admin1

August 12, 2025

A Complete Guide to Rim Valve Stem Choices for Car Owners

Choosing the right rim valve stem for your car helps you keep your tire safe and working well. You need to think about your vehicle type, wheel material, and how you drive. Most drivers use rubber snap-in valve stems for regular tires. If you want better performance or have special wheels, you should look at metal or bolt-in valve stem options. Picking the best rim valve stem gives you good air pressure and helps your tires last longer.

- Rubber snap-in valve stems work for daily driving.

- Metal or bolt-in valve stems give extra strength for high-speed or heavy-duty use.

Tip: Always check your valve stem when you inspect your tires. This simple step boosts safety and performance.

Rim Valve Stem Types Explained

When you choose a rim valve stem, you need to know the main types. Each type fits different vehicles and driving needs. The table below shows the most common types, their uses, and important details:

| Valve Stem Type | Typical Applications | Max Inflation Pressure (PSI) | Hole Diameter in Rim (Inch) | Effective Length Range (Inch) | Industry Valve Number Examples |

|---|---|---|---|---|---|

| Rubber Snap-In (Tubeless) | Passenger cars, light trucks, autocross | Up to 65 | 0.453 or 0.625 | 0.88 to 2.5 | 412, 413, 414, 415, 418, 423, 425 |

| High-Pressure Snap-In (Tubeless) | Medium/heavy trucks, trailers | 80 (0.453 hole), 100 (0.625) | 0.453 or 0.625 | ~1.25 to 2 | 600HP, 602HP, 801HP, 802HP |

| High-Pressure Metal Clamp-In | Any wheel, racing, high-speed applications | Up to 200 | 0.453, 0.625, 6mm, 8mm | Flush to 2 | Various (600HP series and others) |

Snap-In Rubber Valve Stems

You will find snap-in rubber valve stems on most passenger cars and light trucks. These stems use strong rubber, such as butyl or EPDM, which resists air leaks, ozone, and weather. The metal parts inside are usually brass or stainless steel for extra strength. Most snap-in rubber stems fit a 0.453-inch rim hole and handle up to 65 PSI. They come in sizes like 8mm or 10mm and usually measure about 70mm long. This length makes it easy for you to check tire pressure and fill air. These stems work well for daily driving and regular tire maintenance.

| Characteristic | Details |

|---|---|

| Material Composition | Butyl, Nitrile, EPDM rubber; Brass or Stainless Steel core |

| Pressure Rating | 35 to 65 PSI |

| Compatibility | Passenger cars, light trucks, standard rim hole sizes |

| Additional Properties | Ozone, weather, and chemical resistance |

Tip: Snap-in rubber stems are easy to install and replace. Always check for cracks or leaks during tire checks.

Bolt-In Metal Valve Stems

Bolt-in metal valve stems give you extra strength and durability. You often see these on high-performance cars, racing vehicles, or heavy-duty trucks. Metal stems use a clamp and nut to hold the stem tightly in the rim. This design helps prevent leaks, even at high speeds or pressures up to 200 PSI. Metal stems do not wear out as fast as rubber stems, especially if you use tire pressure sensors. You can tighten the nut from outside the wheel, so you do not need to remove the tire for maintenance. Metal stems come in many sizes and shapes, such as straight or bent, to fit different wheels.

- Metal stems last longer and resist vibration.

- They are best for high-speed, high-pressure, or heavy-duty use.

- Some tire pressure monitoring systems (TPMS) need special stems, so always check compatibility.

High-Pressure Valve Stems

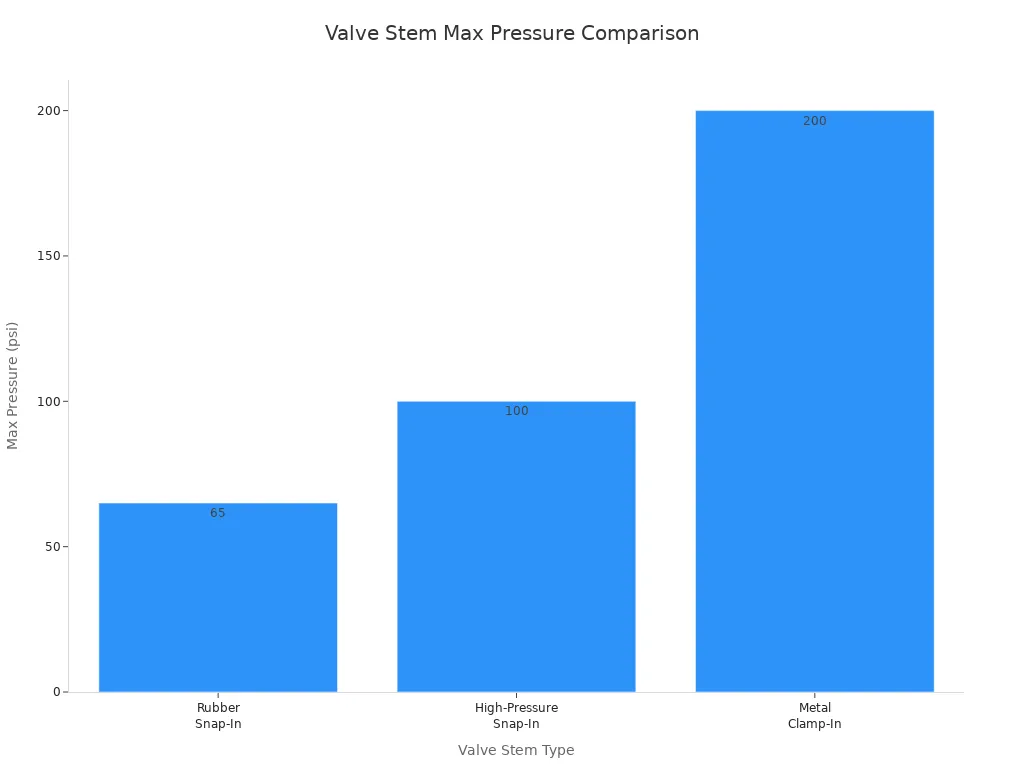

High-pressure valve stems are built for vehicles that need more than 65 PSI, such as trucks, RVs, or racing cars. These stems use brass or stainless steel and often have a clamp-in design for a tight seal. You can see the difference in the chart below, which shows how much pressure each type can handle:

High-pressure snap-in stems can handle up to 80 PSI, while metal clamp-in stems go up to 200 PSI. These stems help prevent air leaks and keep your tires safe, even under tough conditions.

Note: Always choose a rim valve stem that matches your vehicle’s pressure needs. Using the right type keeps your tires safe and helps them last longer.

TPMS-Compatible Valve Stems

If your car uses a tire pressure monitoring system (TPMS), you need a special type of valve stem. TPMS-compatible valve stems work with sensors that check your tire pressure and send data to your dashboard. These valve stems look different from regular ones and have unique features.

You will find two main types of TPMS valve stems:

- Metal clamp-in valve stems

- Rubber snap-in valve stems

Both types hold the sensor inside the tire and help send pressure data. Metal clamp-in stems give you more strength and are better for heavy-duty or high-pressure tires. Rubber snap-in stems work well for lighter vehicles and standard sensors.

TPMS valve stems have special designs:

- Longer valve caps and a beveled brass base help fit the sensor.

- Nickel-plated valve cores prevent corrosion and protect the aluminum barrel.

- Each stem matches a specific vehicle make, model, and year. Standard valve stems do not have this feature.

- TPMS valve stems support sensor signals at 315 MHz or 434 MHz, depending on your car.

You must use the right valve stem for your TPMS sensor. If you use the wrong type, you might see air leaks or get false readings. Metal clamp-in valve stems are best for flow-through external sensors because they stay rigid and prevent leaks. Rubber snap-in stems can flex and may not work well with heavy sensors.

Here is a quick comparison:

| Feature | TPMS-Compatible Valve Stem | Standard Valve Stem |

|---|---|---|

| Sensor Integration | Yes | No |

| Material | Nickel-plated core, brass | Rubber, brass |

| Frequency Support | 315/434 MHz | None |

| Vehicle Specificity | Yes | Universal |

| Corrosion Protection | High | Moderate |

Tip: Always check your valve stem type before installing TPMS sensors. Using the correct stem keeps your tire pressure readings accurate and helps prevent leaks.

If you drive an RV or trailer, upgrade to metal clamp-in valve stems before adding external TPMS sensors. This step gives you better safety and reliability.

Valve Stem Features and Benefits

Durability and Lifespan

When you choose a valve stem, you want it to last and keep your tire safe. Most valve stems use either synthetic rubber or brass metal. Rubber valve stems are easier to install and work well for passenger cars. Over time, sunlight, heat, and moisture can cause rubber to crack and wear out. You should replace rubber valve stems every 2 to 3 years, usually when you change your tires. Metal valve stems, often made from brass, last longer and resist damage from high temperatures and pressure. These can last up to 8 years if you check them for corrosion and keep them clean. Both types can suffer from physical damage, so regular inspection helps you catch problems early.

| Material | Common Type | Installation Ease | Durability | Corrosion Resistance | Lifespan |

|---|---|---|---|---|---|

| Rubber | Synthetic rubber | Easier to install | Less durable, prone to wear | Less susceptible to corrosion | Shorter lifespan, wears out over time |

| Metal | Brass | More difficult to install, may require special tools | More durable, robust material | Can corrode over time | Longer lifespan, up to 10 years |

Air Pressure Ratings and Handling

Valve stems play a key role in keeping tire pressure steady. The type of valve stem and its sealing base affect how well your tire holds air. Brass stems are strong and resist corrosion, making them ideal for heavy-duty use. Aluminum stems are lighter and work well for cars that need less weight. The seal design matters too. Round rubber bases give basic sealing, but molded grommets fit better and help prevent leaks. Removable valve cores let you add sealant or replace the core, which improves maintenance and reduces slow leaks. Always make sure your valve stem fits your rim and matches your tire pressure needs. Tubeless valve stems offer an air-tight seal and work best for tires without inner tubes.

1. Tubeless rubber snap-in valve stem: Good for cars and light trucks, handles up to 65 psi, basic sealing. 2. Tubeless snap-in high-pressure valve stem: Used for trucks, supports higher pressure, has thicker rubber and metal parts. 3. High-pressure metal clamp-in valve stem: Best for heavy-duty vehicles, gives strong sealing and durability.

Tip: Replace valve stems when you mount new tires to keep air pressure stable and prevent leaks.

Compatibility with Wheel Materials

You need to match your valve stem to your wheel material for the best fit and performance. Rubber valve stems work well with steel and alloy wheels that have standard rim holes. Metal valve stems are better for specialty wheels, racing rims, or wheels that face tough conditions. Some wheels need a specific sealing base to create a proper seal and avoid leaks. Tubeless setups require valve stems that fit tightly and support sealant use. If you use a tire pressure monitoring system (TPMS), make sure your valve stem is compatible with the sensor and rim design.

Note: Choosing the right valve stem for your wheel material helps prevent leaks and supports long-term tire performance.

Rim Valve Stem Pros and Cons Comparison

Snap-In vs. Bolt-In

When you choose between snap-in and bolt-in valve stems, you need to think about how you use your car. Snap-in valve stems use rubber and fit easily into the rim hole. You can install them quickly without special tools. Many drivers like snap-in stems for daily use because they work well for regular cars and light trucks. User reviews for high-pressure snap-in stems show a satisfaction rate of 98%. These stems handle up to 100 psi and fit larger wheels, such as those on heavy-duty trailers.

Bolt-in valve stems use metal and a nut to hold the stem tightly in place. You get better durability and higher pressure ratings, up to 200 psi. Bolt-in stems work best for racing, high-speed driving, or heavy-duty vehicles. You can adjust the tightness without removing the tire. This makes bolt-in stems a good choice for specialty wheels.

| Valve Stem Type | Max Pressure (psi) | Typical Applications | Installation & Features |

|---|---|---|---|

| Rubber Snap-In | Up to 65 | Passenger cars, light trucks | Easy snap-in, fits standard rim holes |

| High-Pressure Snap-In | Up to 100 | Medium/heavy trucks, trailers | Thicker rubber, metal barrel, fits larger rim holes |

| Metal Bolt-In | Up to 200 | Racing, high-speed, specialty | Nut-tightened, fits various sizes, adjustable without tire removal |

Tip: If you want easy installation and good performance for daily driving, snap-in stems work well. For high pressure and durability, bolt-in stems are the better choice.

Rubber vs. Metal

Rubber and metal valve stems have different strengths. Rubber stems use synthetic materials like neoprene or nitrile. You get excellent corrosion resistance and good sealing, especially in dusty or wet environments. Rubber stems are flexible and easy to install. They work best for regular driving and light trucks.

Metal valve stems use alloys such as carbon steel or stainless steel. These stems need surface treatments like chrome or nickel plating to resist corrosion. Metal stems are stronger and last longer in high-stress or high-temperature conditions. You need to match the treatment to your environment for the best results.

| Aspect | Rubber Valve Stems | Metal Valve Stems |

|---|---|---|

| Material | Synthetic rubber (neoprene, nitrile) | Carbon steel, stainless steel, surface treated |

| Corrosion Resistance | Excellent | Enhanced by plating or treatments |

| Environmental Resist. | Good in dusty, wet areas | Depends on treatment, strong in harsh conditions |

| Mechanical Strength | Flexible, less heat resistant | Strong, handles stress and heat |

| Application Limits | Best for daily use, lower pressure | Best for high pressure, racing, specialty wheels |

Note: Rubber stems give you easy installation and good sealing. Metal stems offer strength and durability for tough jobs.

High-Pressure vs. Standard

High-pressure valve stems and standard valve stems serve different needs. High-pressure metal stems last longer and keep a tight seal, even with tire pressure monitoring systems (TPMS). You can reuse metal stems when you change tires. They need regular care to prevent rust. Installation is more complex and may require special tools.

Standard rubber valve stems are easier to install and remove. They resist corrosion and need less maintenance. Rubber stems flex more, which helps with off-road driving and daily use. You need to replace them when you change tires because they wear out faster.

| Aspect | Metal Valve Stems (High-Pressure) | Rubber Valve Stems (Standard) |

|---|---|---|

| Durability | Long-lasting, reusable | Wears out, replace with tires |

| Seal & Pressure | Tight seal, stable pressure | Flexible, may leak with TPMS |

| Maintenance | Needs regular care | Low maintenance |

| Installation | More complex, special tools needed | Simple, easy with basic tools |

| Flexibility | Less flexible, can break on impact | More flexible, good for daily driving |

| Cost | Higher | Lower |

| Usage Recommendation | Best for reliability, high pressure | Best for ease, flexibility, daily driving |

- Metal stems give you better pressure stability and last longer.

- Rubber stems are easier to use and cost less, but you need to replace them more often.

Tip: Choose high-pressure metal stems for heavy-duty or racing needs. Use standard rubber stems for everyday driving and easy maintenance.

Valve Stem Selection Guide

Choosing the right valve stem for your car or truck keeps your tires safe and helps them last longer. You need to look at your vehicle type, how you drive, and the design of your wheels. This guide gives you clear valve stem selection tips so you can make the best choice for your needs.

Matching Valve Stems to Vehicle Type

You should always match the valve stem to your vehicle type. Passenger cars and light trucks usually use snap-in rubber valve stems. These work well for tire pressures up to 65 PSI. They are easy to install and cost less. Heavy-duty trucks, SUVs, and high-performance cars need more durable options. Metal clamp-in valve stems handle higher pressures and last longer. They resist heat and tough conditions.

Here is a table to help you compare the main factors for each type:

| Factor | Snap-In Valves | Metal Clamp-In Valves |

|---|---|---|

| Material | Rubber | Metal (aluminum, brass, stainless steel) |

| Installation | Easy, push-in without special tools | Requires wrench, nut tightened to secure |

| Durability | Flexible but less durable, can wear out | More durable, resistant to heat and environment |

| Pressure Capacity | Up to 65 PSI | Handles higher pressures (>65 PSI) |

| Suitable Vehicles | Passenger cars, light trucks, trailers | Heavy-duty trucks, SUVs, high-performance cars |

| Cost | Less expensive, cost-effective | More expensive but offers long-term value |

When you follow these valve stem selection tips, you make sure your tire stays safe and holds air well. Proper valve stem selection gives you the best performance for your vehicle.

Tip: Always check your owner’s manual or ask a tire professional if you are unsure about the right valve stem for your car or truck.

Considering Driving Conditions

Your driving habits play a big role in valve stem selection. If you drive mostly in the city or on smooth roads, standard snap-in rubber valve stems work well. For frequent highway driving, you need valve stems that can handle higher speeds and pressures. High-pressure snap-in or metal clamp-in valve stems prevent sudden air loss at high speeds.

If you drive off-road, you need a valve stem that supports frequent inflation and deflation. Durable stems help you manage tire pressure when you air down for rough terrain and reinflate for pavement. Metal valve stems work best with metal valve extensions, especially at high speeds. This pairing prevents failures that can happen with rubber stems and metal extensions.

You should always think about your driving conditions before making a selection. These valve stem selection tips help you avoid problems and keep your tires working their best.

Note: For mixed driving or extreme conditions, choose a valve stem that matches the highest pressure and toughest environment you expect to face.

Wheel Material and Rim Hole Size

The wheel material and rim hole size affect your valve stem selection. You need a secure fit to keep air in and prevent leaks. Most passenger cars use a .453″ rim hole. Heavy-duty trucks and commercial vehicles often use a .625″ (16mm) hole. Specialty tires may use a .390″ (9.7mm) hole.

Follow these steps for proper valve stem selection:

- Identify your rim hole diameter. Common sizes are .390″, .453″, or .625″.

- Check your wheel material. Steel and alloy wheels usually work with rubber snap-in valve stems. Custom or specialty wheels may need metal clamp-in stems for a tight seal.

- For metal clamp-in TPMS valve stems, always use new seals and nuts. Tighten the nut to the correct torque, usually between 35 and 80 in.-lbs.

- For snap-in rubber valve stems, use approved tire lubricant on the seating surfaces. Avoid petroleum-based greases.

- Never reuse valve stem nuts or self-tapping screws. Old parts can cause leaks or damage.

- For custom wheels, check the rim hole size and shape. Some custom rims do not match standard sizes, so you need to verify the fit for a tubeless tire or TPMS sensor.

You should also consider the material of the valve stem. Rubber, brass, and nickel stems each have different strengths. Choose the one that matches your vehicle and wheel design.

Tip: Always double-check the fit before installing a new valve stem. A secure fit keeps your tire safe and helps your tubeless tire hold air longer.

By following these valve stem selection tips, you make sure your tire, wheel, and valve stem work together for the best safety and performance.

Installation Tips for Rim Valve Stems

DIY Installation Steps

You can install rim valve stems at home if you have the right tools and follow each step carefully. Start by gathering a valve stem tool, a bead breaker, a torque wrench, and a clean, lint-free cloth. Always work in a clean area to avoid dirt getting into your tire or valve.

Here are the main steps for a successful DIY installation:

- Remove the Tire: Use a bead breaker to separate the tire from the rim. This step gives you access to the valve stem hole.

- Clean the Area: Wipe the rim and valve stem hole with a dry, lint-free cloth. Dirt or debris can cause leaks.

- Inspect the Valve Stem: Check for cracks, bent cores, or worn threads. Replace any damaged stems before you continue.

- Insert the New Valve Stem: Push the stem through the rim hole until it seats firmly. Use a valve stem tool for a snug fit.

- Install TPMS Sensors (if needed): Attach the sensor to the valve stem. Do not over-tighten. Use a torque wrench and follow the manufacturer’s torque settings.

- Re-seat the Tire Bead: Carefully re-seat the tire on the rim.

- Inflate the Tire: Fill the tire to the recommended pressure. Check for leaks by spraying soapy water around the valve stem.

- Test Drive: After installation, take a short drive and check the tire pressure again to make sure everything works well.

⚠️ Common mistakes to avoid:

When to Seek Professional Help

Sometimes, you should let a professional handle valve stem installation. Here are situations where expert help is best:

- You need to break and re-seat the tire bead, which requires special tools and skill.

- You do not have the right equipment or feel unsure about the process.

- You want to make sure the valve stem is torqued and sealed correctly to prevent leaks or corrosion.

- You have expensive wheels, such as aluminum rims with O-ring seals, which need precise torque (usually 80 to 125 inch-pounds).

- You want to protect your investment, as professional installation usually costs $10 to $30 and helps avoid costly mistakes.

Professional installers use the right tools and follow strict procedures. They check for leaks, apply the correct torque, and ensure a proper seal. This service gives you peace of mind, especially if you have specialty wheels or a tire pressure monitoring system.

💡 Tip: If you are not confident or lack the proper tools, professional installation is a smart choice. It helps keep your tires safe and your wheels in top condition.

Valve Stem Maintenance and Replacement

Signs of Wear or Damage

You need to check your valve stems often to catch early signs of trouble. Watch for these common warning signs:

- Air escaping when you press or wiggle the valve stem

- Visible cracks or splits on the valve stem surface

- Corrosion or looseness around the base of the valve stem

- Gradual air loss of 1-3 psi per month

- Missing valve caps, which let dirt and moisture enter

- Frequent TPMS warning lights that do not go away after inflating your tires

If you notice any of these issues, you may have a leak or a damaged seal. Frequent air leaks often happen when valve stems become brittle or corroded. Missing caps can also lead to valve stem leaks by letting debris inside. Chemical exposure and over-tightening can damage the stem and cause sudden air loss.

Tip: If your TPMS light keeps coming on, even after you add air, check the valve stem for slow leaks.

Replacement Frequency

You should replace your valve stems every time you get new tires. Rubber valve stems usually last 2 to 3 years, while metal stems can last up to 8 years if you keep them clean and free from corrosion. High mileage, heat, and aging can cause the material to harden or crack, which weakens the seal and increases the risk of leaks. If you drive in harsh conditions or notice any signs of damage, replace the valve stem sooner to prevent failures.

| Valve Stem Type | Typical Lifespan | Replacement Tip |

|---|---|---|

| Rubber | 2-3 years | Replace with every tire change |

| Metal | Up to 8 years | Inspect for corrosion yearly |

Preventing Leaks and Failures

You can prevent leaks and valve stem failures by following a regular maintenance routine. Here are some steps you should take:

- Inspect valve stems, seals, and caps for wear, cracks, or corrosion.

- Clean the valve area with a rag or brush to remove dirt and buildup.

- Use manufacturer-recommended lubricants to keep the stem and sealing surfaces in good condition.

- Make sure you install valve stems correctly and tighten them to the right torque.

- Replace missing or damaged valve caps to keep out moisture and debris.

- Operate your vehicle within the recommended pressure limits to avoid stressing the valve stem.

- Keep spare valve stems and caps in your emergency kit for quick repairs.

By keeping up with these maintenance steps, you reduce the risk of valve stem leaks and sudden air loss. Regular cleaning and inspection help you spot problems early and prevent failures before they happen.

Note: A clean, well-sealed valve stem keeps your tire pressure steady and your ride safe.

Choosing the right rim valve stem boosts safety and helps your tires last longer. You protect your wheels when you inspect valve stems and replace them on time.

- Valve caps and stems block dirt and moisture, stopping air leaks.

- Early detection of damage prevents uneven wear and tire failure.

- Trusted brands like Fortune use strong materials and strict quality checks.

- Warranty support and technical help show product reliability.

Regular care keeps your tires performing well and gives you peace of mind.

FAQ

What is the best valve stem for daily driving?

You should use a snap-in rubber valve stem for daily driving. This type fits most passenger cars and light trucks. It handles up to 65 PSI and resists weather and ozone. You can install it easily without special tools.

How often should you replace valve stems?

You need to replace rubber valve stems every 2 to 3 years or with every tire change. Metal valve stems last up to 8 years. Regular inspection helps you spot cracks or corrosion early.

Tip: Check valve stems during every tire rotation for signs of wear.

Can you reuse metal valve stems?

You can reuse metal valve stems if they show no signs of corrosion or damage. Always replace seals and nuts during installation. Inspect the stem for leaks before reusing.

| Metal Stem | Reusable | Replace Seals/Nuts |

|---|---|---|

| Yes | If undamaged | Always |

Do valve stems affect tire pressure?

Valve stems keep air inside your tire. A damaged or loose stem causes slow leaks. You should check for air loss monthly. Proper valve stem choice helps maintain steady tire pressure.

- Damaged stem: Air leaks

- Good stem: Stable pressure

Are TPMS valve stems different from standard ones?

TPMS valve stems have special designs for sensors. You must use the correct type for your vehicle’s system. TPMS stems support sensor signals and prevent leaks. Standard stems do not work with TPMS sensors.

Note: Always match TPMS valve stems to your car’s make and model.