admin1

May 30, 2025

Comparing Lead Stick-On Wheel Weights and Alternatives

Wheel balancing is essential for achieving smooth and safe rides, and selecting the right wheel weights is crucial. Lead stick-on wheel weights are a top choice due to their high density and superior conformability. These weights effectively distribute weight, ensuring precise tire balance, minimizing vibrations, and enhancing overall driving comfort. Compared to zinc weights, lead stick-on wheel weights adhere more securely to rims, providing enhanced stability. While some alternatives focus on environmental considerations, lead stick-on wheel weights continue to be a reliable option for delivering exceptional performance in critical applications.

Importance of Wheel Balancing

Why Wheel Balancing Matters

Wheel balancing is essential for maintaining your vehicle’s safety and performance. When your tires are balanced, the centers of mass and gravity align perfectly. This alignment ensures that your vehicle remains stable, even at high speeds. Proper wheel balance also reduces vibrations, which can make your ride smoother and more comfortable.

Misaligned wheels can cause several problems. Road imperfections, such as potholes or uneven surfaces, often lead to misalignment. This affects how your vehicle handles and can compromise safety. Over time, unbalanced tires wear unevenly, reducing their lifespan and impacting tire performance.

Advancements in technology have made wheel balancing more accurate. Automatic balancers now eliminate human error, ensuring consistent results. These tools help you achieve proper wheel balance, which is crucial for both everyday driving and challenging road conditions.

| Key Points | Description |

|---|---|

| Importance of Wheel Balancing | Ensures alignment of the centers of mass and gravity, enhancing stability. |

| Effects of Misalignment | Misalignment affects handling and safety due to road imperfections. |

| Automatic Balancing Technology | New tools ensure consistent and accurate wheel balancing. |

Role of Wheel Weights in Balancing

Wheel balancing weights play a critical role in achieving proper wheel balance. These small but essential components help distribute weight evenly across your tires. By doing so, they enhance tire performance, improve control, and ensure safety, especially on rough or wet roads.

There are two main types of wheel balancing weights:

- Clip-ons: These weights attach securely to the rim of steel wheels. They are easy to install and remove, making them a practical choice for many vehicles.

- Adhesive wheel weights: These weights use strong adhesive backing to stick to aluminum or composite wheels. They provide a secure fit and are ideal for modern alloy wheels.

Using the right type of wheel balancing weights ensures that your tires wear evenly. This not only extends their lifespan but also improves fuel efficiency. Whether you drive on highways or rugged terrains, balanced tires make a noticeable difference in your vehicle’s performance.

Features of Lead Stick-On Wheel Weights

Material Properties of Lead

Lead is a dense and malleable material, making it ideal for stick-on wheel weights. Its high density allows for smaller weights to achieve the same balancing effect as larger alternatives, ensuring precise tire balance without adding unnecessary bulk. Lead’s malleability also enables it to conform to the shape of the wheel, providing a snug fit that minimizes the risk of detachment during use.

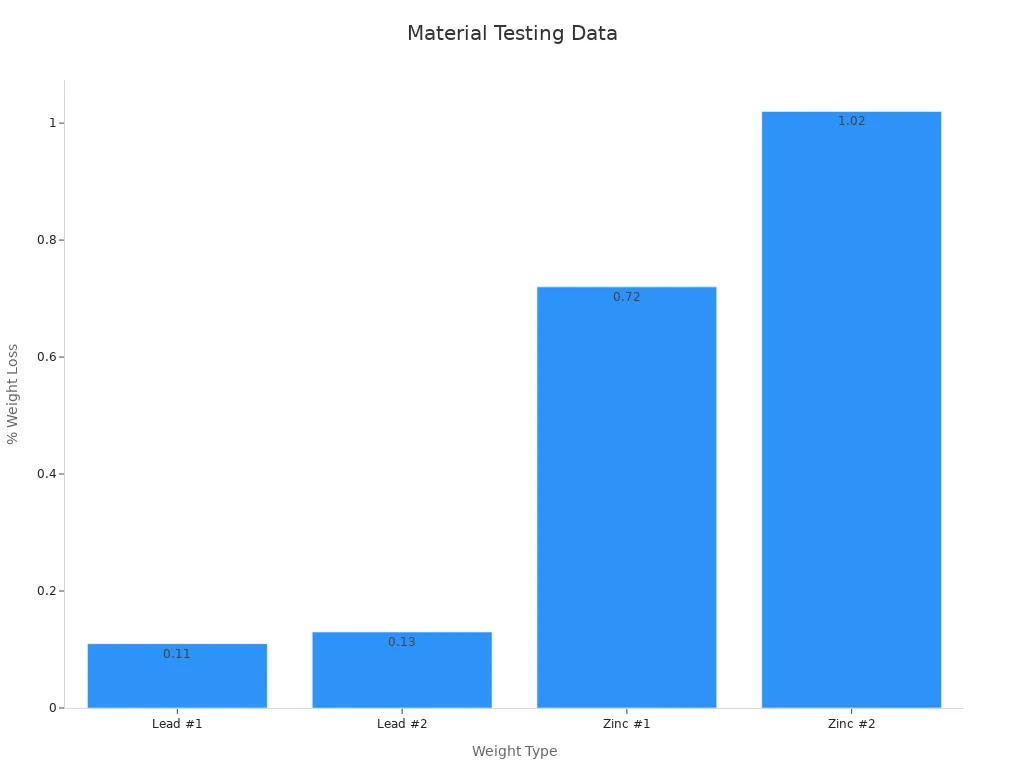

Laboratory tests have demonstrated lead’s durability under various conditions. For example, weight loss tests comparing lead and zinc weights show that lead stick-on wheel weights retain their mass more effectively. The table below highlights the results:

| Weight Type | Mass (Before) | Mass (After) | Difference | (% weight loss) |

|---|---|---|---|---|

| Lead #1 | 32.166 g | 32.130 g | 0.036 g | 0.11% |

| Lead #2 | 32.943 g | 32.900 g | 0.043 g | 0.13% |

| Zinc #1 | 19.471 g | 19.330 g | 0.141 g | 0.72% |

| Zinc #2 | 21.348 g | 21.130 g | 0.218 g | 1.02% |

These results confirm that lead stick-on wheel weights are more resistant to wear and environmental factors, ensuring long-lasting performance.

Adhesive Design and Application

The adhesive backing on stick-on wheel weights is engineered for reliability. You can trust these weights to stay firmly attached to your wheels, even under challenging conditions like high-speed driving or exposure to moisture. The adhesive is designed to bond securely to smooth surfaces, such as alloy wheels, without damaging the finish.

Adhesive wheel weights are easy to apply. Simply peel off the protective layer and press the weight onto the desired location. This straightforward process eliminates the need for specialized tools, saving you time and effort. Additionally, adhesive-backed weights offer flexibility in placement, allowing you to position them precisely for optimal balance.

Laboratory tests have shown that stick-on wheel weights exhibit hardness values ranging from less than 6 to 8 BHN, with some reaching 11.5 BHN. This level of hardness ensures durability comparable to clip-on weights, making adhesive wheel weights a reliable choice for modern vehicles.

Compatibility with Alloy Wheels

Stick-on wheel weights are particularly compatible with alloy wheels, which are common in modern vehicles. Their adhesive design ensures a secure fit without scratching or damaging the wheel’s surface. This makes them an excellent choice for maintaining the aesthetic appeal of alloy wheels.

However, user feedback highlights some considerations when using stick-on weights with alloy wheels. Placement is crucial to avoid interference with brake calipers. Ensuring proper clearance during installation prevents performance issues. While stick-on weights may require more weight to achieve balance compared to clip-on weights, their ability to conform to the wheel’s surface compensates for this difference.

Stick-on wheel weights provide a clean and professional look, enhancing the overall appearance of alloy wheels. Their adhesive backing eliminates the need for visible clips, making them a preferred option for drivers who value aesthetics alongside functionality.

Benefits of Stick-On Wheel Weights

Enhanced Aesthetics

Stick-on weights are ideal for alloy or custom wheels, preserving their sleek appearance. Once installed, they are nearly invisible, blending seamlessly with the wheel’s surface. This design enhances the overall aesthetic of your vehicle, making it look polished and professional. Unlike clip-on weights, stick-on weights do not leave marks or dents on the rim. This feature ensures that your wheels maintain a flawless outer appearance over time.

Drivers often choose adhesive wheel weights for their ability to complement modern wheel designs. Whether you drive a luxury car or a sports vehicle, installing stick-on wheel weights keeps your wheels looking clean and stylish. Their adhesive backing eliminates the need for bulky clips, making them better for low-profile tires where aesthetics matter most.

Precise Tire Balance

Stick-on weights ensure precise tire balance when placed correctly. Clean wheel surfaces allow for accurate weight placement, which minimizes vibrations and improves driving comfort. The adhesive design holds the weights firmly in place, preventing them from shifting during use. This stability contributes to consistent tire performance, even under demanding conditions.

Adhesive wheel weights are quick and easy to install, making them a practical choice for achieving balance accuracy. You can position them exactly where needed, ensuring optimal weight distribution. This precision is particularly important for vehicles with low-profile tires, as it enhances handling and reduces uneven tire wear.

Durability in Various Conditions

Stick-on weights are built to withstand diverse environmental challenges. Their adhesive backing resists moisture, heat, and road debris, ensuring they stay securely attached to your wheels. Whether you drive in rainy weather or on rough terrain, these weights maintain their performance without detaching or degrading.

The durability of stick-on weights makes them ideal for low-profile tires, which often face harsher conditions. Their ability to conform to the wheel’s surface adds an extra layer of reliability. Easy installation further simplifies the process, allowing you to enjoy long-lasting benefits without hassle.

Comparing Stick-On Weights to Alternatives

Clip-On Weights vs. Stick-On Weights

When comparing clip-on wheel weights to stick-on weights, you notice distinct differences in design and application. Clip-on wheel weights attach directly to the rim of steel wheels using a mechanical clip. This method ensures a secure fit, especially for vehicles with traditional steel rims. However, clip-on weights can leave visible marks or scratches on the wheel surface, which may affect the appearance of your vehicle.

Stick-on wheel weights, on the other hand, use adhesive backing to attach to alloy or composite wheels. Their design allows for precise placement, ensuring optimal wheel balancing. Unlike clip-on weights, stick-on weights blend seamlessly with the wheel’s surface, preserving its aesthetic appeal. You can position them exactly where needed, making them ideal for modern vehicles with low-profile tires.

Stick-on weights also offer greater flexibility in placement. You can apply them to areas where clip-on weights may not fit, such as narrow or curved rims. This versatility makes stick-on wheel weights a preferred choice for achieving precise balance in challenging applications.

Lead vs. Non-Lead Materials

The material composition of wheel weights significantly impacts their performance. Lead stick-on wheel weights are known for their high density and malleability. These properties allow smaller weights to achieve the same balancing effect as larger alternatives, ensuring precise tire balance without adding bulk. Lead’s ability to conform to the wheel’s surface enhances its reliability, especially under demanding conditions.

Non-lead materials, such as steel and zinc alloy, have gained popularity due to environmental considerations. While these alternatives offer durability, they often require larger weights to achieve the same balancing effect as lead. This can affect the overall appearance of your wheels, especially if you prioritize aesthetics.

The EPA’s analysis indicates that the risks associated with lead wheel weights are significantly lower than previously described. Specifically, it estimates that dust from lead wheel weights contributes an extremely small fraction to a child’s overall residential lead exposure, even near busy roads.

The EPA’s preliminary assessment shows extremely low risk associated with roadside exposure to lead wheel weights, even when conservative assumptions are made. This includes studies that likely overestimate the frequency of lead wheel weight use in the U.S.

The EPA will not regulate lead wheel weights due to the extremely low risk of lead exposure and the ongoing phaseout of lead weights, with alternatives like steel and zinc alloy now widely available.

Despite the ongoing phaseout of lead weights, lead stick-on wheel weights remain a reliable option for achieving precise wheel balancing. Their superior density and conformability make them a preferred choice for critical applications.

Performance in Heavy-Duty vs. Everyday Applications

The impact of wheel weight types becomes evident when comparing their performance in heavy-duty and everyday applications. Stick-on wheel weights excel in everyday driving conditions. Their adhesive backing ensures a secure fit, even during high-speed driving or exposure to moisture. You can rely on them to maintain consistent tire balance, enhancing driving comfort and reducing vibrations.

In heavy-duty applications, such as off-road driving or commercial vehicles, clip-on wheel weights often perform better. Their mechanical attachment provides added security, ensuring they stay in place under extreme conditions. However, stick-on weights can still be used in heavy-duty scenarios if applied correctly. Their ability to conform to the wheel’s surface adds an extra layer of reliability, making them suitable for rugged terrains.

Stick-on wheel weights also offer advantages for vehicles with low-profile tires. Their adhesive design allows for precise placement, ensuring optimal balance even in challenging applications. Whether you drive on highways or rough roads, stick-on weights provide a versatile solution for maintaining tire performance.

Choosing the Right Wheel Weight

Factors to Consider: Vehicle Type and Driving Conditions

Selecting the right wheel weight depends on your vehicle type and how you drive. For everyday cars, stick-on weights are a practical choice. They provide precise tire balance and maintain the sleek appearance of alloy wheels. If you drive a luxury or sports car, these weights are ideal for preserving the aesthetic appeal of your rims.

For heavy-duty vehicles, such as trucks or off-road SUVs, you may need to evaluate the conditions you face. Stick-on weights work well for moderate off-road use or highway driving. However, if your vehicle frequently encounters rugged terrains or extreme conditions, clip-on weights might offer a more secure option.

Driving conditions also play a significant role. If you often drive in wet or snowy environments, stick-on weights with high-quality adhesive ensure they stay in place. For vehicles exposed to high speeds or sharp turns, proper placement of these weights ensures consistent performance.

Budget and Environmental Impact

Your budget is another important factor when choosing wheel weights. Stick-on weights are often a more cost-effective solution for achieving precise tire balance. They require no specialized tools for installation, saving you money on labor costs. Additionally, their durability ensures long-term performance, reducing the need for frequent replacements.

Environmental impact is also worth considering. Lead stick-on weights offer superior density and performance, but non-lead alternatives like zinc or steel are gaining popularity due to environmental concerns. While these alternatives may require larger weights to achieve the same balance, they align with eco-friendly practices.

If you prioritize cost-effective options without compromising performance, lead stick-on weights remain a reliable choice. However, if environmental considerations are a priority, exploring non-lead materials might be the right path for you.

Choosing the right wheel weight impacts your vehicle’s performance and safety. Lead stick-on wheel weights offer high density and malleability, ensuring precise balance and a sleek appearance. Alternatives like zinc or steel prioritize environmental considerations but may require larger weights for the same effect.

| Material | Density | Durability | Environmental Impact | Aesthetic Appeal |

|---|---|---|---|---|

| Lead | High | Excellent | Moderate | High |

| Zinc | Medium | Good | High | Medium |

| Steel | Medium | Good | High | Medium |

Consider your vehicle type, driving conditions, and local regulations when selecting wheel weights. Stick-on weights suit alloy wheels and everyday driving, while clip-on weights excel in heavy-duty applications. Prioritize your needs to ensure optimal performance and long-term reliability.

FAQ

What are stick-on wheel weights used for?

Stick-on wheel weights balance your vehicle’s tires by evenly distributing weight. This reduces vibrations, improves handling, and extends tire life. They are especially useful for alloy wheels, where aesthetics and precision are important.

How do you install stick-on wheel weights?

Clean the wheel surface thoroughly. Peel off the adhesive backing and press the weight firmly onto the desired location. Ensure proper placement for optimal balance. No special tools are required, making installation quick and easy.

Are lead stick-on wheel weights safe for the environment?

Lead weights are durable and effective, but they raise environmental concerns. Alternatives like zinc or steel are eco-friendlier. However, studies show that lead weights contribute minimally to environmental lead exposure, especially with proper disposal.

Can stick-on weights handle extreme conditions?

Yes, high-quality adhesive ensures stick-on weights stay secure in various conditions, including high speeds, wet roads, and rough terrains. Their durability makes them reliable for everyday driving and moderate off-road use.

What’s the difference between lead and non-lead wheel weights?

Lead weights are denser and smaller, offering precise balance and a sleek look. Non-lead options like zinc or steel are larger but eco-friendly. Your choice depends on performance needs and environmental priorities.