKAGE | 100 pcs/bag, 10 bags/case |

| TPMS-22 | |

|---|---|

| PACKAGE | 100 pcs/bag, 10 bags/case |

| TPMS-23 | |

|---|---|

| PACKAGE | 100 pcs/bag, 10 bags/case |

| TPMS-24 | |

|---|---|

| PACKAGE | 100 pcs/bag, 10 bags/case |

| TPMS-25 | |

|---|---|

| PACKAGE | 100 pcs/bag, 10 bags/case |

| TPMS-26 | |

|---|---|

| PACKAGE | 100 pcs/bag, 10 bags/case |

| TPMS-27 | |

|---|---|

| PACKAGE | 100 pcs/bag, 10 bags/case |

| TPMS-28 | |

|---|---|

| PACKAGE | 100 pcs/bag, 10 bags/case |

| TPMS-29 | |

|---|---|

| PACKAGE | 100 pcs/bag, 10 bags/case |

| TPMS-30 | |

|---|---|

| PACKAGE | 100 pcs/bag, 10 bags/case |

| TPMS-31 | |

|---|---|

| PACKAGE | 100 pcs/bag, 10 bags/case |

| TPMS-32 | |

|---|---|

| PACKAGE | 100 pcs/bag, 10 bags/case |

| TPMS-33 | |

|---|---|

| PACKAGE | 100 pcs/bag, 10 bags/case |

| TPMS-34 | |

|---|---|

| PACKAGE | 100 pcs/bag, 10 bags/case |

| TPMS-36 | |

|---|---|

| PACKAGE | 100 pcs/bag, 10 bags/case |

| TPMS-38 | |

|---|---|

| PACKAGE | 100 pcs/bag, 10 bags/case |

| TPMS-39 | |

|---|---|

| PACKAGE | 100 pcs/bag, 10 bags/case |

| TPMS-40 | |

|---|---|

| PACKAGE | 100 pcs/bag, 10 bags/case |

| TPMS-B | |

|---|---|

| PACKAGE | 100 pcs/bag, 10 bags/case |

| TPMS-S | |

|---|---|

| PACKAGE | 100 pcs/bag, 10 bags/case |

| TV25ALΦ11.3 | |

|---|---|

| PACKAGE | 100 pcs/bag, 10 bags/case |

//

copper valve comparison

Fortune premium truck valve uses high quality EPDM rubber and premium copper rod. We guarantee product sealability and user safety. Our truck tire valves are produced with premium copper and CNC processing machines, which create high precision and smooth surfaces.

Inferior Valve has obvious scratches and blemishes on its surface. Poor processing equipment causes the size of each part of the valves not inaccurate. An inferior valve has lower copper content, smaller external dimension, larger holes on the bottom to reduce material usage. Inferior Valve uses zinc alloy main rod and inferior natural rubber. Zinc alloy valves have poor sealability and material stability. They tend to crack and age. Also, Inferior natural rubber will easily age in the air and break during installation.Therefore, user safety is not guaranteed.

//

rubber valve difference

Fortune Premium Valve uses high quality EPDM rubber and premium copper rod. Therefore, we guarantee product sealability and user safety.

Inferior Valve uses zinc alloy main rod and inferior natural rubber. Zinc alloy valves have poor sealability and material stability. They tend to crack and age. Also, Inferior natural rubber will easily age in the air and break during installation. Therefore, the safety performance is not guaranteed.

//

fortune-sensors

Fully enclosed built-in structure design, can be used in high-speed, high/low temperature and other harsh environment.

The latest Freescale solution offers high signal accuracy and low power consumption. Sensors can last for more than 5 years.

Well designed logic design brings stable communication.

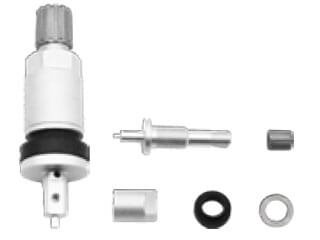

How to Choose a Metal TPMS Valve:

Installation, Maintenance and Benefits

Tire pressure monitoring system (TPMS) is an important part of a vehicle that helps the driver be aware of any significant changes in tire pressure. Of the many components of a TPMS, valve selection is critical to the overall performance and reliability of the system. Fortune will cover selecting a metal TPMS valve tip, discussing its installation and maintenance, and describing its advantages over other valves.

What is a Metal TPMS Valve?

TPMS valves are the component that connects the tire to the TPMS sensor, which transmits the tire pressure data to the vehicle’s computer. Unlike more common, cheaper rubber, metal TPMS valves are made from durable materials such as aluminum or brass. It is more durable, corrosion-resistant, and performs better in adverse weather conditions.

Advantages of Metal TPMS Valves

Durability

One of the main advantages of metal TPMS valve is their durability. Metal valves are less likely to crack or break. This is especially important for vehicles that are often driven in harsh conditions such as extreme temperatures or rough terrain.

Corrosion resistance

Choosing metal valves can greatly reduce the risk of corrosion-related problems. Metal TPMS valves are often coated to enhance their corrosion resistance. This is especially beneficial for vehicles exposed to road salt, moisture, and other corrosive environments. In these environments, rubber valves can degrade over time, leading to leaks and sensor failure.

Performance Improvement

Metal TPMS valves are safer. The strong fit is less likely to deform under pressure and ensures that the TPMS sensor remains properly calibrated.

Aesthetic Appeal

Metal valves are available in a variety of finishes to create a more sophisticated and professional look.

How to choose a metal TPMS valve?

When choosing a metal tire pressure monitoring system (TPMS) valve, there are several factors to consider to ensure you make the best choice for your vehicle. Here are some key points to keep in mind:

Vehicle Compatibility

The first thing to consider when selecting a metal TPMS valve is whether it is suitable. Different vehicles may require TPMS sensors that operate at different frequencies, typically around 315 MHz or 433 MHz.

Material Quality and Durability

Metal TPMS valves are typically made of either aluminum alloy or brass, both of which have their advantages and disadvantages.

Aluminum alloy is lightweight and corrosion resistant, making it the preferred choice for TPMS valves. Aluminum alloys are able to withstand extreme temperatures, which is critical for vehicles that operate in a variety of climates. However, aluminum is more susceptible to physical damage.

Brass is known for its strength and durability. It is less likely to bend or break under pressure, making it a reliable choice for heavy-duty applications. Brass is heavier than aluminum and is more susceptible to corrosion if not properly coated or treated.

Compatibility

Different vehicles may require a specific type of valve tip, so be sure to check your vehicle’s manual or consult with a Fortune professional technician to ensure it is compatible with your vehicle’s TPMS system.

Installation Requirements

When choosing metal TPMS valve, it is important to consider the installation process. Some valves may require special tools or professionals to install, while the vehicle owner himself can easily install others. If you are not good at installing them yourself, it is best to seek the help of a professional to ensure that the valves are installed correctly.

Stem design and angle

Stem design and angle are also key factors to consider.TPMS valves are available in two main designs: straight stem and tilting stem. When selecting a TPMS valve, consider the design and angle that best suits your vehicle’s needs, as well as your personal preferences for maintenance and accessibility.

Straight stem valves are typically easier to access and maintain, making them the preferred choice for many vehicles. Straight stem valves are easy to inflate and deflate tires, which is especially beneficial for drivers who frequently check tire pressure.

Tilting valve stems may be more advantageous in some situations, especially on vehicles with restricted valve stem positions. They can make the valve easier to operate in tight spaces, such as on larger vehicles or vehicles with larger wheel designs. Valve stem length can also affect compatibility, as some vehicles may require a longer stem to ensure a secure fit.

Sensor Integration

Another important factor to consider is sensor integration.TPMS sensors can be integrated or standalone.

Integrated Sensors

Integrated sensors are built into the valve stem and have a compact, streamlined design. This favors vehicles with limited space because it reduces the number of components required. Integrated sensors typically offer better performance and reliability because they are designed to work seamlessly with the valve.

Standalone Sensors

While freestanding sensors may be easier to replace, they take up more space and may require additional parts to install. They are also more susceptible to damage because they are separate from the valve stem. When choosing a TPMS valve, consider whether an integrated or standalone sensor will better meet your needs based on your vehicle design and maintenance preferences.

Sensor type and accuracy

Ultimately, the type of TPMS sensor you choose can have a significant impact on the accuracy and performance of your system.There are two main types of TPMS sensors: direct and indirect.

Direct Tire Pressure Monitoring System (TPMS) sensors measure actual tire pressure and send the information directly to the vehicle’s computer. This provides real-time data and is often considered more accurate than indirect systems. Alerting the driver to specific tire pressure issues allows for timely maintenance and improved safety.

Indirect Tire Pressure Monitoring System (TPMS) sensors do not measure tire pressure directly, but instead use data from the vehicle’s ABS (anti-lock braking system) to estimate tire pressure based on wheel speed. While indirect systems are less expensive and easier to install, they may not be as accurate as direct systems.

Price

While it may be tempting to choose the cheapest, it’s important to consider the long-term value of your investment. High-quality metal TPMS valves may cost more upfront, but their durability and performance will save you money in the long run by reducing the number of replacements and repairs.

Cost and Warranty

Cost is always a factor to consider when choosing any automotive part, and TPMS valves are no exception. Prices vary greatly between OEM and aftermarket, with OEM sensors often costing more due to their unique design and compatibility.

When evaluating cost, it’s also important to consider the warranty offered by the manufacturer. A comprehensive warranty gives you peace of mind and ensures that you are covered in the event of a defect or problem with your tire pressure monitoring system (TPMS) valve. Look for a manufacturer that offers a comprehensive warranty, as this reflects the quality and durability of the product.

Maintenance Notes

Metal TPMS valves are generally lower maintenance than rubber valves, but it’s still important to check them regularly to make sure they’re working properly. Choose a valve that comes with a warranty or guarantee, which will ensure longevity and performance, giving you peace of mind.

Installation and maintenance of metal TPMS valves

Installing metal TPMS valve typically involves the following steps:

- Preparation: Prepare the necessary tools, including tire pressure gauges, valve core tools, and any specific tools needed for your vehicle.

- Remove the Tire: To replace an existing valve, the tire will need to be removed from the wheel. This requires the help of a professional using a changer or Fortune.

- Install Valve: Insert the metal TPMS valve into the wheel valve stem hole. Make sure it is securely fastened and properly aligned.

- Reinstall Tire: With the valve in place, reinstall the tire onto the wheel, making sure it is properly seated.

- Check Pressure: After installation, use a tire pressure gauge to check tire pressure to ensure the TPMS sensor is functioning properly.

Maintenance

To maintain metal TPMS valves, consider the following tips:

- Regular Inspection: Check valves regularly for signs of wear, damage or corrosion. If there are any problems, fix them promptly to prevent leaks.

- Monitor tire pressure: Pay close attention to tire pressure to ensure that the TPMS system readings are accurate. If you find any abnormalities, please have a professional check it.

- Professional Repair: If you are unsure about the condition of your metal TPMS valve or the entire TPMS system, consider having it inspected by a qualified mechanic.

conclusion

Choosing the right metal valve tip for your vehicle’s TPMS is important. To make an informed decision that will improve the safety and efficiency of your vehicle, you need to understand the benefits of metal valves and consider their compatibility, quality, installation requirements, and maintenance. If you install and maintain metal TPMS valve correctly, it will work well, and you will feel s1 afe.