admin1

October 23, 2025

The Essential Guide to Rim Bolts and Wheel Security

Your wheel’s security depends on three key specifications. Choosing the correct rim bolts means you must match their thread size, seat type, and length perfectly to your vehicle. An incorrect fit is a serious safety risk, leading to wheel vibration, component damage, or even complete detachment while driving.

A report from the Scandinavian Tire and Rim Organization found that approximately 900 traffic accidents occur each year because a wheel detaches from a personal vehicle, often due to improper bolt fitment or tightening.

Why Choosing the Correct Rim Bolts is a Safety Imperative

You should never underestimate the importance of your wheel hardware. Using the correct rim bolts is not just about a good fit; it is a fundamental requirement for keeping you and your passengers safe on the road. The connection between your wheels and your car depends entirely on this precision.

The Dangers of an Improper Fit

You risk serious problems when you use the wrong hardware for your wheels. An incorrect fit can introduce a range of dangerous conditions, from minor annoyances to catastrophic failures. These dangers include:

- Persistent Vibration: Mismatched bolts can prevent the wheel from sitting perfectly flat against the hub, causing vibrations you will feel through the steering wheel.

- Component Damage: The wrong seat type will damage the bolt holes on your expensive wheels. Uneven pressure can also warp your brake rotors over time.

- Loosening Hardware: Bolts that are too short do not have enough thread engagement. They can work themselves loose while you drive, creating a hazardous situation.

- Wheel Detachment: This is the worst-case scenario. If the bolts fail or loosen completely, the wheel can detach from your vehicle, leading to a total loss of control.

How Bolts Secure the Wheel to the Hub

You might think bolts carry your car’s weight directly. This is a common misunderstanding. Their main job is to create a powerful clamping force. This force tightly squeezes the wheel against the vehicle’s hub. The immense pressure generates a huge amount of friction between the two metal surfaces.

This friction, not the bolts themselves, handles the intense forces from accelerating, braking, and turning. The bolts simply maintain the pressure needed to create that friction lock.

A proper fit ensures this clamping force is strong and evenly distributed. This creates a secure friction coupling that keeps your wheels safely attached, no matter the driving conditions.

Step 1: Determining Your Correct Thread Size

The first step in choosing the correct hardware is identifying the thread size your vehicle requires. This specification is not a suggestion; it is a precise measurement that ensures the bolt can properly thread into your vehicle’s hub. Using the wrong thread size will make installation impossible or, worse, create a dangerously weak connection.

Understanding Thread Diameter and Pitch

You will see thread size expressed as two numbers, like M12x1.5. This simple code tells you everything you need to know.

- Diameter: The first number (M12) represents the outer diameter of the bolt’s threads. In this example, “M” stands for Metric, and “12” means the diameter is 12 millimeters.

- Pitch: The second number (1.5) is the thread pitch. This measures the distance in millimeters between each thread. A larger number means the threads are farther apart (a coarse thread), while a smaller number means they are closer together (a fine thread).

Note: You cannot mix and match these numbers. An M12x1.5 bolt will not fit a hub designed for an M12x1.25 bolt, even though they have the same diameter. The mismatched pitch will prevent it from threading in correctly and will damage the threads on both the bolt and the hub.

Common Metric vs. Imperial Sizes

Most modern cars use metric thread sizes, while many classic and heavy-duty American vehicles use imperial (inch-based) sizes. You must know which system your vehicle uses.

Metric Sizes The majority of cars on the road today, from European sedans to Japanese SUVs, use metric rim bolts. Some of the most common sizes include:

- M12x1.25

- M12x1.5

- M14x1.25 (used often by BMW)

- M14x1.5

For example, many Acura models like the NSX, MDX, and Integra use either M12x1.5 or M14x1.5 hardware to match original factory specifications. Similarly, the popular M14x1.5 size is standard on many modern American trucks, including 2015-2023 Ford F-150 models and certain Chevy and Dodge vehicles.

Imperial Sizes You will typically find imperial sizes on older domestic cars and many trucks. These are measured in inches. The most common imperial sizes are:

- 1/2″-20

- 9/16″-18

- 5/8″-11

- 5/8″-18

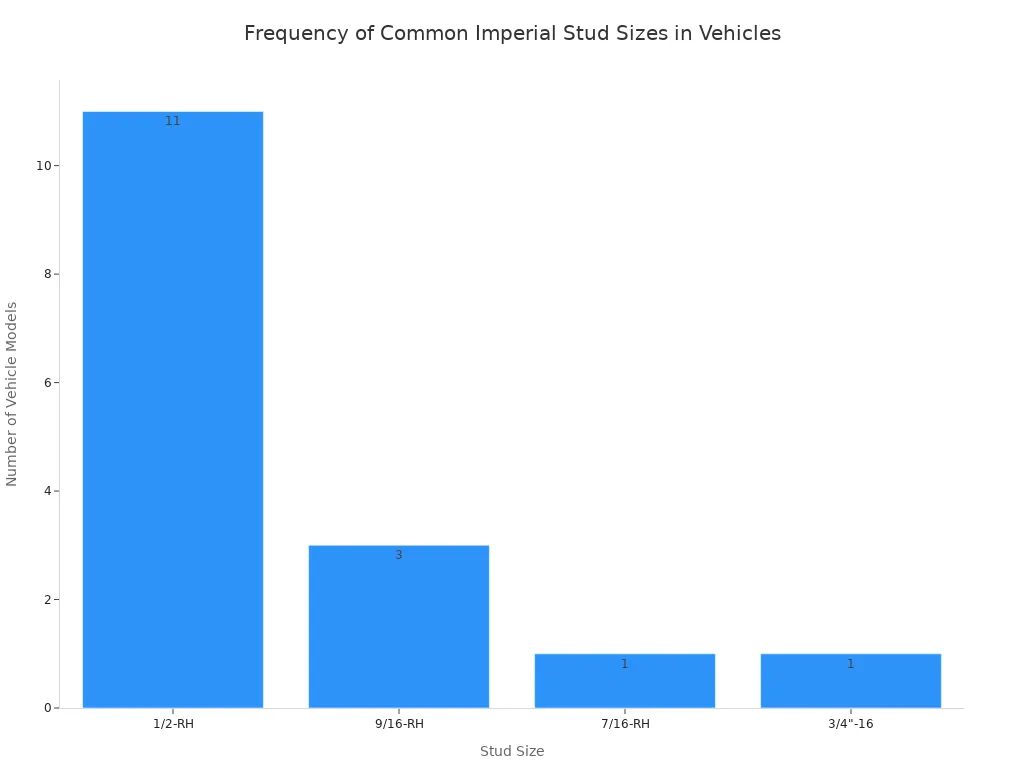

As you can see in the chart below, the 1/2-inch size is extremely common in many classic American trucks.

This table shows how specific models use these imperial sizes. Notice how some truck lines, like the Dodge Ram, switched from imperial to metric-equivalent sizes in later model years.

| Vehicle Model | Years | Stud Size |

|---|---|---|

| Chevy Suburban (2WD) | ’71-’91 | 1/2-RH |

| Dodge 1/2 and 3/4 Ton Trucks | ’79-’93 | 1/2-RH |

| Dodge Dakota and Durango | ’91-’03, ’91-’04 | 1/2-RH |

| Dodge Ram 1/2 Ton Trucks | ’94-’01 | 1/2-RH |

| Dodge Ram 1/2 Ton Trucks | ’02 & Newer | 9/16-RH |

| Ford 1/2 Ton F-100, F-150 | ’54-’96 | 1/2-RH |

| Mazda B-Series Pickup | ’93 & Newer | 1/2-RH |

How to Find Your Vehicle’s Specification

Guessing your thread size is never a good idea. Fortunately, you have several reliable ways to find the correct information.

- Check Your Owner’s Manual: Your vehicle’s owner’s manual is the most trustworthy source for factory stud sizes. You can usually find this information in the section covering wheels, tires, or vehicle specifications.

- Examine Your Existing Bolts: If you have an original bolt, the size is often stamped directly on its head. Look for markings like “M14” or “1.5” to help you identify it.

- Use an Online Database: Several excellent online resources provide comprehensive vehicle fitment data. Websites like Wheel-Size.com and Bolt-Pattern.com offer free, detailed databases. You can enter your vehicle’s make, model, and year to find its bolt pattern, center bore, and required wheel fastener specifications. These sites are regularly updated and cover vehicles from all over the world.

Step 2: Identifying the Correct Seat Type

After confirming your thread size, you must identify the correct “seat type.” The seat is the contact surface where the bolt head meets the wheel. This area is precisely machined to match the bolt holes on your wheel. Using the wrong seat type creates a tiny contact point, concentrating all the clamping force on a small area. This can damage your wheels and cause the bolts to loosen over time.

You can easily identify the three main types of seats by their shape.

| Seat Type | Common Angle/Radius | Visual Identifier |

|---|---|---|

| Conical (Acorn) | 60° Taper | Tapered, cone-like shape |

| Ball (Radius) | R12, R13, or R14 | Rounded, spherical end |

| Mag (Shank) | Flat with Washer | Cylindrical shank with a flat washer |

Let’s look at each one more closely.

Conical Seat (Cone)

The conical seat is the most common type you will encounter. These bolts have a straight, tapered seat with a 60-degree angle. People often call them “acorn” bolts because the shape resembles the top of an acorn.

This design is the standard for a vast number of aftermarket wheels and original equipment (OEM) wheels, especially for domestic vehicles.

In 50 years of owning DOMESTIC vehicles, not a 1 has ever had ball seat lug nuts.

You will find conical seats on a wide range of cars and trucks. For example, the factory wheels on a new Ford Maverick use 60-degree conical seat hardware. Their widespread use makes them the default for many manufacturers.

Ball Seat (Radius)

You can identify a ball seat bolt by its rounded, dome-shaped head. Unlike the straight taper of a conical seat, this one is curved. This design is also called a radius seat. You must match the bolt’s radius (like R13 or R14) to the wheel’s bolt hole for a secure fit.

Ball seats are most frequently used by European car manufacturers. If you drive one of these brands, you likely need ball seat rim bolts for your factory wheels.

- Mercedes-Benz

- Audi

- Volkswagen

- Porsche

⚠️ Warning: Never use a conical bolt on a wheel designed for a ball seat, or vice-versa. The mismatched shapes will only make contact on a very thin edge, creating a dangerously weak connection that will fail under pressure.

Mag Seat (Flat)

The mag seat is visually distinct from the other two. It does not have a tapered or rounded seat. Instead, it features a flat washer that sits flush against the wheel’s surface. These bolts also have an extended, unthreaded cylinder (the shank) that slides into the bolt hole for a snug fit.

This design was popular when aluminum wheels first became common. You will find it used today by several Japanese manufacturers for their factory wheels.

- Toyota is well-known for using mag seat nuts and bolts with an attached washer.

- The design ensures a flush fit on the flat surfaces around the wheel’s lug hole.

- You will also find this style on some Lexus and Mitsubishi vehicles.

Choosing the correct seat is just as critical as choosing the right thread size. Always inspect your wheels and existing hardware to ensure you get a perfect match.

Why Mismatched Seats Are Dangerous

You might think a small difference in shape between the bolt and the wheel is not a big deal. This is a dangerous mistake. The seat is engineered to create a large, stable contact area that evenly distributes the immense clamping force. When you use the wrong seat type, you destroy this critical connection.

Imagine placing a pointed cone into a rounded bowl. It only touches at a single, tiny point. This is exactly what happens when you use a conical bolt on a wheel designed for a ball seat. All the force meant to secure your wheel gets focused on a razor-thin line.

This tiny contact point creates several immediate and severe risks.

| Fitment Type | Contact Area | Result |

|---|---|---|

| Correct Match | Large, even surface contact | Secure clamping force, stable wheel |

| Mismatched | A very small point or thin line | Unstable connection, component failure |

Here are the specific dangers you introduce with a mismatched seat:

- Drastically Reduced Clamping Force: The small contact area cannot properly transfer the torque from your wrench into clamping force. The bolt will feel tight, but the wheel will not be securely clamped to the hub.

- Bolt Loosening: The high pressure on the tiny contact point creates a stress point. Vibrations from driving will cause the bolt to work itself loose much faster than it would with a proper fit.

- Permanent Wheel Damage: A conical bolt’s sharp edge will dig into the softer metal of a ball seat wheel hole. This damages the wheel permanently, making it unsafe to use even with the correct bolts later.

- Bolt Failure: This puts immense stress on the rim bolts. The concentrated force can cause the head of the bolt to stretch, fatigue, and eventually snap off completely, leading to a catastrophic failure.

Safety Alert ⚠️ A mismatched seat creates a false sense of security. Your torque wrench might click at the correct value, but the wheel is not safe. The connection is weak and will fail under normal driving stress. Always visually confirm that your bolt seat and wheel seat are a perfect match.

Step 3: Measuring for the Proper Bolt Length

You have found the right thread size and seat type. Now you must determine the correct bolt length. The length of your rim bolts is just as important for safety. It ensures the bolt has enough grip inside the hub without causing other problems.

Defining Shank Length

When you measure a wheel bolt, you are measuring its shank length. This is the length of the bolt from the bottom of the seat to the tip of the threads. You do not include the head of the bolt in this measurement.

Shank Length: The measurement from the base of the bolt’s seat to the end of the bolt. This is the part of the bolt that passes through the wheel and threads into the hub.

Getting this measurement right ensures a secure connection.

Risks of Bolts Being Too Short

A bolt that is too short is a major safety hazard. It cannot achieve enough thread engagement inside the hub. This creates a weak connection that can easily fail under the stress of driving.

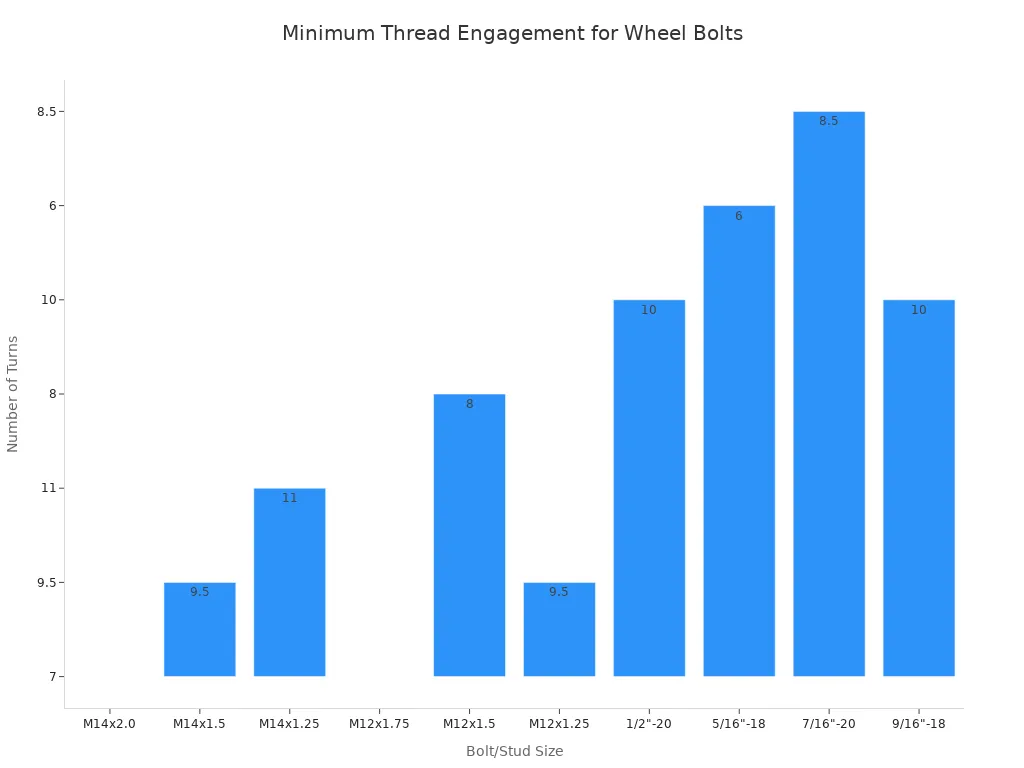

For a safe connection, you need a minimum number of full turns to properly secure the bolt. As a general rule, the length of the engaged thread should be at least equal to the diameter of the bolt. For example, an M12 bolt should have at least 12 mm of its threads engaged in the hub.

You can use this chart to find the minimum number of turns for common bolt sizes.

| Bolt/Stud Size | Minimum Turns |

|---|---|

| M12x1.25 | 9.5 |

| M12x1.5 | 8 |

| M14x1.25 | 11 |

| M14x1.5 | 9.5 |

| 1/2″-20 | 10 |

If you cannot achieve these minimum turns, your bolts are too short and unsafe.

Risks of Bolts Being Too Long

You might think a longer bolt is always safer, but this is not true. A bolt that is too long can cause serious damage. If it extends too far through the hub, it can hit other components behind it.

Possible problems include:

- Damaging brake components like sensors or dust shields.

- Interfering with the parking brake mechanism.

- Preventing the wheel from turning freely.

Always check for clearance behind the hub before installing bolts that are longer than the factory originals.

Adjusting Length for Aftermarket Wheels

You must pay close attention to bolt length when you install aftermarket wheels. Aftermarket wheels often have a thicker mounting pad than your car’s original factory wheels. The mounting pad is the part of the wheel that sits flat against the vehicle’s hub. A thicker pad means your original bolts will be too short to achieve safe thread engagement.

Reusing your old bolts is a serious mistake. They will not thread deep enough into the hub. This creates a weak connection that can easily fail. You need to calculate the correct new length to keep your wheels secure.

Here is a simple method to find the right length for your new bolts:

- Measure Your New Wheel: Use a caliper or ruler to measure the thickness of the new wheel’s mounting pad.

- Measure Your Old Wheel: Measure the thickness of your original wheel’s mounting pad in the same way.

- Find the Difference: Subtract the old wheel’s thickness from the new wheel’s thickness. This number is how much longer your new bolts need to be.

- Calculate New Bolt Length: Add that difference to the shank length of your original factory bolts.

For example, look at this calculation:

| Measurement | Value |

|---|---|

| New Wheel Thickness | 22 mm |

| Old Wheel Thickness | 15 mm |

| Difference | 7 mm |

| Original Bolt Length | 28 mm |

| New Required Length | 35 mm (28 mm + 7 mm) |

Pro Tip: 📏 Always measure, never guess. This same logic applies if you add wheel spacers. You must add the spacer’s thickness to your required bolt length. Using the correct length for your new rim bolts is essential for a safe installation.

Understanding Rim Bolt Materials

The material your rim bolts are made from directly affects their strength, weight, and resistance to corrosion. You have two primary choices: high-strength steel and titanium. Each material offers distinct advantages depending on your needs and budget.

High-Strength Steel: The Industry Standard

Most vehicles use high-strength steel bolts from the factory. This material is the industry standard for good reason. It offers an excellent balance of strength and cost-effectiveness. You will often see these bolts rated with a property class, such as Grade 10.9.

Grade 10.9 bolts are typically made from manganese boron or carbon steel. They possess a very high tensile strength of 1040 MPa, making them more than strong enough to handle the clamping forces required for safe wheel mounting. This strength ensures they can withstand the stresses of daily driving without stretching or failing.

Titanium: The Performance Upgrade

You can choose titanium bolts for a significant performance upgrade. Titanium is a premium material known for its high strength-to-weight ratio. While its tensile strength is comparable to high-strength steel, it is significantly lighter.

This table shows how titanium compares to steel.

| Feature | Titanium Bolts | Steel Bolts |

|---|---|---|

| Weight | ~43% lighter | Standard weight |

| Corrosion Resistance | Excellent | Prone to rust |

| Cost | 5-10 times higher | Inexpensive |

The primary benefit of titanium is the reduction in unsprung weight. Lighter wheels allow your suspension to react faster, improving handling and grip. However, this performance comes at a much higher cost.

The Importance of Quality Manufacturing

The base material is only part of the story. The manufacturing process plays a critical role in a bolt’s safety and longevity. Reputable manufacturers adhere to strict quality control standards, such as ISO 9001, to ensure every bolt meets precise specifications.

Quality manufacturing also includes the use of protective coatings. These coatings prevent rust and corrosion, which can weaken a bolt over time.

Note: A quality coating not only protects the bolt but also ensures consistent torque readings during installation.

Here are some common coatings and their benefits:

| Coating Type | Key Benefit |

|---|---|

| Dacromet/Geomet | Excellent corrosion and heat resistance. |

| Zinc Plating | Good corrosion resistance with a clean look. |

| Chrome Plating | Superior corrosion resistance and a decorative finish. |

Always choose bolts from a manufacturer that can certify its materials and processes. This is your best guarantee of safety and reliability.

The Critical Role of Proper Installation

You have selected the perfect bolts for your wheels. Now, you must install them correctly. Proper installation is not just about making the bolts tight; it is a precise process that guarantees your safety on the road. Following the right steps ensures the clamping force is applied evenly and correctly.

Why You Must Use a Torque Wrench

You must use a torque wrench to tighten your wheel bolts. This tool is not optional. It is the only way to apply the exact amount of rotational force, or torque, needed to achieve the correct clamping pressure. Guessing the tightness by hand or using an impact gun can lead to dangerous outcomes.

- Over-tightening can stretch the bolts beyond their limits, strip the threads, and even crack your wheel. This permanent damage weakens the hardware and can cause it to fail.

- Under-tightening is just as hazardous. Bolts that are too loose will eventually work their way free as you drive. Studies show that fastener failure, often from loose bolts, is the main cause in 85% of reported wheel separations.

Safety First ⚠️ Both over-tightening and under-tightening create an unsafe condition. Always use a calibrated torque wrench to apply the manufacturer’s specified torque value.

Finding Your Vehicle’s Torque Specs

Every vehicle has a specific torque specification for its wheel hardware. You must use this exact value for a safe installation. You can find this information in a few reliable places:

- Your Owner’s Manual: This is the most accurate source. Look in the index for “wheel torque” or “tire changing.”

- Driver’s Side Door Jamb: Some vehicles have a sticker here that lists tire pressure and wheel torque specs.

- Online Resources: You can often find the correct specification by searching online for your vehicle’s make, model, and year.

The Correct Star-Pattern for Tightening

You must tighten your rim bolts in a specific sequence to ensure the wheel mounts flat against the hub. This method, known as the star pattern, distributes the clamping force evenly. Tightening bolts in a circle can cause the wheel to tilt, leading to vibration and unsafe stress on the hardware.

First, snug the bolts by hand. Then, use your torque wrench to tighten them in two stages following the star pattern.

- 4-Lug Wheels: Tighten the bolts in a cross pattern (1, 3, 2, 4).

- 5-Lug Wheels: Follow a star shape (1, 3, 5, 2, 4).

- 6-Lug Wheels: Use a star pattern that crosses the hub (1, 4, 2, 5, 3, 6).

This simple technique is critical for securing your wheels properly.

When to Re-Torque Your Wheels

Your job is not finished just because you tightened the bolts. The hardware needs time to settle. Heat from driving and braking causes the metal in the wheels and bolts to expand and contract. Small vibrations can also cause the hardware to shift slightly. This process can reduce the clamping force you carefully applied. You must re-torque your wheels to ensure they remain secure.

The first re-torque is the most important one. Many automotive service centers recommend you check the torque after driving a short distance. You should plan to re-torque your wheels within the first 50 to 100 miles after any wheel service. Some tire manufacturers, like Continental, advise an even shorter interval, suggesting a re-torque after the first 50 kilometers (about 31 miles). This simple check ensures your rim bolts maintain the correct clamping force after they have settled into place.

Pro Tip: 📝 Set a reminder on your phone or leave a note in your car. Forgetting this step is easy, but completing it is critical for your safety.

You should make re-torquing a regular part of your vehicle maintenance schedule. Here are the key times you need to check your wheel bolt torque:

- After Initial Installation: Always re-torque after driving 50-100 miles on newly installed wheels.

- During Regular Maintenance: You should check the torque every 5,000 miles or each time you rotate your tires.

- After Related Service: Re-torque your wheels any time they are removed for other work, such as brake repairs or suspension adjustments.

This quick and easy procedure is one of the most effective things you can do to prevent a wheel from coming loose. It ensures your rim bolts are always doing their job correctly.

Advanced Security: Locking Wheel Bolts

Your wheels are a valuable part of your vehicle, and you should protect them from theft. Standard rim bolts can be removed with any common lug wrench, leaving your expensive wheels vulnerable. You can add a powerful layer of security by installing a set of locking wheel bolts.

How Locking Bolts Prevent Theft

Locking bolts replace one standard bolt on each wheel with a unique piece of hardware. You cannot remove these bolts with a normal socket. Instead, they require a special matching key or adapter that comes with the set. This simple system effectively stops most thieves in their tracks.

You will find several different designs, each with a unique pattern to deter theft.

- Spline Drive Locks: These are great for tuner-style wheels with small bolt holes. They use a special key tool and offer more stud engagement and a larger seating surface.

- Tuner-Style Locks: These also need a special key for removal. They often have long adapters that engage with keyed splines at the bottom of the bolt.

- Acorn Puzzle-Style Locks: These bolts have smooth sides with unique cuts on the head. The matching key fits into these cuts like a puzzle piece to turn the bolt.

Note: Always keep your locking bolt key in a safe and memorable place inside your vehicle. Without it, you will not be able to remove your own wheels for tire changes or service.

Choosing a Quality Locking Bolt Set

Not all locking bolts offer the same level of protection. When you choose a set, you should look for specific features that make them more secure. A quality set is an investment in your peace of mind.

First, consider the material. You should look for bolts made from high-grade, through-hardened steel. This process hardens the entire bolt, making it extremely resistant to cutting or drilling. It provides much better security than cheaper, case-hardened bolts that are only hardened on the surface.

Second, examine the key design. The best sets use complex, computer-generated key patterns. These systems can create a nearly unlimited number of unique keys. Look for designs with extra narrow grooves, which make it very difficult for a thief to use a lock removal tool.

For example, automotive experts at ‘The Drive’ rate Gorilla Automotive locks as a top choice because their spinning feature makes them very hard to remove without the key. They also recommend McGard sets as a great value option that still provides excellent security.

Your wheel security depends on careful attention to detail. You must always verify the three critical specifications before installation.

Final Safety Checklist

- Correct thread size for your vehicle hub.

- Proper seat type to match your wheels.

- Accurate shank length for safe engagement.

You ensure a secure connection by using a torque wrench for installation. Choosing high-quality rim bolts is an investment in your safety. When you feel unsure, always consult your vehicle’s manual or a trusted professional for guidance.

FAQ

Can I reuse my old rim bolts on new wheels?

You should avoid reusing old bolts with new wheels. Aftermarket wheels often require a different seat type or a longer shank length. Always verify that your old bolts perfectly match the new wheel’s required thread size, seat type, and length to ensure a safe and secure fit.

What happens if I use an impact wrench to tighten my bolts?

You risk your safety by using an impact wrench. It can easily over-tighten bolts, which stretches the metal and damages your wheels. It can also under-tighten them, leading to a loose wheel. You must use a calibrated torque wrench for the correct clamping force.

How often should I check my wheel bolt torque?

You must re-torque your wheels after the first 50-100 miles of driving. After that initial check, you should inspect the torque every 5,000 miles. You should also check it any time a wheel is removed for service, such as for brake repairs or tire rotations.

Are wheel spacers safe to use?

Wheel spacers can be safe if you use them correctly. You must install longer wheel bolts that are equal to the original bolt length plus the thickness of the spacer. This ensures you achieve the minimum required thread engagement for a secure connection.