admin1

October 30, 2025

Stop Struggling With Your Lock Lug Nut Socket

You use wheel locks to protect your investment from theft. This is a smart move, especially as wheel and tire theft claims have risen nearly 90% since 2020.

| Category | Top 20 Wheel & Tire Theft Markets of 2022 (by rank) |

|---|---|

| Most Victimized Vehicles | 1. Honda Accord, 2. Honda Civic, 3. Chevrolet 1500 P/U Tahoe Suburban |

| Frequency Increase | Up 18% in 2022 across all markets combined |

| Source | Premiere Services (insurance-related claims) |

Your locking lug nuts require a specific wheel lock key. The most critical feature of any lock lug nut socket is a precise key pattern. This perfect match ensures the locking socket can grip the locking nut securely without causing damage.

The Most Important Feature of a Lock Lug Nut Socket

The primary job of your locking wheel nuts is to stop thieves. This single feature, the unique pattern, is what makes the entire security system work. Your wheel lock key must match this pattern exactly to transfer torque and turn the nut. A high-quality lock lug nut socket is designed to be a perfect copy of that key.

Why a Perfect Pattern Match is Non-Negotiable

You use wheel locks, or anti-theft lug nuts, to protect your vehicle’s wheels. The system is simple yet effective. The locking mechanism relies on a design that standard tools cannot grip.

- Your locking lug nuts have a unique, computer-generated pattern on the head.

- A special key with a matching pattern is required to install or remove them.

- A thief without the correct key cannot easily remove the locking nut.

- This difficulty forces the thief to move on to an easier target.

The entire system’s effectiveness depends on the integrity of this pattern. The key must engage every groove of the locking nut. This creates a secure connection, allowing you to apply force without slipping. The locking pattern is the heart of the system’s security.

The Dangers of a Poorly-Fitting Socket

Using a poorly-fitting socket is a recipe for disaster. An incorrect or low-quality key will not engage the locking lug nuts properly. When you try to apply force, the tool will slip. This action can strip the pattern on both the key and the nut itself.

Warning: A stripped locking nut is extremely difficult and expensive to remove. You may damage your wheel in the process, turning a simple tire change into a costly repair job.

A loose-fitting socket can also damage your wheel lock key, rendering it useless. You might find yourself stranded with a flat tire and no way to remove the wheel. The purpose of locking wheel nuts is to provide peace of mind. A bad socket creates the exact opposite: frustration and unexpected expenses. The locking mechanism fails when the tool does not fit.

Material Matters: The Foundation of a Durable Socket

An excellent lock lug nut socket starts with a perfect pattern match, but its long-term reliability depends entirely on the material it’s made from. A socket that bends, cracks, or corrodes under pressure is just as useless as one that doesn’t fit. You need a tool built from materials that can handle the high torque required for wheel maintenance without failing. This ensures your investment in security and safety pays off every time you use it.

The material determines the socket’s strength, toughness, and ability to resist the intense forces applied during loosening and tightening. Choosing a tool made from premium steel is not just about durability; it’s about ensuring the tool performs safely and effectively, protecting both the locking wheel nuts and your wheels from damage.

Chrome Molybdenum (Cr-Mo) Steel: The Gold Standard

When you look for high-quality tools, you will often see Chrome Molybdenum steel, or Cr-Mo, listed as the primary material. There is a good reason for this. Cr-Mo steel is the top choice for impact-rated tools because it offers a superior combination of strength, toughness, and impact resistance. Unlike standard chrome vanadium steel, Cr-Mo is specifically engineered to withstand the sudden, powerful jolts from an impact gun.

This superior performance comes from its unique properties. Molybdenum is an alloy that significantly increases steel’s hardness and toughness, especially at high strength levels. This allows a Cr-Mo socket to absorb high-powered blows without cracking.

Did You Know? 💡 Chrome Molybdenum steel has a much higher tensile strength than other common alloys. This means it can endure more stress before it deforms or breaks, making it ideal for high-torque jobs like removing stubborn wheel locks.

| Alloy Type | Ultimate Tensile Strength | Yield Strength |

|---|---|---|

| Cr-Mo Steel (4340) | 186,000 psi | 125,000 psi |

| 8620 Alloy Steel | 97,000 psi | 57,000 psi |

The data shows that Cr-Mo steel can handle almost double the stress of other alloys, ensuring your locking key won’t fail when you need it most.

The Role of a Protective Finish

Even the strongest steel needs protection from the elements. A protective finish is essential for preventing rust and corrosion, which can weaken the tool and compromise the precision of the locking pattern. Two common and effective finishes are black oxide and phosphate coatings.

- Black Oxide: This process creates a thin, durable layer of magnetite on the steel’s surface. It provides mild corrosion resistance and is often treated with oil to create a protective seal that improves both wear resistance and lubricity.

- Phosphate Coating: This method converts the metal surface into an insoluble crystalline phosphate layer. Manganese phosphate, in particular, offers excellent corrosion and wear resistance, making it perfect for high-stress tools used to remove wheel locks.

These coatings do more than just prevent rust. They create a barrier that reduces friction and prevents galling, ensuring the locking key engages smoothly with the nut every time. This protective layer is the final touch that guarantees your tool’s longevity and reliable performance.

Design and Fit: Ensuring a Damage-Free Match

Beyond the strength of the steel, the physical design of your lock lug nut socket is critical. The right shape and a precise internal pattern work together. They ensure you can remove your wheel locks without scratching your expensive rims or stripping the locking lug nuts. A proper fit protects your investment.

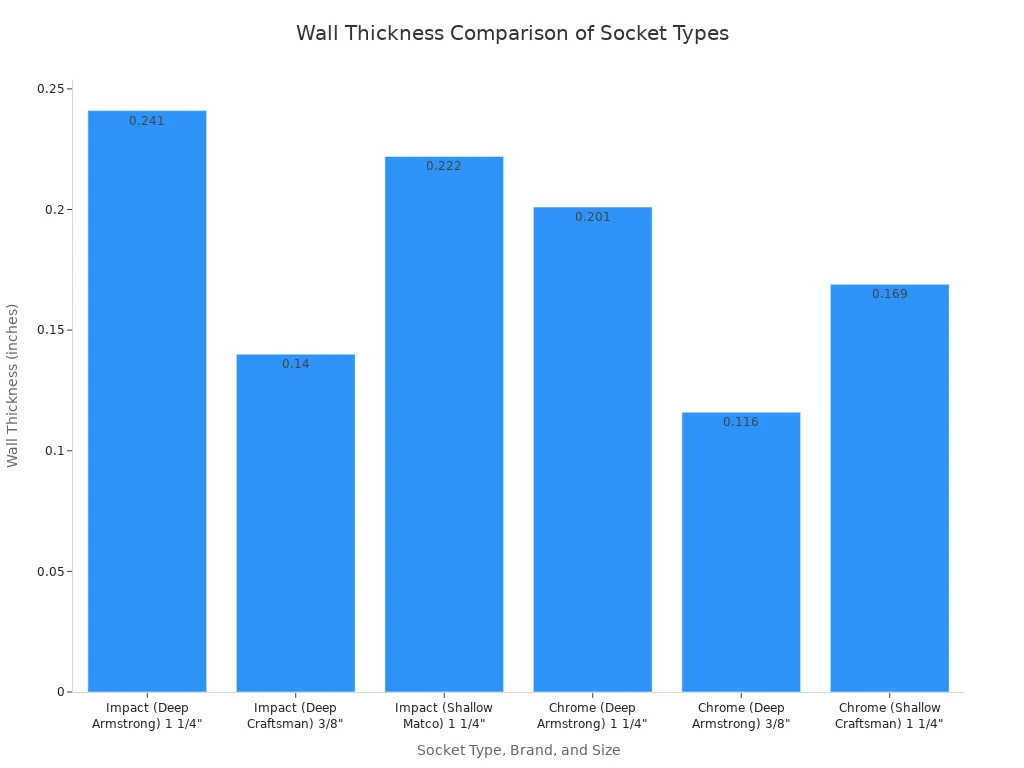

Thin-Wall vs. Standard-Wall Sockets

The space around your locking wheel nuts determines the type of socket you need. Many modern and aftermarket wheels have very little clearance in the lug nut pockets. Using a standard, thick-walled socket in these tight spaces will scratch or gouge the wheel finish. This is where a thin-wall design becomes essential.

You might need a thin-wall socket in these situations:

- Wheels with deep, narrow pockets for the lug nuts.

- Many aftermarket aluminum wheels where clearance is minimal.

- Specific OEM wheels, like those on some Infiniti and Nissan models, which are known to be damaged by thicker sockets.

A thin-wall socket has a smaller outside diameter, allowing it to fit easily without touching the sides of the lug hole. The difference in thickness is significant.

| Socket Type | Size | Outside Diameter (inches) | Wall Thickness (inches) |

|---|---|---|---|

| Impact (Deep Armstrong) | 1 1/4″ | 1.750 | 0.241 |

| Chrome (Deep Armstrong) | 1 1/4″ | 1.681 | 0.201 |

| Chrome (Shallow Craftsman) | 1 1/4″ | 1.641 | 0.169 |

As the data shows, wall thickness can vary greatly. Impact-rated tools are generally thicker for strength, making a thin-wall design even more specialized.

Precision of the Internal Key Pattern

The most important design feature is the precision of the internal locking pattern. A high-quality wheel lock key has an internal pattern that is an exact mirror of your locking lug nuts. This perfect match is not an accident. It comes from advanced engineering and strict quality control during manufacturing.

Important: A precise key engages every surface of the locking pattern on the nut. This distributes the turning force evenly, preventing the stripping of both the key and the nut.

A poorly made key will have rounded or shallow grooves. It will not grip the nut securely. When you apply torque, it will slip and damage the locking mechanism of your wheel locks. The precision of the wheel lock key is the final piece of the puzzle. It ensures the entire security system works as intended, providing a damage-free experience every time.

How to Remove a Wheel Lock: Sizing and Compatibility

Knowing how to remove a wheel lock starts with having the right tools. A perfect fit involves two key factors: the unique locking pattern and the drive size of your wrench. Getting both right ensures a smooth and damage-free removal process for your locking wheel nuts.

Finding Your Correct Wheel Lock Key Number

Losing your locking lug nut key can be stressful, but you can often order a replacement. The key to this process is your key registration number. Manufacturers record this number to help you get a new wheel lock key. If you need to find my wheel lock key information, here is what major brands require:

Note: Your key registration number is the most important piece of information. Keep it in a safe place, like with your vehicle’s paperwork.

- McGard: You can order a new key online if you have your I.D. Registration Card. If you lost the card, you must contact their Customer Service department for help.

- Gorilla: You need the key registration number to order a replacement locking wheel nut key. This number is usually on a silver sticker that came with your wheel locks. The part number of the lock set is not the same as your key registration number.

Verifying the Socket’s Drive Size

Your locking key must also fit the tool you use to turn it, like a lug wrench or impact gun. This connection point is called the drive size. Using the wrong size can prevent you from applying enough force to your locking lug nuts.

For most cars and light trucks, a 1/2-inch drive is the standard and most versatile size. It provides enough power for most automotive jobs. Larger vehicles like heavy-duty trucks or SUVs may require a more powerful 3/4-inch drive tool.

You can verify the correct size in a few simple steps:

- Check Your Tools: Look at the lug wrench that came with your vehicle. The square connector will be a specific drive size, usually 1/2-inch.

- Consult Your Manual: Your vehicle’s owner’s manual often lists the recommended tool sizes for tire changes.

- Match the Socket: Ensure the external hex or drive end of your locking key matches the socket or wrench you plan to use.

Matching the drive size ensures your lug nut key and wrench work together perfectly, making the locking mechanism easy to operate.

Key Usability Features for Locking Lug Nuts

A perfect pattern match is essential, but the physical design of your wheel lock key also determines how easy it is to use. The right external features ensure your key works with the tools you already own. This makes removing your wheel locks a simple, frustration-free task.

The Versatility of an External Hex Head

A key usability feature to look for is an external hex head. This design allows your locking key to be turned by more than one type of tool. A wheel lock key with this feature offers great versatility. You can use it with most standard lug wrenches. It also fits common socket sizes like 13/16” and 7/8”. This flexibility means you likely will not need to buy a special tool just to turn your locking key. It provides a secure grip for your wrench, making the removal of locking lug nuts much simpler.

Choosing the Right Socket Length and Profile

The length and profile of your lock lug nut socket are critical for accessing your locking wheel nuts without damaging your rims. The design you need depends on your wheels.

Pro Tip 💡 Wheels with deep-set lug holes, often called “deep-dish” wheels, require a special socket. An extra deep socket, sometimes up to 4.75 inches long, provides the extended reach needed to access recessed locking lug nuts.

You should understand the different socket profiles to choose the right one for your locking system.

- Shallow (Low-Profile) Sockets: These are best for tight spaces where there is little room above the nut. They are common for engine work but can also be useful for certain wheel designs.

- Deep Sockets: You need these for bolts that stick out far past the nut. They provide the clearance needed for the bolt to go inside the socket.

- Semi-Deep Sockets: This type offers a middle ground. It gives you more reach than a shallow socket but is more compact than a deep one.

Choosing the correct socket profile ensures your key can reach and properly engage the locking mechanism on your wheel locks.

What to Do When You Lose Your Wheel Lock Key

Losing your wheel lock key can feel like a major problem, but you have several options to resolve the situation. Your first step should always be a thorough search. A lost key is often just misplaced. Before you panic, take the time to check common storage spots inside your vehicle.

Identifying Your Key Pattern

If you cannot find your wheel lock key, your next goal is to identify its unique pattern to get a replacement. The easiest way to do this is with the key code that came with your wheel locks. This code is usually on a sticker or card in the original packaging. If you have this code, you can order a new key from the manufacturer. If you cannot find the key, start a systematic search.

Action Plan: Before spending money, check these common places for your missing key:

- Look in your glove box and center console.

- Search the trunk area, especially with the spare tire and tool kit.

- Check under the seats and in the seat-back pockets.

- Inspect the door card storage pockets.

If your search is unsuccessful and you do not have the code, a technician can help identify the locking pattern. They can also replace your unique locking wheel nuts with a universal set, which can sometimes be a cheaper solution. This new set will provide continued security for your wheels.

When to Use a Specialized Removal Kit

You should use a specialized removal kit when you have exhausted all other options. These kits are the last resort for removing locking lug nuts when you do not have the matching wheel lock key. A removal kit is designed to grip and forcibly remove stubborn or damaged anti-theft lug nuts. This process will likely destroy the locking nut, so you will need to replace it.

Using a locking nut removal kit is a job best left to professionals. The process requires specific tools and carries a risk of damaging your wheel if done incorrectly. A technician will have the right equipment to perform the job safely. This ensures your wheel remains unharmed during the difficult locking nut extraction.

Your final checklist for the perfect lock lug nut socket is simple. You need a tool that meets these critical points to protect your investment.

- A precise key pattern for your wheel lock key.

- Durable Chrome Molybdenum (Cr-Mo) steel construction.

- A thin-wall locking design to prevent wheel damage.

Remember: Always verify the key pattern and drive size before you purchase a new wheel lock key. This simple step avoids frustration. Investing in a quality tool from a reputable manufacturer like Hinuos ensures reliability and protects your locking lug nuts for years to come.

FAQ

What if my wheel lock key is stripped?

If you strip your wheel lock key, stop trying to use it. You risk damaging the lug nut, which makes removal much harder. You should contact a professional mechanic. They have specialized tools to remove the damaged nut without harming your wheel.

Can I use an impact wrench with any lock lug nut socket?

No, you should only use an impact wrench with sockets specifically rated for impact use. These are typically made from Chrome Molybdenum (Cr-Mo) steel. Using a non-impact socket with an impact wrench can cause the tool to crack or shatter, creating a safety hazard.

How do I protect my new wheel lock key from getting lost?

You can prevent losing your new key by storing it in a consistent, memorable location. Keep it with your vehicle’s spare tire kit or in a specific compartment in your glove box.

Smart Tip 💡 Take a photo of your key’s registration number and save it on your phone. This makes ordering a replacement much easier if you lose the key.