admin1

June 14, 2025

The Truth About Lead Tire Balancing Weights and Environmental Safety

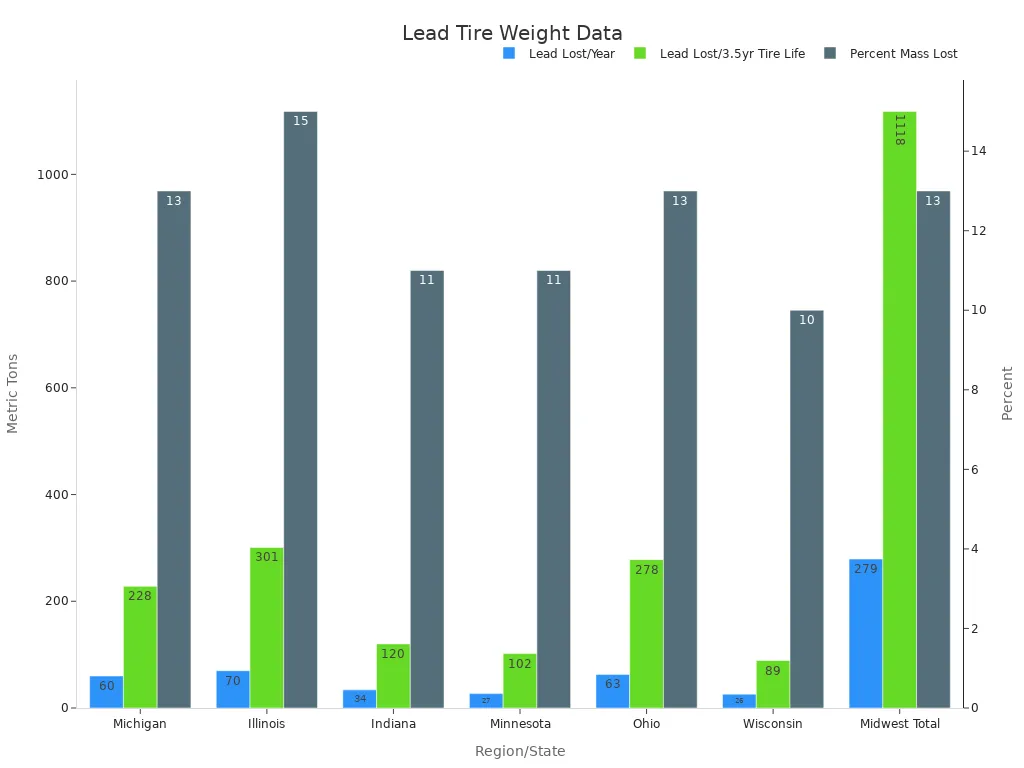

Lead tire balancing weights release large amounts of lead into the environment every year. For example, the Midwest region loses nearly 279 metric tons of lead annually from these weights, as shown below.

New Jersey alone sees up to 26 metric tons of lead tire weights lost each year, greatly increasing health risks for people, especially children. These facts highlight the urgent need for safer choices in tire maintenance.

What Are Lead Tire Balancing Weights?

Purpose and Use in Vehicles

Lead tire balancing weights play a key role in vehicle safety and performance. When a tire spins, even a small imbalance can cause vibrations. These vibrations make rides uncomfortable and can lead to uneven tire wear. Lead wheel weights attach to the rim of the wheel to correct these imbalances. By adding weight where needed, they help keep the tire spinning smoothly.

Lead wheel weights offer several benefits:

- They provide precise balancing because of their high density.

- They help prevent vibrations and uneven tire wear.

- They improve vehicle handling and safety by keeping the tire in better contact with the road.

- Balanced wheels can lead to smoother rides and better fuel efficiency.

- Proper tire balancing reduces wear on the suspension and extends the life of vehicle parts.

Many service centers use lead wheel balancing weights because they are easy to install and last a long time. Regular maintenance and correct installation are important to keep these benefits.

Common Materials Used in Lead Wheel Weights

Manufacturers have used lead for tire balancing weights for many years. Lead has a high density of about 11.3 g/cm³. This means a small piece of lead can provide enough weight to balance a tire. Lead is also soft and easy to shape, which makes it simple to fit onto different types of wheels.

However, concerns about lead’s toxicity and environmental impact have led to the use of other materials. The table below compares the most common materials for wheel weights:

| Material | Density & Size | Durability & Corrosion Resistance | Environmental Impact | Typical Applications |

|---|---|---|---|---|

| Lead | Highest density, compact size | Durable, powder-coated to prevent corrosion | Toxic, banned in some regions | Passenger cars, trucks, motorcycles |

| Zinc | Less dense, larger size | Corrosion resistant, good castability | Lead-free, eco-friendlier | Passenger cars, light trucks |

| Steel | High density, larger than lead | Very strong, recyclable, may rust without coating | Lower environmental footprint | Heavy-duty vehicles, SUVs |

Lead tire weights remain common in some areas, but many regions now prefer zinc or steel for tire balancing. These alternatives offer safer options for both people and the environment.

How Lead Weights Enter the Environment

Loss of Lead Wheel Weights from Vehicles

Lead wheel weights often detach from vehicles during normal driving. The adhesive that holds these weights weakens over time. Vibrations from the road, changes in temperature, and rough driving conditions all contribute to this process. As the adhesive loses strength, the weights loosen and eventually fall off. Physical abrasion from road contact and chemical corrosion also play a role. These factors shorten the lifespan of the weights and increase the chance of loss.

Research shows that once lead weights detach, they do not stay in one place. Vehicles travel across many types of roads, so lost weights scatter widely. City streets, highways, and parking lots all collect these small pieces of lead. The constant movement of cars and trucks spreads the weights even further. This process introduces lead into the environment in many locations.

Note: Even a single lost tire weight can release a significant amount of lead over time. The widespread use of these weights means that the problem affects both urban and rural areas.

Breakdown and Spread of Lead Weights in Soil and Water

After lead weights fall off, they begin to break down. Friction with road surfaces grinds the weights into smaller particles. Rain and wind can carry these particles away from roads. Some particles become airborne, while others settle into soil or wash into storm drains. This process leads to lead in runoff, which then enters rivers, lakes, and groundwater.

Scientific research using advanced tools like scanning electron microscopy reveals that lead wheel weights undergo both physical abrasion and chemical corrosion. The surfaces of these weights show signs of wear and are often coated with tiny lead particles. Some of these particles measure less than one micrometer in size. These small particles can pose health risks if inhaled or ingested. Lead isotopic analysis confirms that the breakdown of these weights adds both particles and dissolved lead to the environment. This contamination affects soil, water, and even the air people breathe.

Lead is a toxic metal. Its presence in the environment can harm plants, animals, and people. Research links lead in runoff from roads to increased levels of lead in nearby water sources. This ongoing cycle of loss and breakdown makes lead weights a persistent source of pollution.

Environmental and Health Risks of Lead Tire Balancing Weights

Soil and Water Contamination from Lead Weights

Lead tire balancing weights create a significant environmental hazard when they fall from vehicles and break down. These weights often end up on roadsides, where they slowly release harmful substances into the soil and water. Studies show that the global use of lead in wheel weights reaches about 64 million kilograms each year. Each vehicle can carry between 200 and 250 grams of lead in these weights. When these weights detach, they vary in size from 5 to 150 millimeters and weigh between 7 and 113 grams. Over time, abrasion and weathering cause the lead to fragment and leach into the environment.

Researchers have measured lead concentrations in surface soils at multiple locations. In Springfield, Missouri, scientists found that lead levels in roadside soils are higher than in other areas. The study linked this contamination to both past automobile emissions and the ongoing loss of lead wheel weights. Across the United States, a review of soil samples from 1996 to 2016 found that urban roadside soils contain an average of 115 parts per million of lead. This level is three times higher than in non-urban areas. Lead tire balancing weights contribute to this contamination, adding to the legacy of leaded gasoline and paint. Rainwater can wash lead particles into storm drains, causing soil and water contamination that affects rivers, lakes, and groundwater. These pollutants can persist for years, making lead weights a long-term environmental hazard.

Impact of Lead Wheel Weights on Wildlife and Ecosystems

Lead weights do not only affect soil and water. They also pose a threat to wildlife and entire ecosystems. When these weights break down, they release lead dust and particles that animals can ingest or absorb. The Environmental Protection Agency estimates that 1.6 million pounds of lead tire weights are lost and pulverized each year in the United States. This waste becomes a source of hazardous waste in the environment.

Wildlife exposed to lead can suffer from severe health problems. Birds, such as whooping cranes, may experience liver and kidney damage, immunosuppression, and neurotoxicity. Lead exposure can also cause reproductive harm and behavioral changes, including increased aggression. Some animals show altered blood chemistry and become more susceptible to diseases like avian malaria. In urban areas, researchers have observed a decrease in species richness due to lead contamination.

Plants and soil microbes are not immune to these harmful toxins. Lead disrupts plant growth, photosynthesis, and mineral uptake. Affected plants may show stunted growth, yellowing leaves, and reduced ability to reproduce. Soil microbial communities also suffer, with reduced activity and changes in composition. This disruption can impact the entire ecosystem, as healthy soil microbes are essential for nutrient cycling and plant health. The presence of lead weights in the environment creates a chain reaction, harming both animals and plants.

Human Exposure and Health Effects of Lead Weights

Humans face serious risks from lead exposure linked to lead tire balancing weights. People can come into contact with lead through soil, dust, water, or even air near busy roads. Children are especially vulnerable because they often play outside and may accidentally ingest contaminated soil or dust. Quantitative research shows that lead from wheel weights can migrate into areas where people live, increasing the risk of exposure.

Lead is a toxic metal that can cause a range of health problems. Even small amounts can affect the nervous system, especially in children. Symptoms of lead poisoning include learning difficulties, behavioral problems, and lower IQ. Adults exposed to lead may develop high blood pressure, kidney damage, and reproductive issues. Workers who manufacture, process, or recycle lead weights face additional hazards. Studies have measured blood lead levels in these workers and found higher rates of exposure compared to the general population.

Lead weights also create hazardous waste when they are discarded or repurposed by hobbyists. Improper handling can release more harmful substances into the environment, increasing the risk of contamination. Reducing exposure to lead from tire weights is essential for protecting public health. The toxic nature of lead and its ability to persist in the environment make it one of the most dangerous pollutants associated with vehicle maintenance.

Regulations and Industry Actions on Lead Wheel Weights

Government Bans and Restrictions on Lead Weights

Many countries have recognized the dangers that lead wheel weights pose to the environment and public health. Canada introduced the prohibition of the manufacture and importation of wheel weights containing lead regulations, which took effect on February 3, 2024. This law bans the manufacture and import of wheel weights with more than 0.1% lead by weight. The goal is to reduce lead releases into the environment, protect wildlife, and encourage the use of safer alternatives like steel weights. Canadian officials highlight the toxicity of lead and its impact when wheel weights fall off vehicles.

In the United States, the Environmental Protection Agency (EPA) reviewed the risks of lead wheel weights under the Toxic Substances Control Act in 2024. The EPA decided not to create new federal rules, but nine states and Canada have already banned these products. Vehicle manufacturers have stopped installing lead wheel weights on new cars sold in the U.S. State-level bans, such as California’s, include strict penalties for violations. These actions have led to a sharp drop in lead waste from vehicles.

Note: Research shows that these bans have reduced lead contamination in soil, water, and air near roads and parking lots.

| Effect Category | Description |

|---|---|

| Environmental Impact | Less lead contamination from wheel weights, which once released up to 1.6 million pounds of lead each year in the U.S. |

| Industry Adaptation | Shift to lead-free alternatives like steel and zinc weights. |

| Health Benefits | Lower lead exposure, especially for children. |

| Legal Enforcement | Penalties for violations encourage compliance. |

| Recycling Efforts | Removed lead weights are now collected and recycled. |

Industry Shifts, Compliance, and Fortune’s Commitment to Safer Products

The industry has responded to these regulations by moving away from lead wheel weights. Manufacturers now use materials such as steel, zinc, copper, and even plastic. Research shows that major automakers and retailers have phased out lead weights, even in places without formal bans. Shops have adopted new safety routines, like wearing gloves and cleaning up lead dust, to protect workers and customers.

Ningbo Fortune Auto Parts Manufacture Co., Ltd. supports these changes. The company follows the prohibition of the manufacture and importation of wheel weights containing lead regulations and supplies lead-free products to global markets. Fortune’s team of engineers focuses on innovation and quality control. The company uses advanced technology and strict inspections to ensure every product meets high standards. Fortune’s commitment to safety and the environment helps reduce the risks linked to lead wheel weights. By choosing safer alternatives, the industry protects both people and the environment from harmful waste.

Safer Alternatives to Lead Tire Balancing Weights

Steel and Zinc Weights as Lead-Free Options

Many manufacturers now use steel and zinc weights as lead-free options for tire balancing. These materials offer strong durability and resist corrosion, making them suitable for modern vehicles, including electric and lightweight models. Zinc provides a good balance between weight and strength, while steel stands out for its exceptional toughness and wear resistance. Both materials meet strict environmental regulations and help reduce ecological risks compared to lead, which is toxic and harmful to the environment.

Automotive shops find steel clip-on weights easy to install and cost-effective. They come in different finishes to match vehicle designs. Zinc weights also perform well in various climates and driving conditions. The industry has shifted toward these alternatives because of legal restrictions and growing awareness of environmental safety. By choosing steel and zinc, companies help prevent pollution and protect ecosystems. These lead-free weights do not leach toxins into soil or water, making them a sustainable choice for tire maintenance.

Tip: Using steel and zinc weights supports cleaner roads and healthier communities.

Effectiveness and Safety Comparison of Lead-Free Weights

Steel and zinc weights perform well in balancing tires, supporting smooth rides and longer tire life. Advances in material science have improved their performance and affordability, even though they may be slightly larger than lead weights due to lower density. Regulatory actions in several U.S. states and other countries have encouraged the adoption of these safer alternatives.

Studies comparing lead and lead-free products show that steel and zinc weights provide similar effectiveness in real-world use. The table below summarizes findings from a systematic review of 11 studies on protective materials, showing that lead-free options can match or even outperform lead in certain conditions:

| Study (Author) | Material Type | Key Findings |

|---|---|---|

| Livingstone et al. | Lead-free vs. lead | Bi-layer lead-free options offer effective protection with less strain |

| Peters et al. | Lead composite, Non-lead | No significant difference in performance at tested thicknesses and voltages |

| Kazempour et al. | Lead-containing, Lead-free | Lead-free composites outperform lead at higher energy levels |

| Kim et al. | Lead, Lead-free (Al, Cu, Sn) | Lead-free can be lighter and still effective |

These results support the use of steel and zinc as reliable alternatives. They help maintain vehicle performance, improve fuel efficiency, and reduce environmental hazards. The industry’s move to lead-free weights reflects a commitment to safety and sustainability.

Lead tire balancing weights remain a major source of environmental and health hazards. Scientific studies show that lead harms humans and wildlife, and mining lead causes lasting damage. Many countries have phased out lead in products like gasoline and paint. Industry leaders, including Fortune, now focus on safer, lead-free alternatives.

- Regulatory actions and market changes drive this shift.

- Lead-free options help in reducing exposure to toxic metals.

Choosing these alternatives protects both people and the environment.

FAQ

What makes lead tire balancing weights harmful to the environment?

Lead tire weights release toxic metal into soil and water when they fall off vehicles. Scientific studies show that lead does not break down easily. It can stay in the environment for many years and harm plants, animals, and people.

Are steel and zinc wheel weights as effective as lead weights?

Steel and zinc weights balance tires well. Research shows these materials provide similar performance to lead. Many automakers and repair shops now use steel or zinc weights because they meet safety standards and help protect the environment.

How can people reduce exposure to lead from tire weights?

People can choose vehicles with lead-free wheel weights. They should ask repair shops to use steel or zinc weights. Regular cleaning of driveways and garages also helps reduce lead dust. These steps lower the risk of lead exposure at home.

Why do some regions still use lead wheel weights?

Some areas have not banned lead wheel weights. Local laws may differ. In these places, shops might use lead weights because they cost less. However, many companies now offer safer, lead-free options to meet growing demand for environmental safety.