admin1

October 18, 2025

Lug Screw Essentials & Wheel Fitment Guide

Are you certain you have the right wheel hardware for your wheel? You can guarantee wheel compatibility with a simple 3-step check: Seat Type, Thread & Size, and Length. Incorrect lug compatibility is a serious safety risk. These issues cause thousands of preventable incidents annually.

| Incident Type | Number of Occurrences |

|---|---|

| Wheel fixing defects | 7,500 to 11,000 |

| Wheel detachments | 150 to 400 |

| Fatal accidents | 3 to 7 |

Using the correct lug screw and lug hardware is vital for every wheel.

Step 1: Match the Lug Seat to Your Wheel

The first step to safe wheel fitment is matching the lug screw seat to the wheel. The “seat” is the contact surface where the lug screw meets the wheel’s lug hole. This connection is critical. It centers the wheel and secures it to your vehicle’s hub. There are three primary seat types. You must use the correct one for your specific wheel.

Conical Seat (Cone)

You will most likely encounter the conical seat. It is the most common design, especially for aftermarket wheels. This seat looks like a cone and typically has a 60° taper. This design provides excellent self-centering action. It ensures the wheel mounts perfectly onto the hub. This feature is a key reason for its broad compatibility across many vehicle makes and models.

The table below outlines the key details of this popular seat type.

| Specification | Detail |

|---|---|

| Seat Type | Conical (Acorn/Cone) |

| Common Angle | 60° |

| Visual Identifier | Tapered cone shape |

| Typical Applications | Most aftermarket wheels; performance applications |

| Key Characteristics | Creates self-centering action; distributes clamping force evenly |

| Standardization | 60-degree tapers offer versatile compatibility |

Conical seat lug screws come in many sizes to fit various applications. Here are a few common examples you might find:

- Conical Seat Lug Bolt – 17mm Hex – 12mm x 1.50 Thread Size – Chrome Finish – 24mm Threaded Length

- Conical Seat Lug Bolt – 17mm Hex – 14mm x 1.25 Thread Size – Chrome Finish – 32mm Threaded Length

- Conical Seat Lug Bolt – 19mm Hex – 12mm x 1.25 Thread Size – Black Finish – 28mm Threaded Length

Ball Seat (Radius)

The ball seat has a rounded, spherical shape. You can think of it like a ball sitting in a cup. This design is different from the straight taper of a conical seat. You will typically find ball seats on original equipment manufacturer (OEM) wheels from European brands like Volkswagen, Audi, and Mercedes-Benz.

Important Note: You should never use a conical lug screw on a wheel designed for a ball seat, or vice versa. The mismatched shapes create a tiny, unsafe contact point. This can cause the lug to loosen or damage the wheel.

Shank Seat (Mag)

The shank seat, also known as a mag seat, has a unique design. It features a straight, flat-bottomed shank that extends past the threads. This shank fits directly into the wheel’s lug hole, providing a very secure and centered fit. A flat washer almost always accompanies this type of lug nut. The washer sits between the nut and the wheel surface. It protects the wheel from damage and helps distribute the clamping force.

You will need shank seat hardware for specific types of wheels.

- They are common on older aluminum wheels, like classic Cragar or Center Line styles.

- Some modern retro-style wheels also require them.

- Certain OEM applications, particularly on some Toyota and Nissan models, use this design.

Shank seats offer excellent stability for these specialized applications. Always confirm if your wheel requires this specific hardware.

Why Mixing Seat Types is Dangerous

You might think a lug screw is “close enough” if it threads in, but mixing seat types is a critical safety mistake. The seat creates the only contact point between your hardware and your wheel. Using the wrong type drastically reduces this contact area. Imagine placing a round ball into a pointed cone. Only a tiny ring makes contact. This same principle applies to your wheels.

This small, incorrect contact point cannot properly secure the wheel. The results are predictable and hazardous:

- Loosening Hardware: Vibrations from driving will quickly work the lug screw loose.

- Wheel Damage: The concentrated pressure will damage the lug holes on your expensive wheel. This can make it impossible to ever secure it correctly.

- Uneven Stress: The clamping force becomes uneven. This puts immense stress on the remaining hardware and wheel studs.

- Catastrophic Failure: A loose or damaged lug connection can lead to severe wheel vibration or, in the worst-case scenario, the wheel detaching from the vehicle while you are driving.

Safety Alert: Never compromise on seat type. The correct match ensures maximum contact, proper clamping force, and a secure connection. An incorrect match guarantees an unsafe condition for you and others on the road. Many aftermarket wheels use a conical seat, but you must always verify.

How to Identify Your Wheel’s Seat

You can easily identify your wheel’s seat type with a quick visual inspection. Look directly into the lug holes on the wheel. The shape of the surface where the hardware will rest tells you everything you need to know. If you have the old lug hardware that you know is correct, you can also inspect its shape.

Here is what you should look for:

- Conical Seat: You will see a beveled, angled surface inside the hole. This cone-shaped taper is typically set at a 60-degree angle. This is the most common design for aftermarket wheels and many other applications.

- Ball Seat: The surface will be rounded and smooth, like an inverted bowl. It has a distinct spherical shape with no sharp angles.

- Shank (Mag) Seat: The area around the lug hole will be completely flat. This design requires a lug nut with a straight shank and a separate flat washer to create a flush, secure fit.

Checking the seat type is a simple but essential step for all wheel applications. It ensures your hardware can do its job correctly.

Step 2: Verify the Correct Thread Pitch and Diameter

After confirming the seat type, your next critical task is to verify the thread pitch and diameter of your lug screw. This ensures the hardware can thread smoothly and securely into your vehicle’s hub. Using the wrong thread size will either prevent installation or, worse, damage the threads on your hub, leading to a costly and dangerous situation.

What is Thread Pitch?

You can think of thread pitch as the spacing of the threads on a screw. The official definition is the distance from the peak of one thread to the peak of the next. This measurement is critical for ensuring a perfect fit. For most screws you will encounter, the pitch is a straightforward measurement.

There are two common systems for measuring thread pitch:

- Metric: This system measures the distance between threads in millimeters (mm). A

1.50pitch means the threads are 1.50 mm apart. - Imperial (SAE): This system uses Threads Per Inch (TPI). It counts how many threads fit into one inch of length. A

1/2"-20screw has 20 threads per inch.

A lug screw’s full designation combines diameter and pitch, like 12mm x 1.50 or 14mm x 1.25. The first number (12mm) is the diameter of the screw, and the second number (1.50) is the thread pitch. Getting both right is essential for compatibility.

Common Thread Pitches for Vehicles

Vehicle manufacturers use different thread standards, often based on the region where the car was designed. While there are exceptions, you can use these general guidelines to narrow down what your vehicle might need.

Pro Tip: 💡 The information below is a general guide. Your vehicle’s owner’s manual or the manufacturer’s official specifications are always the most reliable sources for confirming thread compatibility.

The table below shows common thread standards for different vehicle applications.

| Region / Manufacturer Type | Common Thread Pitches |

|---|---|

| North American (Ford, GM, Chrysler) | 1/2″-20, 9/16″-18, 14mm x 1.50 |

| European (BMW, VW, Audi, Mercedes) | 12mm x 1.50, 14mm x 1.25, 14mm x 1.50 |

| Asian (Toyota, Honda, Nissan, Hyundai) | 12mm x 1.25, 12mm x 1.50 |

Knowing these regional trends can help you quickly identify the likely thread pitch for your car, but you must always verify it before purchasing new hardware.

How to Measure Your Lug Screw Thread

If you have an existing lug screw but do not know its specifications, you can easily measure it with a tool called a thread pitch gauge. This tool has a series of small, toothed leaves, each marked with a specific pitch size.

Here is how you can find the correct measurement for your hardware:

- Select a Gauge Leaf: Start with a leaf you think might be a match.

- Test the Fit: Press the teeth of the gauge leaf against the threads of your lug screw.

- Check for Gaps: Look closely for any light passing between the gauge and the screw threads. A perfect fit will have no gaps. The gauge should sit snugly without rocking back and forth.

- Adjust if Needed: If the gauge rocks, it is incorrect. If the points seem too close together, the gauge’s pitch is too fine. If they are too far apart, it is too coarse.

- Confirm the Match: Continue trying different leaves until you find one that meshes perfectly with the threads along its entire length.

- Switch Systems if Necessary: If no metric leaves seem to fit, switch to your imperial (TPI) gauge and repeat the process. Some metric and imperial sizes are very close, so finding the exact match is key.

Once a leaf fits perfectly, the number stamped on it is your thread pitch. You can then use a caliper or ruler to measure the screw’s diameter to get the full size.

Where to Find Your Vehicle’s Specifications

Measuring an old lug screw is a great method if you have one. However, you may not have a correct screw to reference. You must find the official specifications for your vehicle. Guesswork is not an option when it comes to safety. Luckily, you can find this information in several reliable places.

Pro Tip: 💡 Before you start your search, locate your vehicle’s Vehicle Identification Number (VIN). This 17-digit code is the unique fingerprint for your car. You can find it on the driver’s side dashboard (visible through the windshield) or on the door jamb sticker. Providing the VIN ensures you get the exact specifications for your specific model, guaranteeing perfect compatibility.

Here are the best places to find your vehicle’s lug screw specifications:

Your Owner’s Manual Your car’s owner’s manual is the most trustworthy source of information. Look in the index for sections titled “Wheels and Tires,” “Capacities and Specifications,” or “Technical Data.” The manual will list the exact thread diameter and pitch required for your vehicle. Some manuals for European cars may even specify the required seat type (ball or conical) for OEM wheels.

The Manufacturer’s Dealership You can call the parts department at a dealership for your vehicle’s brand. The staff there have access to the manufacturer’s official database. Give them your VIN, and they can tell you the precise lug hardware specifications. This is a quick and highly accurate method.

Trusted Online Auto Parts Retailers Many reputable online auto parts stores have vehicle lookup tools. You enter your car’s year, make, and model. The website then shows you parts that fit. You can use this tool to find the thread size for lug screws listed for your car. Always double-check this information with another source if possible, as databases can sometimes have errors for specific sub-models or special applications.

A Professional Mechanic or Tire Shop Your local mechanic or a specialized tire shop is an excellent resource. These professionals handle different vehicle applications daily. They have access to professional-grade tools, fitment guides, and databases to identify the correct hardware for your car quickly and accurately.

The table below summarizes where you can look and what you can expect to find.

| Source | Information Provided | Reliability |

|---|---|---|

| Owner’s Manual | Thread Size, Torque Specs | Excellent |

| Dealership Parts Dept. | Thread Size, Seat Type, Length | Excellent |

| Online Retailer | Thread Size | Good (Verify) |

| Professional Mechanic | All Specifications | Excellent |

Using these resources removes all doubt. You can be confident you are purchasing and installing the correct hardware for your vehicle.

Step 3: Confirm Proper Lug Screw Length and Engagement

You have the right seat and thread size. Now you must confirm the lug screw length. The length determines how much the hardware threads into the hub. This is called thread engagement. Correct engagement is the final key to a safe wheel installation.

The Critical Role of Thread Engagement

Thread engagement is the amount of contact between the threads of your lug hardware and the threads on your vehicle’s hub or wheel stud. This contact is essential for creating the clamping force that holds your wheel securely. Without enough engagement, the hardware cannot be tightened correctly.

Safety First: A general rule for safe wheel mounting is that the thread engagement must be at least equal to the diameter of the fastener. For example, a 12mm stud requires at least 12mm of thread engagement.

Insufficient engagement prevents the lug hardware from achieving the correct preload, or stretch, when torqued. This means the wheel will not be clamped tightly against the hub. Vibrations from driving can easily cause the hardware to loosen, leading to wheel damage or a dangerous detachment.

Measuring for Correct Lug Bolt Length

For vehicles that use lug bolts, you must choose the correct length for your specific applications. This is especially important when you switch to aftermarket wheels or add wheel spacers, as they can change the required length.

To find the right length:

- Place the new wheel onto the vehicle’s hub.

- Insert a lug bolt through the wheel’s lug hole until it touches the hub.

- Measure how much the bolt shank extends past the back of the wheel. This measurement is the amount of engagement you will have.

- Compare this to your vehicle’s required engagement depth to ensure a secure fit.

Checking for Proper Lug Nut Engagement

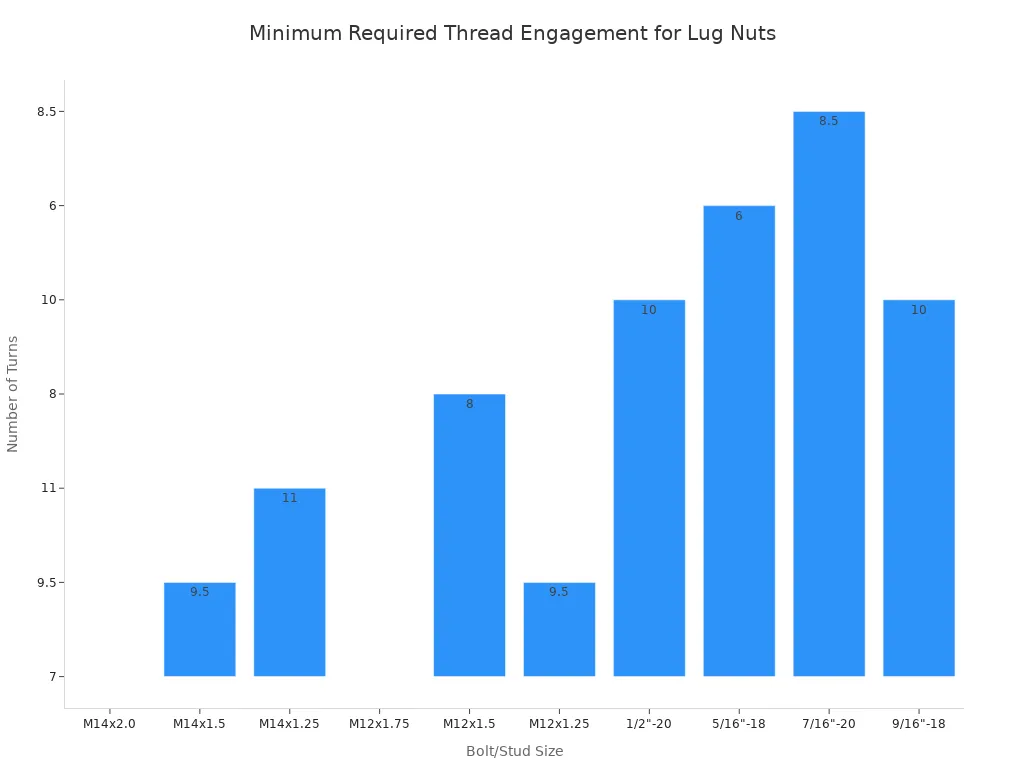

For vehicles with wheel studs and lug nuts, you can verify proper engagement by counting the number of turns. After hand-tightening the lug nut, use a wrench and count how many full rotations it takes to secure the lug. This number should meet or exceed the minimum requirement for your stud size. Different applications require a different number of turns for safe engagement.

The table below shows the minimum number of turns for common stud sizes.

| Bolt/Stud Size | Number of Turns |

|---|---|

| M14x1.5 | 9.5 |

| M14x1.25 | 11 |

| M12x1.5 | 8 |

| M12x1.25 | 9.5 |

| 1/2″-20 | 10 |

| 7/16″-20 | 8.5 |

Meeting these minimums ensures your wheel is safely attached.

Risks of a Lug Screw Being Too Short or Too Long

Choosing the right length for your lug screw is just as important as the seat and thread. Both short and long hardware create unique and serious safety hazards. You must ensure the length provides correct thread engagement without interfering with other parts.

Dangers of a Lug Screw That Is Too Short

A short lug screw is a major safety risk because it cannot achieve proper thread engagement. This lack of engagement means the threads cannot handle the forces of a properly torqued wheel.

The consequences are severe:

- Stripped Threads: The few threads making contact can easily strip from the vehicle’s hub or stud. This permanently damages the component.

- Loosening Hardware: Insufficient engagement prevents the lug from clamping the wheel securely. Road vibrations will quickly cause it to loosen.

- Wheel Detachment: A loose or stripped lug can lead to catastrophic failure, where the wheel separates from the vehicle while driving.

Safety Alert: ⚠️ Never use a lug screw that provides less than the minimum required thread engagement. The risk of failure is extremely high.

Dangers of a Lug Screw That Is Too Long

A lug screw that is too long creates a different set of problems. The hardware can bottom out on components behind the wheel hub before it fully tightens the wheel.

This creates two critical issues:

- False Torque: You might reach the correct torque value on your wrench, but the wheel is still loose. The torque reading comes from the bolt hitting the hub assembly, not from clamping the wheel.

- Component Damage: The end of the long lug can strike and destroy critical parts behind the hub.

The table below shows parts commonly damaged by long hardware.

| Component | Potential Damage |

|---|---|

| Brake Calipers | Can be cracked or gouged. |

| ABS Sensors | Wires can be severed, disabling your ABS. |

| Dust Shields | Can be bent, causing grinding noises. |

| Parking Brake | Mechanisms inside the hub can be broken. |

Proper length ensures full engagement and avoids these costly and dangerous outcomes.

Lug Bolts vs. Lug Nuts: Understanding the Difference

You will encounter two main systems for attaching a wheel: lug bolts and lug nuts. While both secure your wheel, they function differently. Understanding which system your car uses is essential for getting the right hardware.

What Are Lug Bolts?

A lug bolt is a single piece of hardware. It is a long screw with a head on one end and threads on the other. You install it by passing the bolt through the wheel’s lug hole and threading it directly into the vehicle’s hub. This design requires you to hold the wheel in place while aligning the bolt holes, which can be tricky. Many European car brands, like BMW and Volkswagen, use this system.

What Are Lug Nuts and Wheel Studs?

The second system uses two separate parts: wheel studs and lug nuts. Wheel studs are threaded posts that are fixed to the vehicle’s hub and stick out. You can hang the wheel on these studs, which makes alignment much easier. You then use lug nuts to secure the wheel onto the studs. Most American and Japanese vehicles use lug nuts. This system is very common, and you will find many types of lug nuts available. The lug nuts do the final job of clamping the wheel.

The table below shows the key differences between the two systems.

| Feature | Lug Bolt System | Lug Nut System |

|---|---|---|

| Structure | A single bolt secures the wheel. | A stud is fixed to the hub; lug nuts tighten onto it. |

| Installation | You must align the wheel and bolt holes. | The wheel hangs on studs for easy alignment. |

| Common Use | European vehicles (BMW, VW, Audi) | American & Japanese vehicles (Ford, Toyota) |

Identifying Which System Your Car Uses

You can easily tell which system your car has. Simply remove a wheel cover or look at the center of your wheel.

- If you see threaded posts sticking out from the hub before the lug nuts are on, your car uses wheel studs and lug nuts.

- If you see threaded holes in the hub and no posts, your car uses lug bolts.

Knowing your system is the first step to choosing the correct hardware. Using the wrong type is impossible, but knowing the difference helps you find the right parts, like the correct lug nuts for your wheel. Many people prefer the ease of use that comes with lug nuts.

Choosing a High-Quality Lug Screw

Selecting the right wheel hardware goes beyond just fitment. The quality of your lug screw directly impacts your safety and your vehicle’s performance. You should always choose hardware from a reputable source to ensure your wheel remains secure.

Material Matters: Steel vs. Titanium and Aluminum

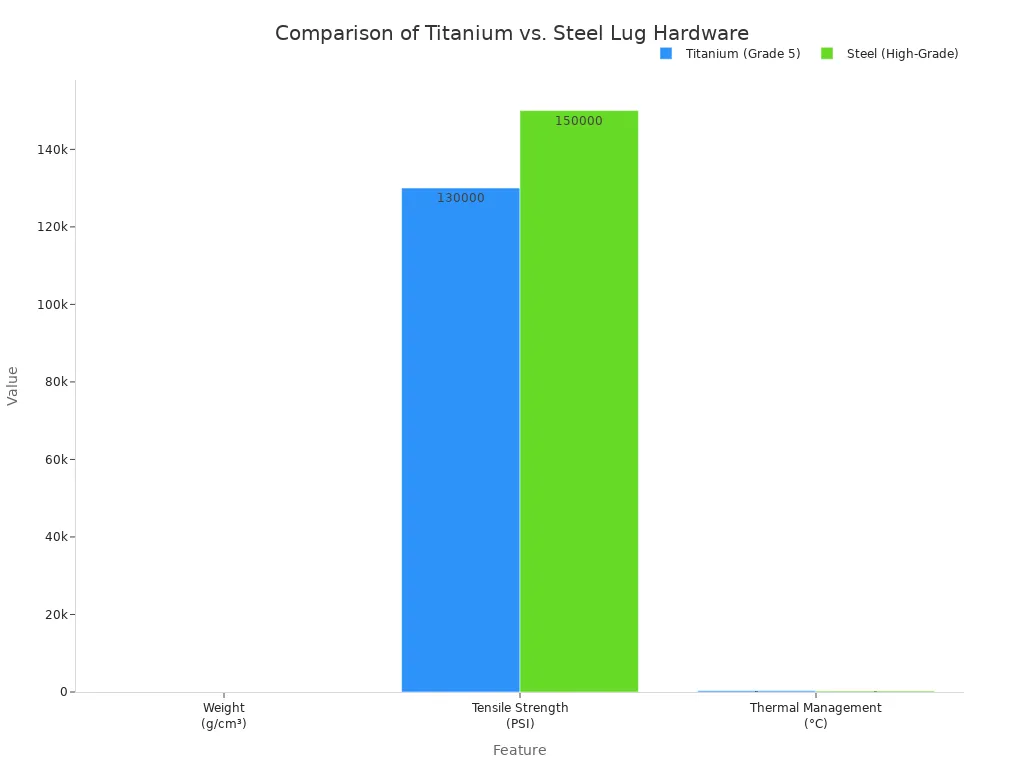

The material of your wheel hardware determines its strength, weight, and durability. Steel is the most common material for its strength and cost-effectiveness, making it ideal for daily driving. For high-performance applications, you might consider titanium.

Titanium offers an exceptional strength-to-weight ratio. It is about 40% lighter than steel, which reduces unsprung mass and can improve your vehicle’s handling and acceleration performance. This material also provides superior corrosion resistance, making it a great long-term investment. Aluminum is another lightweight option, but it is not as strong as steel or titanium and can be prone to stripping under high stress.

The table below compares the two most popular materials for performance wheel hardware.

| Feature | Titanium (Grade 5) | Steel (High-Grade) |

|---|---|---|

| Tensile Strength | Excellent (≥950 MPa) | Very Good (≥800 MPa) |

| Corrosion | Does not rust | Can corrode over time |

| Heat Resistance | Maintains strength at high heat | Can weaken with heat cycles |

| Best For | Track and performance cars | Daily drivers, heavy-duty use |

Why Quality Hardware from a Trusted Manufacturer is Key

You should never compromise on the quality of your wheel hardware. A trusted manufacturer adheres to strict industry standards to guarantee safety and performance. When shopping, you can look for manufacturers with certifications that prove their commitment to quality.

Key certifications include:

- ISO 9001: This ensures the company follows a quality management system for consistent production.

- IATF 16949: This is a specific standard for the automotive industry that guarantees parts meet vehicle manufacturer requirements.

Choosing certified hardware gives you peace of mind that every lug is built for safety and top-tier performance.

Signs of Worn or Low-Quality Lug Hardware

You should regularly inspect your wheel hardware for signs of wear or damage. Using a compromised lug is a major safety risk. A damaged lug can fail, potentially causing your wheel to detach.

Safety Tip: ⚠️ If you see any of these signs, replace your hardware immediately. Do not drive on a wheel with damaged hardware.

Look for these common warning signs:

- Corrosion: Check for rust, pitting (tiny holes), or flaking on the surface.

- Stripped Threads: Damaged or flattened threads indicate the hardware was over-torqued or cross-threaded.

- Rounded Heads: If the head of the lug is rounded, it will be difficult to torque correctly.

- Cracks: Any visible cracks mean the hardware has failed and must be replaced.

A Guide to Safe Lug Screw Installation

Proper installation is the final step to ensuring your wheel is secure. Following the correct procedure with the right tools prevents damage and guarantees safety on the road. This guide covers the essential steps for a perfect installation.

Why You Must Use a Torque Wrench

You must use a torque wrench for every wheel installation. This tool allows you to apply a precise amount of rotational force, or torque. An impact gun is fast, but it is not accurate and can have a variance of 20% or more. A torque wrench is highly accurate, often within +/- 5%, ensuring each lug receives the correct clamping force.

Warning: ⚠️ Incorrect torque is dangerous. Too little torque allows the lug to loosen from road vibrations, which can cause wheel wobble or detachment. Too much torque can strip threads, stretch the lug screw, and warp your brake rotors, leading to expensive repairs.

Finding Your Vehicle’s Torque Specifications

Every vehicle has a specific torque value for its wheel hardware. You must use the manufacturer’s recommended torque specification for a safe installation. The best place to find this information is in your vehicle’s owner’s manual.

You can also find reliable torque data from the vehicle manufacturer’s dealership or trusted online sources. The table below shows where to look.

| Source | Reliability | Notes |

|---|---|---|

| Owner’s Manual | Excellent | The most accurate source for your specific vehicle. |

| Dealership | Excellent | Parts department can provide exact specs. |

| Online Guides | Good | Use guides from reputable retailers, not generic charts. |

Always use the specific torque value for your car to ensure a secure wheel.

The Star Pattern: Tightening Lugs Correctly

You must tighten your hardware in a star or crisscross pattern. This method ensures the wheel mounts evenly against the hub. Tightening lugs in a circle can cause the wheel to flex or shift, resulting in uneven torque and a loose fit. The star pattern applies uniform pressure across the mounting surface. This technique is critical for a safe and balanced installation. Simply tighten one lug, then move to the one directly across from it, continuing until all are tightened to the correct torque.

The Importance of Re-Torquing Your Wheels

Your job is not finished after the initial installation. You must perform a final safety check called a re-torque. This step ensures your hardware remains secure after the initial drive. New wheels and hardware can settle slightly once you are on the road. Heat from your brakes and vibrations from driving can cause tiny shifts. These shifts can reduce the clamping force, making your initial torque less effective. A re-torque check confirms everything is still tight and safe.

You should always re-torque your lug hardware after a new installation. The recommended time for this check is within the first 50 to 100 miles of driving. If you do not drive that far right away, you should perform the check within 3 to 7 days. This simple follow-up is crucial for safety. It verifies the initial torque and prevents lugs from loosening.

Pro Tip: 💡 A re-torque does not mean you need to tighten the lugs further. You should set your torque wrench to the correct specification and check that each lug is still at the proper torque. If the wrench clicks without the lug turning, the torque is correct.

You should make re-torquing a regular part of your vehicle maintenance. A consistent schedule guarantees your wheel stays secure for the long term.

- Initial Re-torque: Check the torque after driving 50-100 miles following any wheel installation.

- Regular Maintenance Re-torque: Verify the torque every 5,000 miles or during your normal tire rotations.

- Post-Service Re-torque: Always re-check your torque after any service that involves removing a wheel, like brake or suspension work.

Remember, your wheel hardware is a critical safety component for every wheel. You can guarantee a safe wheel fitment using a simple checklist. This is your key takeaway for any wheel installation.

Your Safety Checklist:

- Seat: Match the hardware seat to the wheel.

- Size: Verify the correct thread pitch and diameter.

- Length: Confirm proper thread engagement.

If you are ever unsure about your wheel hardware, you should consult a professional for guidance. Confidently fitting your wheel begins with mastering these essentials.

FAQ

Can I reuse my old lug screws?

You should avoid reusing old lug screws. They stretch and weaken over time from metal fatigue. For maximum safety, you should always install new hardware when you get new wheels. This ensures a secure and reliable fit.

What happens if I use an impact wrench instead of a torque wrench?

An impact wrench lacks precision. It can easily over-tighten your hardware, stripping threads and warping rotors. It can also under-tighten them, risking a loose wheel. You must use a torque wrench for accurate and safe installation.

Do I need different lug hardware for steel and alloy wheels?

You might need different hardware. The most important factor is the seat type, not the wheel material. You must match your lug screw’s seat (conical, ball, etc.) to the new wheel’s design for a safe fit.

Why do my new wheels need a re-torque?

New wheels settle against the hub after you drive. Heat and vibration can slightly reduce the clamping force. You must re-torque your wheels after 50-100 miles. This final check ensures your hardware remains tight and your wheel is secure.

Quick Tip: 💡 Always keep a copy of your vehicle’s torque specification in your glove box. This makes it easy to reference for any future tire service or safety check.