admin1

November 7, 2025

The Ultimate 2025 Guide to Car Wheel Bolts

Your safety on the road depends on secure wheels. Using the wrong hardware can have serious consequences. A recent report from the Scandinavian Tire and Rim Organization (STRO) highlights this risk:

- Approximately 900 accidents happen each year from wheels detaching.

- Around 30,000 wheels come loose annually.

You can avoid this danger. You must select the correct car wheel bolts for a secure wheel. Match five key specifications: thread size, seat type, shank length, head type, and material. An incorrect lug bolt or a loose lug nut puts you at risk. A bad lug fit can damage your wheel. The wrong lug nut can cause a loose lug. Every lug and nut must be correct. Your safety depends on each lug and nut.

Find Your Thread Size and Pitch

Think of a wheel bolt as a screw. It must fit perfectly into the threaded holes in your car’s wheel hub. The first step to a secure fit is matching the thread size. This measurement ensures the lug bolt can screw in smoothly and hold tight. Getting this wrong means the bolt will not install correctly. An incorrect lug can lead to serious safety issues.

What is Thread Size?

Thread size is a two-part measurement. It tells you the bolt’s diameter and its thread pitch. You will see it written in a standard format, like M14 x 1.5.

- M14: The “M” stands for Metric. The number “14” is the bolt’s diameter in millimeters.

- 1.5: This number is the pitch. It is the distance in millimeters from the peak of one thread to the peak of the next.

A smaller pitch number means the threads are closer together. A larger number means they are farther apart. You must match both the diameter and the pitch. A lug with the wrong pitch will not screw in properly, even if the diameter is correct. This can damage the threads on the lug and your hub.

Tech Tip: Understanding Thread Terms To be precise, manufacturers use specific terms for these measurements. Knowing them helps you understand product descriptions.

- Major Diameter: This is the bolt’s widest point, measured from the top of the threads. For an M14 bolt, this is 14 mm.

- Minor Diameter: This is the bolt’s narrowest point, measured at the bottom or root of the threads.

- Pitch: This is the exact distance between corresponding points on two adjacent threads.

How to Find Your Vehicle’s Specifications

You have several reliable ways to find the correct thread size for your car wheel bolts. You should never guess this specification. Each method helps you confirm the right size for a safe fit.

1. Check Your Owner’s Manual Your vehicle’s owner’s manual is the most trustworthy source. Car manufacturers list the factory specifications inside. Look in the index for sections on “wheels,” “tires,” or “specifications.” The manual will state the required size for the factory lug bolt or nut.

2. Inspect an Existing Lug Bolt Many manufacturers stamp the size directly onto the head of the lug bolt. Carefully remove one lug from your wheel. Clean the head and look for markings like “M12x1.5” or “14×1.25”. This is a quick way to confirm the size, but always double-check if the bolt is old or worn.

3. Use Online Databases The internet offers powerful tools for finding vehicle data. Several websites maintain large databases of wheel and tire information. These resources are excellent for finding your car’s original equipment (OEM) specs.

- Wheel-Size.com: This site has a massive global database. You can enter your car’s make, model, and year to find detailed fitment data, including thread size for the correct lug and nut.

- Offset.com: This tool helps you find OEM wheel specifications. You select your vehicle’s trim level to get accurate data, including the bolt pattern and thread size.

- WheelSetGo: This site offers a “Bolt Pattern Guide” through its partner company. You can look up your vehicle to find the exact details you need for your lug and nut combination.

4. Consult a Professional When in doubt, ask an expert. A reputable auto parts supplier or a trusted mechanic can identify the correct specifications for you. They have the tools and experience to guarantee you get the right part for the job.

Identify the Correct Seat Type for Your Wheels

After confirming your thread size, you must identify the correct seat type. The seat is the contact point. It is where the lug bolt or nut touches the wheel. This contact area must match the lug hole on your wheel perfectly. This perfect match creates the clamping force that holds your wheel securely to the car.

Why Seat Type is a Critical Safety Factor

The seat type ensures your wheel is centered and locked in place. A mismatch between the lug seat and the wheel seat is extremely dangerous. It prevents the lug from making full contact with the wheel surface. Instead of a flush fit, the two parts meet only on a thin edge.

This “edge contact” creates a major problem. It concentrates all the clamping force onto a tiny area. This high stress can cause the metal to crack. It also makes it impossible for the lug to achieve proper engagement. You might tighten the nut to the correct torque specification, but the connection is not secure. This situation is known as “false torque.” Your torque wrench clicks, but the wheel is not truly tight.

The consequences of this failure are severe.

- Studies show that 45% to 50% of wheel separations are caused by a loose lug or nut.

- In the United States, an estimated 40 to 60 wheel detachments happen every week.

- These events lead to about 20 reported accidents weekly.

Using the wrong seat type is a primary cause of loose hardware. You must ensure the shape of your bolt’s seat is an exact match for the recess in your wheel.

The 3 Main Seat Types: Conical, Ball, and Flat

You will encounter three primary seat types on passenger vehicles. Each has a distinct shape designed to fit a specific type of wheel. You cannot interchange them.

Safety First! ⚠️ Never use a bolt if you are unsure of its seat type. A visual inspection is your best tool. Compare a new bolt to an old one from the same wheel to confirm a match.

1. Conical Seat (or Acorn Seat) This is the most common seat type, especially for aftermarket wheels.

- Shape: It has a straight, cone-shaped surface.

- Angle: Most conical seats have a 60-degree taper. Some specialty race wheels, like those for NASCAR, use a 45-degree taper, but 60-degree is the standard for most cars you see on the road.

- How it Works: The cone shape helps center the wheel on the hub as you tighten the lug.

2. Ball Seat (or Radius Seat) This seat type is common on many European vehicles, including those from Volkswagen, Audi, and Mercedes-Benz.

- Shape: It has a rounded, spherical, or ball-shaped surface.

- How it Works: The curved seat fits into a matching curved recess in the wheel. It looks similar to a conical nut once installed, but the seating surface is distinctly round. You must not use a conical bolt on a wheel designed for a ball seat.

3. Flat Seat (or Mag Seat) This type looks very different from the other two.

- Shape: It has a flat base.

- How it Works: A flat seat relies on a flat washer to make contact with the wheel. The bolt also typically has a longer, smooth shank that slides into the lug hole to help center the wheel. The clamping force comes from the washer pressing against the flat surface of the wheel.

To make it simple, here is a quick comparison:

| Seat Type | Shape | Key Feature |

|---|---|---|

| Conical | Cone-shaped | 60-degree angled surface |

| Ball | Rounded / Spherical | Curved seating surface |

| Flat | Flat with a washer | Flat base with a separate washer |

Choosing the correct seat is just as important as finding the right thread size. Always inspect your wheels and your existing hardware to determine which of these three types you need for your specific car wheel bolts.

Calculate Shank Length and Select Head Type

You have the thread size and seat type. Now you must determine the correct shank length and head type. These details ensure your car wheel bolts can be installed correctly and securely.

Measuring for Proper Shank Length

The shank is the threaded part of the lug bolt. Its length is critical. A shank that is too short will not engage enough threads in the hub. A shank that is too long can cause serious damage. If the lug bolt is too long, it can bottom out inside the hub assembly. This prevents the lug from properly securing the wheel, creating a false torque reading and potentially stripping the hub’s threads.

Safety Check: The Rule of 6 to 8 Turns A good rule of thumb is to ensure your lug bolt achieves at least 6 to 8 full rotations when you thread it in by hand. For example, a bolt with a 1.5mm pitch needs about 8 turns to achieve 12mm of thread engagement, which is a safe depth. Fewer turns mean the lug is not secure.

Choosing Between Hex and Tuner Style Heads

The head is the part of the lug your tool grabs. You will choose between two main styles: standard hex and tuner.

- Hex Head: This is the most common type. It uses a standard hexagonal socket. The most common sizes for the nut are 17mm, 19mm, and 21mm.

- Tuner Head: This style has a smaller diameter and requires a special key or adapter. You often need this type for aftermarket wheels with small lug bores where a standard socket and nut will not fit.

Each head type has trade-offs between security and convenience. A special key makes the lug harder to remove, offering some theft protection.

| Feature | Hex Head | Tuner (Spline) Style |

|---|---|---|

| Tool Access | Uses a standard socket | Requires a special key |

| Security | Less secure; common tools fit | More secure; key is needed |

| Best For | Most factory wheels | Aftermarket wheels with small lug holes |

Always choose the head type that fits your wheel and your tools. The right lug and nut combination is essential for safety.

Final Checks: Material, Grade, and How to Torque My Wheel Lug Nuts

You are almost ready for a safe installation. Your final checks involve the bolt’s material, its strength grade, and the correct installation procedure. These details ensure your car wheel bolts provide maximum safety. A proper installation is critical.

Understanding Bolt Materials and Strength Grades

The material of your lug bolt determines its strength and resistance to rust. Most lug bolts are steel, but high-performance options like titanium exist. Titanium offers excellent corrosion resistance, making it ideal for wet or salty climates.

| Material | Tensile Strength | Corrosion Resistance |

|---|---|---|

| Steel | High strength | Can rust without a coating |

| Titanium | Very high strength | Naturally rust-proof |

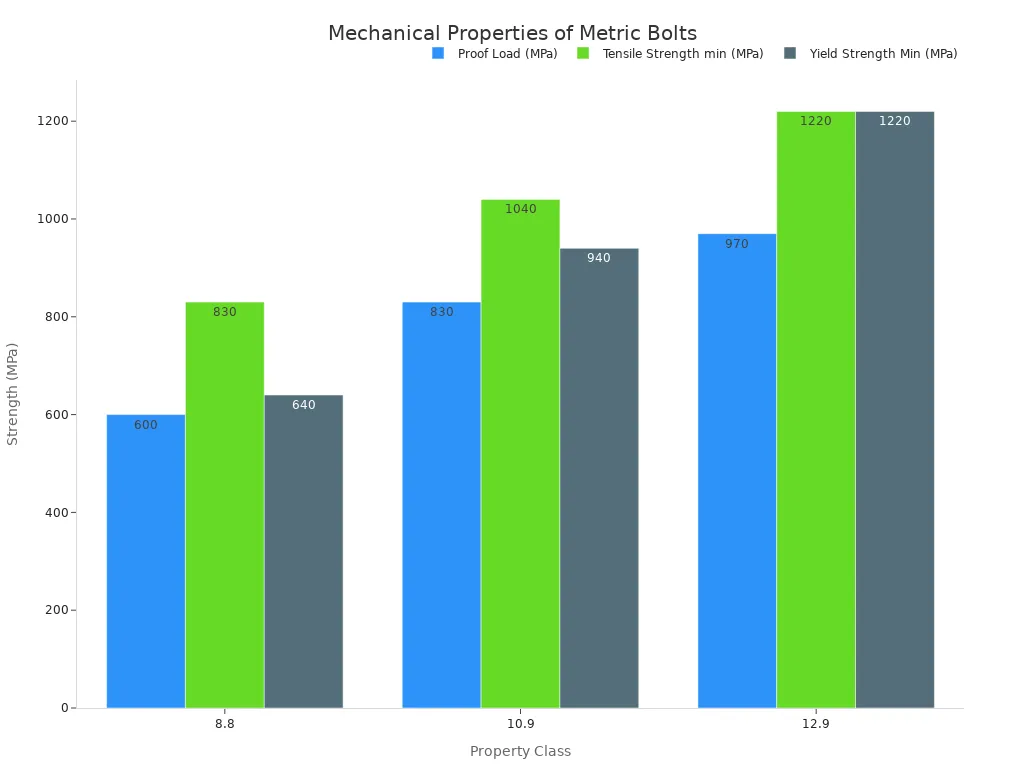

You can identify a bolt’s strength by the number stamped on its head. This is its property class, like 8.8, 10.9, or 12.9. A higher number means a stronger lug. For example, a Class 10.9 lug has a minimum tensile strength of 1040 MPa.

The Difference Between Car Wheel Bolts and Lug Nuts

You might hear people use the terms lug bolts and lug nuts interchangeably, but they are different.

- Lug Bolts: This is a single piece with a head and threads. The lug screws directly into the wheel hub. European cars from BMW, Audi, and Volkswagen often use this system.

- Lug Nuts: This system uses two pieces. A stud is permanently fixed to the hub, and a separate nut tightens onto these wheel studs. American and Japanese cars commonly use a nut and stud. The nut secures the wheel to the wheel studs.

Your vehicle uses one system or the other. You cannot mix them. Using the correct hardware is essential for a secure installation. The nut must match the wheel studs.

Proper Torque for Wheel Lug Nuts

How do I torque my wheel lug nuts? You must tighten each lug to a specific value using a torque wrench. This value is called the torque specification. Using the wrong torque is dangerous.

Warning ⚠️

- Under-tightening a lug allows the wheel to vibrate and loosen, which can cause the wheel to fall off.

- Over-tightening a lug can stretch and weaken the wheel studs or lug bolt, causing the stud to break.

Always check your owner’s manual for your vehicle’s specific wheel torque specs. The correct torque ensures the nut or lug applies the right amount of clamping force. A safe installation depends on the correct torque. The installation process requires precision. For a safe installation, you must properly torque each nut. This installation step is vital. A good installation uses a star pattern to tighten each lug nut. This ensures the wheel sits flat against the hub. This installation method prevents warping. A successful installation keeps you safe.

| Wheel Bolt/Stud Size | Recommended Torque (lb-ft) |

|---|---|

| M12x1.5 | 100 lb-ft |

| M14x1.5 | 140 lb-ft |

You must always check the five key factors for every single lug. Your new wheel may need different lug nuts than the original lug nuts. Never risk your safety with an unknown lug or nut. For guaranteed quality, you should source components from a certified manufacturer.

A trusted supplier like Ningbo Fortune follows strict automotive standards, such as ISO 9001. This focus on defect prevention ensures every lug bolt and nut is made to the highest quality. Your safety depends on the right lug and nut.

FAQ

Can I reuse my old wheel bolts?

You should inspect each lug bolt for rust, thread damage, or stretching. A damaged lug is unsafe. If you see any signs of wear, you must replace the bolts. Never reuse a compromised lug. Your safety depends on strong hardware.

What happens if I use an impact wrench?

An impact wrench can easily over-tighten a lug nut. This action can stretch the bolt or stud, causing it to fail. Always use a torque wrench for the final tightening. This ensures each nut has the correct clamping force.

Do I need different bolts for winter wheels?

Yes, you often need a different lug for winter wheels. Steel winter wheels are usually thinner than alloy wheels. They may also have a different seat type. You must match the lug and nut to the specific wheel for a secure fit.

How often should I check my lug nut torque?

You should re-check the torque on each lug nut after driving about 50 miles on new or reinstalled wheels. This simple check ensures every nut remains secure as the wheel settles. Regular checks prevent loosening.