admin1

August 1, 2025

How Air Valve Stem Types Affect Your Vehicle’s Performance

When you think about keeping your car safe and running well, you might not notice the small air valve stem on each tire. This tiny part plays a big role in your vehicle safety and performance. If you pick the right air valve stem, you help stop air leaks and keep your tires at the best pressure. You drive with more confidence, knowing your tires will last longer and work better.

Air Valve Stem Basics and Their Role in Tire Performance

What Is an Air Valve Stem?

You might see a small tube sticking out from your wheel. That’s the air valve stem. It lets you add air to your tire and keeps the air sealed inside. The air valve stem has a few important parts: the stem itself, a valve core, a rubber grommet or O-ring, and a cap. Each part works together to keep your tire inflated and safe.

The valve core sits inside the stem. It opens when you press on it to let air in or out. When you stop pressing, it closes and seals the air inside. The cap adds another layer of protection. It keeps dirt and water out, and it can even help stop leaks if the core fails.

Tip: Always keep the cap on your air valve stem. It helps prevent dirt and moisture from getting inside, which can cause leaks.

How Tire Valve Stems Maintain Tire Pressure and Safety

Tire valve stems do more than just let you fill your tires. They help your tires hold the right amount of air, which keeps you safe on the road. If your tire valve stems get damaged or worn out, you might lose air without even noticing. This can make your tires wear out faster or even cause a blowout.

Here are some key ways tire valve stems keep your tires working well:

- They seal the air inside your tire, stopping slow leaks.

- The valve core controls airflow, letting you add or release air as needed.

- The cap keeps out dirt and water, which can damage the valve.

- Quality stems match your wheel and vehicle, making sure they fit right and work well.

- Shorter stems lower the risk of bending or breaking, especially at high speeds.

You should check your valve stems every time you get your tires rotated or replaced. Look for cracks, leaks, or signs of damage. If you spot any problems, replace the stem right away. Most experts say you should inspect them about once a month. Keeping your valve stems in good shape helps your tires last longer and keeps you safer on the road.

Note: Using quality tire valve stems and checking them often can prevent sudden air loss and keep your tires performing their best.

Types of Tire Valve Stems and Their Impact

Rubber Tire Valve Stems

You probably see rubber valve stems on most cars and light trucks. These stems are flexible and easy to install. They help absorb bumps and vibrations from the road, which protects your tire and rim. Rubber valve stems are also affordable, so you can replace them without spending much money. Many tire shops recommend changing them every time you get new tires.

Here’s a quick look at how rubber valve stems compare to metal ones:

| Aspect | Rubber Valve Stems | Metal Valve Stems |

|---|---|---|

| Flexibility | Flexible, absorbs impacts | Rigid |

| Cost | Low, cost-effective | Higher |

| Durability | Wears out faster, especially in heat or sunlight | Lasts longer, resists cracking |

| Installation | Easy, quick replacement | Needs special tools |

| Pressure Rating | Up to 65 PSI (standard), up to 80 PSI (high-pressure) | Up to 200 PSI (heavy-duty) |

Tip: Rubber valve stems work best for everyday driving, but they can dry out and crack over time, especially if your car sits in the sun a lot.

Metal and Brass Tire Valve Stems

If you drive a heavy-duty truck or a vehicle that faces tough conditions, you might need a metal or brass valve stem. These stems handle higher pressure and last longer than rubber. A brass valve stem resists corrosion and stands up to extreme weather. You can count on it to keep your tire pressure steady, even if you drive in rain, snow, or heat. A nickel valve stem also offers great resistance to rust and works well in harsh climates.

- Metal stems are strong and don’t crack easily.

- Brass valve stems keep working even when exposed to moisture.

- You won’t need to replace them as often as rubber stems.

Note: Metal stems cost more at first, but they save you money in the long run because you won’t have to replace them as often.

Snap-In vs. Clamp-In Tire Valve Stems

You can choose between snap-in and clamp-in tire valve stems. Snap-in stems, usually made of rubber, fit most passenger vehicles. You just pull them through the rim hole, and they seal in place. These stems are easy to replace and resist corrosion. Most snap-in stems handle up to 65 PSI, but some high-pressure versions go up to 80 PSI for heavier vehicles.

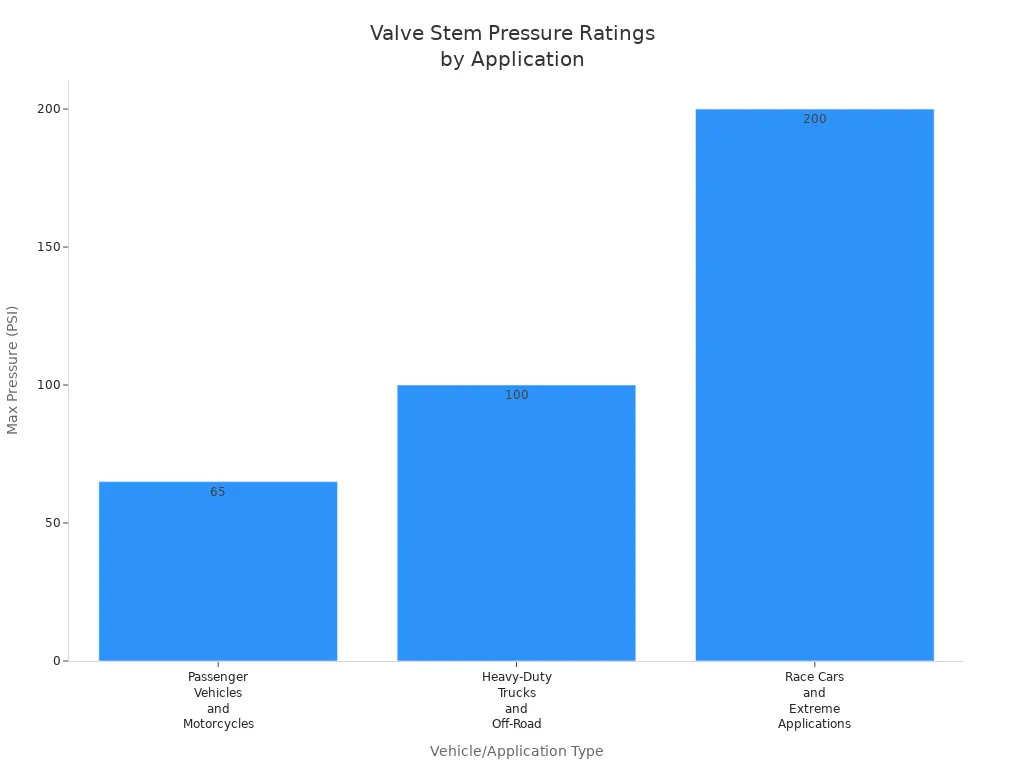

Clamp-in stems, often made of metal, use a nut to hold them tight against the wheel. These stems work best for high-speed or heavy-duty vehicles. They can handle up to 200 PSI and are common on race cars and big trucks. Clamp-in stems come in different shapes and sizes to fit special wheels.

Here’s a table showing which valve stems fit different vehicles:

| Vehicle Type | Common Valve Stem Type | Pressure Rating (PSI) | Rim Hole Diameter (inches) |

|---|---|---|---|

| Passenger Vehicles | Standard Rubber Valve Stems | Up to 65 | 0.453, 0.625 |

| Heavy-Duty Trucks | Metal Valve Stems | Up to 200 | Around 0.625 |

| Motorcycles | Rubber Valve Stems | Up to 65 | Around 0.327 |

| Tractors/Off-Road | High-Pressure Metal Valve Stems | 100 or more | Around 0.625 |

Remember: Snap-in stems are quick and easy for most cars, while clamp-in stems give you extra strength for tough jobs.

High-Pressure Tire Valve Stems

When you drive a heavy-duty truck, a race car, or even a big tractor, you need more than just a regular valve stem. High-pressure tire valve stems keep your tires safe when you run them at higher pressures. These stems work hard in tough jobs, like hauling heavy loads or racing at high speeds.

You’ll find two main types: high pressure tubeless snap-in valves and high pressure metal clamp-in valves. High pressure tubeless snap-in valves look a lot like the regular rubber ones you see on most cars, but they’re built stronger. They handle up to 80-100 PSI, which makes them perfect for bigger trucks and off-road vehicles. Their shorter length helps reduce stress on the valve, so you don’t have to worry about them bending or breaking.

High pressure metal clamp-in valves take things up a notch. These are the go-to choice for race cars, heavy-duty trucks, and vehicles that need to handle up to 200 PSI. They use a metal body and a nut to clamp tightly to the wheel. This design gives you extra strength and a better seal, even in extreme temperatures or rough conditions.

Here’s a quick table to help you see the differences:

| Vehicle Type / Application | Valve Stem Type | Typical Pressure Rating Supported | Notes on Usage and Design |

|---|---|---|---|

| Passenger Vehicles and Motorcycles | Tubeless Rubber Snap-In Valves | Up to 65 PSI | Most common, suitable for standard passenger vehicles and motorcycles. Diameter .453″ to .625″, length .88″ to 2.5″. |

| Heavy-Duty Trucks and Off-Road | High pressure tubeless snap-in valves | Up to 80-100 PSI | Designed for bigger trucks and heavy-duty tires. Shorter length (1.27″ to 2″) to reduce stress on valve. |

| Race Cars and Extreme Applications | High pressure metal clamp-in valves | Up to 200 PSI | For very high speeds and extreme tire pressures. Compact design, can be straight or cornered for performance. |

Tip: If you drive in extreme heat or cold, high pressure tubeless snap-in valves and high pressure metal clamp-in valves can handle wide temperature swings without losing their seal.

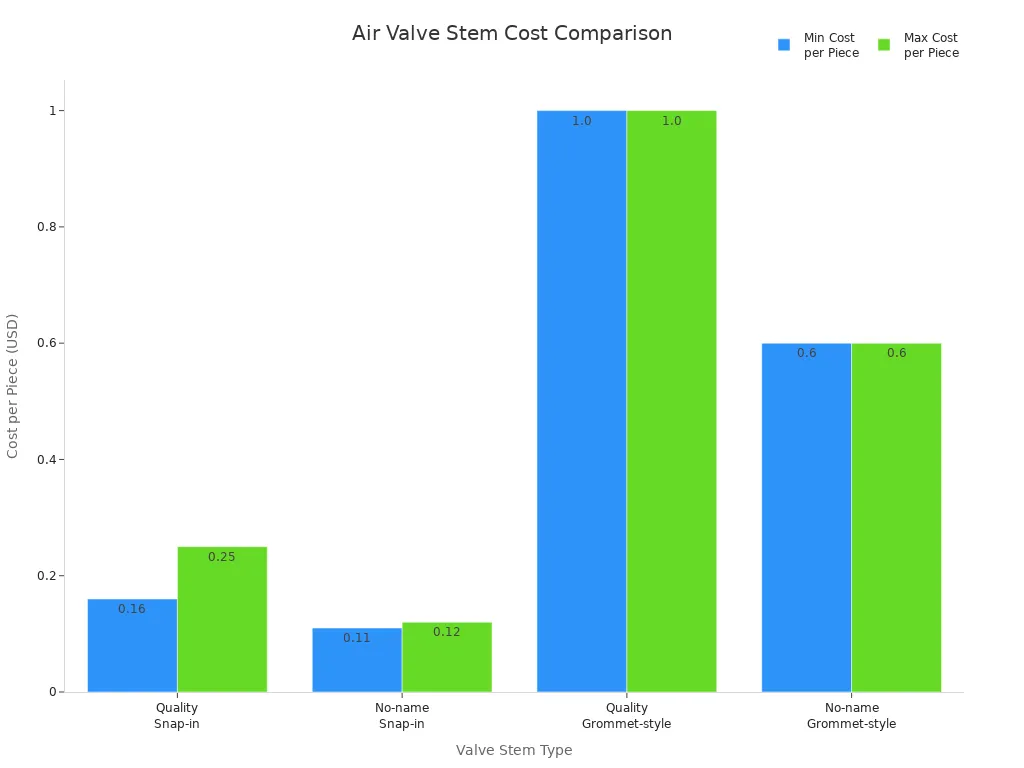

High-pressure valve stems give you peace of mind when you need it most. They last longer, seal better, and keep your tires at the right pressure, even when you push your vehicle to the limit. Take a look at this chart to see how much more pressure these stems can handle compared to standard ones:

If you want your heavy-duty or commercial vehicle to perform its best, don’t overlook the importance of the right valve stem. The right choice keeps your tires safe, your ride smooth, and your mind at ease.

How Air Valve Stem Types Affect Tire Pressure Monitoring System and Performance

Tire Pressure Retention and Air Leaks

You want your tires to hold air as long as possible. The type of air valve stem you pick makes a big difference here. Rubber stems work well for most cars, but they can dry out and crack, especially if you drive in hot or sunny places. When this happens, air starts to leak out slowly. You might not notice until your tire looks low or your dashboard light comes on.

Metal stems last longer, but they can corrode if you drive where there’s a lot of road salt or moisture. Corrosion weakens the seal and lets air escape. If you use a tire pressure monitoring system, even a small leak can trigger a warning. That’s why you should check your valve stems for cracks, rust, or damage every time you check your tires.

Tip: Always keep the valve cap on. It helps block dirt and water, which can cause leaks and mess with your tire sensors.

Durability, Heat, and Weather Resistance

Not all valve stems handle tough weather the same way. Here’s what you need to know:

- High heat makes rubber stems brittle and can shorten the battery life of external tire sensors. You might see more false alerts or need to replace sensors sooner.

- Cold weather causes the air inside your tires to shrink. This drops your tire pressure and can set off low-pressure warnings. Cold also slows down the battery in your sensors, so they might not work as well.

- Moisture and road salt attack metal valve cores. Over time, this leads to corrosion, which can break the seal and let air out. Ice can even damage sensors attached to the stem.

Let’s look at how long different valve stems last:

| Valve Stem Material | Average Lifespan Under Typical Driving Conditions | Environmental Impact | Maintenance Recommendation |

|---|---|---|---|

| Rubber | 4 to 6 years | Degrades faster with extreme temperatures, UV exposure, road salt | Replace every 4-6 years or with new tires; inspect for cracks and dry rot |

| Metal | Longer than rubber, but variable | Can corrode in humid or salty environments | Regular inspection during tire maintenance; replace if corroded or damaged |

You should replace rubber stems every 3-5 years or whenever you get new tires. Metal stems last longer, but you still need to check them for rust or damage. If you drive in harsh weather, inspect your valve stems more often.

Compatibility with Tire Pressure Monitoring System

If your car has a tire pressure monitoring system, you need to make sure your valve stems work with it. Some sensors attach directly to the valve stem, so the stem must fit just right. Here are some common issues you might run into:

| Compatibility Issue | Explanation |

|---|---|

| Use of nickel-plated valve cores | These prevent corrosion that can ruin your sensor. If you use the wrong core, you might have to replace the whole sensor. |

| Valve grommets, nuts, and caps | These parts need to match your sensor and stem. If they wear out or don’t fit, you could get leaks or sensor errors. |

| Correct torque application | Tighten valve cores and nuts to the right level. Too loose or too tight can damage the sensor or cause leaks. |

| Use of original parts | Always use the right parts for your sensor. The wrong ones can make your system stop working. |

| Valve stem as sensor antenna | Some sensors use the stem as an antenna. If you swap out the stem for the wrong type, your sensor might not send a signal. |

| Use of quality pressure gauges | Accurate gauges help you keep the right pressure and avoid false warnings from your system. |

You want your tire pressure monitoring system to work every time you drive. Pick the right valve stem, use the right parts, and check everything during tire service. This keeps your sensors working and your tires safe.

Choosing the Right Air Valve Stem for Your Vehicle

Matching Tire Valve Stems to Tire Pressure and Vehicle Type

You want your valve stems to match your vehicle and tire pressure needs. Picking the right one keeps your tires safe and helps you avoid air leaks. Check out this table to see how different criteria affect your choice:

| Criteria | Details and Requirements |

|---|---|

| Rim Thickness at Stem Hole | Over 0.205 inches? Use metal clamp-in stems. Thinner rims can use snap-in stems like TR413 or TR415. |

| Stem Hole Diameter | TR600HP/TR602HP fit 0.453-inch holes. TR801HP/TR802HP fit 0.625-inch holes. |

| Valve Stem Pressure Rating | TR413/TR415: up to 65 psi. TR600HP/TR801HP: up to 100 psi. Metal clamp-in: up to 200 psi. |

| Vehicle and Tire Application | Light trucks with heavy ply tires may need higher pressure stems (TR600HP or metal clamp-in). |

| Use of Extensions | Metal extensions only for metal clamp-in stems. Plastic extensions for TR600HP/TR801HP snap-in stems. |

| Installation | Lubricate snap-in stems with non-petroleum lubricant. Inspect stem hole for damage. Torque clamp-in stems to specs. |

| Safety Concerns | Wrong stem can cause failure, air loss, or even tire blowouts at high speeds or pressures. |

Tip: Always double-check your rim thickness and hole size before you install valve stems. This helps you avoid leaks and keeps your tires at the right pressure.

Considering Driving Conditions and Usage

Think about where and how you drive. Off-road, high-speed, or city driving all need different valve stem features. Here’s a quick guide:

| Driving Condition | Tire Pressure Range | Valve Stem Needs | Why It Matters |

|---|---|---|---|

| Off-Road (Sand, Mud) | 12-20 psi | Stems must handle frequent pressure changes. Caps keep out dirt and water. | Lower pressure helps traction. Stems need to resist damage. |

| High-Speed Driving | Up to 200 psi | Metal clamp-in stems and nickel-plated cores work best. | High pressure prevents heat build-up. Stems must handle speed and pressure. |

If you drive off-road, you’ll want valve stems that can take a beating and keep out mud and water. For highway speeds, metal clamp-in stems give you the strength and tire pressure considerations you need.

Identifying the Correct Size and Fit

Getting the right size and fit is key for a good seal and safe driving. Here’s what you should look for:

- Match the valve stem to your rim hole diameter. Most passenger cars use 0.453″ or 0.625″ holes.

- Choose the right length. Low-profile rims need shorter stems. Deep rims need longer stems.

- Make sure the valve stem fits your tire pressure and vehicle type.

- For TPMS, always use stems that match your sensor and wheel design.

When you install valve stems, follow these steps for a proper seal:

- Push the valve stem through the rim hole from inside the wheel. Make sure the rubber base sits flush.

- Pull the stem from the outside so it’s firmly in place.

- Check for cracks or brittleness. Replace valve stems if you see any wear.

- Replace valve stems every time you get new tires for the best seal.

Note: A good installation keeps your tires inflated and helps you avoid sudden air loss.

Common Issues from Incorrect Tire Valve Stem Selection

Air Leaks and Pressure Loss

Picking the wrong valve stem for your tires can cause a lot of trouble. You might not notice it right away, but small problems can turn into big ones fast. Here’s what can happen:

- Valve stems that don’t match your wheel size or type may not seal tightly. This poor fit lets air escape, even if you just filled your tires.

- If you use a valve stem made from the wrong material, it can crack or get brittle from sunlight, heat, or cold. Cracks let air leak out slowly, so your tires lose pressure over time.

- Moisture and road salt can corrode the inside parts of the valve stem. Corrosion weakens the seal and causes more air leaks.

- Sometimes, the valve stem gets damaged during installation or when you check your tire pressure. If the stem isn’t the right type, it’s easier to harm it and cause leaks.

- Without the right valve cap, dirt and water can get inside. This makes leaks worse and can even mess up your tire sensors.

Tip: Check your valve stems for cracks, rust, or damage every time you check your tire pressure. A quick look can save you from a flat tire later.

Tire Damage and Safety Risks

When your tires lose air because of a bad valve stem, you face more than just a slow leak. You put your safety at risk. Here’s what you need to watch for:

- Cracked or rigid rubber valve stems can lead to sudden air loss. If your tire goes flat while you’re driving, you could lose control.

- Air leaks from damaged valve stems cause your tires to run underinflated. This makes your tires wear out unevenly and faster than normal.

- Underinflated tires hurt your fuel economy. You’ll spend more money on gas and need new tires sooner.

- If you use the wrong valve stem with your tire pressure sensors, you might get false warnings or lose air without knowing it.

- Metal valve caps on the wrong stems can cause corrosion. This can fuse the cap to the stem or damage the valve, making it hard to check or fill your tires.

- Damaged valve stems can affect your car’s handling and braking. Stopping distances get longer, and your car may not steer as well.

Note: Always use valve stems that match your vehicle and tire needs. Regular inspections and the right parts help keep you safe on the road.

Choosing the right air valve stem keeps your tires safe and your ride smooth. You should always match the stem to your vehicle, tire pressure, and driving style. Check out this quick guide:

| Vehicle Type | Stem Length | Pressure Rating | Rim Hole Size |

|---|---|---|---|

| Passenger Car | 1.25–1.5 in | Up to 65 psi | 0.453/0.625 in |

| Heavy-Duty Truck | 2–2.5 in | Up to 200 psi | 0.625 in |

| Motorcycle | ~0.88 in | Up to 65 psi | ~0.327 in |

| Tractor/Off-Road | 1.25–3 in | Metal stems | 0.625 in |

- Replace valve stems when you get new tires.

- Inspect for cracks or leaks often.

- Use metal stems for heavy-duty jobs.

- Make sure your stem fits TPMS sensors.

When you pick Fortune, you get reliable, high-quality valve stems made with advanced equipment and strict quality checks. You can trust Fortune to keep your tires performing their best.

FAQ

How often should you replace your tire valve stems?

You should replace your valve stems every time you get new tires. If you drive in harsh weather or notice cracks, swap them out sooner. Regular checks help you catch problems before they cause air leaks.

Can you mix rubber and metal valve stems on the same vehicle?

You can, but it’s best to match all four for even performance. Metal stems work better for high pressure or heavy-duty use. Rubber stems suit most daily drivers. Pick the type that fits your driving needs.

Do all valve stems fit tire pressure monitoring systems (TPMS)?

Not all valve stems fit TPMS sensors. Always check your vehicle’s manual or ask your tire shop. Using the wrong stem can cause leaks or sensor errors. TPMS-compatible stems keep your system working right.

What are signs that your valve stem needs replacing?

Look for cracks, splits, or leaks around the base. If you see rust on metal stems or the cap feels stuck, it’s time for a new one. A slow loss of tire pressure often points to a bad valve stem.