admin1

October 1, 2025

Lug Bolts or Lug Nuts Which Fastener Is Best for Your Wheels

Choosing the right fastener for your wheels keeps you safe and helps your car perform its best. You need to match your fastener to your vehicle’s design and driving style. Lug bolts work well for some cars, while other vehicles use different systems. Always check your car’s manual for the correct type. If you feel unsure, ask an expert like Fortune for advice. Using the right part prevents problems on the road.

What Are Lug Bolts and Lug Nuts?

Lug Bolts Defined

You may notice that some vehicles use lug bolts to secure their wheels. Lug bolts are fasteners that screw directly into the wheel hub. You do not need a separate stud. The bolt passes through the wheel and threads into the hub itself. This design is common in many German vehicles. For example, you will find lug bolts on cars from BMW, Mercedes, Porsche, and Volkswagen. The bolt holds the wheel tightly in place and helps keep everything aligned.

Lug Nuts Defined

Lug nuts work differently. You first have wheel studs that stick out from the hub. You place the wheel onto these studs. Then, you screw the lug nuts onto the studs to hold the wheel in place. Most Japanese and American vehicles use this system. You will see lug nuts on many new cars from these manufacturers. The nut design makes it easy to remove and replace wheels, especially if you need to change a tire on the road.

Differences Between Lug Bolts and Lug Nuts

You might wonder about the main differences between lug bolts and lug nuts. The biggest difference is how each fastener attaches the wheel to the vehicle. Lug bolts screw into the hub, while lug nuts screw onto studs. This affects how you install and remove your wheels. The choice between these fasteners often depends on the manufacturer’s preference, not performance. Here is a quick summary:

- German brands like BMW, Mercedes, Porsche, and Volkswagen use lug bolts.

- Japanese and American brands usually use lug nuts.

- Both systems keep your wheels secure, but the installation process is different.

Tip: Always check your vehicle’s manual before buying new fasteners. Using the right type keeps your wheels safe and secure.

Key Differences Between Lug Bolts and Lug Nuts

Design and Structure

You can see a clear difference in how lug bolts and lug nuts are built. Lug bolts have a threaded shaft and a head. You screw the bolt directly into the wheel hub. Lug nuts, on the other hand, work with wheel studs. The nut threads onto the stud to hold the wheel in place.

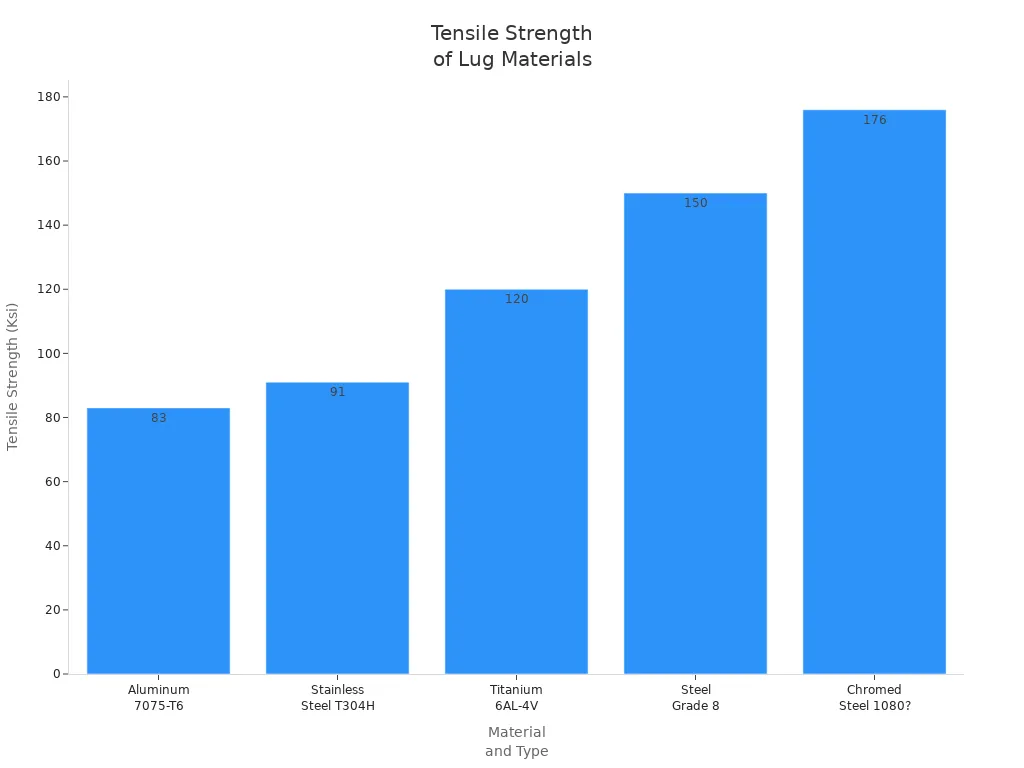

The materials used for these fasteners matter for strength and durability. Manufacturers use metals like aluminum, stainless steel, titanium, and chromed steel. Each material has a different tensile strength, which shows how much force the fastener can handle before breaking. You can compare the strengths in the table below:

| Material | Type | Tensile Strength (Ksi) |

|---|---|---|

| Aluminum | 7075-T6 | 83 |

| Stainless Steel | T304H | 91 |

| Titanium | 6AL-4V | 120 |

| Steel | Grade 8 | 150 |

| Chromed Steel | 1080 | 176 |

You get better strength and reliability when you choose high-quality materials. This helps keep your wheels secure, especially during high-speed driving or heavy loads.

Installation Process

You will notice a big difference in how you install lug bolts vs lug nuts. With lug bolts, you need to line up the wheel holes with the hub and then thread each bolt into place. This process can take more time because you must hold the wheel steady while you insert the bolts.

When you use lug nuts, you slide the wheel onto the studs. The studs help guide the wheel into position. You then screw the nuts onto the studs. This makes changing a tire easier, especially if you need to do it quickly on the side of the road.

Tip: Always tighten your fasteners in a star pattern. This helps distribute pressure evenly and keeps your wheels balanced.

Safety matters during installation. In the United States, wheel detachments happen about 40 to 60 times per week, causing around 20 accidents weekly. Loose wheel nuts cause nearly half of these incidents. In the United Kingdom, there are 7,500 to 11,000 cases of loose wheel nuts each year. This leads to 150 to 400 wheel detachments, with 10 to 27 injury accidents and 3 to 7 fatal accidents. You can reduce these risks by checking your fasteners regularly and following proper installation steps.

Vehicle Compatibility

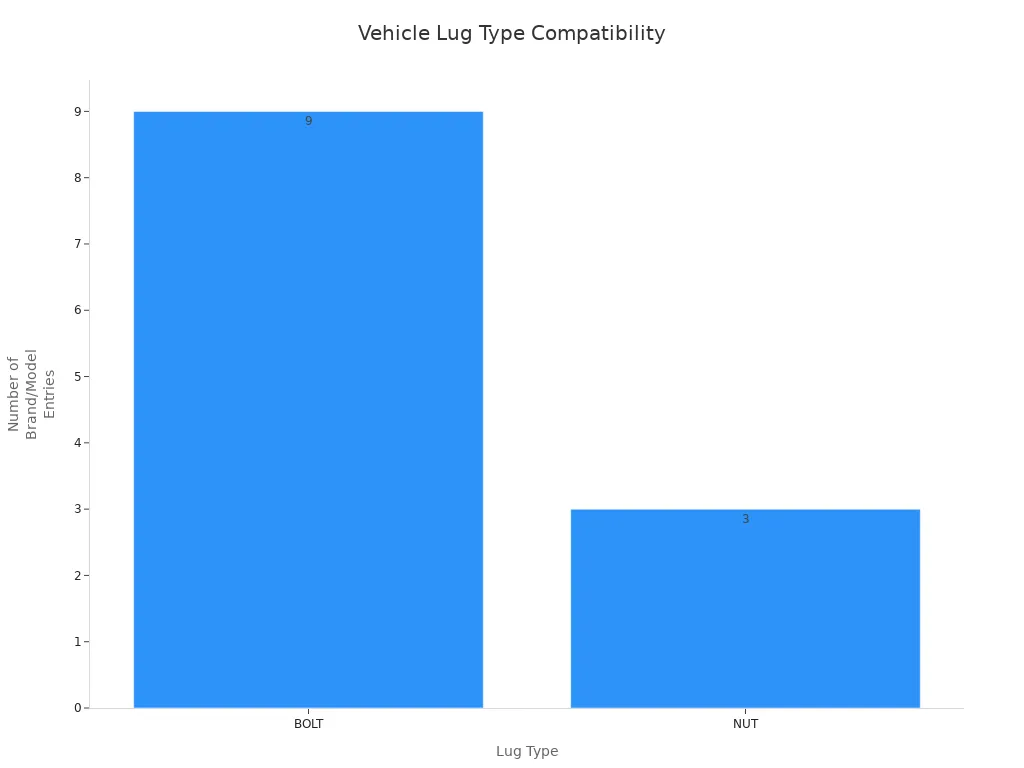

You need to match your fastener type to your vehicle. Most German brands use lug bolts. You will find lug bolts on cars like Porsche 924, Boxster, Cayenne, 911, Alfa Romeo 145, 146, 155, and many Audi models. Japanese and American brands usually use lug nuts. Acura, Saturn, and Scion models use lug nuts for their wheels.

| Vehicle Brand | Model | Lug Type |

|---|---|---|

| Porsche | 924 | BOLT |

| Porsche | Boxster, Cayenne, 911 | BOLT |

| Alfa Romeo | 145, 146 | BOLT |

| Alfa Romeo | 155 | BOLT |

| Audi | 4000S | BOLT |

| Audi | 80 | BOLT |

| Audi | 4000, Quattro | BOLT |

| Audi | 5000 (Non-Turbo) | BOLT |

| Audi | TT | BOLT |

| Acura | Various Models | NUT |

| Saturn | Various Models | NUT |

| Scion | Various Models | NUT |

You should always check your owner’s manual or ask a professional before buying new fasteners. Using the wrong type can make your wheels unsafe and lead to problems on the road.

Security and Safety

You want your wheels to stay secure every time you drive. The right fastener plays a big role in keeping you safe. When you compare lug bolts vs lug nuts, you notice that each system offers unique safety features.

Lug bolts screw directly into the hub. This design creates a strong connection between the wheel and the vehicle. You need to make sure each bolt is tightened to the correct torque. If you do not use the right torque, the wheel can loosen over time. Many German cars use lug bolts because they provide a tight fit and help prevent movement.

Lug nuts attach to wheel studs. The studs guide the wheel into place and make installation easier. You can quickly check if a lug nut is loose because it sits on the outside of the wheel. This makes regular inspections simple. You should always tighten lug nuts in a star pattern. This method spreads the pressure evenly and helps keep the wheel balanced.

Safety Tip: Use a torque wrench to tighten your fasteners. This tool helps you avoid over-tightening or under-tightening, which can damage the wheel or cause it to come loose.

Loose fasteners can lead to dangerous situations. Data shows that in the United States, loose wheel nuts cause about 20 accidents every week. In the United Kingdom, there are up to 11,000 cases of loose wheel nuts each year. These incidents can result in injury or even death. You can lower your risk by checking your fasteners often and following the manufacturer’s instructions.

You should also consider the material of your fasteners. Strong metals like chromed steel and titanium offer better resistance to stress and corrosion. High-quality fasteners last longer and keep your wheels secure, even in tough driving conditions.

Here is a quick checklist to help you stay safe:

- Inspect your fasteners every month.

- Use the correct torque for your vehicle.

- Replace damaged or worn fasteners right away.

- Follow the installation pattern recommended by your manufacturer.

You protect yourself and others when you pay attention to these details. Reliable fasteners keep your wheels in place and help you avoid accidents.

Pros and Cons of Lug Bolts vs Lug Nuts

Lug Bolts Advantages

You find several advantages of lug bolt systems when you look at how they work in a wheel assembly. Lug bolts combine the stud and nut into one piece, which can simplify the design of your wheels. You do not need separate studs, so you reduce the number of parts. This can make manufacturing and maintenance easier for some vehicles.

Many European cars use lug bolts because they help create a tight fit between the wheel and the hub. This design can improve alignment and reduce movement during driving. You get a clean look since the bolts sit flush with the wheel surface. Some drivers prefer this appearance for their vehicles.

You also notice that lug bolts can save space in the hub area. This can help engineers design lighter and more compact wheel assemblies. If you want a system that combines strength and simplicity, you may see the advantages of lug bolt designs.

Tip: Always check the torque specifications for your lug bolts. Proper tightening keeps your wheels secure and prevents loosening over time.

Lug Bolts Disadvantages

You need to consider the disadvantages of lug bolt systems before making a choice. Automotive repair professionals report several challenges with lug bolts:

- Damage to threaded studs or bolt holes can occur if you do not handle installation carefully. This damage may lead to costly repairs.

- Misalignment of bolt holes during installation can prevent proper securing of the wheel. You may need extra effort to hold the wheel in place while threading each bolt.

If you struggle to align the wheel holes with the hub, you may find installation more difficult compared to systems with studs. You must hold the wheel steady and insert each bolt one at a time. This process can take longer, especially if you need to change a tire quickly.

You should also know that if a lug bolt or its threads become damaged, you may need to replace the entire hub or repair the threaded hole. This can increase maintenance costs and time. These issues highlight the disadvantages of lug bolt systems for some drivers.

Lug Nuts Advantages

You see many advantages of lug nut systems when you examine how they secure your wheels. Lug nuts work with wheel studs, which guide the wheel into position and make installation easier. You slide the wheel onto the studs, then tighten the nuts to hold everything in place.

Vehicle safety studies show that lug nuts play a crucial role in keeping your wheels secure. Properly tightened lug nuts are essential for safe driving. If you do not tighten them enough, your wheels can loosen over time, especially at high speeds. This increases the risk of accidents.

You benefit from several features when you use lug nuts:

- Proper torque specifications help ensure that lug nuts hold the wheel securely.

- Under-tightened lug nuts can lead to wheel detachment, which creates dangerous situations on the road.

- Over-tightening can damage wheel studs, which may compromise their integrity and increase the risk of failure.

You can inspect lug nuts easily because they sit on the outside of the wheel. This makes regular checks simple and helps you spot problems before they become serious. Many drivers appreciate the convenience and safety that lug nuts provide. You may find that the advantages of lug nut systems suit your needs, especially if you want quick and reliable wheel changes.

Lug Nuts Disadvantages

When you use lug nuts to secure your wheels, you may face some challenges that affect safety and convenience. Understanding these disadvantages helps you make better choices for your vehicle.

Risk of Stud Damage

You rely on wheel studs to hold the lug nuts in place. If you over-tighten a lug nut, you can stretch or strip the stud. Damaged studs may break under stress, which can cause the wheel to loosen or detach. You need to replace broken studs, and this repair takes time and money.Potential for Uneven Tightening

You must tighten lug nuts in a star pattern. If you do not follow this method, you can create uneven pressure on the wheel. Uneven tightening may warp the wheel or brake rotor. This problem can lead to vibrations while driving and may reduce braking performance.Corrosion and Seizing

Lug nuts sit exposed to water, salt, and dirt. Over time, rust can build up on the threads. Corroded lug nuts may seize onto the studs, making removal difficult. You might need special tools or extra force to loosen stuck nuts. This issue often appears in regions with harsh winters or coastal climates.Limited Security Features

Standard lug nuts do not offer advanced anti-theft protection. Thieves can remove regular lug nuts with basic tools. You can buy locking lug nuts, but these add cost and require a special key for removal.

Note: You should inspect your lug nuts regularly. Look for signs of rust, wear, or damage. Replace any faulty parts right away to keep your wheels secure.

| Disadvantage | Impact on Vehicle | Solution |

|---|---|---|

| Stud Damage | Wheel may loosen | Replace damaged studs |

| Uneven Tightening | Vibration, warping | Use star pattern |

| Corrosion/Seizing | Difficult removal | Apply anti-seize grease |

| Limited Security | Theft risk | Use locking lug nuts |

You need to pay attention to these issues when you maintain your wheels. Careful installation and regular checks help you avoid problems and keep your vehicle safe.

When to Use Lug Bolts vs Lug Nuts

OEM Recommendations

You should always start with your vehicle manufacturer’s advice. Car makers design each wheel assembly to work with a specific type of fastener. If your owner’s manual says to use lug bolts, you need to stick with that choice. Many German brands, like BMW and Audi, use lug bolts for their wheels. Japanese and American brands often recommend lug nuts. Following these guidelines helps you avoid problems with fitment and safety. You protect your wheels and keep your car running smoothly when you follow OEM recommendations.

Aftermarket Wheels

When you upgrade or replace your wheels, you need to check compatibility with your fasteners. Aftermarket wheel manufacturers want their products to fit many vehicles, so they use standardized features. Most aftermarket wheels use a conical seat with a 60-degree taper. This design works with both lug bolts and lug nuts, making installation easier. You also get fitment support from manufacturers to help you choose the right fastener and ensure proper performance.

| Specification Type | Description |

|---|---|

| Conical Seat | Standardized 60-degree taper for broad compatibility |

| Fitment Support | Assistance provided for proper installation and performance |

If you want to change your wheels, always check the seat type and ask for fitment advice. This step helps you avoid issues with installation and keeps your wheel assembly secure.

Performance and Customization

You may want to improve your car’s performance or customize its look. Motorsports teams and car enthusiasts often choose fasteners based on speed and safety. Lug bolts give a clean appearance because you do not see exposed threads. You need two hands to start each bolt, which can slow down wheel changes. Lug nuts and studs make tire changes faster. You can hang the wheel on the studs and use bullet nose studs for even quicker swaps. In racing, longer studs can be glued into the wheels for speed.

| Aspect | Lug Bolts | Lug Studs |

|---|---|---|

| Ease of Wheel Changes | Requires two hands to start bolts | Wheel hangs on studs, easier to start |

| Safety | One thread interface to fail | Two interfaces (stud and nut) |

| Appearance | Cleaner look without exposed threads | Threads stick out past the nut |

| Mechanical Advantage | No significant advantage noted | Faster tire changes with bullet nose studs |

| Consistency of Torque | Varies with tightening process | More consistent due to fixed length of studs |

Tip: If you want faster tire changes for racing or track days, lug nuts and studs offer a clear advantage. For a sleek look and simple design, lug bolts work well.

You need to match your fastener choice to your driving needs. Whether you want speed, style, or reliability, understanding these differences helps you make the best decision for your wheels.

Maintenance Considerations

You need to keep your wheel fasteners in top condition to ensure safe driving. Regular maintenance helps you avoid problems with your wheels and keeps your vehicle running smoothly. Both lug bolts and lug nuts require attention, but you will notice some differences in how you care for each type.

Start by checking your fasteners every month. Look for signs of rust, wear, or damage. If you see any cracks or stripped threads, replace the fastener right away. Damaged fasteners can weaken your wheel assembly and increase the risk of wheel detachment.

Clean your fasteners when you rotate or change your tires. Use a wire brush to remove dirt and rust from the threads. For lug nuts, apply a small amount of anti-seize lubricant to the threads if you live in an area with lots of rain or snow. This step helps prevent the nuts from sticking to the studs.

Always use a torque wrench when tightening your fasteners. Tighten them to the manufacturer’s recommended torque. Over-tightening can stretch or break the fastener. Under-tightening can cause the wheel to loosen while you drive. Follow a star pattern when tightening to spread the pressure evenly.

Here is a simple checklist for wheel fastener maintenance:

- Inspect fasteners for rust, cracks, or damage.

- Clean threads before installation.

- Use anti-seize lubricant in wet or snowy climates.

- Tighten with a torque wrench to the correct specification.

- Follow a star pattern for even pressure.

Tip: Replace all fasteners if you notice repeated problems or if you upgrade your wheels. This ensures the best fit and safety for your vehicle.

Proper maintenance keeps your wheel assembly secure and extends the life of your wheels and fasteners.

How to Choose the Right Wheel Lug Nuts or Lug Bolts

Check Your Vehicle Type

You need to start by identifying your vehicle’s requirements. Every car has a specific wheel assembly design, which determines the type of fastener you should use. Begin by counting the number of bolt holes on your wheel. Next, measure the Bolt Circle Diameter (BCD) using a tape measure or caliper. For a 5-lug wheel, multiply the distance between holes by 1.05 to get the BCD. Record these measurements for accuracy. The bolt pattern tells you how many fasteners secure your wheel and the diameter of the pitch circle. Always compare your findings with your owner’s manual to confirm if you need wheel lug nuts or lug bolts. Using the original lug nuts or bolts recommended by your manufacturer helps maintain safety and performance.

Tip: Accurate measurements prevent fitment issues and keep your wheels secure.

Consider Your Wheel Design

Wheel design plays a big role in choosing the right fastener. Manufacturers use different mounting options, which influence your decision. Take a look at the table below to see how each component affects wheel design:

| Component | Description | Influence on Wheel Design |

|---|---|---|

| Wheel Lug Nut | A small, threaded fastener that fastens the wheel to the hub. | Allows for easy installation and removal, affecting wheel design choices. |

| Wheel Lug Bolt | A single threaded rod that screws directly into the wheel hub. | Provides a different mounting option, influencing design preferences among manufacturers. |

If your wheels are designed for lug nuts, you benefit from easier installation and removal. Wheels built for lug bolts offer a different mounting style, which some manufacturers prefer for clamping vehicle wheels. Always match your fastener to the wheel’s seat type and mounting method to avoid compatibility problems.

Assess Your Driving Needs

Your driving habits and conditions influence your choice of fastener. If you participate in racing or change tires often, lug nuts and studs make tire swaps faster and easier. Teams prefer this setup because it reduces the risk of misalignment and damage during frequent wheel changes. Lug bolts can be more prone to thread damage if you change wheels often. For daily driving, both systems provide reliable security when installed correctly. If you upgrade to aftermarket wheels, consider how the new design affects performance and resale value. Custom wheels can improve your car’s look and handling, but poor choices may lead to fitment issues and lower resale value. Always select fasteners that match your driving needs and wheel design for the best results.

Note: Regularly check and maintain your fasteners to ensure ongoing safety and performance.

Step-by-Step Selection Guide

Choosing the right wheel fastener does not have to feel overwhelming. You can follow these simple steps to make the best choice for your vehicle and driving needs:

Check Your Owner’s Manual

Start by reading your vehicle’s manual. The manufacturer lists the correct type of fastener for your car. You will find details about size, thread pitch, and torque specifications. This information helps you avoid mistakes.Identify Your Wheel Type

Look at your wheels. Factory wheels often use the same fasteners as listed in your manual. If you have aftermarket wheels, check the seat type—conical, ball, or flat. The seat type must match your fastener for a secure fit.Measure Bolt Pattern and Thread Size

Use a tape measure or caliper to measure the distance between bolt holes. Count the number of holes. Write down the bolt pattern (for example, 5×114.3). Check the thread size and pitch, which you can find stamped on the old fastener or in your manual.Consider Your Driving Habits

Think about how you use your vehicle. If you drive daily in city traffic, standard fasteners work well. For racing or frequent tire changes, you may prefer lug nuts and studs for faster swaps.Inspect for Quality and Certification

Choose fasteners made from strong materials like chromed steel or titanium. Look for products with ISO9001 or similar certifications. High-quality fasteners last longer and keep your wheels safe.Consult an Expert if Unsure

If you feel uncertain, ask a professional. Companies like Fortune offer expert advice and reliable products. You can contact them for help with fitment and selection.

Tip: Always use a torque wrench to tighten your fasteners. This tool helps you reach the correct torque and prevents damage.

| Step | What to Do | Why It Matters |

|---|---|---|

| Check Manual | Find specs and type | Ensures correct fit |

| Identify Wheel Type | Match seat style | Prevents loose wheels |

| Measure Pattern | Confirm bolt pattern and thread | Avoids installation errors |

| Assess Habits | Choose for your driving style | Improves safety and convenience |

| Inspect Quality | Pick certified, strong fasteners | Increases durability |

| Ask an Expert | Get professional advice | Ensures best choice |

By following these steps, you make sure your wheels stay secure and your vehicle performs at its best.

You see clear differences between lug bolts and lug nuts. The table below highlights the key points:

| Aspect | Lug Bolt | Lug Nut |

|---|---|---|

| Structure | Threaded rod, hex head | Threaded nut, conical/hex head |

| Installation | Screws into hub | Threads onto stud |

| Material | Alloy steel | Aluminum |

| Stress Handling | Handles high stress | Handles axial stress only |

| Ease of Use | More difficult | Easier |

You should always follow your vehicle’s manual and seek expert advice. Experts help you match bolt patterns, hub sizes, and torque specs for safe fitment. Using the wrong fastener can cause brake wear, vibrations, or even fastener failure. Trusted professionals like Fortune provide quality products and guidance. Always use a torque wrench and check your fasteners often to keep your wheels secure.

FAQ

What happens if you use the wrong type of wheel fastener?

You risk wheel misalignment or even wheel detachment. Using the wrong fastener can damage your wheel hub or studs. Always match your fastener to your vehicle’s specifications. This keeps your wheels secure and prevents accidents.

Can you switch from lug bolts to lug nuts on your car?

You cannot easily switch between lug bolts and lug nuts. Your vehicle’s hub design determines which fastener you use. Some custom conversions exist, but you should consult a professional before making changes. Always follow your manufacturer’s recommendations.

How often should you check your wheel fasteners?

You should inspect your wheel fasteners every month. Check them after long trips or rough roads. Use a torque wrench to ensure proper tightness. Regular checks help prevent loosening and keep your wheels safe.

Do aftermarket wheels require different fasteners?

Many aftermarket wheels use a standard conical seat, but some need special fasteners. Always check the wheel’s instructions or ask the supplier. Using the correct fastener ensures a proper fit and safe driving.

Why is torque important when tightening wheel fasteners?

Proper torque keeps your wheels secure. Too much torque can damage threads or studs. Too little torque can cause the wheel to loosen. Always use a torque wrench and follow your vehicle’s specifications for best results.