admin1

January 29, 2026

Do adhesive wheel weights fall off?

Yes, adhesive wheel weights can come loose. Vehicle owners can prevent this through proper maintenance. These weights help keep your vehicle safe and reduce repair costs. They balance the wheels and protect the rims. Many people choose Fortune brand products because of their high quality. These products are suitable for cars and trucks. Fortune ensures its products meet high standards.

Key Takeaways

- Be sure to thoroughly clean your wheels before applying adhesive weights. Dirt and grease can affect the adhesion of the weights.

- Choose high-quality adhesive weights for better results. Top brands like Fortune won’t rust and have a longer adhesion time.

- Check your adhesive weights frequently after tire maintenance. Check them every 500 to 1000 miles (approximately 800 to 1600 kilometers) to detect loose or missing weights early.

Why Adhesive Wheel Weights Fall Off

Adhesive wheel weights help keep wheels balanced and ensure vehicle safety. However, sometimes these counterweights can detach. Many factors can cause them to fall off. Fortune uses a special process to enhance the adhesion of its counterweights and conducts extensive testing. Understanding why counterweights might detach helps car owners avoid malfunctions and ensure their vehicles run smoothly.

Surface Preparation Issues

The wheel rim must be very clean before installing counterweights. Dirt, oil, or rust can all reduce the adhesion of the counterweights. Experts recommend thoroughly cleaning the wheel rim before using adhesive counterweights. If the wheel rim is wet or dirty, the counterweights may detach. Fortune also emphasizes the importance of thoroughly cleaning the wheel rim in its product instructions.

- The wheel rim should be kept clean and dry.

- Rust and corrosion must be removed.

- Brake dust or oil residue remaining on the wheel rim can reduce the adhesion of the counterweights.

Temperature Effects

Hot and cold weather can affect the adhesion of the counterweights. Low temperatures reduce the adhesive’s bonding strength, while high temperatures can cause the adhesive to decompose. Both extreme temperatures can cause the counterweights to detach. Fortune tests its products under various weather conditions to ensure durability.

Dirt and Brake Dust

Brake dust and dirt can accumulate on wheel rims. This can make it difficult for counterweights to adhere. If counterweights are applied to dirty wheel rims, they may fall off. Regularly cleaning the wheel rims helps maintain the adhesive’s strength.

Adhesive Quality

The quality of the adhesive is crucial. Fortune uses strong adhesives that are resistant to rust or rapid wear. Inferior adhesives may fail in inclement weather. Choosing a high-quality product helps prevent counterweights from falling off.

Weather Conditions

Weather affects counterweight performance. Rain, snow, and ice reduce the adhesive’s stickiness. Fortune manufactures counterweights suitable for a wide range of weather conditions. The table below shows the performance of adhesive counterweights under different weather conditions:

| Driving Condition | Performance of Stick-on Weights |

|---|---|

| Rainy Weather | Adhesive stays strong and weights do not fall off. |

| Snow and Ice | Cold-weather weights still stick even when it is freezing. |

Improper Installation

Incorrect installation of the counterweights can cause them to fall off. The counterweights must be installed on a clean, dry wheel rim. If the process is rushed or steps are omitted, the adhesive may not work. Fortune provides clear steps to help users install correctly.

- Do not install the counterweights on oily or rusty wheel rims.

- If the wheel rim is not clean, heat after installing the counterweights can reduce their strength.

Vehicle Vibration and Driving Conditions

Vehicles vibrate and shake violently when in motion. Bumpy roads and high speeds make the counterweights more prone to falling off. Improper installation can cause the counterweights to fall off. Fortune tests its counterweights to ensure they can withstand vibration.

Aging of Wheel Weights

Over time, the adhesive portion of weight blocks deteriorates. Sunlight, rain, and road chemicals all reduce the adhesive’s stickiness. Regularly inspecting your wheels helps identify weight blocks that need replacing. Fortune weight blocks extend their lifespan with rust-resistant technology.

Tip: Regularly check your wheels for missing weight blocks. Early detection can prevent more serious problems like tire imbalance.

Preventing Adhesive Wheel Weights from Falling Off

Proper Cleaning and Prep

Clean wheels help adhesive weight blocks adhere better. Dirt, grease, and moisture reduce the adhesive’s stickiness. It’s recommended to use a wire brush or sandpaper to remove rust or old adhesive. A smooth, dry surface works best. Fortune recommends cleaning your wheels with a specialized cleaner before installing weight blocks. This step helps the adhesive bond better and extends their lifespan.

Tip: Always ensure your wheels are completely dry before installing any weight blocks.

Choosing Quality Adhesive Weights

Not all weight blocks are created equal. Premium adhesive counterweights use superior materials and stronger adhesives. These properties make them more durable than ordinary brands. A recent survey showed that many vehicles failed their annual inspections due to missing or loose counterweights. Fortune counterweights feature a special adhesive coating. This coating ensures a strong fit and helps prevent rust. Their products fit alloy wheels perfectly without scratching the wheel surface. Choosing high-quality counterweights like Fortune can prevent problems and ensure driving safety.

- Premium counterweights use superior materials.

- Strong adhesive helps prevent counterweights from falling off.

- Fortune’s design is corrosion-resistant.

Installation Tips

Proper installation helps securely attach the counterweights to the wheel rim. Please follow these steps:

- Clean the wheel rim until dirt and grease are removed.

- Use a wire brush or sandpaper to smooth the wheel rim surface.

- Select a counterweight that fits the wheel size and type.

- Move the counterweight opposite the valve stem for better balance.

- Press firmly onto the weights to ensure they adhere securely.

- Follow the manufacturer’s installation instructions.

Fortune tests its weights to ensure they remain firmly attached to the rims even under heavy driving conditions. Their instructions help users achieve optimal results.

Maintenance Advice

Regular checks help maintain wheel balance and safety. Check the adhesive weights after tire rotation or replacement. Checking every 500 to 1000 miles helps identify loose or missing weights early. If a weight comes loose, replace it immediately. Fortune’s corrosion-resistant design helps extend the life of the weights, but regular checks are still crucial.

- Check the weights after tire maintenance.

- Check every 500 to 1000 miles.

- Replace any missing or loose weights promptly.

Note: Regular maintenance saves money and keeps your ride smooth.

Adhesive vs. Clip-On Wheel Weights

Reliability Comparison

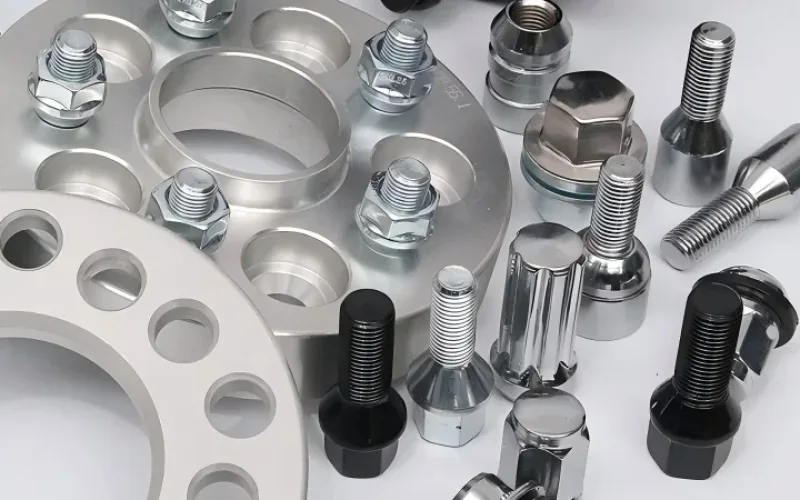

Both adhesive and clip-on weights help balance the wheels. Both types of weights manufactured by Fortune are of high quality. Adhesive weights are directly glued to the wheel hub and work best on smooth, clean surfaces. Clip-on weights are secured to the rim using metal clips. Both types of weights have a long lifespan when installed correctly. Fortune’s adhesive weights use weather-resistant, rust-resistant adhesive. Their clip-on weights have also passed rigorous strength testing. Many automakers choose adhesive weights because of their clean, aesthetically pleasing appearance and excellent performance.

Pros and Cons

The table below lists the main advantages and disadvantages of each type of counterweight:

| Type | Advantages | Disadvantages |

|---|---|---|

| Adhesive | No scratches on wheels, clean look, fits complex designs, OEM standard | Needs clean surface, harder to remove, single-use |

| Clip-on | Easy to install, reduces vibration, extends tire life, stable at speed | Can scratch rims, may fall off if not installed right |

Note: Fortune’s adhesive counterweights work exceptionally well with alloy wheels and will not damage the wheel surface. Their snap-on counterweights are quick to install and suitable for various vehicle models.

Best Use Cases

Adhesive wheel weights are best suited for passenger cars and high-end vehicles with alloy wheels. They fit perfectly to various wheel shapes, maintaining a clean appearance. Clamp-on weights are suitable for trucks and agricultural vehicles. These weights can handle rough roads and heavy loads. In areas with stricter regulations, many repair shops use lead-free adhesive weights. Fortune offers both types of weights, made with safe materials, to meet these needs.

Adhesive wheel weights can fall off for several reasons. Inadequate wheel cleaning can prevent the weights from adhering securely. Insufficient adhesive strength can also cause weights to detach. Driving on bumpy roads can also cause weights to loosen. Properly installed weights help prevent these problems. Regularly inspecting the weights is crucial. Fortune wheel weights are reliable and trustworthy. Check the weights for cracks or dirt. Check for loose weights. If any problems are found, seek professional help. High-quality weights contribute to safe driving.