admin1

July 24, 2025

What Are the Different Types of Tyre Valve Stem and Their Uses

You rely on the tyre valve stem every time you check or adjust air pressure in your tires. Most vehicles use tubeless rubber snap-in, high-pressure snap-in, or high-pressure metal clamp-in types. The Schrader valve, found on nearly all automobile tires, fits many tubeless systems. Each tyre valve stem handles specific pressure levels and fits certain rims. Picking the right tire valve stem ensures your tires hold air safely and match your vehicle’s needs.

What Is a Tyre Valve Stem?

Function and Importance

You might not notice the tyre valve stem every day, but it plays a vital role in your vehicle’s safety. The tyre valve stem acts as the entry and exit point for air in your tire. When you use a tire pressure gauge, you check the air inside through this small but essential part. The valve stem lets you add or release air, helping you keep the right tire pressure for safe driving.

A properly working tire valve stem keeps air from escaping. This helps your tires stay inflated at the correct level. Good tire pressure supports better handling, longer tire life, and improved fuel efficiency. If your tire valve stems fail, your tires can lose air quickly, which may lead to poor steering or even a flat tire. You depend on the valve stem to keep your tires safe and your vehicle running smoothly.

Note: Keeping your tire valve stems in good condition helps prevent sudden air loss and keeps your tires performing at their best.

How Tire Valve Stems Work

Tire valve stems use a simple but effective design. Each stem has a body, a core, and a cap. The valve core controls the airflow. When you press the core with a tire pressure gauge or air pump, air moves in or out. When you stop pressing, the core seals shut, trapping air inside the tire.

- Most valve stems are made from rubber or metal. Metal stems, such as those made from brass or stainless steel, resist corrosion and last longer.

- The valve cap adds another layer of protection. It keeps dirt and moisture out of the valve core.

- Some stems have anti-rotation features. These prevent twisting, which can cause leaks.

- High-quality rubber gaskets and reinforced stems help seal the air tightly, even under high pressure or extreme temperatures.

You should always make sure your valve stems are installed correctly and the caps are secure. This helps prevent air leaks and keeps your tires at the right pressure.

Main Tire Valve Stem Types and Their Uses

Tubeless Rubber Snap-In Valve Stems

You see tubeless rubber snap-in tire valves on most passenger cars, SUVs, and light trucks. These valve stems have become the standard for everyday vehicles because they are easy to install and cost-effective. You can find them in many sizes, usually ranging from 0.7 inches to 2.5 inches in length. They fit rim holes of either 0.453 inches or 0.625 inches in diameter, making them compatible with a wide range of wheels.

Tubeless rubber snap-in valves work best for tire pressures up to 65 PSI. This matches the needs of most passenger vehicles and light-duty trailers. You can spot these valves by their flexible rubber body and plastic or metal cap. Many drivers prefer them because you can replace them quickly during a tire change.

Tip: Always check that your tubeless rubber snap-in tire valve fits your rim size and pressure needs before installation.

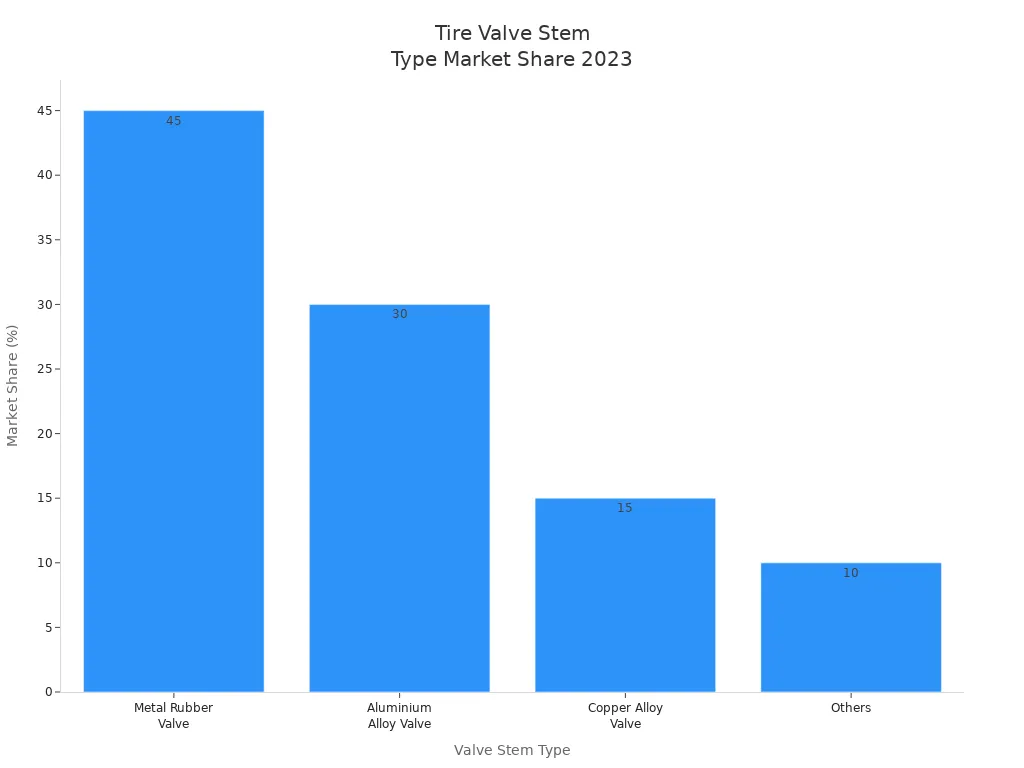

Here is a table showing the market share and usage details for different tire valve stem types:

| Tire Valve Stem Type | Market Share (2024) | Usage Details |

|---|---|---|

| Rubber Tire Valves | 72% (volume share) | Most widely used in passenger vehicles; includes tubeless rubber snap-in valves dominant in revenue; over 1 billion sold globally; favored for low cost and easy installation. |

| Metal Tire Valves (Schrader) | 28% (volume share) | Common in passenger vehicles, especially commercial and high-performance vehicles; about 400 million sold; superior pressure resistance and thermal tolerance. |

You will find that tubeless rubber snap-in tire valves dominate the market. Their popularity comes from their versatility, low cost, and ease of use. You can use them on most passenger cars, small to medium trucks, and SUVs. They provide a reliable seal for tubeless tires and help keep your tires properly inflated.

- Tubeless rubber snap-in tire valves are the most common type for passenger cars, light-duty trailers, and light trucks.

- They hold a maximum cold tire inflation pressure of 65 PSI.

- These valves often have plastic covers but can also feature chrome sleeves or metal caps for a stylish look.

High-Pressure Snap-In Valve Stems

When you need to handle higher tire pressures, you should look at high-pressure snap-in valves. These valve stems are designed for medium- to heavy-duty trucks and trailers. They can manage pressures up to 80 PSI for rim holes of 0.453 inches and up to 100 PSI for rim holes of 0.625 inches. The construction uses a thicker rubber base and a metal barrel, which helps them withstand greater stress.

| Rim Hole Size | Maximum Cold Inflation Pressure | Typical Applications | Valve Stem Features |

|---|---|---|---|

| 0.453″ | Up to 80 psi | Medium- to heavy-duty trucks, trailers | Thick rubber snap-in base, metal barrel, plastic pressure cap |

| 0.625″ | Up to 100 psi | Medium- to heavy-duty trucks, trailers | Thick rubber snap-in base, metal barrel, plastic pressure cap |

You will find tubeless snap-in high-pressure tire valves on vehicles that carry heavier loads or travel long distances. These valves give you extra strength and durability compared to standard rubber snap-in valve stems. They help prevent air leaks even when your tires face higher pressures and temperatures.

- High-pressure snap-in valves are ideal for medium- to heavy-duty trucks and trailers.

- Tubeless snap-in high-pressure tire valves fit rim holes of 0.453″ or 0.625″ and range from 1.25″ to 2″ in length.

- You should use these valves when your tires require more than 65 PSI but less than 100 PSI.

Note: Always match the valve stem’s pressure rating to your vehicle’s tire requirements for safety and performance.

High-Pressure Metal Clamp-In Valve Stems

For the highest levels of durability and leak prevention, you should consider high-pressure metal clamp-in tire valves. These valve stems use a metal body, often made from aluminum, brass, or stainless steel. You secure them to the wheel using a rubber grommet and a retaining nut, which creates a tight seal against the rim.

High-pressure metal clamp-in valves can handle tire pressures up to 200 PSI. This makes them the best choice for heavy-duty trucks, racing vehicles, and high-performance cars. Their metal construction resists heat, chemicals, and environmental stress much better than rubber snap-in valve stems.

| Feature | Metal Clamp-In Valve Stems | Snap-In Valve Stems |

|---|---|---|

| Material | Metal (aluminum, brass, stainless steel) | Rubber |

| Durability | High; resistant to heat, chemicals, and pressure | Lower; can wear out under extreme conditions |

| Pressure Capacity | Up to 200 psi; suitable for high-performance/racing | Up to 65 psi; suitable for standard vehicles |

| Leak Prevention | Better due to secure metal body and retaining nut | More prone to leaks over time |

| Typical Use | Heavy-duty, racing, high-performance vehicles | Standard passenger vehicles |

You will notice that high-pressure metal clamp-in tire valves offer better leak prevention. The retaining nut can be placed inside or outside the rim. If you place it outside, you can service the valve without removing the tire. This feature saves you time and effort during maintenance.

- High-pressure metal clamp-in valves use a rubber grommet and retaining nut for a secure fit.

- They are suitable for tire pressures up to 200 PSI.

- You should use these valves for heavy-duty, racing, or high-performance vehicles.

Tip: Choose high-pressure metal clamp-in tire valves when you need maximum durability and leak protection for demanding applications.

TPMS-Specific Valve Stems

You see tire pressure monitoring systems (TPMS) in almost every modern vehicle. These systems help you keep your tires at the right pressure by sending real-time data to your dashboard. TPMS-specific valve stems play a key role in this process. They connect directly to the sensors that measure your tire pressure.

When you choose a valve stem for a vehicle with TPMS, you must make sure it is compatible with the system. TPMS-compatible valve stems come in both rubber and metal designs. Many vehicles use a clamp-in valve stem for TPMS because it creates a secure seal and resists leaks, even at high speeds or under tough conditions.

You need to match the valve stem size to your rim hole. Most passenger vehicles use a 0.453-inch hole, while heavy-duty trucks use a 0.625-inch hole. The valve stem must also handle the tire’s pressure rating to prevent leaks or failure. Material choice matters, too. Metal stems, such as those made from brass or nickel, resist heat and corrosion better than rubber stems. This makes them a smart choice for vehicles that face high temperatures or heavy loads.

You should know that first-generation TPMS sensors often had problems with corrosion. Galvanic corrosion can happen when you use metallic valve caps with metal valve stems. This can cause the cap to seize and even break the stem, damaging the sensor. Using the wrong valve core, like a standard brass core instead of a nickel-coated one, can also harm the sensor and make repairs harder.

OEM TPMS sensors come with valve stems designed for a perfect fit. These stems use durable materials that resist corrosion and last through many inflation cycles. When you use the right TPMS-specific valve stem, you get accurate pressure readings and reliable performance from your tire pressure monitoring systems.

Tip: Always check your vehicle’s manual or consult a tire professional before replacing a TPMS valve stem. This helps you avoid sensor damage and keeps your tire pressure monitoring systems working correctly.

- TPMS-specific valve stems are essential for vehicles with tire pressure monitoring systems.

- You must use the correct size and material for your vehicle and driving conditions.

- Clamp-in valve stem for TPMS offers extra security and durability, especially for high-performance or heavy-duty vehicles.

Other Types of Valve Stems (Schrader, Presta, Dunlop)

You may come across different types of valve stems on bicycles, motorcycles, and some specialty vehicles. The three most common are Schrader, Presta, and Dunlop valves. Each type has a unique design and use.

Here is a table that compares these valve stems:

| Valve Type | Diameter | Pressure Tolerance | Typical Application | Key Design Features |

|---|---|---|---|---|

| Presta (Sclaverand/French) | 6.5 mm | Up to 15 bar | Sports bicycles (road bikes, mountain bikes) | Small diameter, lightweight, available in various lengths to fit rim height, high pressure tolerance |

| Schrader (American) | 8.5 mm | Up to 10 bar | Everyday and touring bikes | Larger diameter, robust construction, valve core hidden inside stem, compatible with car tire pumps, slightly heavier |

| Dunlop (Woods/English) | Standard size | Up to 6 bar | Many everyday bikes | Easy to handle and replace without tools, lower pressure tolerance, not suitable for road, gravel, or mountain bikes due to pressure limits and less accurate pressure adjustment |

You find the Schrader valve on most car tires and many bicycles. It has a sturdy design and works with standard air pumps. The valve core sits inside the stem, which protects it from dirt and damage. You can inflate Schrader valves at most gas stations.

Presta valves appear mostly on high-performance bicycles. They have a slimmer shape and can handle higher pressures. You often see them on road bikes and mountain bikes. Presta valves are lighter and fit narrow rims, making them popular for racing.

Dunlop valves, also called Woods or English valves, are common on everyday bikes in some countries. They are easy to use and replace, but they cannot handle high pressures. You should not use Dunlop valves for road or mountain bikes that need precise pressure control.

When you look at the different types of valve stems, you see that each one fits a specific need. Schrader valves work well for cars and general bikes. Presta valves suit high-pressure bicycle tires. Dunlop valves offer simplicity for basic bikes.

Note: Always choose the valve stem that matches your tire type and pressure needs. This helps you keep your tires safe and performing well.

Components of Different Types of Valve Stems

Valve Core

You will find the valve core inside every tire valve stem. This small but powerful part acts as the main seal that keeps air inside your tire. The valve core uses a spring-loaded pin and a rubber seal. When you press the pin, you can add or release air. Once you stop pressing, the pin pops back and seals the opening tightly. This design helps your tire hold air, even at high pressures up to 300 psi.

The valve core sits between the cap and the body of the valve stem. You must make sure it is screwed in tightly. If dirt or moisture gets inside, the seal can fail and cause air leaks. For aluminum sensor stems, nickel-plated valve cores work best because they resist corrosion.

Tip: Always check that your valve core is clean and secure to prevent air loss and keep your tires safe.

Valve Cap

The valve cap may look simple, but it plays a big role in protecting your tire valve. You screw the cap onto the end of the valve stem. It acts as a shield against dust, water, and road salt. These things can damage the valve core or cause it to stick.

Here are some key benefits of valve caps:

- Prevent dust, debris, and water from entering the valve stem

- Protect the valve core from corrosion and blockages

- Help maintain tire pressure by sealing the valve stem

- Extend the life of your valve stem, especially in wet or dirty conditions

Valve caps help keep your tires working well. You should always replace missing or damaged caps to avoid problems.

Valve Extensions and Adapters

Sometimes, you need extra help to reach the valve stem. Valve extensions and adapters make this possible. You use them when the valve stem sits in a hard-to-reach spot, like on dual wheels or deep rims.

| Type of Extension | Best Use Case | Material Options | Key Features |

|---|---|---|---|

| Threaded Extender | Easy access for low-to-medium pressure | Brass, PVC, Stainless Steel | Simple to install, cost-effective |

| Flanged Extender | High-pressure or high-torque systems | Stainless Steel, Carbon Steel | Leak-proof, rigid, stable |

Valve extensions improve safety and make tire maintenance easier. You should choose the right length, thread size, and material for your vehicle. Some extensions come with O-rings or locking nuts for a better seal. By using the right extension or adapter, you can check and inflate your tires without hassle.

Note: Valve extensions are especially helpful for trucks, RVs, and vehicles with dual wheels. They save time and reduce the risk of air leaks.

How to Choose the Right Tire Valve Stem

Matching Valve Stems to Vehicle Type

You need to match the valve stem to your vehicle for safety and performance. Different vehicles require different types of valve stems. Here are some important factors to consider:

- Snap-in valves are made of rubber. You can install them easily, and they work well for passenger cars and light trucks with tire pressures up to 65 PSI.

- Metal clamp-in valves use metal for extra strength. These valves handle higher pressures and suit high-performance vehicles, heavy-duty trucks, and harsh driving conditions.

- Snap-in valves offer flexibility but do not resist extreme temperatures or high pressure as well as metal clamp-in valves.

- Metal clamp-in valves resist heat, chemicals, and pressure better, which helps prevent leaks and failures.

- Snap-in valves push into the rim, while clamp-in valves need tightening with a wrench to a specific torque.

- Your choice depends on your vehicle type, driving conditions, and budget.

| Factor | Details and Considerations |

|---|---|

| Tire Inflation Pressure | Snap-in valve stems (e.g., TR413, TR415) suitable up to 65 psi; high-pressure snap-in (TR600HP, TR801HP) up to 100 psi; metal clamp-in stems up to 200 psi |

| Vehicle Type | Passenger cars and light trucks typically use snap-in valves; medium/heavy-duty trucks require high-pressure or metal clamp-in valves |

| Valve Stem Hole Size | TR600HP/TR602HP fit .453-inch holes; TR801HP/TR802HP fit .625-inch holes; snap-in stems not for holes thicker than .156 inches; clamp-in required if > .205 inches thickness |

| Environmental/Operational Conditions | High speeds and off-road use favor metal clamp-in stems for durability; metal valve extensions not recommended on snap-in stems due to risk of breakage |

| Installation and Maintenance | Snap-in stems require lubrication with non-petroleum lubricant; inspect valve hole for damage or buildup; clamp-in stems require specific torque (e.g., 24-45 in/lbs for TR416S) |

| Valve Stem Extensions | Only plastic extensions for snap-in high-pressure stems; metal extensions only for metal clamp-in stems, kept as short as possible |

Tip: Always check your vehicle’s manual to confirm the correct valve stem type for your wheels.

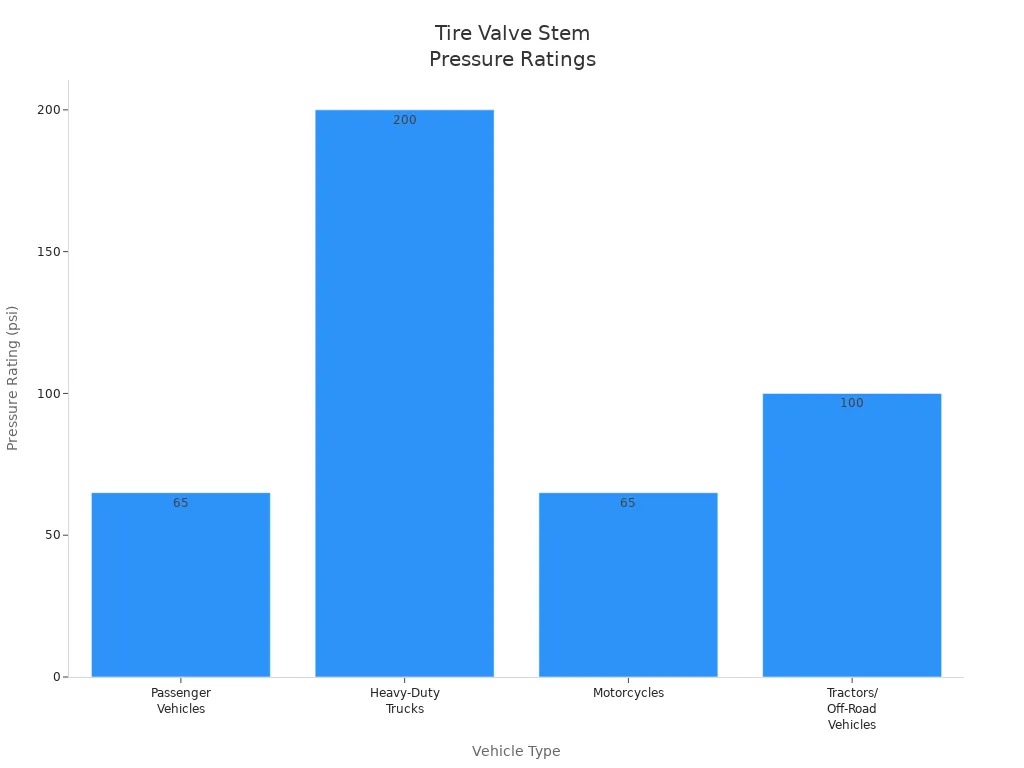

Pressure Ratings and Application

You must select a valve stem that matches your tire’s pressure needs. Using a valve stem with a low pressure rating can cause it to crack or fail, especially at high speeds or in hot weather. Always check the recommended psi levels for your tires before choosing a valve stem.

| Vehicle Type | Valve Stem Material | Pressure Rating (psi) | Reason/Notes |

|---|---|---|---|

| Passenger Vehicles | Rubber | Up to 65 | Standard use, sufficient for typical pressures |

| Heavy-Duty Trucks | Metal | Up to 200 | High pressure demands, durability required |

| Motorcycles | Rubber | Up to 65 | Lower pressure needs, standard rubber stems |

| Tractors/Off-Road Vehicles | Metal | 100 or more | High pressure and rugged conditions |

- Always match the valve stem’s pressure rating to your tire’s inflation needs.

- For higher pressure tires, use high-pressure snap-in or metal clamp-in valve stems.

- Use metal valve extensions only with metal valve stems to avoid failure.

Note: The right valve stem helps your tires hold air at the correct pressure and keeps you safe on the road.

TPMS Compatibility

If your vehicle uses tire pressure monitoring systems, you must choose a valve stem that works with the sensors. TPMS sensors come in one-piece and two-piece designs. For two-piece sensors, you should replace the valve stem and all related parts—like the grommet, retaining nut, valve core, and cap—whenever you remove the sensor. This prevents air leaks and protects the sensor.

Using a non-compatible valve stem with tire pressure monitoring systems can cause air leaks and damage the sensor. This may lead to system errors or even make the system stop working. If you do not follow the correct installation steps or use the right torque, you can also cause sensor malfunction. In some cases, using the wrong parts can break regulations and result in fines or liability.

Always use valve stems designed for your TPMS system. This keeps your tire pressure monitoring systems accurate and your vehicle safe.

Identifying and Replacing Valve Stems

You can keep your tires safe by learning how to spot and replace worn or damaged valve stems. A faulty valve stem can cause slow air leaks, flat tires, or even sudden tire failure. Here’s how you can identify and replace a bad valve stem:

How to Identify a Faulty Valve Stem

- Listen for a hissing sound near the valve stem. This noise often means air is escaping.

- Apply soapy water to the uncapped valve stem. If you see bubbles forming, you have a leak.

- Check the valve stem for cracks, brittleness, or signs of corrosion.

- Notice if your tire loses pressure more often than usual. Frequent air loss can signal a problem with the valve stem.

Tip: Always make sure the valve cap fits snugly. It keeps out dust and moisture, which helps prevent corrosion.

Steps to Replace a Valve Stem

You can follow these steps to safely replace a valve stem:

- Park your vehicle on a flat surface and use a jack to lift it. Remove the tire by loosening the lug nuts.

- Take out the valve core with a valve core removal tool. This will release all the air from the tire.

- Use a bead breaker or tire irons to separate the tire bead from the rim so you can reach the valve stem.

- Pull out the old valve stem from inside the wheel. If it is stuck, cut it carefully with pliers.

- Select a new valve stem that matches your wheel’s specifications.

- Insert the new valve stem through the hole in the rim and seat it firmly using a valve stem tool.

- Reseat the tire bead by inflating the tire until you hear it pop into place.

- Reinstall the valve core if it was removed earlier.

- Inflate the tire to the recommended pressure and check for leaks again with soapy water.

- Remount the tire and tighten the lug nuts securely.

You should always check your valve stems when you get new tires. Replacing a worn valve stem is simple and helps keep your tires in top condition.

Maintenance and Replacement Tips for Tire Valve Stems

Inspecting for Wear or Damage

You should check your tire valve stems regularly to keep your vehicle safe. Look for these common signs of wear or damage:

- Cracks on the valve stem, often caused by extreme temperatures, can lead to slow air loss or even sudden deflation.

- Damaged or missing valve caps allow dirt and moisture to enter, which may cause leaks or harm the valve core.

- Corrosion on metal parts, especially from road salt or moisture, weakens the valve and increases the risk of failure.

- Improper installation can cause poor sealing, leading to air leaks if the valve is not fully seated.

Regular inspections help you spot these problems early. By catching issues before they get worse, you prevent air leaks that can cause underinflated tires, poor handling, and even blowouts. Keeping valve caps secure also protects against dirt and moisture, which helps your tires last longer.

Tip: Make valve stem checks part of your monthly tire inspection routine for better safety and performance.

When and How to Replace Valve Stems

You should replace valve stems whenever you mount new tires. Many tire professionals recommend this practice because it helps avoid future leaks and keeps your tires in top shape. Some people only replace valve stems when they see obvious damage, but waiting can lead to unexpected problems.

Here are some best practices:

- Replace valve stems at every tire change or if you notice cracks, brittleness, or leaks.

- Inspect valve stems monthly, along with your tire tread.

- Always replace the entire assembly, including the cap, core, and stem, for the best results.

- If your vehicle uses a TPMS sensor, make sure to replace the valve stem with a compatible part.

Replacing valve stems during tire mounting is often cheaper and more convenient than waiting until problems appear.

Preventing Leaks and Ensuring Longevity

You can prevent air leaks and extend the life of your valve stems by following a few simple steps:

- Inspect valve stems for cracks or brittleness, especially before long trips.

- Use valve caps to keep out dirt and moisture.

- Clean valve stems regularly, especially in winter, to prevent corrosion.

- Park in shaded areas or use valve stem covers to protect against UV damage.

- Have professionals install valve stems or use proper tools to ensure a tight seal.

- Replace worn valve cores if you adjust tire pressure often.

Regularly checking the tightness of your valve stems and replacing them when needed helps maintain proper tire pressure. This improves fuel efficiency, steering, and braking, making your drive safer and smoother. Always keep valve caps on to protect your investment and enjoy longer-lasting tires.

You have learned about four main types of tire valve stems: tubeless rubber snap-in, high-pressure snap-in, high-pressure metal clamp-in, and TPMS-specific stems. Each type fits different vehicles and pressure needs. Choosing the right valve stem helps prevent air loss, protects sensors, and keeps your tires safe.

- Regularly check valve stems for cracks or leaks.

- Keep valve caps on to block dirt and moisture.

- Replace stems every 4 to 6 years or with new tires.

Fortune tests every valve stem for leaks and meets ISO 9001 standards, so you can trust their products for lasting safety and performance.

FAQ

What is the most common type of tire valve stem?

You will find tubeless rubber snap-in valve stems on most passenger cars and light trucks. These stems are easy to install and cost-effective. They fit most standard wheels and handle pressures up to 65 PSI.

How often should you replace tire valve stems?

You should replace valve stems every time you get new tires. If you see cracks, leaks, or corrosion, change them right away. Most experts recommend replacing valve stems every 4 to 6 years for safety.

Can you use metal valve stems on any vehicle?

You can use metal valve stems on many vehicles, especially heavy-duty trucks and high-performance cars. These stems handle higher pressures and resist heat. Always check your vehicle’s manual to make sure metal stems fit your wheels.

What happens if a valve stem leaks?

A leaking valve stem lets air escape from your tire. This can cause underinflation, poor handling, and even a flat tire. You should fix or replace a leaking valve stem as soon as possible to stay safe.

Are all valve stems compatible with TPMS sensors?

Not all valve stems work with TPMS sensors. You must use TPMS-compatible stems for vehicles with tire pressure monitoring systems. Using the wrong stem can damage the sensor or cause system errors.

Tip: Always match your valve stem type to your vehicle’s needs for the best performance and safety.