admin1

June 22, 2025

Lead Balancing Weights Experience Rapid Growth in Green Technology Adoption

Lead balancing weights have played a major role in tire balancing for decades. Today, strict regulations and growing awareness of environmental risks drive a rapid transition to eco-friendly wheel weights. The automotive industry faces strong pressure to replace traditional lead wheel weights with environmentally friendly alternatives. Strict emissions standards like the EU’s Euro 6 and US CAFE have pushed manufacturers toward green and sustainable solutions. In the US, transportation creates 28% of greenhouse gas emissions, and light-duty vehicles account for more than half of that amount. The transition to lead-free wheel balancing weights helps protect the environment and supports global sustainability. As the number of vehicles worldwide climbs to nearly 1.5 billion, the demand for safer, eco-friendly alternatives in wheel balancing and tire balancing grows. This shift reflects society’s call for cleaner technology and a healthier environment.

Drivers Behind the Shift to Eco-Friendly Lead Balancing Weights

Regulatory Bans on Lead Wheel Weights

Regulatory bans have played a major role in the transition from lead wheel weights to eco-friendly alternatives. Nine U.S. states, including California, Illinois, and Washington, have banned the sale, distribution, or use of lead wheel weights. California enforces fines up to $2,500 per day for violations. Washington uses escalating fines to encourage compliance. These strict rules make it difficult for manufacturers to produce different wheel weights for each state, so most companies have switched to lead-free options nationwide. In Canada, a ban on manufacturing or importing wheel weights with more than 0.1% lead by weight took effect in February 2024. The European Union’s End of Life Vehicle Directive, passed in 2005, banned lead in vehicles, including wheel balancing weights. This regulation forced manufacturers to adopt lead-free alternatives across Europe and influenced North American automakers like General Motors and Ford to use steel wheel weights for all vehicles.

State legislation and international regulation have reduced lead content in wheel weights from over 90% to about 0.1%. Today, 95% of new light-duty vehicles in the U.S. use lead-free wheel weights. These changes have also increased recycling incentives for old lead wheel weights, supporting sustainable practices in the automotive industry.

| Aspect | Details |

|---|---|

| States with Lead Wheel Weight Bans | Nine U.S. states including California, Illinois, Washington, Maine, Vermont, New York, etc. |

| Canadian Regulation | Ban on manufacturing/importing wheel weights with >0.1% lead by weight (effective Feb 2024) |

| Industry Impact | Automotive manufacturers have largely switched to lead-free alternatives (zinc, steel alloys) |

| Nationwide Effect | De facto nationwide change due to impracticality of producing different weights per state |

| Statistical Reduction | Lead content in wheel weights reduced from >90% to ~0.1% |

| Industry Compliance | 95% of new light-duty vehicles in U.S. reported no use of lead wheel weights |

| Economic Impact | Increased recycling incentives for lead wheel weights due to value and regulations |

| Penalties for Non-Compliance | Fines up to $2,500/day in California; escalating fines in Washington |

Environmental and Health Impacts of Lead Balancing Weights

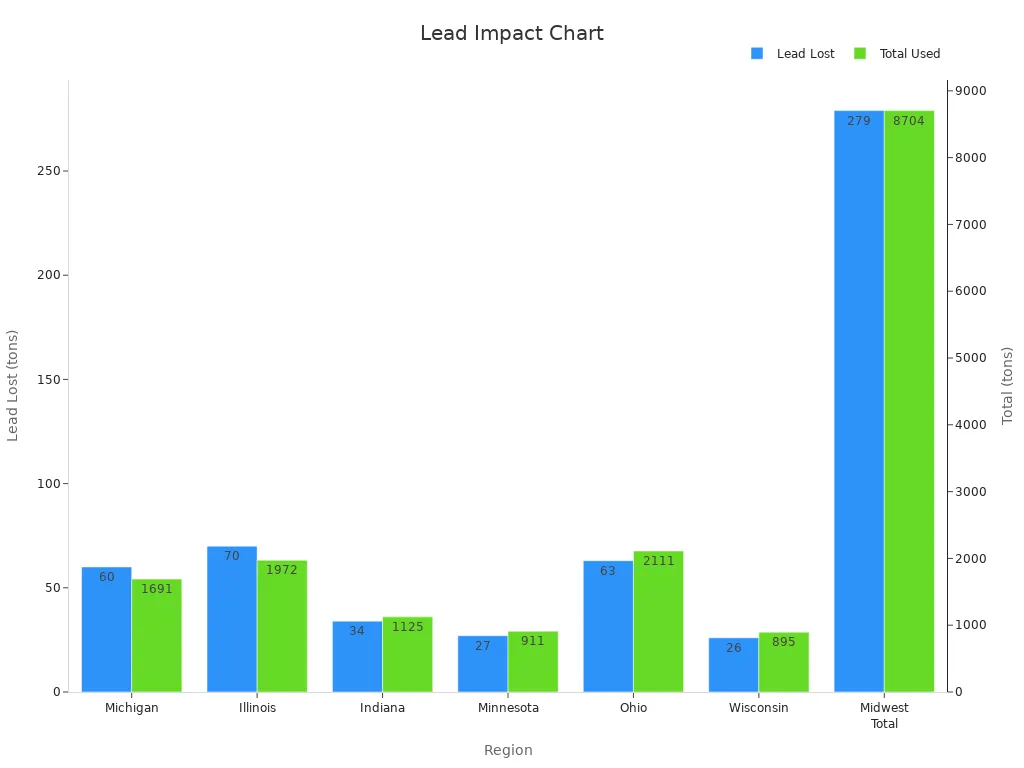

Lead balancing weights have caused serious environmental and health problems. When vehicles lose lead wheel weights on roads, the lead breaks down into dust. This dust can wash into rivers and lakes, polluting water and harming wildlife. In the Great Lakes states, about 2,500 metric tons of lead are used each year for wheel weights. Around 275 metric tons end up on urban roads annually. In Michigan alone, nearly 500 metric tons of lead are used for tire balancing, with 60 metric tons lost on streets every year.

Lead exposure affects many body systems. The nervous system is the most sensitive. Children exposed to lead can suffer from developmental delays, learning problems, and behavioral issues. Adults may experience high blood pressure, kidney problems, and heart disease. Lead can also harm the reproductive system and cause poor pregnancy outcomes. Once lead enters the body, it can stay in bones for decades, releasing slowly over time and increasing long-term health risks.

- Lead exposure affects the nervous, cardiovascular, endocrine, renal, and reproductive systems.

- In children, lead poisoning can cause cognitive impairment, developmental delays, and seizures.

- In adults, lead can cause mood changes, decreased motor skills, and even lead encephalopathy in severe cases.

- Lead accumulates in bones and can be released during stress, pregnancy, or aging.

These dangers have made the transition to lead-free alternatives in wheel balancing and tire balancing a top priority for public health and environmental protection.

Market Demand for Sustainable Wheel Balancing Weights

Market demand for sustainable wheel balancing weights continues to grow rapidly. Customers want safer, eco-friendly products that do not harm the environment. Strict regulations and health concerns have pushed manufacturers to develop lead-free alternatives such as zinc, steel, and composite wheel weights. These alternatives offer durability, corrosion resistance, and recyclability. High-performance and luxury vehicle owners prefer these options for their quality and environmental benefits.

Market data shows a clear shift from lead-based wheel weights to sustainable materials. Manufacturers now innovate with zinc-based and steel wheel weights to meet rising demand. The growth of electric vehicles has increased the need for lightweight, custom balancing solutions. Digital wheel balancing machines and new adhesive technologies help improve precision and support the use of eco-friendly wheel weights.

| Key Factors | Details |

|---|---|

| Market Segments | Stick-on and clip-on weights dominate; self-adhesive and adjustable weights growing |

| Material Alternatives | Steel and zinc preferred for compliance and cost; plastic emerging as lightweight option |

| Regional Drivers | North America and Europe lead due to strict regulations; Asia-Pacific fastest growth |

| Industry Adoption | OEMs lead demand; aftermarket and retail segments growing |

| Regulatory Influence | Stringent standards in North America and Europe drive shift to non-lead materials |

| Future Trends | Demand for lightweight, customizable weights for electric/hybrid vehicles |

| Environmental Impact | Shift aligns with sustainability initiatives and reduction of toxic materials |

| Economic Factors | Cost-effectiveness of steel and zinc supports transition; emerging markets present challenges |

The transition program to lead-free wheel weights is supported by both regulation and consumer demand. As more people choose eco-friendly products, the industry continues to invest in new materials and technologies. The lead-free wheel weight movement is expected to grow, with experts predicting a full non-lead transition within the next decade.

Alternative Materials for Non-Lead Wheel Weights

Automotive manufacturers and service providers now use a variety of alternative materials to replace traditional lead wheel weights. These new materials help reduce environmental risks and meet strict regulations. They also offer improved performance and durability for modern vehicles. The most common alternatives include steel, zinc, and composite or polymer-based eco-friendly materials. Each type brings unique benefits and addresses different needs in wheel balancing.

Steel Wheel Balancing Weights

Steel wheel balancing weights have become the most popular alternative to lead. Many manufacturers, such as Perfect Equipment Inc., Plombco, and Hennessy Industries, switched to steel after regulatory bans on lead. Steel offers several advantages for wheel balancing:

- Steel does not release harmful toxins into the environment.

- Steel wheel weights resist corrosion better than lead, especially when coated with advanced finishes.

- Steel is recyclable and supports sustainability goals.

- Steel weights provide the strength needed for secure wheel balancing, even in harsh weather.

The U.S. EPA estimates that 1.6 million pounds of lead fall off vehicles each year, contaminating air and water. California banned lead wheel weights to address these concerns. Steel wheel balancing weights help prevent this pollution. Tire shops report smooth transitions to steel, with only minor installation challenges. Steel also meets the growing demand for lightweight, eco-friendly wheel balancing solutions, especially for electric vehicles.

Note: A life cycle assessment found that steel offers environmental benefits, especially for vehicles with shorter service lives and electric vehicles. Steel’s eco-friendly properties and economic advantages make it a strong choice for wheel balancing.

Steel wheel balancing weights align with modern vehicle requirements. They balance durability, corrosion resistance, and environmental compliance. Regulatory support and consumer preference for durable, environmentally friendly products continue to boost steel weight adoption.

Zinc Wheel Balancing Weights

Zinc wheel balancing weights serve as another effective lead-free alternative. Zinc provides a balance between density and corrosion resistance. Manufacturers use zinc because it is less toxic than lead and does not harm soil or water. Zinc wheel weights are also recyclable, supporting eco-friendly practices.

- Zinc wheel balancing weights resist corrosion, even in wet or salty conditions.

- Zinc offers good malleability, making it easy to shape for precise wheel balancing.

- Zinc wheel weights meet strict environmental regulations in North America and Europe.

Zinc wheel balancing weights work well for both stick-on and clip-on applications. They provide reliable performance for a wide range of vehicles. Advances in manufacturing have improved the quality and reliability of zinc weights. These lead-free options help reduce pollution and support global efforts to phase out toxic materials in automotive components.

| Material | Density | Corrosion Resistance | Recyclability | Environmental Impact |

|---|---|---|---|---|

| Lead | High | Low | Moderate | High (toxic) |

| Steel | Medium | High | High | Low (eco-friendly) |

| Zinc | Medium | High | High | Low (eco-friendly) |

| Composite | Low | High | Varies | Very Low |

Zinc wheel balancing weights continue to gain popularity as more regions adopt strict regulations. They offer a practical and legal choice for manufacturers and service providers.

Composite and Polymer-Based Eco-Friendly Weights

Composite and polymer-based eco-friendly materials represent the latest innovation in wheel balancing. These non-lead wheel weights use advanced materials such as fiber-reinforced polymers, glass fiber, and natural fiber composites. Manufacturers choose these materials for their lightweight properties and high strength-to-weight ratios.

Polymers and composites provide several benefits:

- Lightweight design reduces overall vehicle weight, improving fuel efficiency.

- Excellent impact resistance and rust resistance extend product lifespan.

- Customizable shapes and colors enhance vehicle aesthetics.

In the automotive sector, a 10% reduction in vehicle weight can lower energy use by 6-8%. Composite wheel balancing weights help achieve these savings. Fiber-reinforced polymers, such as glass and carbon fiber composites, are favored for their high performance and lightness. Natural fiber composites, made from renewable resources like jute and flax, offer a reduced carbon footprint.

However, some challenges remain. Composite and polymer-based weights can cost more than traditional materials. Durability may vary, especially if the material absorbs moisture. Manufacturers use surface treatments to improve fiber-matrix adhesion and overall quality. Despite these challenges, composite wheel balancing weights support sustainability efforts and align with global net-zero emission goals.

Tip: Composite and polymer-based eco-friendly materials are still in development. They hold great promise for the future of wheel balancing, especially as technology advances and costs decrease.

Automotive manufacturers continue to explore new adhesive wheel weights made from these innovative materials. These alternatives meet the demands of modern vehicles by balancing durability, corrosion resistance, and environmental compliance. As research and development progress, composite and polymer-based eco-friendly materials will play a larger role in the wheel balancing industry.

Comparing Performance and Benefits of Non-Lead Wheel Weights

Non-lead wheel weights have become the standard in modern wheel balancing. Manufacturers and service providers now rely on eco-friendly materials to meet strict regulations and consumer expectations. These alternatives include steel, zinc, and advanced composites. Each type offers unique benefits for wheel balancing, especially when compared to traditional lead weights.

Adhesive wheel weights stand out as a popular choice among non-lead options. They use strong adhesives to attach directly to the wheel surface. This method allows for precise placement, which improves wheel balancing accuracy. Technicians can install adhesive wheel weights quickly and without special tools. This efficiency reduces labor time and supports high-volume service centers.

Adhesive wheel weights also help protect the environment. They eliminate the risk of toxic lead entering soil and water. Studies show that lead wheel weights lose up to 80% of their mass within days after detachment. This rapid breakdown leads to hundreds or even thousands of metric tons of lead deposited on roads each year. By switching to non-lead wheel weights, the automotive industry reduces this environmental hazard.

Manufacturers have developed adhesive wheel weights using eco-friendly materials such as fiber-reinforced polymers and glass fiber composites. These materials resist corrosion and reduce overall vehicle weight. Lighter wheel weights help lower unsprung mass, which improves handling and fuel efficiency. Electric and hybrid vehicles benefit from these properties because they require precise wheel balancing and reduced weight for optimal performance.

Adhesive wheel weights offer several practical advantages:

- They fit a wide range of wheel designs, including modern alloy wheels.

- Their low profile maintains the appearance of custom and high-end wheels.

- Innovations in adhesive technology have improved bonding strength, even in extreme temperatures or wet conditions.

- Proper surface preparation and weight selection ensure reliable adhesion and long-lasting balance.

Note: Adhesive wheel weights align with global sustainability goals. They support regulatory compliance and meet the growing demand for green automotive solutions.

While direct comparative data on abrasion or durability between lead and non-lead wheel weights remains limited, market trends and advances in material science show that non-lead alternatives perform effectively. Manufacturing processes such as gravity casting, pressure die casting, and forging enhance the durability of these materials. Adhesive wheel weights, in particular, have proven their value in both OEM and aftermarket applications.

A comparison of key benefits highlights the strengths of adhesive wheel weights and other non-lead alternatives:

| Feature | Adhesive Wheel Weights | Lead Wheel Weights | Steel/Zinc Weights | Composite Weights |

|---|---|---|---|---|

| Environmental Impact | Very Low | High | Low | Very Low |

| Installation Ease | High | Moderate | Moderate | High |

| Corrosion Resistance | High | Low | High | High |

| Compatibility | Wide | Moderate | Wide | Wide |

| Weight Precision | High | High | High | High |

| Aesthetic Impact | Minimal | Moderate | Minimal | Minimal |

Adhesive wheel weights continue to gain popularity due to their environmental benefits, ease of use, and compatibility with modern wheel designs. As the industry moves toward more sustainable practices, these non-lead alternatives will play a key role in the future of wheel balancing.

Market Impact and Growth of Eco-Friendly Wheel Balancing Weights

Global Market Trends and Growth Statistics (Fortune Insights)

The global market for adhesive wheel weights is growing quickly. Rising vehicle production and more frequent tire servicing drive this growth. Many consumers now want sustainable solutions, so manufacturers focus on eco-friendly products. The market report from Fortune Insights shows that innovation plays a big role. Companies develop new adhesive wheel weights to meet changing needs. The rise of electric vehicles also increases demand for specialized balancing solutions. From 2024 to 2031, experts expect the market to expand as more people choose adhesive wheel weights for their vehicles. Strategic partnerships and new technology help companies keep up with these trends.

Regional Adoption of Eco-Friendly Wheel Balancing Weights

Adoption rates for adhesive wheel weights vary by region. Asia Pacific leads the market, holding about 45% of the share in 2023. This region grows fast because of strong automotive industries in China, India, and Japan. More people buy cars, and local companies invest in production. E-commerce and urbanization also boost demand. North America holds about 25% of the market. Strict safety standards and regulations, like California’s Proposition 65, push companies to use adhesive wheel weights. Europe has about 20% of the market. Strong environmental rules and a focus on sustainability drive adoption there. Other regions, such as Latin America and the Middle East, show growth potential but face challenges like weaker regulations and lower consumer spending.

| Region | Market Share (2023) | Key Adoption Drivers |

|---|---|---|

| Asia Pacific | ~45% | Automotive growth, rising incomes, vehicle sales, local production, e-commerce, urbanization |

| North America | ~25% | Safety standards, EV trends, regulations, aftermarket demand |

| Europe | ~20% | Environmental rules, sustainability focus, innovation, leading manufacturers |

Leading Manufacturers and Innovators in Non-Lead Wheel Weights

Many companies lead the way in producing non-lead wheel weights. Fortune Auto Parts stands out for its high-quality adhesive wheel weights. The company uses advanced manufacturing systems and tests products for corrosion resistance. Fortune Auto Parts holds ISO 9001 certification and uses AI to check for defects, reaching over 99% accuracy in weight placement. Other top manufacturers include WEGMANN, TOHO KOGYO, 3M, Hennessy, and Baolong. These companies focus on product innovation, eco-friendly materials, and precision manufacturing. Asia Pacific remains the largest market, but North America and Europe also see strong growth due to regulations and high demand for aftermarket products. Steel weights dominate the market, but zinc weights grow quickly because they are lighter and resist corrosion.

Companies continue to invest in automation and new materials to meet the needs of modern vehicles and support a cleaner environment.

Practical Implications for Manufacturers and Service Providers

Manufacturing and Quality Control for Eco-Friendly Wheel Balancing Weights

Manufacturers use advanced methods to produce eco-friendly wheel balancing products. Lean manufacturing principles help companies reduce waste and pollution. These methods focus on making each step in production more efficient. By mapping out the value stream, manufacturers can spot and remove steps that do not add value. This approach leads to better use of resources and less environmental impact. Many companies now invest in green technology and carbon control policies. They also rework imperfect items instead of throwing them away. This practice increases economic efficiency by 2.13% and improves sustainable practices by 37.10%. Quality control teams use real-time monitoring and automation to check each batch of adhesive wheel weights. These steps help ensure that every product meets strict standards for wheel balancing and tire balancing.

Installation and Performance of Non-Lead Wheel Weights

Service providers benefit from the latest adhesive wheel weights. High-performance adhesives pass tough tests for peel strength, wet conditions, and corrosion resistance. These wheel weights stay attached even in heat, humidity, or salty roads. Technicians find that adhesive wheel weights are easy to install and fit many wheel designs. Automation and precision tools, such as CNC machines, help reduce errors and speed up installation. Balanced tires with these products last up to 20% longer, according to the Rubber Manufacturers Association. This means less uneven tire wear and better driving stability. Composite materials in adhesive wheel weights can lower weight by 34% while increasing strength. These improvements help vehicles run smoother and safer.

Cost Considerations for Businesses and Consumers

Switching to adhesive wheel weights can lower costs for both businesses and consumers. Companies save money by reducing waste and reworking products instead of discarding them. Automation cuts down on manual labor and mistakes. For consumers, longer tire life and fewer repairs mean lower maintenance costs. Adhesive wheel weights also support better fuel efficiency and safety. These benefits make eco-friendly wheel balancing and tire balancing solutions a smart choice for the future.

Consumer Benefits of Eco-Friendly Wheel Balancing Weights

Environmental Impact Reduction with Non-Lead Wheel Weights

Non-lead wheel weights help protect the environment in many ways. When drivers use lead-free wheel weights, they prevent toxic metals from entering soil and water. Lead can harm plants, animals, and people. By switching to safer materials like steel and zinc, drivers support cleaner air and water. These materials do not break down into harmful dust on roads. Many cities now see less pollution from wheel weights because of this change. People who choose eco-friendly products help reduce the risk of lead poisoning in their communities.

Product Availability and Compatibility in the Market

Today, consumers can find a wide range of eco-friendly wheel balancing weights. Market surveys show a strong move from lead-based products to safer options like steel and zinc. Manufacturers invest in research to create products that meet both safety rules and performance needs. Steel and zinc stand out for their durability and resistance to rust. Companies offer both clip-on and adhesive weights, making it easy to match different wheel types. Adhesive weights have become popular, especially for electric and hybrid vehicles that need precise balancing. Regions with strict environmental laws, such as Europe and North America, lead in adopting these products. Many top brands focus on advanced materials and new technology, which increases global availability and compatibility.

- Steel and zinc are the most common eco-friendly materials.

- Adhesive weights fit many modern wheels, including those on electric vehicles.

- Manufacturers continue to improve products for better performance and safety.

Long-Term Value and Performance of Eco-Friendly Solutions

Eco-friendly wheel balancing weights offer lasting value for drivers. Steel and zinc weights resist corrosion, so they last longer than older lead weights. These materials also support sustainable practices by being easy to recycle. Drivers notice fewer problems with tire wear and enjoy smoother rides. Many products now use advanced adhesives that keep weights in place, even in tough weather. As more people choose electric and hybrid vehicles, the need for reliable, lead-free solutions grows. Over time, these products help save money by reducing repairs and supporting a cleaner environment.

Future Outlook for Lead Balancing Weights and Green Technology

Emerging Materials and Technologies in Wheel Balancing Weights

The future of wheel balancing weights looks promising as new materials and technologies enter the market. Companies now explore lightweight metals like aluminum and magnesium alloys. These metals help reduce the weight of vehicles, which can improve fuel efficiency and lower emissions. Aluminum, in particular, has become the fastest-growing material in the automotive industry. Manufacturers use high-pressure die casting to make aluminum parts quickly and with less waste. This process also lowers production costs. The industry focuses on lightweighting because lighter vehicles use less energy. Electric and autonomous vehicles benefit the most from these changes. As a result, wheel balancing weights may soon use more of these advanced materials. Traditional lead weights break down and release harmful particles, so the move to safer materials remains urgent.

The Role of Policy and Industry Collaboration in Eco-Friendly Adoption

Policy and industry collaboration play a key role in the shift to eco-friendly wheel balancing weights. Governments and businesses work together to create rules and incentives that support green technology. Financial incentives, such as tax credits and subsidies, help companies invest in new materials and processes. For example, the European Union’s support for renewable energy has led to rapid growth in green products. In the United States and Asia-Pacific, similar programs encourage innovation and sustainability. Research shows that when governments and industries cooperate, adoption rates for green technology rise sharply. Partnerships like the Mission Possible Partnership and the Climate Pledge unite companies and set clear goals for reducing emissions. These efforts build trust and help everyone move toward a cleaner future.

Ongoing Innovation and Education for Sustainable Wheel Balancing

Innovation and education remain vital for the future of sustainable wheel balancing. Companies invest in automated systems that make installation faster and more precise. These systems reduce labor costs and improve product quality. As electric vehicles become more common, the need for specialized wheel balancing solutions grows. Training programs teach workers how to use new materials and technologies safely. Educational campaigns help consumers understand the benefits of eco-friendly products. When people learn about the impact of their choices, they are more likely to support green technology. Ongoing research and knowledge-sharing keep the industry moving forward, ensuring that wheel balancing weights continue to improve in safety, performance, and sustainability.

The transition from lead wheel weights to eco-friendly alternatives shapes the future of the automotive industry. Global vehicle production and strict regulations drive this change. Companies now use zinc, steel, and composite materials instead of lead. Key trends include:

- Environmental rules in Europe and North America speed up the shift.

- Asia Pacific leads in market share due to rapid growth.

- Electric vehicles increase demand for sustainable solutions.

Continued innovation and consumer awareness ensure that lead balancing weights support a cleaner, safer world.

FAQ

What are eco-friendly wheel balancing weights made of?

Manufacturers use materials like steel, zinc, and advanced composites. These materials do not contain lead. They resist corrosion and can be recycled. Many companies choose these options to meet strict environmental rules and improve vehicle safety.

Why did countries ban lead wheel weights?

Governments banned lead wheel weights because lead harms people and wildlife. Studies show that thousands of metric tons of lead enter the environment each year from lost wheel weights. These bans help protect water, soil, and public health.

Do non-lead wheel weights perform as well as lead weights?

Yes. Steel, zinc, and composite wheel weights provide reliable balance and durability. Tests show that these materials meet or exceed industry standards for performance. Many automakers now use only non-lead weights on new vehicles.

Are eco-friendly wheel weights more expensive?

Eco-friendly wheel weights may cost slightly more than lead weights. However, they last longer and reduce environmental cleanup costs. Over time, drivers and businesses save money through better tire life and fewer repairs.