admin1

August 17, 2025

How to Choose the Right TPMS Valve Stem for Your Vehicle

Choosing the right valve stem for your vehicle matters more than you might think. Over 92% of vehicles in the United States have a tpms valve, and more than 104 million vehicles use these sensors every day. Take a look at how common these systems are:

| Region/Country | TPMS Adoption / Penetration |

|---|---|

| United States | 92% of vehicles on roads equipped with TPMS (2023) |

| Europe | 100% compliance for new vehicles since 2014 |

| Global | Over 327 million TPMS units installed (2024) |

When you match the tpms valve to your vehicle, you help the sensor do its job. The right valve stem keeps your tires safe by helping the sensors catch pressure changes early. This can stop air leaks and keep you safe on the road.

TPMS Valve Basics and the Importance of Valve Stem Selection

What Is a TPMS Valve Stem?

You might wonder what a TPMS valve stem does in your vehicle. This small part connects your tire to the tire pressure sensor. It holds the sensor inside the wheel and lets the sensor measure the air in your tire. The sensor sends tire pressure readings to your car’s computer. You see these readings on your dashboard. In many vehicles, the sensor sits right inside the valve stem. This setup gives you fast and accurate readings.

Here’s what a TPMS valve stem does for your tire pressure monitoring system:

- It acts as the link between your tire and the tire pressure sensor.

- It houses the sensor that checks your tire’s air pressure.

- It sends pressure readings to your vehicle’s computer for real-time updates.

- It helps the sensor spot pressure changes and alerts you if the tire loses air.

- It keeps your tires safe by making sure the sensor works well.

- It helps you save fuel by warning you about low tire pressure.

- It helps your tires last longer by keeping the pressure right.

- It helps your vehicle meet safety rules in the United States and Europe.

Why the Right Valve Stem Matters for Your Vehicle

Choosing the right valve stem for your vehicle is not just about fit. It is about safety, accuracy, and reliability. If you use the wrong valve stem, you might get slow air leaks. This can make your tire pressure sensor give wrong readings. Bad readings can damage the sensor or even cause the whole system to fail. If the sensor is not tight enough, it can break. This can lead to unsafe driving, like tire blowouts or uneven tire wear.

Tip: Always use the correct valve stem for your vehicle. Make sure it is clean and not damaged. Tighten it just right to protect the sensor.

The law in the United States and Europe says your vehicle must have a working tire pressure monitoring system. The system must alert you if your tire pressure drops by more than 20%. The TPMS valve stem helps your sensor meet these rules. Good valve stem selection keeps your tire pressure sensor working well. This means you get accurate readings, better sensor accuracy and precision, and more safety on the road.

When you pick a valve stem, think about the factors to consider when choosing a tire pressure sensor. The right choice gives you the best accuracy, reliability, and safety. That is the importance of tmps for every vehicle.

Identifying Your Vehicle’s Tire Pressure Sensor and TPMS Type

Direct vs. Indirect Tire Pressure Sensor Systems

When you look at your vehicle’s tire pressure sensor, you might wonder how it works. There are two main types: direct and indirect systems. Each type uses different sensors and gives you different levels of accuracy and reliability.

Here’s a quick table to help you see the differences:

| Aspect | Direct TPMS | Indirect TPMS |

|---|---|---|

| Sensing Technology | Physical sensors inside each tire measuring pressure directly | Uses ABS and wheel speed sensors to estimate pressure based on wheel rotation speed |

| Accuracy | High accuracy; real-time, precise readings per tire | Less accurate; estimates pressure changes indirectly; cannot identify specific tire |

| Maintenance | Requires battery replacement every 5-7 years; sensors can be damaged by environment | No batteries; minimal maintenance; recalibration needed after tire rotation or changes |

| Reliability & Durability | Sensors prone to wear, damage, and battery failure | More durable; fewer components subject to failure; avoids sensor wear |

| Cost | Higher initial and maintenance cost due to sensors and batteries | More cost-effective; uses existing vehicle systems, reducing hardware costs |

| Alerts & Monitoring | Provides specific alerts for each tire; detects slow leaks early | Provides general alerts; cannot specify which tire is underinflated |

Direct systems use a tire pressure sensor inside each tire. These sensors give you real-time readings and high accuracy. You get alerts for each tire, so you know exactly which one needs air. Indirect systems use your vehicle’s ABS and wheel speed sensors. They estimate pressure by looking at how fast each wheel spins. Indirect systems need less maintenance and have better reliability, but they can’t tell you which tire is low.

How to Determine Your Vehicle’s TPMS Type

You can figure out your vehicle’s tire pressure sensor type with a few simple steps. Start by checking your dashboard. If you see a warning light shaped like a tire with an exclamation mark, your vehicle has a TPMS. Next, look at your owner’s manual. It will tell you if your system is direct or indirect.

You can also inspect your valve stems. Metal stems often mean you have direct sensors inside the tire. If you want to be sure, use a TPMS scan tool. These tools read the sensors and show you the type and readings. Some scan tools can even use your vehicle’s VIN to find the right information.

Here are some tips to help you:

- Use a TPMS diagnostic tool to scan your vehicle and check the tire pressure sensor type.

- Keep your scan tool updated so it works with the latest sensors and vehicles.

- Ask a professional mechanic if you’re not sure about your system.

- Test your sensors before replacing them to make sure they work.

- Program new sensors and perform a relearn procedure after installation.

Tip: Always match your tire pressure sensor and valve stem to your vehicle’s make, model, and year for the best accuracy and reliability.

Valve Stem Selection: Ensuring Compatibility with Your Vehicle

Matching Make, Model, and Year

When you start selecting a valve stem for your vehicle, you might think you only need to know the make, model, and year. That sounds simple, but there’s more to it. Many vehicles have different trim levels, wheel types, and even different sensors within the same model year. If you want the right valve stem, you need to look at a few extra details.

Here’s a step-by-step way to find the correct TPMS valve stem specifications for your vehicle:

- Check your vehicle’s make, model, and year.

- Look for your trim level. Some trims use different tire valve stems or sensors.

- Count the wheel lugs. For example, a 2019 Ram 1500 can have five or six lugs, and each uses a different sensor.

- Identify the valve type. Is it snap-in or clamp-in? Sometimes, a previous owner may have changed it.

- Find your vehicle’s production date. Some models, like the 2021 Jeep Gladiator, switched TPMS systems mid-year.

- Look at your dashboard. The TPMS display type (Hi-Line or Lo-Line) can help you match the sensor.

- Check the sensor frequency. Most sensors use 315 MHz or 433 MHz, but you may need a TPMS diagnostic tool to confirm.

- The best way? Check the OE part number on your current TPMS sensor.

- Use a TPMS diagnostic tool to test your sensor and confirm all these details before you order replacements.

Tip: Don’t guess when selecting a valve stem. Always double-check these details to avoid headaches later.

You can run into compatibility issues if you skip any of these steps. Here’s a table showing some of the most common problems and what can happen if you don’t match your valve stem correctly:

| Compatibility Issue | Description / Cause | Impact / Consequence |

|---|---|---|

| Improper Vehicle Application Verification | Wrong year, make, or model; not using VIN for accurate data | Wrong sensor fitment, system warnings, or failure to function properly |

| Wrong Sensor Type | Using non-compatible sensor types | Sensor incompatibility, failure to communicate with vehicle system |

| Failure to Program or Relearn Sensors | Skipping relearn or improper programming | TPMS warning lights, incorrect tire pressure readings, safety concerns |

| Physical Fitment Problems | Corrosion, incorrect valve cores, damaged stems | Sensor damage, air leaks, premature sensor failure |

| Not Replacing Service Parts | Reusing old seals, nuts, valve cores, or caps | Air leaks, corrosion, sensor malfunction |

| Incorrect Torque Application | Overtightening or undertightening valve nuts or cores | Sensor damage, air leaks, compromised sensor assembly |

| Using Incompatible or Outdated Tools | Tools not compatible with sensor or vehicle | Inability to program or relearn sensors, wasted time and resources |

| Sensor Battery Life | Aging sensors with dead batteries | Sensor failure, undetected tire pressure issues |

| Shared Components with Other Systems | Sensors sharing receivers with keyless entry systems | Complicated procedures, need to avoid interference during programming |

If you want your TPMS to work well, you need to pay attention to these details. Valve stem selection is not just about the part itself. It’s about making sure everything fits and works together for your vehicle.

OEM vs. Aftermarket TPMS Valve Stems

Now, let’s talk about your choices. You can pick between OEM (Original Equipment Manufacturer) and aftermarket TPMS valve stems. Each option has its own pros and cons, so you need to know what matters most for your vehicle.

Here’s a quick look at how they compare:

| Aspect | OEM TPMS Valve Stems/Sensors | Aftermarket TPMS Valve Stems/Sensors |

|---|---|---|

| Quality | Vehicle-specific, consistent high quality | Quality varies widely by brand |

| Durability | Long battery life, typically 5-7 years | Often shorter lifespan, some fail within days/months |

| Warranty | Manufacturer warranty included | Frequently no manufacturer warranty |

| Compatibility | Pre-programmed, guaranteed vehicle compatibility | May require manual programming, compatibility risks |

| Installation | Plug-and-play, supported by dealerships and shops | May require specialized tools or professional help |

| Cost | Higher upfront cost ($50–$100 per sensor) | Lower upfront cost ($20–$60 per sensor) |

OEM valve stems are made for your vehicle. They last longer, usually five to seven years, and come with a warranty. You get a plug-and-play solution, so you don’t have to worry about programming or fitment. Dealerships and repair shops know how to install them, and you get support if you need it.

Aftermarket tire valve stems can save you money up front. They are easy to find and often work with many vehicles. Some brands, like Autel and Huf, offer programmable sensors that meet or exceed OE standards. But you need to be careful. Quality can vary a lot. Some aftermarket sensors last a long time, but others might fail quickly. Many do not come with a warranty, and you may need special tools or help to program them.

Note: If you use an aftermarket valve stem, always buy from a trusted brand. Check reviews and make sure it matches your vehicle’s specs.

When you think about valve stem selection, remember that the right valve stem keeps your TPMS working and your tires safe. If you want peace of mind, OEM is the safest bet. If you want to save money and don’t mind a little extra work, aftermarket can be a good choice. Just make sure you check all the details before selecting a valve stem for your vehicle.

Choosing the Right Valve Stem Material and Fit

When you pick tire valve stems for your vehicle, you need to think about both the material and the fit. These choices affect how well your TPMS works, how long your tires last, and how safe your ride feels. Let’s break down what you need to know.

Rubber, Metal, Brass, and Nickel Options

You’ll see tire valve stems made from rubber, aluminum, brass, and sometimes nickel-plated parts. Each material has its own strengths and weaknesses. Here’s a table to help you compare:

| Material | Advantages | Disadvantages |

|---|---|---|

| Rubber | Flexible, absorbs vibrations, easy to replace, cost-effective | Wears out faster, not for high-pressure, can crack under UV light |

| Aluminum | Lightweight, corrosion-resistant, durable | Costs more, can get damaged by impacts |

| Brass | Strong, handles high pressure, reliable, highly corrosion-resistant | Heavier, more expensive than rubber, but less than aluminum |

| Nickel | Prevents corrosion when used as plating on valve cores | Not usually used for full stems, mainly for plating |

Rubber stems work well for most passenger vehicles. They flex with the wheel and absorb bumps. You can replace them easily when you change tires. Aluminum and brass stems are better for heavy-duty vehicles or racing. They last longer and resist corrosion, but they cost more. Nickel-plated valve cores help prevent corrosion, especially if you have aluminum wheels or TPMS sensors.

Tip: If you drive in harsh weather or use your vehicle for towing, metal stems give you extra strength and durability.

Wheel Hole Size, Stem Length, and Pressure Ratings

Getting the right fit for your tire valve stems is just as important as picking the right material. You need to match the stem to your wheel’s hole size, stem length, and the pressure your tires need.

Wheel Hole Sizes

Most vehicles use one of two standard sizes: 0.453 inches for wheels 15 inches and smaller, and 0.625 inches for wheels 16 inches and larger. Some motorcycles use even smaller holes, around 0.327 inches. If you drive a heavy-duty truck, you’ll likely need the larger size.Stem Length

The typical stem length is about 1-1/4 inches. This length works for most TPMS sensors and fits standard wheels. If your wheel rim is deeper, you may need a longer stem. Always check your wheel’s design before you buy.Pressure Ratings

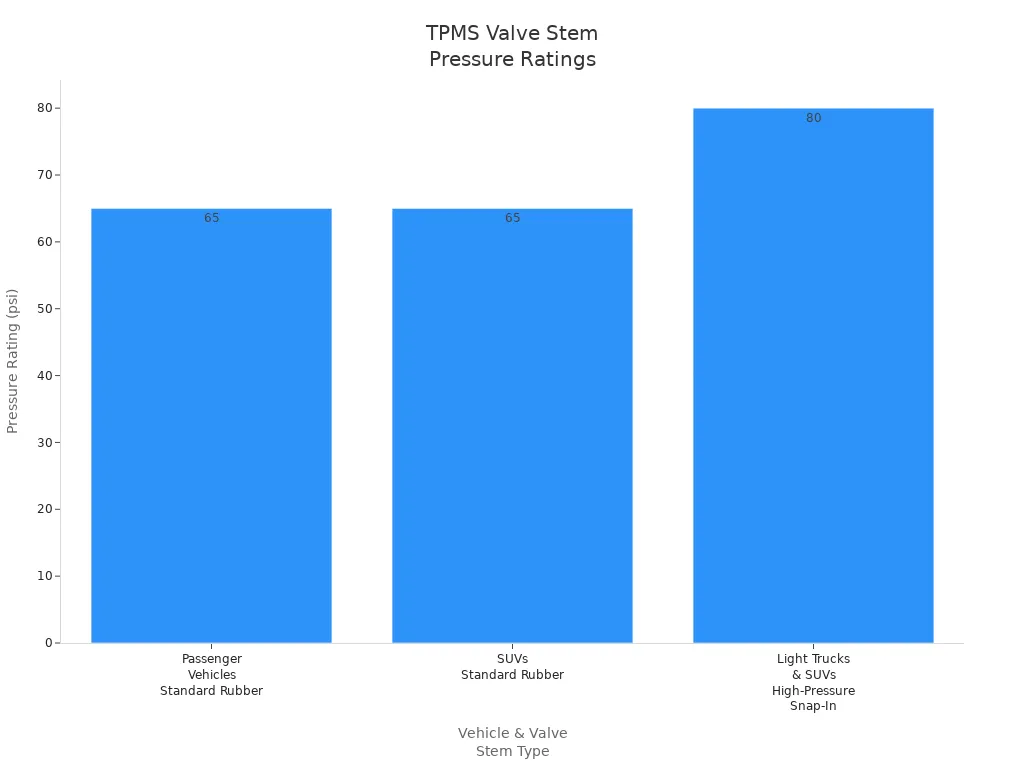

Pressure ratings matter for safety. Here’s a quick chart to show what you need for different vehicles:

| Vehicle Type | Valve Stem Type | Pressure Rating (psi) |

|---|---|---|

| Passenger Vehicles | Standard Rubber Valve Stems | Up to 65 |

| SUVs | Standard Rubber Valve Stems | Up to 65 |

| Light Trucks & SUVs | High-Pressure Tubeless Snap-In | Up to 80 |

| Heavy-Duty Trucks | Metal Valve Stems | Up to 200 |

Rubber stems handle up to 65 PSI, which covers most passenger vehicles and SUVs. If you drive a light truck or need higher pressure, look for high-pressure snap-in stems rated up to 80 PSI. Metal stems can handle up to 200 PSI, perfect for racing or heavy-duty trucks.

Temperature Ratings

Rubber stems work from -40°F to 180°F. Metal stems go from -65°F to 250°F. If you drive in extreme heat or cold, metal stems are the safer choice.Valve Stem Design and Compatibility

Snap-in rubber stems are easy to install and work for everyday driving. Clamp-in metal stems are best for steel wheels and high-speed or high-pressure use. Nickel-plated valve cores help prevent corrosion, especially with aluminum wheels and TPMS sensors.Other Fit Factors

Always match the stem angle and length to your wheel’s rim depth. This helps seal the stem and keeps air from leaking. Use the right grommet size for your wheel diameter. Tighten the valve stem nut snugly, but don’t overtighten.

Note: If you want your TPMS to work well, always check your vehicle’s specs before you buy tire valve stems. The right fit keeps your tires safe and your sensors working.

You can see how choosing the right material and fit for your tire valve stems makes a big difference. You get better performance, longer life, and fewer problems down the road. Take a few minutes to check your wheel size, stem length, and pressure needs. Your vehicle will thank you!

Installation Tips and Common Mistakes to Avoid

Proper Installation for Tire Pressure Sensor and Valve Stem

Getting the correct installation of your tire pressure sensor and valve stem is key to maintaining proper tire pressure and avoiding air loss. You want to start with a clean workspace. Wipe the valve stem with a dry, lint-free cloth to remove dirt and corrosion. Inspect the stem for cracks, bent cores, or worn threads. If you see damage, replacing tire valve stems is the safest move.

Here’s a step-by-step guide for proper installation:

- Gather your tools: torque wrench, tire pressure gauge, valve core tool, and new sensors.

- Remove the tire to access the valve stem and check the tire’s condition.

- Take out the old valve stem carefully, making sure not to damage the valve seat. This helps prevent air loss.

- Mount the sensor directly onto the valve stem. Align it properly and fasten securely.

- Reinstall the valve stem and tighten it using the manufacturer’s torque specs. This ensures a proper fit and torque, which keeps the seal tight.

- Calibrate the tire pressure sensor system as the instructions say. This step guarantees accurate sensor readings.

- Test the system by checking sensor communication and tire pressure readings.

Always use new seals, nuts, and valve cores. Never reuse old nuts—they can crack and cause leaks. When you tighten the sensor nut, use a torque wrench set to the right value (usually 35 to 80 in-lbs). Over-tightening can damage the sensor or cause air loss. Make sure the sensor sits flush against the wheel before tightening. Follow the manufacturer’s instructions during tire mounting to avoid sensor loss or damage.

Tip: Professional inspection and replacing tire valve stems during tire service help prevent dangerous tire failures and serious safety risks.

Common Errors in Valve Stem Selection and Maintenance

Mistakes during installation or maintenance can lead to hazards like air loss, sensor failure, and even tire failures. Here are the most common errors and how you can avoid them:

- Using the wrong type of tire pressure sensor for your wheel design can cause fitting issues and sensor loss. Always check your vehicle’s specs before choosing sensors.

- Installing sensors on dirty or damaged valve stems leads to leaks and inaccurate readings. Clean and inspect every stem before installing sensors.

- Over-tightening sensors damages threads and seals, causing air loss. Use a torque wrench and follow the correct torque values.

- Failing to program or sync sensors results in false alerts and miscommunication. Pair each sensor to the right wheel position.

- Ignoring battery replacement schedules causes sensor loss and unexpected failures. Replace batteries every 3–5 years.

- Not checking tire pressure after installation risks undetected mis-inflation and tire failures. Always measure and adjust pressure manually.

- Skipping a test drive after setup means you might miss sensor communication issues. Take a short drive to confirm all sensors work.

- Reusing old seals, nuts, or valve cores leads to leaks and corrosion. Always use new service kits when replacing tire valve stems.

- Not performing a factory relearn after tire rotation or sensor service causes incorrect tire location data and false alerts.

Regular inspection is important. Look for cracks or leaks every month. Keep valve caps on to prevent dirt and moisture from causing air loss. Replace stems when you see wear or damage. Use only approved lubricants and avoid petroleum-based products, which can degrade rubber and lead to hazards. Professional replacement is recommended if you’re unsure, as tire pressure sensor systems are complex and pressurized.

Note: Following these steps helps you avoid serious safety risks and keeps your sensors working for the long haul.

Choosing the right TPMS valve stem keeps you safe on the road and helps your tires last longer. When you pick the correct stem, you prevent air loss and avoid dangerous tire failures, especially at high speeds. TPMS sensors give you real-time pressure updates, so you can spot underinflation early and protect customer safety. Always double-check these steps before you buy:

- Confirm your TPMS type.

- Match your vehicle’s make, model, and year.

- Choose the right material for your needs.

- Check the fit, pressure rating, and stem size.

- Follow proper installation steps.

Keeping your tire pressure right improves safety, saves fuel, and extends tire life.

FAQ

What happens if I use the wrong TPMS valve for my vehicle?

If you use the wrong TPMS valve, you risk air loss and sensor errors. This can cause inaccurate readings and even dangerous tire failures. Always focus on valve stem selection that matches your vehicle for safety and reliability.

How do I know if I need to replace my tire valve stems?

You should consider replacing tire valve stems if you see cracks, corrosion, or leaks. Old stems can cause air loss and hazards. Regular checks help you avoid serious safety risks and keep your tire pressure monitoring system working well.

Why is proper installation important for tire pressure sensors?

Proper installation ensures sensor accuracy and precision. If you skip correct installation, you might get false readings or sensor loss. This can lead to tire failures and customer safety concerns. Always follow the right steps for a proper fit and torque.

What are the main factors to consider when choosing a tire pressure sensor?

You need to check compatibility, fit, and pressure rating. Look at your vehicle’s make, model, and year. The importance of tmps means you should focus on accuracy, reliability, and maintaining proper tire pressure to avoid hazards and loss.

Can I install tire valve stems myself, or should I get professional help?

You can install tire valve stems at home if you have the right tools and follow instructions. For best results and to avoid air loss or sensor damage, many people choose professional service. This helps prevent serious safety risks and ensures reliability.