admin1

November 17, 2025

Everything You Need to Know About Spacer Lug Nuts

Spacer lug nuts are special fasteners. You use them to mount wheel spacers securely to your vehicle’s hub. Using the correct lug nuts is essential for your safety. They ensure the spacer and wheel are properly attached, preventing serious accidents. The desire to customize a vehicle’s look with wheel spacers is a major trend, with the market growing significantly.

| Metric | 2023 | 2032 (Projected) | Annual Growth Rate |

|---|---|---|---|

| Global Wheel Spacer Market Size | ~490 million USD | >850 million USD | 4.5% to 8.8% |

This popularity highlights the need for proper installation knowledge. As one industry expert notes:

“OEM, Ford and GM lug nuts are very hot, but probably our hottest commodity are aluminum spacers.”

Step 1: Match Thread Pitch for Your Vehicle

Choosing the right spacer lug nuts begins with one crucial detail: thread pitch. You must match the lug nut’s threading to your vehicle’s wheel studs. An incorrect match will prevent a secure connection and lead to dangerous failure. Getting this step right is the foundation for a safe wheel installation.

What is Thread Pitch?

Thread pitch is the specific measurement of the threads on your wheel studs. Think of it as the unique fingerprint of your hardware. Manufacturers use two different systems for this measurement. The Imperial system measures threads per inch (TPI), while the Metric system measures the distance between threads.

| Feature | Imperial System (Lug Nuts) | Metric System (Lug Nuts) |

|---|---|---|

| Measurement Unit | Threads per inch (TPI) | Pitch (millimeters) |

| Definition | Number of threads per inch | Distance between threads |

Safety Tip: Proper thread engagement is essential for safety. The industry standard requires the nut to engage a length of thread equal to the stud’s diameter. For example, a 12mm stud needs 12mm of thread engagement to safely secure the wheel.

How to Find Your Vehicle’s Thread Size

Finding the correct size for your lug nuts is simple. Several methods can help you identify your vehicle’s specifications.

- Check Your Owner’s Manual: Your car’s manual often lists the thread size for your wheel hardware.

- Use Online Databases: Websites like

Wheel-Size.comare excellent resources. They provide detailed fitment data, including thread size, center bore, and the wheel bolt pattern for your specific model. - Measure Manually: If you cannot find the information online, you can measure the studs yourself.

- A thread pitch gauge is the easiest tool. You match its teeth to your stud’s threads to find the size.

- You can use calipers to measure the distance between two threads for a metric pitch.

- You can also compare the stud to a bolt or nut with a known thread size.

Confirming the thread pitch ensures your new lug nuts will properly fasten the spacer and wheel assembly.

Step 2: Select the Correct Lug Nut Seat Type

After confirming your thread pitch, you must identify the correct lug nut seat type. The “seat” is the area where the lug nut makes contact with the wheel’s surface. Using the wrong seat type creates a tiny contact point, which can cause the hardware to loosen and the wheel to fail. There are three main types you will encounter.

Conical (Acorn) Seat

You can easily spot a conical seat by its 60-degree, cone-shaped bottom. This is the most common style, especially for aftermarket wheels. The tapered design is engineered for safety and precision.

- It helps center the wheel perfectly on the hub as you tighten it.

- It creates a snug fit and distributes pressure evenly across the wheel seat.

- It prevents dangerous vibrations and helps maintain alignment.

Note: Many high-performance wheel brands, like Vossen, design their products specifically for conical 60-degree lug seats. This highlights its reliability for secure fastening.

Ball (Radius) Seat

A ball seat lug nut has a rounded, spherical base instead of a sharp cone. You will typically find this type on original equipment manufacturer (OEM) wheels from certain brands. It is crucial to use ball seat lug nuts if your wheels are designed for them.

You will often see ball seats on vehicles from these manufacturers:

- Honda and Acura models frequently use ball seat hardware.

- German brands like Audi, Volkswagen, and Mercedes-Benz also commonly use them.

These can have different radius measurements, such as R12 or R14, so always confirm the exact specification for your vehicle.

Mag (Shank) Seat

The mag seat design is very different. These lug nuts feature a flat washer and an extended, smooth shank that slides into the lug hole of the wheel. This design offers a unique method of securing the wheel. The shank helps keep the wheel centered, while the flat washer creates a large, flush contact area for excellent clamping force.

This style is common on many Toyota and Lexus trucks and SUVs, including:

- Toyota Tundra (2007+) & Sequoia (2008+)

- Toyota Tacoma (2005+) & 4Runner

- Lexus LX (1998+) & GX (2023+)

⚠️ Installation Tip: When using shank-style lug nuts, you must ensure the shank is the correct depth. A shank that is too long will bottom out before the washer can properly clamp the wheel.

Step 3: Choose the Right Style of Spacer Lug Nuts

You have matched the thread pitch and seat type. Now, you must select the correct style of nut for your spacer installation. The physical shape of the spacer lug nuts is just as important as their threading. Using the wrong style creates a dangerous situation where your wheel cannot mount correctly. Two features are critical: an open-ended design and a low-profile head.

Why Open-Ended Nuts Are Essential

You must use open-ended lug nuts to attach the spacer to your vehicle’s hub. An open-ended nut is hollow from top to bottom. This design allows your vehicle’s original wheel studs to pass completely through the nut. Most wheel spacers are thinner than the length of the studs. This means the studs will stick out past the surface of the spacer.

⚠️ Critical Safety Warning: Never use closed-end (acorn) nuts to install a wheel spacer. The stud will hit the top of the nut before it is tight. This gives you a false torque reading and leaves the spacer dangerously loose, which can cause the entire wheel to detach while driving.

A closed-end nut will bottom out on the stud, preventing you from properly clamping the spacer to the hub. This is a catastrophic failure point. The open-ended design guarantees you can achieve the correct clamping force for a secure foundation.

The Need for a Low-Profile Design

The nuts securing your spacer must also have a low-profile head. This means they must be short enough to sit flush with or below the spacer’s mounting surface. After you tighten these nuts, the outer face of the spacer must be completely flat. Your wheel needs this flat surface to mount securely.

If the nuts are too tall, they will interfere with the back of the wheel. This interference causes several major problems:

- It prevents the wheel from sitting flat against the spacer.

- It creates a gap, leading to severe vibration.

- It puts uneven stress on your wheel studs and the wheel itself.

This situation is extremely unsafe and will damage your components. Always check that the nuts you use are short enough to fit inside the spacer’s recessed pockets, allowing your wheel to make full, safe contact.

Step 4: Verify Material and Strength Grade

You have the right size and style. Now, you must confirm the material and strength of the nuts. The material of your spacer lug nuts is not just a minor detail. It is a critical safety feature. Your lug nuts face immense forces from acceleration, braking, and cornering. Using weak hardware is a risk you should never take.

The Importance of High-Strength Steel

You must choose spacer lug nuts made from high-strength steel. This ensures they can handle the extreme stress of securing your wheel assembly. A top-tier material for this job is SCM435 chromoly steel. It provides an excellent balance of strength and toughness, making it ideal for high-load parts like lug nuts.

The specific elements in SCM435 steel give it these properties:

- Chromium (Cr) adds hardness and resists corrosion.

- Molybdenum (Mo) improves strength, especially at high temperatures.

This composition makes the steel strong enough to resist stretching and breaking under load. Reputable manufacturers use materials like SCM435 to guarantee safety and performance.

| Element | Percentage Range (%) |

|---|---|

| Carbon (C) | 0.33-0.38 |

| Chromium (Cr) | 0.9-1.2 |

| Molybdenum (Mo) | 0.15-0.30 |

| Manganese (Mn) | 0.60-0.85 |

Understanding Strength Grade Ratings

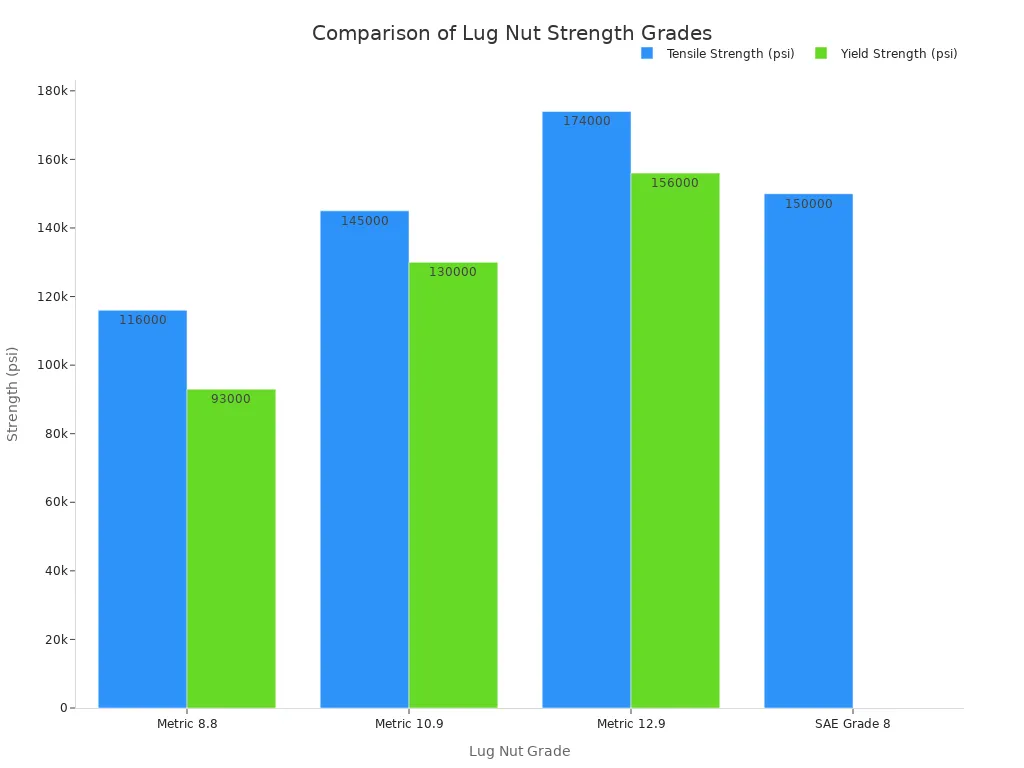

Lug nuts have strength ratings, often called a “class” or “grade.” This number tells you the nut’s strength. For metric hardware, you will see ratings like 8.8, 10.9, or 12.9. These numbers come from the ISO 898 standard.

Did You Know? For a Class 10.9 nut, the “10” means it has a minimum tensile strength of 1000 MPa. The “.9” means it will begin to yield (stretch) at 90% of that value. Higher numbers mean a stronger nut.

For any performance or spacer application, you should use high-strength hardware. Class 10.9 is a widely accepted standard for securing a passenger car wheel safely. Heavy-duty trucks require even stronger hardware, often using Grade 10 nuts for the wheel and Grade 12.9 studs. Always choose a grade that meets or exceeds the requirements for your vehicle.

Choosing a lug nut with a proven material and a high-strength grade ensures your wheel stays securely attached, giving you confidence and peace of mind on the road.

How to Properly Install a Wheel Spacer

Knowing how to properly install a wheel spacer is the final, most important step for your vehicle’s safety. A correct installation ensures your wheel spacers and wheel function as a single, solid unit. This process requires precision, the right tools, and a specific two-stage method. Following these steps prevents dangerous vibrations and potential hardware failure.

The Critical Two-Stage Torquing Method

You must tighten your hardware in two separate stages. This ensures both the spacer and the wheel are perfectly secure. Rushing this process can lead to an unbalanced and unsafe wheel assembly.

Here are the essential installation tips:

- Stage One: Secure the Spacer. Mount the spacer onto your vehicle’s hub. Use the open-ended spacer nuts you selected. Tighten them in a star pattern to the torque value specified in your owner’s manual. This even pressure seats the spacer correctly.

- Stage Two: Mount the Wheel. Place your wheel onto the new studs of the spacer. Use your original lug nuts to attach the wheel. Again, tighten them in a star pattern to the same factory torque specification.

This two-part method guarantees that every component is clamped with the correct and even force.

Why a Torque Wrench is Mandatory

You must use a torque wrench for this job. An impact wrench is great for removal, but it is too powerful and inaccurate for installation. Using one for final tightening can have disastrous results. Over-tightening with an impact wrench can stretch and weaken your wheel studs, causing them to crack and fail while you are driving.

⚠️ Safety Alert: In one documented case, a driver experienced a severe shimmy. An inspection revealed two studs had sheared completely off at the hub. The other lug nuts had backed off so much that a finger could fit between the wheel and the hub. The cause was over-stressing the studs with an impact wrench, which nearly led to the entire wheel detaching.

A torque wrench is the only tool that applies a precise, measured amount of force. This precision is not optional. It is the only way to protect your hardware and ensure your wheel stays safely attached.

A Guide to the Safe Use of Wheel Spacers

Proper installation is only half the battle. The safe use of wheel spacers requires ongoing attention and an understanding of potential risks. Your diligence ensures your vehicle remains reliable and your safety is never compromised. These final safety considerations are essential for every driver using wheel spacers.

The Dangers of Incorrect Hardware

Using the wrong hardware creates an improper configuration that will eventually fail. The lug nut seat and the wheel seat must match perfectly. This contact area transfers the entire load from your wheel. A mismatch results in dangerous over-stressing of the components. For example, installing 60-degree lug nuts on a wheel with 45-degree seats causes only the edges to touch. This concentrates all the force on a tiny area, which can promote cracking and make it impossible to secure the wheel.

Other hardware mistakes create similar hazards:

- Incorrect Thread Pitch: This prevents proper tightening and can strip your studs.

- Wrong Nut Style: Using closed-end nuts on the spacer will leave it loose.

- Low-Strength Materials: Weak nuts can stretch or break under normal driving forces.

Each of these errors can lead to severe vibration or the complete detachment of your wheel.

Post-Installation Safety Checks

Your work is not finished after the initial installation. You must perform critical safety checks to ensure everything remains secure. This simple follow-up is the most important part of the process.

Your Post-Installation Checklist:

- Re-Torque After a Short Drive. You must check and re-tighten all lug nuts after a brief period of driving. For instance, Spidertrax instructions specify that you should check and re-tighten the lug nuts after driving 50 miles. This allows the hardware to settle and ensures a lasting, secure fit.

- Listen for Noises. Pay attention to any new clicking, grinding, or popping sounds coming from your wheels. These can indicate a loose component.

- Feel for Vibrations. A new vibration in your steering wheel or seat often points to an unbalanced or loose wheel assembly.

If you notice any of these warning signs, pull over immediately in a safe location. Do not continue driving. Inspect your wheel spacers and wheel hardware to find the source of the problem.

You now have the knowledge to choose the right spacer lug nuts. Your final checklist ensures a secure wheel:

- Correct Thread Pitch & Seat Type

- Open-Ended/Low-Profile Design

- High-Strength Material

Remember, the quality of your lug nuts is just as important as the wheel spacers. Sourcing from a trusted manufacturer like Fortune ensures you get premium, tested spacer lug nuts for your wheel. This gives you peace of mind. Prioritizing the right lug nuts for your wheel spacers is the most important step you can take for your vehicle’s wheel safety and your vehicle’s wheel performance.

FAQ

What is the difference between wheel spacers and wheel adapters?

What is the difference between wheel spacers and wheel adapters?

wheel spacers push your wheel out from the hub. wheel adapters also push the wheel out. However, wheel adapters change your vehicle’s bolt pattern. This lets you mount a different style of wheel to your vehicle.

Can I reuse my original lug nuts for wheel spacers?

Can I reuse my original lug nuts for wheel spacers?

You cannot use old nuts for this job. You need special nuts to attach the wheel spacers to your vehicle. Your original nuts then attach the wheel to the wheel spacers or wheel adapters. This is critical for your vehicle’s safety.

Are wheel spacers safe for my vehicle?

Are wheel spacers safe for my vehicle?

Yes, with correct installation. Quality wheel spacers and wheel adapters are safe for your vehicle. Proper torque ensures your wheel is secure. A safe wheel assembly on your vehicle depends on good wheel spacers and wheel adapters.

Do wheel spacers affect my vehicle’s alignment?

Do wheel spacers affect my vehicle’s alignment?

Yes, wheel spacers widen your vehicle’s track. You should get a professional wheel alignment after installing wheel spacers or wheel adapters. This step ensures proper handling for your vehicle and its new wheel stance.

How thick can my wheel spacers be?

How thick can my wheel spacers be?

Thickness depends on your vehicle’s fender clearance. The wheel must not rub. Measure the gap before choosing wheel spacers or wheel adapters. The right wheel spacers or wheel adapters fit your specific vehicle. wheel spacers and wheel adapters must be sized correctly for the wheel.