admin1

November 8, 2025

How to Pick the Perfect Lug Nuts for Trucks in 2025

Proper fitment is a critical safety issue when selecting lug nuts for trucks. Your choice depends on three key areas of compatibility. An incorrect match can loosen your wheels or damage your lug nuts. This challenge is common when you choose lug nuts for aftermarket wheels. Correctly identifying these specifications is the only way to guarantee safety and performance.

Your Safety Checklist: To ensure perfect fitment and total compatibility, you must match these three specifications for your specific wheels and lug nuts:

- Seat Type

- Thread Size

- Length

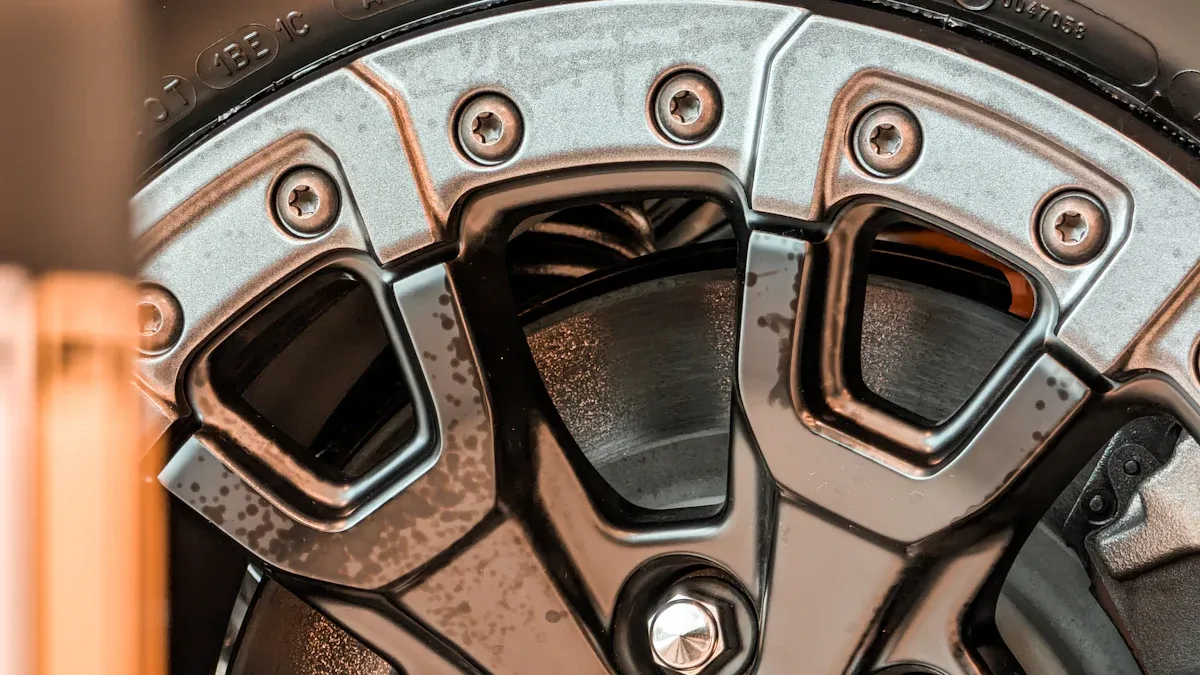

Step 1: Match the Seat Type for a Secure Fit

Your first step is matching the lug nut seat to your wheel. This is the most important factor for a safe connection. An incorrect seat type will prevent the lug nuts from seating properly, leading to a dangerously loose wheel.

What is a Lug Nut Seat Type?

The lug nut seat is the contact point where the lug nut touches the wheel. This small area performs a huge job. It safely transfers the vehicle’s load and creates the clamping force that holds your wheel securely to the hub. The shape of the seat also helps center the wheel perfectly on the axle. This precise alignment is critical for a secure fitment and prevents the hardware from loosening while you drive.

The 3 Common Seat Types for Truck Wheel Lug Nuts

Most truck wheels use one of three seat designs. You must identify which one your wheels have to ensure proper compatibility. Each type has a distinct shape.

| Seat Type | Visual Description |

|---|---|

| Conical (Acorn) | Has a cone-shaped, 60-degree tapered end. |

| Ball (Radius) | Features a rounded, spherical end like a ball. |

| Shank (Mag) | Uses a flat washer with a cylindrical shank. |

These are the primary designs you will encounter for wheel lug nuts. Choosing the correct one is essential for safety.

How to Identify Your Wheel’s Seat Type

You must inspect the lug holes on your wheel to find the correct seat type. The wheel determines the seat you need. Factory (OE) wheels and aftermarket wheels often require different seats. For example, many factory Honda wheels use a ball seat, while most aftermarket wheels use a conical seat.

Safety Tip: Never assume different seat types are interchangeable. Using conical lug nuts on a wheel designed for ball seats creates an unsafe connection. Always confirm the seat design of your specific wheels to guarantee perfect compatibility and fitment for your lug nuts for trucks.

Step 2: Determine the Correct Thread Size for Your Lug Nuts

After confirming the seat type, your next task is to find the correct thread size. The thread size of your lug nuts must perfectly match the wheel studs on your truck’s hub. This ensures the nuts can be threaded on smoothly and tightened securely. Using the wrong thread size will damage both the studs and the nuts, making a safe fitment impossible.

Understanding Thread Diameter and Pitch

A thread size specification has two parts: diameter and pitch. The diameter is the thickness of the wheel stud. The pitch measures the distance between the threads. You must match both for correct compatibility.

How you measure thread pitch depends on the standard used:

- US Standard (Imperial): Pitch is measured in Threads Per Inch (TPI). A

1/2-20size means the stud is 1/2 inch in diameter with 20 threads per inch. - Metric: Pitch is the distance in millimeters between each thread. A

14mm x 1.5size means the stud is 14mm in diameter with 1.5mm between threads.

Safety Note: ⚠️ An incorrect pitch will cause the lug nuts to bind or strip during installation. This prevents them from achieving the necessary clamping force, which compromises the safety and compatibility of your wheel setup.

Common Thread Sizes for Trucks

Trucks use a variety of thread sizes depending on the manufacturer, model, and year. Heavy-duty trucks often use larger, stronger studs. Here are some common thread sizes you might find on popular truck models.

| Make/Model Example | Common Thread Size |

|---|---|

| Chevrolet/GMC 1/2 Ton (99-on) | 14mm x 1.5 |

| Chevrolet/GMC 3/4 & 1 Ton (04-on) | 14mm x 1.5 |

| Nissan Murano (03-on) | 12mm x 1.25 |

| Plymouth Trail Duster (79-82) | 1/2-RH |

Always verify the exact size for your specific truck. This chart shows examples, but your vehicle’s requirements are unique. Proper fitment depends on this detail.

Where to Find Your Truck’s Thread Size

Finding your truck’s thread size is straightforward. You have a few reliable options to ensure perfect compatibility for your new lug nuts for trucks.

- Check Your Owner’s Manual: Your vehicle’s owner’s manual is the most accurate source. Manufacturers list the factory wheel stud specifications in the manual, giving you the exact thread size you need.

- Measure an Existing Lug Nut: If you cannot find your manual, you can take one of your current lug nuts to an auto parts store. They have tools to measure the thread size for you.

Step 3: Ensure Proper Length and Thread Engagement

Once you have the right seat and thread size, you must confirm your lug nuts are long enough. Proper length ensures sufficient thread engagement, which is the amount of contact between the nut’s threads and the wheel stud’s threads. This contact creates the force that holds your wheel on securely.

The Rule for Safe Thread Engagement

The industry has a simple rule for safe thread engagement. The length of the threads engaged inside the nut must be at least equal to the diameter of the wheel stud. For example, a 1/2-inch stud needs at least 1/2 inch of thread engagement. Anything less is unsafe and can cause the nut to loosen or strip.

A practical way to check this is by counting the number of full turns you get when tightening a nut by hand. The table below shows the recommended number of turns for common truck thread sizes to achieve safe thread engagement.

| Stud Size | Recommended Turns |

|---|---|

| 1/2″-20 | 10 |

| 9/16″-18 | 10 |

| M12x1.5 | 8 |

| M14x1.5 | 9.5 |

Safety First: Always count the turns when installing new custom wheel lug nuts. This simple check confirms you have a secure connection.

Closed-End vs. Open-Ended Lug Nuts

You will choose between two main styles: closed-end and open-ended.

- Closed-End: These lug nuts have a capped end. This design protects your wheel studs from moisture, dirt, and road salt. It prevents rust and corrosion, which can be costly to repair. For daily driving, closed-end custom wheel lug nuts offer the best protection.

- Open-Ended: These nuts are open on both sides. They are mainly used for racing applications or with extra-long wheel studs that would stick out from a closed-end nut.

For most trucks, closed-end custom wheel lug nuts are the superior choice for durability and stud protection.

When to Use Extended Thread (ET) Custom Wheel Lug Nuts

Some aftermarket wheels have very thick mounting pads, which leaves less of the wheel stud exposed. This can prevent standard custom wheel lug nuts from achieving safe thread engagement. In this situation, you need Extended Thread (ET) custom wheel lug nuts.

ET custom wheel lug nuts feature an extended shank that reaches deeper into the wheel’s lug hole. This design allows the nut to grab more of the stud’s threads. Using standard custom wheel lug nuts when ET custom wheel lug nuts are required is dangerous. It results in poor thread engagement and can lead to wheel failure. Always check if your specific wheels require ET custom wheel lug nuts for a safe fit.

Step 4: Select the Right Material and Finish

You have identified the fitment, but your job is not done. The material and finish of your lug nuts determine their strength, safety, and lifespan. Choosing the right combination protects your investment and ensures long-term reliability.

Steel vs. Aluminum Lug Nuts for Trucks

When you look at the materials used for wheel lug nuts, steel and aluminum are the two primary options. For a truck, the choice is clear. Steel is significantly stronger than aluminum. This strength, known as tensile strength, is a material’s ability to resist being pulled apart under tension.

A quick comparison shows the massive difference:

| Material | Tensile Strength (psi) |

|---|---|

| Automotive-Grade Steel | 58,000 – 72,500 |

| Aluminum | ~13,000 |

Aluminum can also deform under heavy loads, which reduces the clamping force holding your wheel. This makes steel the only safe option for the high-stress demands of a truck.

Why Steel is the Standard for Strength and Safety

High-quality steel is the industry standard for lug nuts for trucks for a reason. It offers unmatched strength and durability. Manufacturers create top-tier steel wheel lug nuts through specific processes that guarantee safety.

Key Features of Premium Steel Lug Nuts:

- Made from high-quality forged carbon steel for maximum strength.

- Heat-treated and hardened for superior durability and wear resistance.

- Built to handle extremely high torque, often rated up to 500 ft-lbs.

- Designed to prevent stripping and swelling over time.

Experiments show that aluminum wheel lug nuts can fail under high torque. The material can deform, increasing friction without adding any real clamping force. This can lead to a loose wheel, making forged steel the only trustworthy choice for safety.

Choosing a Finish for Durability and Corrosion Resistance

The finish on your lug nuts is more than just for looks; it is a protective shield against rust and corrosion. There are several available finishes for wheel lug nuts, each offering different levels of protection.

- PVD (Physical Vapor Deposition): This is a modern, high-performance finish. PVD is harder than traditional chrome, resists chipping and peeling, and provides excellent protection against road salt.

- Chrome: A classic choice, but older chrome plating can sometimes chip, peel, or allow moisture to cause rust.

- Zinc and Black Oxide: These are common, cost-effective finishes. However, they offer minimal corrosion resistance on their own. In salty or humid environments, they may not prevent rust without an additional protective oil or wax coating.

For maximum durability, a premium finish like PVD is an excellent investment.

Step 5: Master the Proper Installation and Torque

You have the right parts. Now you must install them correctly. Proper installation and torque are the final, critical steps to ensure your wheels are secure. Using the right amount of force, or torque, prevents damage and keeps you safe on the road.

Why Correct Torque is Non-Negotiable

Torque is the rotational force you apply when tightening a fastener. Applying the correct torque ensures your wheel is held to the hub with the right amount of clamping force. Both too much and too little torque create dangerous situations.

The Dangers of Incorrect Torque ⚠️

- Over-torquing can stretch wheel studs past their limit, causing them to crack or break. It can also strip threads and warp your brake rotors, leading to a pulsating brake pedal.

- Under-torquing is just as hazardous. A loose nut can vibrate off, causing the other nuts to fatigue and fail. This can lead to a catastrophic wheel separation while driving.

Incorrect torque also damages other components. Overtightening an axle nut by just 25% can cause a wheel bearing to fail in as little as six months. This is because too much force alters the precise internal spacing of the bearing, leading to premature wear and failure.

How to Find Your Truck’s Torque Specification

Every truck has a specific torque value recommended by the manufacturer. You must use this exact value. You can find your truck’s correct torque specifications in two primary places:

- Your Owner’s Manual: This is the most reliable source for factory specifications.

- A Sticker on the Driver’s Door Jamb: Many vehicles list tire and wheel information here.

Torque values vary by model. For example, a half-ton truck might require 140 ft-lbs, while a heavy-duty model needs more.

| Model Example | Torque Spec |

|---|---|

| ’04-’12 Chevy Colorado | 103.5 ft-lb (140 Nm) |

Always confirm the exact number for your specific truck.

The 4-Step Safe Installation Process

Using a calibrated torque wrench is the only way to guarantee accuracy. Follow these steps for a safe installation.

- Hand-Tighten First: Thread all the lug nuts on by hand until they are snug. This prevents cross-threading.

- Lower the Vehicle: Lower the jack until the tire just touches the ground. This stops the wheel from spinning while you tighten.

- Tighten in a Star Pattern: Use your torque wrench to tighten the nuts in a star pattern. This applies pressure evenly across the wheel. For a 5-lug wheel, you tighten every other nut. For 6 or 8-lug wheels, you tighten in a crisscross sequence.

- Work in Stages: Do not apply full torque all at once. Tighten the nuts in three stages—for example, first to 50 ft-lbs, then to 100 ft-lbs, and finally to the full 140 ft-lbs. This ensures the wheel seats perfectly flat against the hub.

The Critical Importance of Re-Torquing

Your work is not finished after the initial installation. You must perform a final, critical safety check: re-torquing your lug nuts. This simple step ensures your wheels remain securely fastened after they have had a chance to settle. Many people skip this check, creating a serious safety risk. You should always re-torque your lug nuts after driving a short distance on a new set of wheels.

Driving puts immense force on your wheels. This causes small changes that can make your lug nuts loosen. The industry standard is to re-torque your lug nuts after the first 50 to 100 miles of driving. This process corrects any minor loosening that occurs as the parts settle together.

Why Do Lug Nuts Loosen? 🤔 Several factors can reduce the clamping force on your wheels after you start driving:

- Wheel Settling: New alloy wheels can compress slightly under the vehicle’s weight, creating a tiny gap.

- Surface Debris: Small amounts of rust or dirt on the hub surface can get crushed, which reduces the tightness.

- Bolt Stretching: Over-tightening a lug nut can stretch the wheel stud. A stretched stud loses its ability to hold the correct torque.

- Thermal Cycles: The heating and cooling of your wheels and hubs during driving can also cause parts to expand and contract.

To re-torque, wait for your wheels to cool down completely. Use your calibrated torque wrench set to the correct specification. Loosen each lug nut slightly, then tighten it back to the proper torque value. Always follow the star pattern. This quick re-check confirms your wheels are perfectly seated and secure for the long haul. It is a non-negotiable step for truck safety.

You can now confidently choose the right lug nuts for trucks. Your final safety check is simple. You must confirm the correct seat type, thread size, and length for your wheels. Always select high-quality lug nuts made from steel for maximum durability. For a safe installation, use a calibrated torque wrench and re-torque your high-quality lug nuts after driving 50-100 miles. This guarantees your wheels stay secure.

Your Final Safety Checklist ✅

- Correct Seat Type

- Correct Thread Size

- Proper Length

FAQ

Can I reuse my old lug nuts?

You should avoid reusing old lug nuts if they show signs of rust, rounding, or thread damage. Worn lug nuts can fail to hold torque correctly. For maximum safety, you should always install new, high-quality lug nuts when you get new wheels.

What are lug nut locks and do I need them?

Lug nut locks are special lug nuts that require a unique key for removal. They help protect your expensive wheels and tires from theft. You can use one lock per wheel in place of a standard lug nut for added security.

How do I choose a quality lug nut manufacturer?

You should select manufacturers with proven quality systems. Look for companies with ISO 9001 certification. These manufacturers, like Fortune Auto Parts, use premium materials and perform strict testing on every product. This guarantees strength, safety, and a perfect fit for your truck.

How often should I check my lug nut torque?

You must re-torque your lug nuts after the first 50-100 miles of driving. After that, you should check the torque periodically. A good practice is to check them every time you rotate your tires or perform other routine maintenance on your truck.