admin1

July 17, 2025

Your Step-by-Step Guide to Picking Metal Valve Stems

Picking the right tire valve stem for your vehicle can feel tricky, but you can avoid headaches with a few smart moves. Many people run into trouble by choosing the wrong pressure rating or skipping a check on rim hole size. Sometimes, over-tightening a sensor or installing on a dirty surface leads to leaks and shortens the life of your tire valve. If you want the best results, always match your right tire valve stem to your car’s needs and double-check for a proper fit. Metal valve stems offer strength and safety, especially when you use them the right way.

What to Consider When Choosing a Tire Valve

When you start looking for a new tire valve stem, you want to make sure it fits your vehicle and driving needs. There are a few important things to keep in mind. Let’s break down what to consider when choosing a tire valve so you can make the best choice for your wheels.

Compatibility with Your Vehicle and Wheels

You can’t just grab any tire valve stem and expect it to work. Your vehicle and wheels have their own requirements. Here’s what you should check:

- Material and Durability: Choose brass, steel, or aluminum stems for long-lasting use. These materials handle tough conditions and resist corrosion.

- Stem Finish: Smooth finishes help reduce friction and wear. Some stems have special coatings like chrome plating or DLC for extra durability.

- Valve Length and Seat Fit: Make sure the stem length matches your wheel design. If it’s too short or too long, you might have trouble getting a good seal.

- Concentricity and Machining Quality: A well-made stem seals better and lasts longer. Look for precise machining and a snug fit.

- Valve Stem Type: Some vehicles need snap-in stems, while others use clamp-in stems. Check your owner’s manual or ask a professional if you’re not sure.

- Seal Quality: High-quality rubber gaskets help prevent leaks and keep your tires safe.

- Professional Guidance: When in doubt, talk to a tire expert or check your vehicle manual.

Tip: Always match the tire valve stem to your specific vehicle model and wheel type. This helps avoid leaks and keeps your tires performing at their best.

Pressure Rating and Temperature Needs

Not all tire valve stems are built for the same job. You need to think about pressure ratings and how your tires will be used. Here’s a quick look at the recommended pressure ratings for different vehicles:

| Vehicle Type | Recommended Valve Stem Type | Pressure Rating (psi) |

|---|---|---|

| Passenger Cars | Standard Rubber Valve Stem | Up to 65 |

| Heavy-Duty Trucks | Metal Valve Stem | Up to 200 |

| Motorcycles | Rubber Valve Stem | Up to 65 |

| Tractors/Off-Road | High-Pressure Metal Stem | 100 or more |

If you drive a heavy-duty truck or use your vehicle for towing, you need a tire valve stem that can handle higher pressure ratings. Some high-pressure metal stems can go up to 200 psi. For most passenger cars, a standard stem rated up to 65 psi works fine.

Temperature also matters. Metal valve stems work better in extreme heat or cold. Traditional rubber seals can get hard and brittle in freezing weather or lose their seal in high heat. Metal seals stay strong from freezing cold to scorching hot, so you don’t have to worry about leaks.

- Metal seals keep air in, even when temperatures swing from -423°F to over 2,000°F.

- They last longer and need less maintenance in tough conditions.

Note: Always check the pressure ratings on your tire valve stem before installing. Using the wrong stem can lead to leaks or even blowouts.

TPMS and Rim Hole Size Requirements

Modern vehicles often use a Tire Pressure Monitoring System (TPMS). If your car has TPMS, you need a tire valve stem that works with the sensors. Here’s what you should know:

- Material: Brass and nickel-plated stems are best for TPMS. They resist corrosion and handle high heat.

- Sensor Compatibility: The stem must fit the TPMS sensor so you get accurate tire pressure readings.

- Pressure Ratings: Make sure the stem can handle the pressure your tires need.

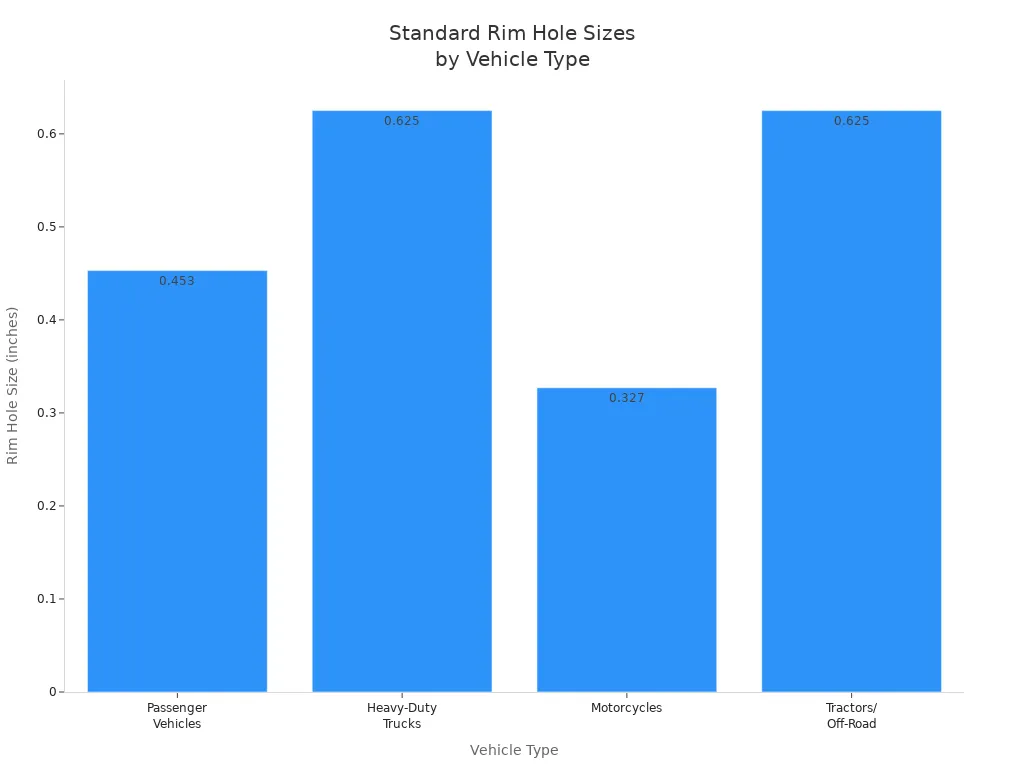

- Rim Hole Diameters: The stem must match the rim hole size for a tight fit. Common rim hole diameters are 0.453 inches for passenger vehicles and 0.625 inches for heavy-duty trucks. Specialty vehicles may use other sizes.

- Proper Installation: Use the right tools to avoid damaging the sensor or stem.

Here’s a quick guide to standard rim hole diameters and their impact:

| Vehicle Type | Standard Rim Hole Sizes (inches) | Notes on Fitment Impact |

|---|---|---|

| Passenger Vehicles | 0.453, 0.625 | Correct size prevents air leaks and ensures tire safety |

| Heavy-Duty Trucks | 0.625 | Larger holes fit heavy-duty metal valve stems |

| Motorcycles | ~0.327 | Smaller holes for specialized stems |

| Tractors/Off-Road | ~0.625 | Common size for rugged applications |

If you use the wrong size, you risk leaks or sensor problems. Always double-check rim hole diameters before buying a new tire valve stem.

Why Metal Valve Stems Matter

Benefits Over Rubber Tire Valve Stems

When you look at tire valve stems, you might wonder why so many experts recommend metal over rubber. The answer comes down to how each type stands up to real-world driving. Rubber stems break down over time. Heat from your brakes, cold winter mornings, and even road grime all speed up the process. You might see cracks or even leaks after a few years. That’s not something you want when you’re counting on your tires.

Metal valve stems give you a big advantage. Here’s why drivers and technicians choose them:

- They handle much higher pressures—up to 200 psi—so they work well for trucks, trailers, and high-speed cars.

- Metal stems resist heat, so you don’t have to worry about them failing after a long drive or a day at the track.

- You can check and tighten the retaining nut without removing the tire, making maintenance easier.

- Most metal stems use rubber grommets for a tight seal, but the metal body lasts much longer.

- Metal valve caps with rubber washers keep air in, even when things get hot.

If you want a tire valve stem that lasts and keeps your tires safe, metal is the way to go.

Durability and Safety in Harsh Conditions

You face all kinds of weather and road conditions. That’s where the importance of tire valve really shows. Metal valve stems stand up to harsh environments better than rubber. Take a look at how they compare:

| Feature | Metal Valve Stems | Rubber Valve Stems |

|---|---|---|

| Material Composition | Brass, stainless steel | Rubber |

| Strength and Durability | Superior, withstands extreme strain | Prone to wear and cracking |

| Corrosion Resistance | High, even with chemicals and salt | Prone to ozone and UV damage |

| Pressure Capacity | Up to 200 psi | Up to 65 psi |

| Heat Dissipation | Excellent, safe for high speeds | Lower, risk of failure in heat |

| Safety Impact | Reduces risk of sudden deflation | Higher risk of leaks and failure |

Drivers who switch to all-metal stems notice fewer leaks and better performance, even after years of use. If you drive in snow, rain, or on rough roads, you want a valve stem that won’t crack or corrode. Metal options, especially those made from brass or stainless steel, keep your tires secure and your ride safe.

Types of Metal Valve Stems

When you start looking at the different types of tire valves, you’ll see that not all metal valve stems are the same. Each type has its own strengths and best uses. Let’s break down the main options so you can pick the right one for your wheels.

Brass, Nickel-Plated, and Stainless Steel Options

You’ll find three main materials when shopping for metal valve stems: brass, nickel-plated, and stainless steel. Each one brings something different to the table.

Here’s a quick comparison to help you see the differences:

| Performance Attribute | Brass Valve Stems | Stainless Steel Valve Stems |

|---|---|---|

| Corrosion Resistance | Moderate; can corrode in salty or harsh environments | High; resists rust, even with chemicals or salt |

| Durability | Good for everyday use and moderate pressure | Excellent for high pressure and tough jobs |

| Temperature Tolerance | Handles normal temps, not great for extremes | Stays strong in very hot or cold conditions |

| Cost | Lower; budget-friendly | Higher; costs more but lasts longer |

| Suitability | Cars, light trucks, non-corrosive places | Marine, chemical, high-pressure, and harsh areas |

Brass valve stems work well for most cars and light trucks. They’re easy to install and cost less. If you drive in places with lots of salt or chemicals, you might want to choose stainless steel. Stainless steel valve stems last longer and fight off rust, even in the worst weather. Nickel-plated stems add another layer of protection, especially if you use aluminum wheels or need to prevent corrosion around sensors.

Tip: If you want the best protection against rust and extreme weather, stainless steel is your go-to choice.

High-Pressure and Clamp-In Metal Valve Stems

Some vehicles need extra-strong valve stems. That’s where high-pressure metal stems and clamp-in designs come in. You’ll see these on trucks, racecars, and vehicles that carry heavy loads.

Here’s why drivers pick these tough valve stems:

- Clamp-in stems use a rubber grommet and a nut to lock them in place. This design keeps air in, even at high speeds.

- They handle tire pressures up to 200 psi, which is much higher than regular stems.

- You can use them on wheels with different hole sizes, like 0.453″ or 0.625″.

- They stand up to heat, vibration, and rough roads.

- These stems work great with tire pressure monitoring systems (TPMS).

- You’ll find them on high-speed cars, heavy-duty trucks, and off-road vehicles.

Here’s a table showing some popular types and where you might use them:

| Type of Metal Valve Stem | Key Features | Typical Applications |

|---|---|---|

| High-Pressure Metal Clamp-in Valve | Rubber grommet, fits 0.453″/0.625″ holes, straight or bent, up to 200 psi, inside/outside nut | Racing, high-speed, heavy-duty vehicles |

| Metal Clamp-in Valve Stem for TPMS | Holds TPMS sensor, nickel-plated core, prevents corrosion | Cars with direct TPMS sensors |

| Metal Valve Stem Extensions | Metal extenders, 0.5″ to 2″, tough for harsh conditions | Trucks, vehicles with wheel covers |

You want high-pressure metal stems if you drive fast, haul heavy loads, or need extra safety. These stems keep your tires sealed tight, even when the road gets rough.

Note: Always check your tire’s pressure rating before picking a valve stem. Using the right stem keeps you safe and your tires in top shape.

Angled and Specialty Tire Valve Stems

Sometimes, you need a valve stem that’s not straight. Angled and specialty stems make it easier to reach the valve, especially on big trucks or motorcycles.

Here’s a look at when you might need these special stems:

| Valve Stem Type | Typical Vehicle Use | Reason for Necessity |

|---|---|---|

| 45-Degree Angled Stem | Heavy-duty trucks | Easier to reach the valve |

| 90-Degree Angled Stem | Motorcycles, off-road vehicles | Fits in tight spots where straight stems won’t |

| Specialty Valve Stems | Trucks, tractors, off-road | Handles different pressures, rim sizes, and temps |

If you have a wheel that’s hard to reach, an angled stem can save you time and hassle. Specialty stems also help if your vehicle needs a certain pressure or has a unique rim design.

Pro Tip: Always match the angle and size of your valve stem to your wheel. This makes checking and filling your tires much easier.

Checking Tire Valve Stem Fit and Compatibility

Matching Valve Stem Length and Diameter

When you pick new tire valve stems, you want to make sure they match your wheels perfectly. The length and diameter of the stem matter more than you might think. If you choose the wrong size, you could end up with air leaks or even a sudden flat. That’s not something you want on the road.

Valve stem hole diameters in wheel rims usually come in three main sizes: 8mm (for some small cars and motorcycles), 11.5mm (0.453″, which is the most common for cars), and 16mm (0.635″, often found on tractors). Each size matches a specific type of tire valve stem, like TR4 or TR11. You need to match the stem type and size to your rim hole for a proper fit. If you use the wrong diameter, the stem might not seal well, and you could lose air.

Here’s a quick look at the key measurements you should check:

| Measurement Aspect | Details / Values |

|---|---|

| Hole diameter in wheel rim | 8mm, 11.5mm (0.453″), 16mm (0.635″) |

| Valve stem lengths | From flush to 2″, depending on your wheel and needs |

| Valve stem type | TR4, TR6, TR11, TR13, TR15 (based on rim and use) |

| Sealing mechanism | Rubber grommet with metal clamp-in stems |

If you pick a stem that’s too short, you might struggle to check or fill your tires. If it’s too long, it could get damaged or break off. Always measure your rim hole and check your owner’s manual before buying.

Tip: Use a soap and water mix on the valve stem after installation. If you see bubbles, you have a leak and need to check the fit.

Ensuring Proper Fit for Rim Depth and Design

Every wheel has its own shape and depth. Some rims are thick, while others are thin or have unique designs. You need to make sure your tire valve stems fit the rim depth and style. If the stem doesn’t sit right, you might get leaks or damage the stem over time.

Metal valve stems, especially clamp-in types, use a rubber grommet and a nut to create a tight seal. This setup works well for most rim designs, but you still need to double-check the fit. If your rim is extra deep or has a special shape, you might need a longer stem or a bent design.

Incorrect fit can cause problems. If the stem is loose, air can escape. If it’s too tight or at the wrong angle, it might wear out faster. Always match the stem to your rim’s depth and design for the best results.

Remember: A proper fit keeps your tires safe and helps them last longer. Take a few minutes to measure and check before you install new stems.

Quality and Durability in Metal Valve Stems

Material Quality and Corrosion Resistance

When you pick a valve stem, you want it to last. The material makes a big difference in how well it stands up to weather, road salt, and even water. Some metals fight off rust and corrosion better than others. Here’s what you should know:

- Stainless steel, especially grades 304 and 316, gives you excellent corrosion resistance. Grade 316 works even better if you drive near the ocean or in places with lots of salt.

- Brass and bronze work well for most cars and trucks. Brass costs less, but it can wear out faster in tough conditions.

- Special alloys like Monel K500, Alloy 718, and titanium Grade 5 offer top-notch strength and corrosion resistance. You’ll see these in really harsh or offshore environments.

If you want your valve stems to last for years, stainless steel and special alloys are your best bet. They keep working even when the weather gets rough or the roads get salty.

Tip: Stainless steel valve stems are a smart choice if you want less maintenance and more peace of mind.

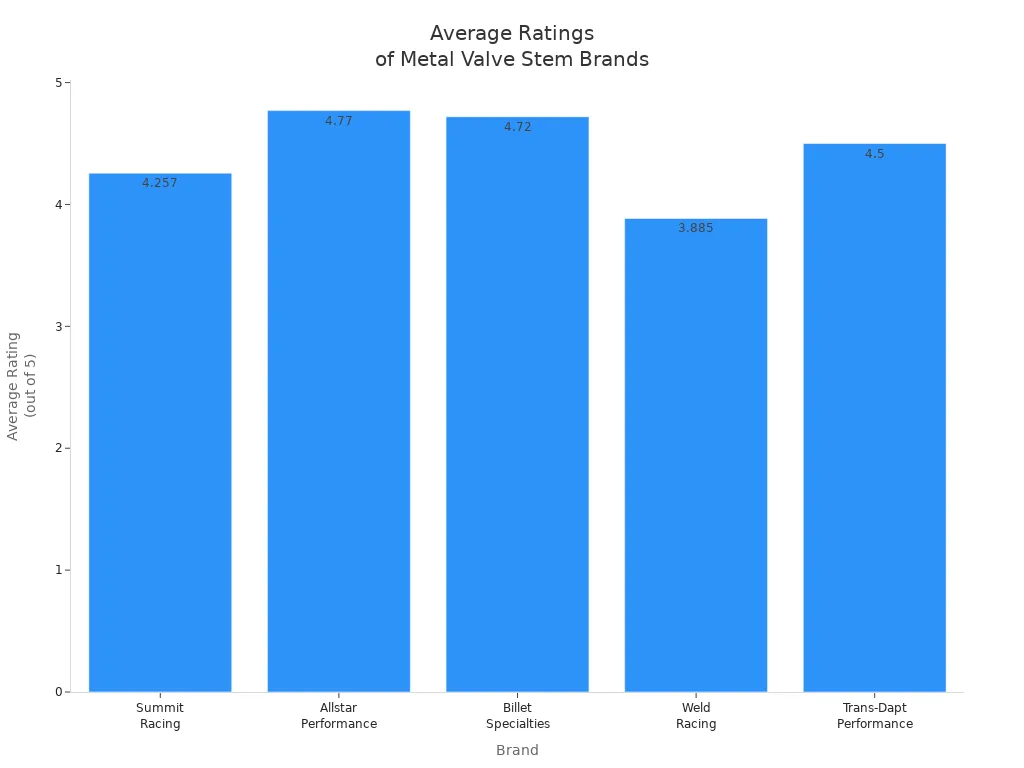

Brand Reputation, Certification, and Warranty

You want to trust the parts you put on your car. That’s why it helps to look at brands with a strong reputation for quality. Some brands stand out for their reliable products and high ratings:

| Brand | Material(s) | Product Example | Rating (out of 5) | Notes |

|---|---|---|---|---|

| Summit Racing | Steel, Chrome Plated | SUM-755536 (Set of 4) | 3.6 | Bolt-on, steel valve stems |

| Allstar Performance | Brass/Stainless Steel | ALL44134 (Each) | 4.77 | Bolt-on, brass valve stems |

| Billet Specialties | Steel, Chrome | 999900 (Set of 4) | 4.72 | Bolt-on, steel valve stems |

| Weld Racing | Steel, Chrome Plated | P613-0350 (Set of 5) | 4.27 | Bolt-on, steel valve stems |

| Trans-Dapt Performance | Chrome | 4108 | 4.5 | Chrome valve stems |

When you shop for metal valve stems, check for certifications. Look for SAE J1205 and J1206 standards. These show the valve stems passed tests for quality and durability. You should also see if the manufacturer has ISO9001 or QS9000 certification. This means they follow strict rules for making and checking their products.

Always pick valve stems from brands that show their logo and country of origin. This helps you avoid low-quality parts and gives you more confidence in your purchase.

If you want extra peace of mind, look for a good warranty. Trusted brands often back their products with strong guarantees, so you know you’re covered if something goes wrong.

Installation Tips for Metal Valve Stems

Getting ready to install metal valve stems? You want the job done right the first time. Here are some practical installation tips to help you avoid leaks and keep your tires safe.

Preparing for Installation

Before you start, gather your tools and check your parts. Make sure you have the correct valve stems for your wheels. Clean the valve hole on the rim. Dirt or debris can stop the stem from sealing well. Inspect the rim for any nicks, burrs, or corrosion. If you see rough spots, smooth them out with a file or sandpaper. Always choose the shortest valve stem that fits your wheel. Shorter stems bend less and lose less air. If you are replacing tire valve stems, check the old ones for cracks or signs of wear. This helps you spot problems before they cause trouble.

Tip: Always use a self-sealing valve cap. It keeps air in, even if the valve core leaks a little.

Proper Installation Steps for Tire Valve Stems

Follow these steps to install your new metal valve stems:

- Thread the OE-style metal valve stem into the wheel’s valve hole by hand.

- Tighten the stem steadily. You might feel some resistance before it seats fully.

- Keep tightening until the breakaway locking flange snaps free.

- Once the flange breaks, the stem will seat and seal against the rim.

- The broken flange acts as a thread locker, so the stem stays tight while you drive.

- Use a torque wrench to tighten the stem to 35 in-lbs (4 Nm). This ensures a secure, leak-free fit.

If you are replacing tire valve stems on a vehicle with TPMS, deflate and remove the tire first. This prevents damage to the sensor.

Post-Installation Safety Checks

After you finish, take a few minutes to check your work. Make sure the valve core is clean and free of dirt. Do not overtighten the core, or you could damage the seal. Inspect the area around the valve stem for corrosion, especially on alloy wheels. Replace seals or stems if you see rust or pitting. Use a soap and water solution to check for leaks—bubbles mean you need to reseat the stem. Confirm that the valve stem matches your wheel and vehicle type. Professionals recommend checking valve stems for cracks or leaks during every tire service. Using plastic valve caps can help prevent corrosion and make it easier to add air later.

Remember: Careful installation and regular checks keep your tires safe and your ride smooth.

Summary Checklist for Choosing Metal Valve Stems

Picking the right metal valve stem can feel like a lot, but you can make it simple with a good checklist. Here’s a handy table to help you remember the most important things to check before you buy or install a new valve stem:

| Checklist Item | Details / Recommendations |

|---|---|

| Pressure Ratings | Match the valve stem’s pressure rating to your tire’s needs. Metal stems work for high pressures, up to 200 psi. |

| Rim Hole Diameter | Make sure the valve stem fits your rim hole. For example, 0.625 inches is common for heavy-duty trucks. |

| Temperature Ratings | Metal valve stems handle extreme temperatures, from -65°F to 250°F. Great for tough jobs. |

| Proper Fit | A good fit stops leaks and blowouts. Use size charts or your manual to double-check. |

| Inspection Criteria | Check for corrosion, cracks, or leaks. Use soapy water to spot leaks after installation. |

| Installation Tips | Use the right tools, don’t over-tighten, and make sure the stem sits flat on the rim. |

Want to make sure you get it right every time? Follow these steps:

- Always use metal valve stems with metal extensions. This keeps them strong under weight and speed.

- Never use rubber stems with metal extensions. If you have rubber stems, stick with plastic extensions.

- Check your tire’s pressure needs. Pick a valve stem that matches or beats that rating.

- For high-pressure tires, choose high-pressure snap-in or clamp-in metal stems.

- Before you install, put a non-petroleum lubricant on the stem. This helps prevent damage.

- Look at the stem hole. Remove sharp edges, rust, or extra paint so you get a tight seal.

- After installing, test for leaks with soapy water. Watch for bubbles.

🛠️ A careful checklist keeps your tires safe and your ride smooth. Double-check each step, and you’ll avoid most common valve stem problems!

When to Seek Professional Help for Tire Valve Stems

Sometimes, you just need an expert. Metal valve stems might look simple, but installing them the wrong way can cause real trouble. If you feel unsure or run into problems, it’s smart to ask a professional for help.

You might wonder, “Why can’t I just do it myself?” Here’s what can go wrong if you don’t have the right tools or experience:

- Uneven pressure can build up if you don’t tighten the stem correctly. This can lead to slow leaks or even a sudden flat.

- If you misalign the valve stem during installation, you might see leaks or the stem could wear out much faster than normal.

- Using the wrong type of metal cap, especially with TPMS sensors, can cause electrolysis. This is a chemical reaction between different metals. Some car brands, like Acura, have seen this problem often.

- Electrolysis can damage your TPMS unit, which means you won’t get accurate tire pressure readings.

Tip: If your car has a Tire Pressure Monitoring System, always double-check that your valve stems and caps are compatible. This helps you avoid sensor problems down the road.

You should also call a pro if you notice any of these signs:

- Air keeps leaking from your tire, even after you install a new valve stem.

- The valve stem feels loose or wobbly.

- You see corrosion or white powder around the stem or cap.

- Your TPMS warning light stays on after you change the stem.

A tire shop or auto service center has the right tools and training. They can spot problems you might miss and make sure your valve stems work perfectly. You’ll drive away with peace of mind, knowing your tires are safe and ready for the road.

You now know how to pick and install the right metal valve stems for your vehicle. Regular checks keep your tires safe and your valve stems working well.

- Inspect your metal valve stems every month for cracks or leaks.

- Let a professional check them during every tire service.

- Keep plastic caps on and use a little silicone lubricant once a year.

If you ever feel unsure, reach out to a trusted expert or manufacturer like Fortune.

- Experts help you choose the best materials and size for your needs.

- They make sure installation is done right, so you avoid leaks and problems.

- You also get advice on keeping your valve stems in top shape for years.

FAQ

What makes metal valve stems better than rubber ones?

Metal valve stems last longer and handle higher pressure. You get better protection against heat, cold, and road salt. If you want fewer leaks and more safety, metal is the way to go.

How do I know if a metal valve stem fits my wheel?

Check your rim hole size and match it to the valve stem’s diameter. Most passenger cars use 0.453-inch holes. Heavy-duty trucks often use 0.625-inch holes. Always measure before you buy.

Can I use metal valve stems with TPMS sensors?

Yes, you can. Just make sure the metal valve stem is TPMS-compatible. Look for stems made from brass or nickel-plated materials. These resist corrosion and work well with sensors.

How often should I check or replace my metal valve stems?

You should inspect your valve stems every month. Look for cracks, leaks, or corrosion. Replace them if you see damage or during every tire change. Regular checks keep your tires safe.

Do I need special tools to install metal valve stems?

You need a torque wrench and a valve stem puller for the best results. These tools help you tighten the stem correctly and avoid leaks. If you feel unsure, ask a tire professional for help.