admin1

November 19, 2025

The Dos and Don’ts of Installing Lug Nuts to Prevent Cross-Threading

You can prevent cross-threading by starting threaded lug nuts by hand for several turns. This simple action ensures proper alignment and stops damage before it starts. Forcing a resistant nut creates a cross threaded lug nut. A cross threaded lug nut can easily ruin a cross-threaded bolt, creating an unsafe wheel condition.

Tip: You can avoid this costly cross-threading. A damaged cross-threaded bolt from a cross threaded lug nut is a problem you can easily prevent with careful installation.

The “Dos”: Your Checklist to Avoid Cross-Threading

Following a few simple rules makes your wheel installation safe and secure. You can easily prevent damage by adding these “Dos” to your routine. This checklist is your guide to a perfect, damage-free installation every time.

DO Start Every Lug Nut by Hand

This is the most important rule to avoid cross-threading. Your fingers are sensitive tools. They can feel when threads are not aligning correctly. A power tool cannot provide this feedback and will force the nut on, causing damage.

You should spin each lug nut by hand for at least three to four full rotations. The nut should turn smoothly with very little resistance. If you feel it bind or become difficult to turn, stop immediately. This resistance is a clear sign of misalignment. Unscrew the nut and try again.

Pro Tip: 💡 Place the lug nut into a socket with a short extension. Use the extension to hand-tighten the nut. This gives you better reach and control, making it easier to feel the threads engage properly.

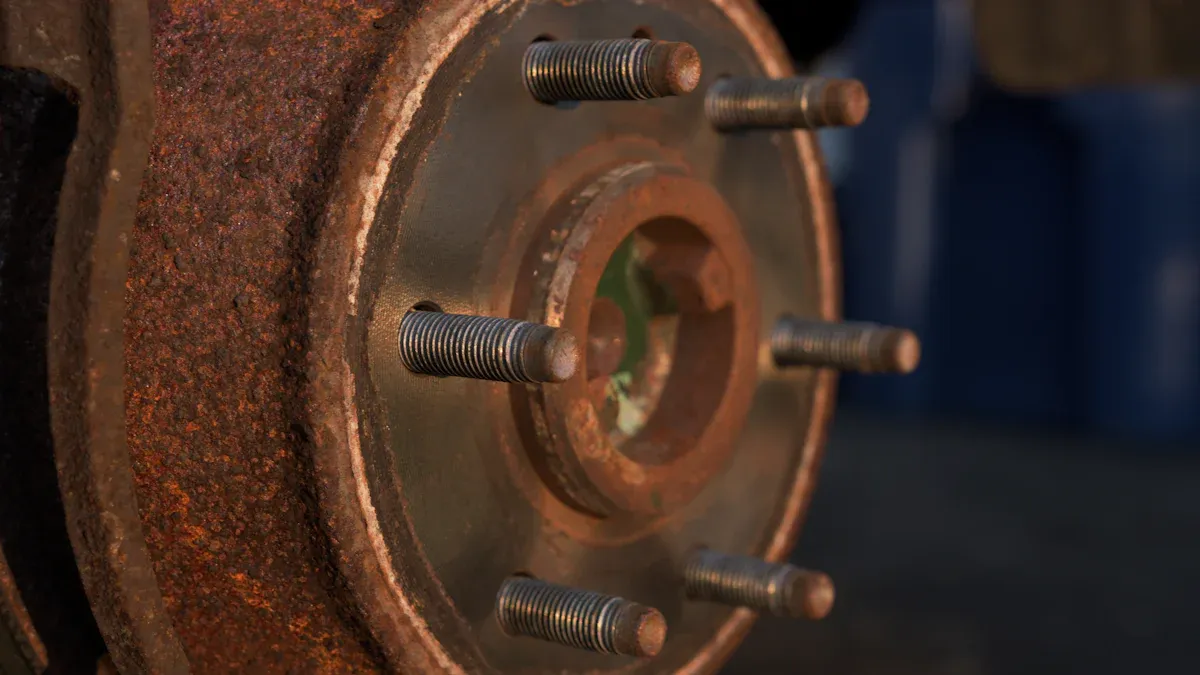

DO Clean Threads Before Installation

Clean hardware is essential for a secure fit. Rust, dirt, and old grime can build up on both the wheel stud (the bolt) and inside the lug nut. This debris creates friction. It can make you think the nut is tight when it is not, or it can cause the binding that leads to cross-threading.

Before you install the lug nuts, take a moment to inspect the threads. Use a stiff wire brush to clean any visible rust or dirt from the wheel studs. For a more thorough job, you can use specialized tools designed for this purpose.

- WHEEL TEQ Stud & Hub Cleaner: This tool is made to clean studs and hubs without causing damage.

- STEELMAN 60099 Wheel Stud Cleaning Set: This kit provides multiple brush sizes to scrub rust and grime from studs and lug bolts. It attaches to a power drill or impact gun for fast cleaning.

- Tire Toolz-Stud Cleaner (SC100): This tool uses durable carbon steel brushes to remove rust and dirt and fits most air drills.

Cleaning the threads is a simple step that helps you avoid a stubborn cross threaded lug nut.

DO Use the Correct Lug Nuts for Your Vehicle

Not all lug nuts are the same. Using the wrong type, size, or thread pitch is a guaranteed way to cause damage. You must match the lug nut to your specific wheels and vehicle. There are two main things to check: the seat type and the thread size.

First, check the seat type. The seat is the part of the lug nut that makes contact with the wheel. Using the wrong seat type prevents the nut from centering correctly and applying even pressure. This can damage your wheels and cause the lug nuts to loosen over time.

| Lug Nut Type | Shape | Common Use |

|---|---|---|

| Conical (Tapered) | Cone-shaped seat | Most aftermarket wheels and many standard vehicles |

| Ball (Radius) | Rounded or spherical seat | Many European cars (Honda, Audi, Volkswagen) |

| Mag (Flat Seat) | Flat surface with a washer | Some OEM wheels (e.g., Toyota, some GM/Chrysler) |

You can identify the correct type by looking at the lug nut holes on your wheel. A cone-shaped hole needs a conical nut. A rounded hole needs a ball seat nut. A flat surface requires a mag-style nut with a flat washer.

Second, you must confirm the thread size and pitch. The thread diameter is the thickness of the stud, and the pitch is the distance between threads. Using a lug nut with the wrong thread specifications will create a cross threaded lug nut instantly. This is a critical safety issue and a key part of how to avoid cross-threading bolts. Forcing a 12×1.5mm nut onto a 12×1.25mm stud will destroy the threads on both parts. Always check your vehicle’s manual or consult a parts professional to confirm the correct size for your car.

DO Apply Straight, Even Pressure

You must apply pressure straight onto the wheel stud as you start a lug nut. The nut should sit perfectly flat against the wheel’s surface. A tilted or angled nut is a primary cause of damage. Applying straight pressure ensures the threads engage correctly from the very first turn. This simple action is key to a safe and secure installation.

Proper technique is essential to get this right. Follow these steps to ensure you apply straight, even pressure every time:

- Position the Nut Squarely: Hold the lug nut with your fingers. Align it directly with the wheel stud. You should feel the opening of the nut sit flush against the tip of the stud before you even begin to turn it.

- Hand-Tighten Until Snug: Turn the nut by hand. It should spin on smoothly for several rotations. Continue turning until it feels snug against the wheel. This initial contact is crucial for proper wheel alignment and helps you avoid cross-threading.

- Avoid Tools for Initial Tightening: You should not use any wrenches or power tools at this stage. A tool can easily force a misaligned nut, causing immediate cross-threading and damaging both the nut and the stud. Your fingers provide the sensitivity needed to feel if something is wrong.

Quick Check: After a few turns, gently wiggle the lug nut. A properly threaded nut will feel solid with no side-to-side wobble. If the nut feels tilted or loose, you have likely started a cross-threading issue. Stop, unscrew it, and start over.

Once all lug nuts are hand-tightened and snug, you can then use a wrench. You will tighten them fully using a specific sequence, like the star pattern. This method distributes pressure evenly across the wheel hub, preventing warping and ensuring the wheel is securely mounted.

The “Don’ts”: Common Mistakes That Cause Damage

Knowing what to do is only half the battle. You must also know what not to do. Avoiding a few common mistakes will protect your wheels, your studs, and your safety. These “Don’ts” are the most frequent causes of thread damage.

DON’T Start with a Power Tool

This is the fastest way to create a problem. You should never use an impact wrench or power drill to start a lug nut. A power tool applies rotational force too quickly and powerfully. It spins the nut before the threads can properly align. This forceful rotation can cause the nut’s threads to cut into the wheel stud’s threads at an angle, creating a cross-threaded bolt in an instant. Your hands provide feedback that a machine cannot.

Warning: ⚠️ Using a power tool to start a lug nut is a primary cause of cross-threading. The tool will not stop when it feels resistance and will ruin the threads on both parts.

Some modern impact wrenches have features designed to reduce damage. While these are helpful for final tightening, they are not a substitute for starting the nut by hand. These features include:

- Torque-Limiting Sticks: These accessories limit the wrench’s final torque output. They help prevent over-tightening but do not help with the initial thread alignment.

- Adjustable Torque Settings: Many cordless wrenches allow you to set a specific torque level. A low setting might seem safe, but it can still apply enough force to create a cross threaded lug nut if the threads are misaligned from the start.

Even with these technologies, the risk is too high. Always start every lug nut by hand for several turns.

DON’T Force a Resistant Lug Nut

Resistance is your first and most important warning sign. A properly aligned lug nut should spin on smoothly with just your fingertips. If you feel the nut bind, stop, or become difficult to turn, do not grab a wrench and force it. Forcing it is a guarantee you will create a cross threaded lug nut.

When you feel resistance:

- Stop immediately. Do not try to push through it.

- Unscrew the nut completely.

- Inspect the threads on both the nut and the stud for any visible damage or debris.

- Realign the nut and try again.

Forcing a resistant nut will strip the threads, turning a simple task into a costly repair. You will damage the nut and create a cross-threaded bolt that must be replaced. Listening to this tactile feedback is a core principle of how to avoid cross-threading bolts.

DON’T Ignore a Tilted or Angled Nut

A visual check is just as important as the feel of the threads. A lug nut must sit perfectly flat against the wheel surface. If it looks tilted or crooked in any way, it is not aligned correctly. Ignoring this visual cue will lead to a damaged cross-threaded bolt.

Look closely at the nut after you have hand-tightened it. A misaligned nut will be obvious if you know what to look for.

- The nut will appear crooked compared to the other lug nuts.

- It will sit at an angle instead of being flush with the wheel’s surface.

- You will see a noticeable tilt, often with a larger gap on one side of the nut than the other.

After a few hand turns, give the nut a gentle wiggle. A properly seated nut will feel solid. A tilted one will wobble. If you see or feel any tilt, you are starting a cross-threading issue. Unscrew it and start over. Taking an extra five seconds to fix the alignment prevents serious damage.

DON’T Use Dirty or Damaged Hardware

You should never install lug nuts that are dirty, rusty, or damaged. Using compromised hardware is just as bad as using the wrong technique. Strong lug threads are essential for proper torquing of the lug nuts. They must also be robust enough to withstand the forces your vehicle creates, especially during turns.

Reusing lug nuts with severe rust or worn threads creates significant safety hazards. Weakened threads can fail under normal driving conditions. This can lead to a catastrophic failure where the wheel could come loose. The small cost of new hardware is nothing compared to the cost of an accident.

Safety First: ⚠️ A damaged lug nut or stud is a ticking time bomb. If you see any signs of wear, rust, or damage, replace the part immediately. Do not take the risk.

Before you install any lug nut, you should perform a quick visual inspection. This simple check can save you from a major headache.

What to Look For:

- On the Lug Nut: Check for stripped or flattened threads inside the nut. Look for cracks in the nut body or heavy rust that you cannot clean off.

- On the Wheel Stud: Inspect the threads for any signs of being flattened, stripped, or “smeared.” Check for deep rust or corrosion that a wire brush cannot remove.

Attempting to force a damaged nut onto a stud is a recipe for disaster. It will cause immediate cross-threading and ruin the stud. This action creates a cross-threaded bolt that is unsafe and must be replaced. Even if you manage to get it on, the connection will be weak. A damaged nut on a good stud can still create a cross-threaded bolt, making future removal nearly impossible without breaking the stud.

Proper Tightening Technique for Threaded Lug Nuts

You have hand-started all your lug nuts. Now you must tighten them correctly. Proper tightening ensures your wheel is secure and prevents damage. Following a specific technique for your threaded lug nuts is just as important as starting them by hand.

Follow the Star Pattern for Even Torque

You should always tighten lug nuts in a star or crisscross pattern. This method distributes pressure evenly across the wheel hub. Tightening nuts in a circle can cause the wheel to sit crooked. This misalignment leads to serious problems.

- It creates severe vibrations while you drive.

- It causes increased wear on parts.

- It shortens the life of your wheel components.

The pattern changes based on how many lugs your wheel has. For an 8-lug wheel, you would follow this sequence:

- Tighten nut 1.

- Move across to tighten nut 5.

- Move to nut 3.

- Move across to tighten nut 7.

- Continue this pattern (2, 6, 4, 8) until all are snug.

Use a Calibrated Torque Wrench

A torque wrench is the only tool that can tighten lug nuts to the exact specification your vehicle requires. Using a standard wrench or an impact gun for final tightening is just guessing. A calibrated torque wrench ensures accuracy. Different wrenches have different levels of precision.

| Wrench Type | Typical Accuracy |

|---|---|

| Beam Wrench | ±3% to ±5% |

| Click-Type Wrench | ±4% |

| Digital Torque Wrench | ±1% to ±2% |

Note: 📝 For best results, you should calibrate your torque wrench once a year or after every 5,000 uses. This ensures it provides an accurate reading every time.

Avoid Over-Tightening

More is not better when it comes to torque. Over-tightening lug nuts is dangerous. It can cause more damage than under-tightening. Too much force can stretch the wheel studs, permanently damaging the threads. This can make a future removal feel like you have a cross threaded lug nut. In the worst case, the stud can break while you are driving. Over-tightening can also warp your brake rotors, which you feel as a pulsing or shaking when you brake. Always use a torque wrench set to your vehicle’s recommended specification to avoid these costly and unsafe problems with your threaded lug nuts. A damaged stud from over-tightening is as bad as a cross threaded lug nut from poor installation.

To Lube or Not to Lube? Understanding the Debate

The question of whether you should lubricate lug nut threads is a hot topic among mechanics and DIYers. While it might seem like a good idea to prevent rust, most vehicle manufacturers give a clear answer: no. The torque values they provide are calculated for clean, dry threads.

Every car I have ever owned has specified in the owners manual that nuts are installed without lubrication. The torque values provided are based on that instruction.

Adding lubricant significantly decreases friction. This means that when you use a torque wrench set to the factory specification, you apply much more stretching force (tension) to the wheel stud. This extra strain can stretch the stud beyond its designed limit, causing permanent damage or even causing it to break while you drive. Wheel studs are critical safety parts. Manufacturers perform extensive testing to determine the correct torque for dry threaded lug nuts to ensure they are tight without being over-stressed.

Some people still argue for lubrication to prevent seizing, especially in areas with harsh winters. They often follow a rule of thumb, reducing the torque value by about 25% to account for the lower friction. However, this is a guess. The true measure of tightness is bolt tension, not torque. Lubricant makes your torque wrench an unreliable tool for measuring that tension.

Research shows how risky this can be. The effect of lubrication on bolt stress is significant and can be inconsistent.

| Lubrication Condition | Average Bolt Stress (Ksi) |

|---|---|

| No Lubrication | 28.8 |

| Partial Lubrication | 34.2 |

| Proper Lubrication | ~40.0 |

As you can see, lubrication dramatically increases the stress on the hardware. For your threaded lug nuts, the safest path is always to follow your manufacturer’s instructions. This ensures your wheels are secure without risking catastrophic failure.

How to Fix a Cross-Threaded Bolt and Nut

You felt resistance while tightening a lug nut, and now you suspect a problem. A cross-threaded bolt is a serious issue, but you can often address it if you act quickly. Knowing how to fix a cross-threaded bolt starts with stopping all work immediately.

Stop Immediately and Assess the Situation

The moment you feel a lug nut bind or become difficult to turn, stop. Do not grab a bigger wrench to force it. Continuing to tighten a misaligned nut will only cause more severe damage to both the nut and the wheel stud. You will turn a small mistake into a major repair.

Important: Your first action is to carefully unscrew the nut. If it is only slightly cross-threaded, it may come off with gentle counter-clockwise pressure. If it is seized, you may need a professional to remove it without breaking the stud.

Once the nut is off, you can begin to assess the damage. This is the first real step to fix a cross-threaded bolt.

Carefully Inspect the Threads for Damage

You need to look closely at the threads on both the wheel stud and the lug nut. Your inspection will tell you if the problem is minor or severe. This check determines how to fix a cross-threaded bolt. You can categorize the damage to decide on the right solution.

- Minor damage: You might see light burrs or debris in the threads. This can often be fixed by cleaning the threads with a wire brush. For a better repair, you can use a thread chaser tool to clean and realign the threads without removing metal.

- Moderate damage: The threads may look flattened or slightly crossed. A tool called a tap can sometimes be used to reshape the threads on the stud. However, this requires skill to avoid making the cross-threaded bolt weaker.

- Severe damage: You will see missing or mangled threads on the cross-threaded bolt. The stud may even have cracks. In this case, the part is unsafe and must be replaced. Attempting a repair on a severely damaged stud is not an option.

When to Replace Damaged Parts

You must replace parts when the damage is too great for a safe repair. Wheel studs must be replaced when their threads are mangled or trashed. This often happens when a cross threaded lug nut is forced on with a power tool. The resulting cross-threaded bolt is no longer safe for use. Even if you manage to remove the nut, the ruined stud cannot hold the correct torque and will fail.

Safety Warning: ⚠️ Never reuse a stud with visibly damaged or stripped threads. A failed stud can cause your wheel to come off while driving.

Replacing a damaged stud is the only way to truly fix a cross-threaded bolt that is severely compromised. The cost of this repair can vary.

- Replacing a single wheel stud often costs between $90 and $160.

- If two or three studs on one wheel need replacement, the cost can range from $140 to $260.

- Sometimes, the damage requires replacing the entire hub assembly, which can increase the cost to $250 to over $600.

These costs show why preventing a cross threaded lug nut in the first place is so important. Careful installation saves you from expensive and dangerous problems.

Consulting a Professional for Stud Replacement

Sometimes, a problem is too big for a DIY fix. You must know when to step back and call a professional. A severely damaged cross-threaded bolt is a serious safety risk. Attempting to fix it without the right tools or experience can make the problem worse. A professional mechanic has the skills and equipment to replace a stud correctly and safely. This ensures your wheel is secure.

Knowing how to fix a cross-threaded bolt is one thing. Knowing when not to is even more important. You should consult a mechanic if you encounter any of these issues:

- The lug nut will not budge, and you cannot remove it without extreme force.

- You see severe damage to the stud’s threads after removing the nut.

- The wheel stud itself feels loose or spins in the hub.

- You are unsure about your ability to fix a cross-threaded bolt safely.

Expert Tip: 💡 A mechanic can use specialized tools to remove a seized nut without damaging the wheel or hub. They can then press out the old cross-threaded bolt and install a new one, restoring the connection to factory standards.

Forcing a repair on a compromised cross-threaded bolt is not worth the risk. A professional can properly fix a cross-threaded bolt, giving you peace of mind that your vehicle is safe to drive. The cost of a professional repair is small compared to the cost of an accident caused by wheel failure.

You can prevent cross-threading by always starting lug nuts by hand. The biggest mistake is using a power tool to start them. This almost guarantees a cross threaded lug nut and leads to serious safety issues. A bad installation from cross-threading can cause dangerous problems.

- Vibrations: A poorly secured wheel from a cross threaded lug nut can cause vibrations that get worse with speed.

- Poor Handling: Improper installation, including cross-threading, can make your steering feel unresponsive.

Making careful installation a habit is the best way to avoid cross-threading. You will keep your wheels secure and prevent expensive repairs.

FAQ

What exactly is cross-threading?

Cross-threading occurs when you misalign the threads of a lug nut and a wheel stud. Forcing the nut to turn cuts new, incorrect threads into the stud. This action damages both parts and creates a weak, unsafe connection that can easily fail.

Can you reuse old lug nuts?

You can often reuse lug nuts if they are in good condition. You must inspect them before every installation. Replace any nut that shows signs of rust, stripped threads, or cracks. Using damaged hardware creates a serious safety risk for your vehicle.

What happens if you drive with a cross-threaded lug nut?

Driving with a cross-threaded nut is extremely dangerous. The damaged connection cannot hold the proper torque. This causes the wheel to vibrate and can lead to the wheel coming loose while you are driving, resulting in a total loss of vehicle control.

How do you find the correct torque for your lug nuts?

You can find the correct torque specification in your vehicle’s owner’s manual. This value is critical for safety. Always use a calibrated torque wrench to tighten your lug nuts to this exact specification to avoid damage from over-tightening or under-tightening.