admin1

November 10, 2025

How to Choose the Right Wheels Lug Nuts for Your Car

Your safety on the road depends on secure wheels. Choosing the right wheels lug nuts is a critical step for proper wheel selection. You must match your wheel hardware to three key specifications: seat type, thread size, and length. This ensures perfect compatibility and correct wheel fitment. An incorrect lug nut fitment can lead to wheel damage or total failure.

Safety Alert: ⚠️

The National Transportation Safety Board estimates 750-1,050 wheel separations occur on large trucks annually. Incorrectly installed wheel hardware is a major cause. Checking your equipment compatibility is a crucial safety step.

Step 1: Identify the Correct Lug Nut Seat Type

The first step in choosing the right hardware is matching the lug nut seat to your wheel. A mismatch here is a common and dangerous mistake. You must ensure the shape of the nut perfectly fits the shape of the wheel’s lug hole.

What is a Lug Nut Seat?

The “seat” is the contact surface where the lug nut presses against the wheel. This area centers the nut and applies the clamping force that holds your wheel securely in place. Wheels are designed with a specific seat type machined into the lug holes. Your nuts must have the same seat type to make full contact.

Important Note: 💡

Using the wrong seat type prevents the nut from seating properly. This can cause the nuts to loosen over time, damage your wheels, and lead to a wheel separating from your vehicle while driving.

Conical (Acorn) Seat

The conical seat is the most common type you will find. It has a straight, cone-shaped surface that tapers down to a point. People often call this style an “acorn” seat because of its shape.

Most aftermarket wheels use a conical seat design. Aftermarket conical nuts, like the M12x1.5 Spline Wheel Acorn Lug Nuts, almost always feature a standard 60° cone seat. This 60-degree angle ensures a wide and secure contact area with the wheel.

Ball (Radius) Seat

The ball seat has a rounded, spherical, or dome-shaped surface. It looks different from the straight-sided conical seat. You must not use a ball seat nut on a wheel designed for a conical seat, or vice versa. The shapes are not interchangeable.

Ball seat lug nuts are common on the original factory wheels of many European cars.

- Many European brands that do not use lug bolts often rely on ball seat nuts.

- Porsche is a well-known example of a manufacturer that uses ball seat hardware.

You will typically find this seat type on original equipment manufacturer (OEM) wheels rather than aftermarket ones.

Mag (Shank) Seat

The mag seat lug nut is unique because it uses two parts to secure the wheel. It has a long, straight “shank” and a separate flat washer. Mag shank lug nuts look very different from conical nuts. They feature this straight shank instead of a tapered design. You insert the shank directly into the wheel’s lug hole.

This design serves two purposes:

- The shank centers the wheel precisely on the hub.

- The flat washer presses against the wheel’s flat mounting surface to create the clamping force.

You often find this style on factory wheels, especially those with a chrome-plated finish. The washer is a critical part of the assembly. You must always use it with a mag seat nut.

Expert Tip: ⚙️

Never use a mag seat nut without its washer. The washer is what applies the pressure to hold the wheel on. Without it, the nut cannot properly torque down, and the wheel will be dangerously loose.

How to Check Your Wheel’s Seat Type

You must correctly identify your wheel’s seat type before buying new hardware. A visual inspection is the most reliable method. Here are four simple ways you can check:

Examine Your Old Lug Nuts. The easiest way is to look at the nuts you are replacing. If they came with the wheels, their shape will tell you what you need. A cone shape means conical, a rounded dome means ball, and a flat washer with a shank means mag.

Inspect the Wheel’s Lug Hole. Take one lug nut off and look inside the hole on the wheel.

- A tapered, 60-degree angle cut into the hole requires a conical seat.

- A curved or rounded edge inside the hole requires a ball seat.

- A flat surface around a straight, non-tapered hole requires a mag seat.

Perform a Simple Fit Test. You can use a new or existing conical nut to test an unknown wheel. Place the conical nut into the lug hole. If it sits perfectly flush and makes full contact with the sides, you have a conical seat wheel. If it rocks back and forth or only touches on a thin edge, you likely have a ball seat wheel.

Consult the Manufacturer. If you are unsure, check the source. For factory wheels, your vehicle’s owner’s manual may list the specification. For aftermarket wheels, visit the wheel manufacturer’s website. They will list the correct seat type for that specific wheel model.

Step 2: Understanding Different Sizes of Lug Nuts

After you confirm the seat type, your next task is to find the correct size for your wheels lug nuts. Getting the size wrong means the nuts will not thread onto your wheel studs at all. This step ensures a perfect fitment. The size of a lug nut has two critical parts: its thread diameter and its thread pitch. You must match both for proper compatibility.

Decoding Thread Diameter and Pitch

Think of a lug nut and wheel stud like a regular nut and bolt. They must have the same thread to screw together. The two measurements that define this are diameter and pitch.

- Thread Diameter: This is the outside width of the wheel stud. For metric nuts, you measure this in millimeters (e.g., 12mm or 14mm). For SAE nuts, you measure it in inches (e.g., 1/2 inch or 9/16 inch).

- Thread Pitch: This measures how close the threads are to each other. The way you measure thread pitch is different for metric and SAE nuts.

This table shows how the measurement method for pitch changes:

| Lug Nut Type | Measurement Method |

|---|---|

| Metric | Distance in millimeters between each thread |

| SAE | The number of threads per inch (TPI) |

Let’s look at an example. A common lug nut size is M12x1.5.

- M12 means the thread diameter is 12 millimeters.

- 1.5 means the distance from one thread to the next is 1.5 millimeters.

How to Find Your Car’s Thread Size

You must find the exact lug nut thread and size for your specific vehicle. Guessing is not an option, as an incorrect size will not work. Here are four simple methods to find the correct specification:

- Check Your Owner’s Manual. Your vehicle’s owner’s manual is the most reliable source. Look in the index for “wheels,” “tires,” or “specifications.” The manual often lists the required lug nut size.

- Search Online. A quick internet search can provide the answer. Use your vehicle’s year, make, and model. For example, search for

"2021 Honda Civic lug nut thread size". Reputable auto parts websites are a great resource. - Examine an Existing Lug Nut. Many manufacturers stamp the size directly onto the lug nut itself. Remove one from your wheel and inspect it closely for markings like “M12x1.5” or “1/2-20”.

- Visit an Auto Parts Store. A professional at an auto parts store can help you. They have tools called thread pitch gauges to measure your existing hardware and confirm the exact size you need.

Pro Tip: ⚠️

Never try to force a lug nut that feels tight. Forcing the wrong thread will damage the stud and the nut, leading to expensive repairs and an unsafe wheel connection. Always confirm compatibility before you start tightening.

Common Metric Thread Sizes

Most cars and SUVs on the road today use metric thread sizes. While many variations exist, a few sizes are extremely common across different manufacturers. Knowing these common thread pitches can help you narrow down your search.

Here are some of the most frequent metric sizes and the brands that often use them:

- M12x1.25: You will find this size on many Nissan, Subaru, and Infiniti vehicles.

- M12x1.5: This is one of the most popular sizes. It is standard on most Honda, Acura, Toyota, Lexus, and many other Japanese and Korean cars.

- M14x1.5: This larger, stronger thread is common on modern vehicles, especially larger cars, trucks, and SUVs. You will see it on most late-model GM, Ford, and many European vehicles like BMW and Volkswagen.

- M14x2.0: This is a less common size but is used on some older, heavy-duty trucks.

Always verify the exact size for your vehicle, as manufacturers can use different sizes even within the same model year.

Common SAE Thread Sizes

While most modern cars use metric hardware, you will find SAE (Society of Automotive Engineers) sizes on many classic American cars, older trucks, and some heavy-duty vehicles. SAE nuts use inches for their measurements. The thread pitch is measured by counting the number of threads per inch (TPI).

A few SAE sizes are very common on domestic vehicles. You should know these when working on older models.

- 1/2″-20: This is arguably the most common SAE size. You will find it on countless older Ford, Dodge, and GM cars and light trucks. The “1/2″” refers to a half-inch diameter, and the “20” means there are 20 threads per inch.

- 7/16″-20: This slightly smaller thread is also popular. You can find it on many older GM and Ford passenger cars.

- 9/16″-18: You will see this larger, coarser thread on heavy-duty trucks and some modern Dodge trucks. The “18” indicates a lower thread count, or a coarser pitch, for added strength.

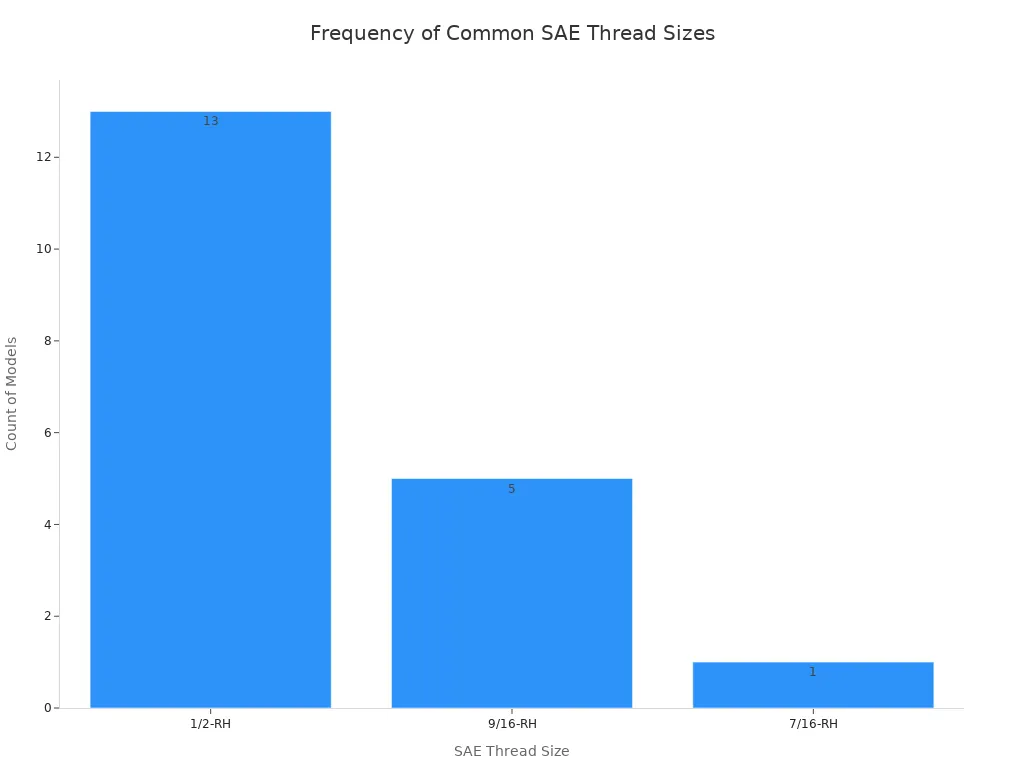

The table below shows some examples of popular American trucks and the SAE lug nut thread they use.

| Make | Model | Year | SAE Thread Size |

|---|---|---|---|

| Dodge | 1/2 & 3/4 Ton Trucks | ’79-’93 | 1/2″-RH |

| Dodge | Dakota & Durango | ’91-’04 | 1/2″-RH |

| Dodge | Ram 1/2 Ton Trucks | ’94-’01 | 1/2″-RH |

| Dodge | Ram 1/2 Ton Trucks | ’02 & Newer | 9/16″-RH |

| Dodge | Ram 3/4 Ton Trucks | ’94 & Newer | 9/16″-RH |

| Ford | 1/2 Ton F-100, F-150 | ’54-’96 | 1/2″-RH |

| Chevy | Suburban (2WD) | ’71-’91 | 1/2″-RH |

| Chevy | Suburban (4X4) | ’71-’91 | 7/16″-RH |

As you can see from the data, the 1/2″-RH size is extremely common, especially on trucks made before the early 2000s. The chart below visualizes how frequently each size appears in this sample of vehicles.

Always Double-Check! 🧐

Vehicle manufacturers sometimes change specifications mid-generation. Always confirm the exact lug nut size for your specific year and model before making a purchase. An incorrect thread will not fit.

Step 3: Select the Proper Lug Nut Length

Once you know the seat type and size, you must choose the correct lug nut length. The length is not just for looks; it is essential for safe thread engagement. Proper engagement ensures the nut can handle the forces of driving without failing.

The Rule for Safe Thread Engagement

Safe thread engagement is the most important factor for a secure wheel connection. You must have enough of the lug nut’s thread gripping the wheel stud. A simple rule ensures a safe connection.

The Golden Rule of Engagement: 📏

The length of thread engagement must be equal to or greater than the diameter of the wheel stud. For example, if your car has M12x1.5 studs, you need at least 12 millimeters of thread engagement.

Insufficient engagement creates a weak point. The threads can strip under pressure, causing the nut to loosen and the wheel to become unstable. Always confirm you have enough engagement for a safe fitment.

Open-End vs. Closed-End Lug Nuts

You can choose between two main styles based on your needs: open-end and closed-end.

Closed-end lug nuts have a capped end. This design protects your wheel studs from dirt, water, and road salt. This protection is very helpful in areas with harsh weather, as it prevents rust and corrosion from damaging the thread.

Open-end lug nuts are necessary in specific situations. You should choose this style if:

- You use extended wheel studs for racing or with dually wheels.

- You need to visually inspect thread engagement, a common requirement for racing safety checks.

- You want to simplify compatibility, as you do not need to worry about the stud being too long.

Special Considerations for Wheel Spacers

Wheel spacers push your wheels outward, which changes your hardware needs. Using spacers means your original studs may no longer be long enough for safe engagement. The type of spacer determines what you need.

| Spacer Type | Effect on Stud Length | Effect on Lug Nuts |

|---|---|---|

| Slip-on Spacers | You must install longer wheel studs. | Your original lug nut may work if it allows enough engagement. |

| Bolt-on Spacers | Hub studs do not need to be longer. | They come with a set of nuts to attach the spacer to the hub. |

Adding spacers requires you to re-evaluate your entire wheel hardware setup. You must ensure the final combination of spacer, stud, and lug nut provides adequate engagement and overall compatibility.

Step 4: Choose the Right Style for Your Wheels Lug Nuts

After confirming the fitment, you can choose a style of wheel hardware that suits your needs. The style affects both the look of your wheels and the tools you need for installation. You can select from several common types of wheels lug nuts.

Spline Drive (Tuner) Lug Nuts

Spline drive nuts, also called tuner nuts, are a popular choice for aftermarket wheels. These wheels often have small-diameter lug holes where a standard socket will not fit. This style of wheel hardware solves that problem.

A spline drive lug nut requires a special key for installation and removal. Many people choose them because a normal impact socket is too large for the lug holes on their new wheels.

Spline drive aftermarket wheel lug nuts offer several key advantages:

- Narrower Profile: Their slim design is perfect for custom wheels with very little space around the lug holes.

- Enhanced Security: The unique key pattern acts as a theft deterrent because a standard wrench cannot remove them.

- Snug, Secure Fit: The small diameter helps create a secure fit, which is important for performance driving.

Standard Hex Lug Nuts

Standard hex lug nuts are the most common type of wheel hardware. They have a classic hexagonal shape that you can install or remove with a standard lug wrench or socket. You will find this style on most factory vehicles.

These nuts come in several common sizes. Knowing the correct socket size for your lug nut is important for your toolkit.

- Common Metric Sizes: 17mm, 19mm, and 21mm.

- Common SAE Sizes: 11/16″, 3/4″, and 13/16″.

- Larger Vehicles: Trucks and large SUVs may use a 7/8″ hex size.

Always use the correct size socket to avoid rounding off the corners of the nut.

Wheel Locks for Added Security

Wheel locks are a special type of lug nut designed to prevent wheel theft. One lock replaces one standard lug nut on each wheel. They feature a unique, computer-generated pattern on the head. You can only remove them with a special matching key. This makes it very difficult for thieves to steal your wheels. If you have expensive custom or factory wheels, investing in a set of wheel locks provides excellent security and peace of mind.

A Final 3-Point Checklist Before You Buy

You are almost ready to purchase your new wheels lug nuts. Before you complete your order, run through this final checklist. This quick review ensures you get the perfect fitment the first time.

Confirm Your Seat Type

First, you must double-check the seat type. The shape of the lug nut must match the shape of the wheel’s lug hole. A mismatch here is a serious safety risk.

Safety Check! ⚠️

Using a conical nut on a ball seat wheel (or vice versa) creates a tiny contact point. This prevents the nut from torquing correctly and can cause it to loosen while you drive. Always confirm your wheel needs a conical, ball, or mag seat.

Verify Your Thread Size

Next, you need to verify the thread size. An incorrect size simply will not work. You must match both the diameter and the pitch. For example, an M12x1.5 nut will not fit on an M12x1.25 stud. Check your owner’s manual or an existing nut to find the correct specification. This step is essential for hardware compatibility.

Check for Sufficient Length

Finally, confirm the lug nut provides enough length for safe thread engagement. The nut must grip enough of the stud to create a strong, secure connection. Remember the golden rule: the length of thread engagement must be equal to or greater than the stud’s diameter. Insufficient thread engagement can cause the threads to strip under load, leading to wheel failure. This final check guarantees your wheels are mounted with maximum safety and proper compatibility.

Proper Installation for Maximum Safety

Choosing the right wheel hardware is only half the battle. Proper installation ensures your wheels are secure and your engagement with the road is safe. Following the correct steps for tightening your lug nuts is a non-negotiable part of vehicle safety.

Finding Your Torque Specification

You must tighten your lug nuts to a specific tightness, or torque. You can find the correct torque specifications for your vehicle in your owner’s manual. Applying the right amount of torque is critical. Too much or too little can cause serious problems.

- Over-torquing can stretch the bolts, strip the threads, and even damage your brake rotors.

- Under-torquing allows the nuts to loosen from road vibrations, which can cause steering wheel vibrations or, in the worst case, total wheel loss.

Using the recommended torque specifications ensures proper torque applications and a secure connection.

Using the Star Tightening Pattern

You should always tighten your lug nuts in a specific order to ensure the wheel sits flat against the hub. This method is called the star or crisscross pattern.

The star (or crisscross) pattern for tightening lug nuts is critical because it ensures even pressure distribution and prevents misalignment on the wheel hub.

To do this, you will lightly tighten one nut, then the one directly across from it. Continue this pattern until all nuts are snug. This process guarantees even clamping force and full engagement of the wheel hardware. After snugging them down, you will repeat the pattern to apply the final torque for lug nuts with a torque wrench. This installation method is essential for safety.

Why You Must Re-Torque Your Wheels

Your work is not finished after the initial installation. You must re-torque your lug nuts after driving a short distance. Experts recommend you re-torque your wheels after driving between 25 and 100 miles. This step is vital for long-term safety.

Several factors can cause your wheel hardware to loosen after the first drive:

- Thermal Cycles: Heat from braking causes the metal to expand and contract, which can reduce the initial torque.

- Joint Settling: The new hardware settles into place, creating tiny gaps that reduce clamping force and engagement.

- Contaminants: Tiny bits of dirt or rust can create a “false torque,” which disappears as you drive.

A quick re-torque ensures full engagement and corrects any loosening. You must re-torque the nuts to prevent them from becoming dangerously loose. A final re-torque is your best defense against wheel failure.

You can choose the right wheels lug nuts with confidence. The process is a straightforward check of seat type, thread size, and length. Following these steps ensures a safe wheel fitment and gives you peace of mind. Your wheel hardware is critical for safety.

A Note from the Experts ⚙️

As a leading manufacturer since 1996, Fortune Auto Parts knows that using high-quality lug nuts is non-negotiable. A safe installation requires the correct torque and high-quality lug nuts for a perfect fitment. Always double-check each lug nut specification before purchase and re-check the torque after installation to guarantee a secure fitment.

FAQ

🤔 Can I reuse my old lug nuts?

You should avoid reusing old lug nuts. They can have stretched threads, rust, or rounded corners from previous use. For maximum safety and a secure fit, you should always install new, correctly specified lug nuts with your wheels.

💡 What is the difference between lug nuts and lug bolts?

Lug nuts fasten onto wheel studs that are permanently part of your vehicle’s hub. In contrast, lug bolts are long screws that pass through the wheel and thread directly into the hub. Many European cars use lug bolts instead of nuts.

🔧 Do I really need a torque wrench?

Yes, a torque wrench is essential for safety. It ensures you tighten each lug nut to the manufacturer’s exact specification. This prevents damage from over-tightening and stops the wheel from loosening while you drive. Always use one for proper installation.

⚙️ Why do some wheels need spline drive nuts?

Many aftermarket wheels have small-diameter lug holes. A standard hex socket is too large to fit inside. Spline drive nuts are narrower and use a special key, making them the perfect solution for installing these types of custom wheels securely.