admin1

July 24, 2025

What You Need to Know About High Pressure Valve Stems

You rely on high pressure valve stems to keep your tires inflated and your vehicle running safely. These small parts handle higher air pressure than standard stems, which helps protect you from sudden air loss and supports strong tire performance. Choosing the proper fit for your vehicle prevents leaks and reduces the risk of tire damage. A high pressure valve stem plays a key role in your overall safety, so you should always select the right one for your needs.

High Pressure Valve Stems and Vehicle Safety

What Makes High Pressure Valve Stems Essential

You depend on high pressure valve stems to keep your tires safe and reliable. These valve stems handle much higher air pressure than standard ones. You often see them on heavy-duty trucks, commercial vehicles, and even some passenger cars that need extra strength. When you use the right tire valve stem, you help your tires hold air even under tough conditions.

Here are some reasons why high pressure valve stems are essential for your safety:

- They prevent sudden air loss, which can cause you to lose control of your vehicle or even lead to rollovers.

- Shorter valve stems reduce the risk of bending or breaking, which helps stop leaks.

- Durable materials like brass and high-temperature rubber grommets keep the valve working well, even when your tires get hot.

- Self-sealing valve stem caps add another layer of protection by keeping air in, even if the core leaks.

- Proper fit ensures the valve matches your wheel and vehicle type, which is key for vehicle safety.

- On vehicles with a tire pressure monitoring system (TPMS), careful handling of the valve stem prevents sensor damage and keeps your tire pressure readings accurate.

- Regular checks for corrosion around the valve stem hole, especially on alloy wheels, help you maintain a tight, leak-free seal.

High pressure valve stems are built to handle pressures from 65 PSI up to 200 PSI or more. This strength is vital for commercial trucks and heavy-duty vehicles. These stems keep your tire pressure steady, even when you carry heavy loads or drive at high speeds. By using quality tire valve stems that meet industry standards, you improve your vehicle’s stopping power and control. You also lower the risk of dangerous tire failures.

Risks of Using Incorrect Tire Valve Stems

Choosing the wrong tire valve can put you and your vehicle at risk. Incorrect stem selection can lead to leaks, air loss, and even tire blowouts. If you use a valve stem that cannot handle your tire’s pressure, you may face serious problems.

Here are some risks you should know:

- Using a valve stem not rated for your tire pressure can cause it to fail, leading to sudden air loss.

- Longer valve stems can bend or break more easily, which may result in leaks or total valve loss.

- Corrosion around the valve stem hole can weaken the seal, letting air escape and increasing the chance of tire failures.

- If you do not use the right valve stem for your TPMS, you might damage the sensor, which can stop you from getting accurate tire pressure alerts.

- Failing to check for cracks or missing valve caps can let dirt and moisture in, which may cause the valve to stick or leak.

- Not using a valve stem that matches your wheel size or type can lead to poor sealing and dangerous tire failures.

You should always select tire valve stems that match your tire’s pressure rating and your vehicle’s needs. Proper installation and regular checks help you avoid leaks and keep your tires performing at their best. By paying attention to these details, you protect yourself from dangerous tire failures and keep your vehicle running safely.

Types of Tire Valve Stems for High Pressure Applications

Metal vs. Rubber High Pressure Valve Stems

You will find two main types of high pressure tire valve stems: metal and rubber. Each type has unique strengths. Metal valve stems, such as brass valve stem or nickel valve stem, offer high durability and can handle extreme pressures. These stems often last for decades and resist corrosion. You can use them for heavy-duty trucks, racing vehicles, and any tire valve that needs to hold up to 200 PSI. Rubber valve stems, on the other hand, are flexible and cost-effective. They work well for medium-duty trucks and trailers, supporting pressures up to 100 PSI. However, rubber valve stems have a shorter lifespan and may not perform as well under heat or stress.

| Feature | Metal Valve Stems | Rubber Valve Stems |

|---|---|---|

| Pressure Tolerance | 150-200+ PSI | 60-100 PSI |

| Material | Brass, Steel, Nickel | Rubber, Brass Core |

| Lifespan | Decades, corrosion resistant | Shorter, can fail under stress |

| Application | Heavy-duty, racing, high pressure | Medium-duty, flexible, lower pressure |

Tip: For vehicles that run at high speeds or carry heavy loads, you should choose a metal tire valve stem for better safety and performance.

Snap-In and Clamp-In Valve Stem Designs

You can choose between snap-in and clamp-in designs for your tire valve stems. Snap-in rubber valve stems are easy to install and fit most medium to heavy-duty trucks and trailers. These stems support inflation pressures above 65 PSI and come in rim hole sizes of 0.453″ and 0.625″. Clamp-in metal valve stems use a rubber grommet and a retaining nut to create a tight seal against the wheel. You will see these on high-performance vehicles and racing cars, where tire valve pressure can reach up to 200 PSI. Clamp-in stems come in straight or bent styles, and you can position the retaining nut inside or outside the rim.

- Snap-in rubber valve stems: Best for quick installation and moderate pressure.

- Clamp-in metal valve stems: Best for high pressure, durability, and secure fit.

Specialty Valve Stems for Unique Vehicle Requirements

Some vehicles need specialty tire valve stems to handle unique pressures or harsh environments. High-pressure snap-in valves use a thick rubber base with a metal barrel. These work well for medium and heavy-duty trucks, supporting pressures up to 100 PSI. High-pressure metal clamp-in valves, made from materials like brass or nickel, can handle up to 200 PSI. You should use these for racing, high-performance vehicles, or trucks that face extreme conditions. Metal clamp-in valves resist heat, chemicals, and rough weather better than rubber types. If your vehicle operates in tough environments or needs extra pressure, a specialty tire valve stem will give you the best results.

Valve Stem Selection: How to Choose the Right Fit

Matching Valve Stems to Tire Pressure Ratings

You need to match your valve stem selection to your tire pressure requirements. Each tire has a recommended pressure range, and not every valve stem can handle high levels. If you use a stem that cannot support your tire pressure, you risk leaks or sudden air loss. This can lead to unsafe driving conditions.

Start by checking your vehicle’s recommended tire pressure. You can find this information in your owner’s manual or on the tire placard inside your door. Once you know the pressure, look for a right valve stem that meets or exceeds this rating. For example, heavy-duty trucks often need valve stems that can handle 100 PSI or more. Passenger cars may use stems rated for lower pressures.

Tip: Always choose a tire valve that matches your tire pressure considerations. This helps you avoid premature wear and keeps your tires performing at their best.

If you haul heavy loads or drive at high speeds, you should select a valve stem with a higher pressure rating. This ensures a proper fit and reduces the risk of air loss. Remember, choosing a tire valve that matches your needs is a key part of vehicle safety.

Ensuring Compatibility with Tire Pressure Monitoring System

You must also make sure your valve stem works with your tire pressure monitoring system (TPMS). This system checks your tire pressure and alerts you if it drops too low. Using the wrong valve stem can cause sensor errors or even damage the system.

Here are some important points to consider:

- Valve stem type TPMS sensors last longer and resist damage during tire changes better than strap-on sensors.

- Original metal valve stems attached to sensors are stronger than newer rubber valve stems, which can wear out faster and cost more to replace.

- The right valve stem material and compatibility help your sensors last longer and keep your tire pressure readings accurate.

- Corrosion on metal valve stems can harm TPMS sensors and reduce their reliability.

- Galvanic corrosion can cause metal valve caps to stick to valve stems, which may break the sensor.

- Replacing original nickel-coated valve cores with incompatible brass cores can cause them to seize and damage the sensor.

- If your valve stem does not fit your TPMS, you may get false readings or lose sensor function.

You should always check your TPMS requirements before you pick a valve stem. This helps you keep your system working well and ensures you get reliable tire pressure alerts.

Selecting the Best Material for Durability and Performance

The material of your valve stem affects how long it lasts and how well it performs. Different materials offer different levels of strength, corrosion resistance, and pressure tolerance. You want a right valve stem that fits your needs and stands up to tough conditions.

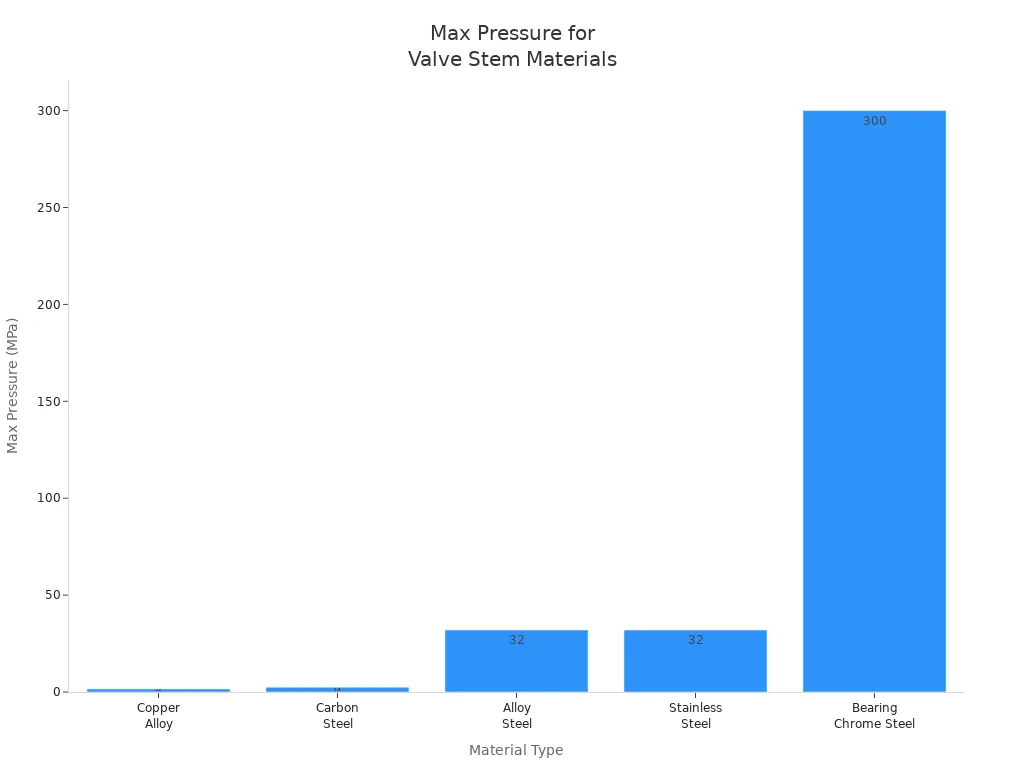

Here is a table showing common materials used for high pressure valve stems and their properties:

| Material Type | Typical Grades | Pressure Range (MPa) | Temperature Range (°C) | Durability Impact / Notes |

|---|---|---|---|---|

| Copper Alloy | QA19-2, HPb59-1-1 | ≤ 1.6 | ≤ 200 | Good for low pressure; limited strength and temperature tolerance. |

| Carbon Steel | A5, 35 | ≤ 2.5 | ≤ 450 | Needs surface treatment; not ideal for corrosion-prone areas. |

| Alloy Steel | 40Cr, 38CrMoA1A, 20CrMo1V1A | ≤ 32 (40Cr), 10-14 | ≤ 570 | High strength and temperature tolerance; surface treatments improve resistance. |

| Stainless Steel | 2Cr13, 3Cr13, 1Cr17Ni2, 1Cr18Ni12Mo2Ti | ≤ 32 (general), ≤ 6.4 (acid resistant) | ≤ 600 | Excellent corrosion resistance; nitriding improves scratch resistance; great for harsh environments. |

| Bearing Chrome Steel | GCr15 | ≤ 300 | ≤ 300 | Used for ultra-high pressure; high wear resistance and strength. |

You will find that 431 stainless steel is a popular choice for valve stems. This material offers high tensile strength, excellent corrosion resistance, and strong wear resistance. It can handle high pressure and harsh environments without bending or breaking. You also get good machinability, which means manufacturers can make precise valve components for a perfect fit.

When you focus on valve stem selection, always consider the material. Stainless steel and alloy steel work best for high pressure and tough conditions. Rubber and copper alloy may suit lower pressure needs, but they do not last as long in harsh environments.

Note: The best material for your valve stem depends on your vehicle, tire pressure, and driving conditions. Always check the manufacturer’s recommendations before making your choice.

Evaluating Quality and Brand Reputation

When you choose high pressure valve stems, you want to trust that they will last and keep your tires safe. Quality matters more than you might think. A high-quality valve stem can prevent leaks, resist harsh weather, and keep your tire pressure steady. You should always look for brands with a strong reputation for quality and reliability.

What to Look for in Quality

You can spot a high-quality valve stem by checking the materials and manufacturing standards. Leading brands often use strong metals like 410 stainless steel, 17-4 stainless, or 4130 alloy steel. Some even add special coatings, such as Xylan® or nitride hardening, to fight corrosion and wear. These features help the valve stem last longer, even in tough conditions. Brands like Valveworks USA test each stem carefully to make sure it meets strict standards. This attention to detail gives you peace of mind on the road.

Real-World Feedback

User experiences with high pressure valve stems can vary. Some drivers report that metal valve stems work perfectly for years. Others have seen metal stems fail and switch back to rubber types. Tire technicians sometimes notice more failures with metal stems than with rubber ones. Many people feel satisfied with certain brands and proper installation, but you will not find official ratings or direct brand comparisons. Most feedback comes from personal stories, not large studies.

- Some users never have problems with metal valve stems.

- Others see failures and prefer rubber stems.

- Tire experts sometimes see more issues with metal stems.

- Satisfaction depends on the brand and how well the stem is installed.

- No official customer satisfaction ratings exist for valve stems.

Tip: Always check reviews and ask your tire shop for advice. A trusted brand with a history of quality can make a big difference in your valve stem selection.

Cost vs. Quality: What You Pay For

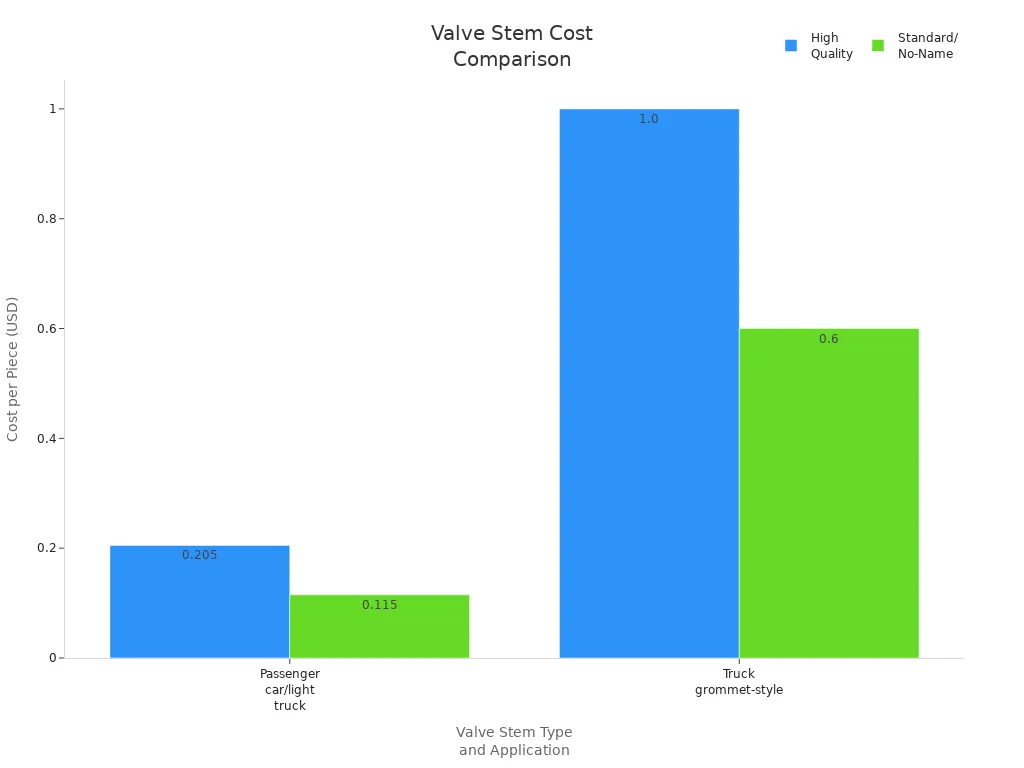

You might wonder if paying more for a high-quality valve stem is worth it. The answer is yes, especially for high pressure or heavy-duty use. High-quality valve stems use EPDM rubber, which stays flexible in cold weather and resists ozone and chemicals. Standard or no-name stems often use natural rubber, which can dry out and crack after about two years. This can lead to leaks and safety problems.

Here is a table that shows the differences:

| Aspect | High Quality Valve Stems | Standard/No-Name Valve Stems |

|---|---|---|

| Cost per piece (passenger car/light truck) | 16 to 25 cents | 11 to 12 cents |

| Cost per piece (truck grommet-style) | Around $1 | 60 cents or less |

| Material Used | EPDM rubber (synthetic, durable, ozone resistant) | Natural rubber (less durable, prone to drying and cracking) |

| Compliance | Meets SAE 1205-1206 ozone resistance standards | Does not meet SAE ozone resistance standards |

| Durability | Remains flexible in cold, resists ozone and chemical attack | Dries out and becomes brittle after ~2 years, leading to cracks and leaks |

| Safety and Reliability | Lower risk of failure, better long-term performance | Higher risk of failure, potential safety issues |

| Application Notes | Required for high pressure tires (>65 psi), heavy-duty trucks | Often unsuitable for high pressure or demanding applications |

You can also see the cost difference in this chart:

Paying a little more for quality now can save you money and trouble later. High-quality stems last longer and keep your tires safer. They also meet important industry standards, which means you can trust them for demanding jobs.

Brand Reputation Matters

You should always consider the brand when making your valve stem selection. Brands with a long history in the industry often have better quality control and more reliable products. They invest in better materials and test their products more carefully. This focus on quality helps you avoid problems down the road. When you choose a trusted brand, you get peace of mind and better performance for your vehicle.

Key Features of High Pressure Valve Stems

Durability and Corrosion Resistance

You want your tire valve to last, especially when you drive in tough conditions. High pressure valve stems stand out because they use strong materials like brass and aluminum. These metals resist rust and damage much better than rubber. You often see brass stems on heavy-duty trucks and commercial vehicles. Aluminum stems work well for racing and performance cars. Both types handle high speeds and rough weather.

Here is a quick comparison:

| Valve Stem Type | Corrosion Resistance | Durability | Typical Applications |

|---|---|---|---|

| Brass | High | High | Heavy-duty trucks, industrial equipment |

| Aluminum | Moderate to High | Moderate | Racing, performance cars, TPMS systems |

| Rubber | Low | Low | Standard passenger vehicles |

High pressure valve stems also use metal caps and nickel-plated cores. These features help prevent corrosion and keep the stem working longer. You get better protection against water, salt, and road chemicals.

Air Retention and Leak Prevention

You rely on your tire valve to keep air inside your tires. High pressure valve stems use thicker rubber bases and metal barrels to create a tight seal. Metal clamp-in designs use a rubber grommet and a retaining nut. This setup holds air even at pressures up to 200 psi. Standard rubber stems cannot match this level of performance.

Lab tests show that these stems pass strict air retention checks. Pneumatic testing uses air or nitrogen to find leaks. Experts measure how many bubbles escape per minute. High pressure stems meet tough standards, so you can trust them to keep your tires inflated. You avoid sudden air loss and keep your vehicle safe.

Tip: Always check your tire valve for leaks after installation. A good seal means better safety and longer tire life.

Installation Ease and Maintenance

You can install most high pressure valve stems with basic tools. Snap-in types push into place quickly. Clamp-in metal stems need a wrench to tighten the retaining nut. Both types fit different rim hole sizes and lengths, so you find the right match for your tire valve needs.

Maintenance stays simple. You should check for cracks, corrosion, or loose caps during regular tire checks. Metal caps protect the valve from dirt and moisture. Nickel-plated cores resist sticking and make removal easier. If you spot damage, replace the stem right away to avoid leaks.

Note: Regular inspection of your tire valve helps prevent problems before they start. Clean and replace parts as needed for the best results.

Installation and Maintenance Best Practices for Tire Valve Stems

Step-by-Step Installation Guide

You can achieve proper installation of a high pressure tire valve by following a clear process. This helps you avoid leaks and keeps your tires safe. Use these steps for correct installation:

- Apply Loctite to the threads of the upper stem and insert it into the pivot sleeve with a 3/8” wrench.

- Add grease inside the yoke assembly to block the hole at the bottom.

- Pour oil inside the yoke to cover the lower adjusting screw.

- Place the pivot on the lower adjusting screw with the bevel side facing up.

- Install the lower spring plate, spring, and upper spring plate. Grease the upper spring plate.

- Push the stem through the lower adjusting screw to install the diaphragm assembly.

- Replace the bonnet, making sure the pressure port and breather plug hole line up.

- Use the right wrenches to install bolts and lifting rings. Tighten bolts to 25-30 ft-lbs in a crisscross pattern. Do not overtighten.

- Place the O-ring on the upper adjustment screw, add grease, and thread it into the bonnet.

- Install the breather plug into the bottom pressure port with the hole facing the bonnet.

- Apply 30 psi of supply pressure to lower the stem.

- Attach the indicator tag and travel indicator onto the coupling block. Tighten bolts with a 7/16” socket.

Tip: Always double-check your work to ensure you have a secure fit. This helps you avoid problems when inflating tires.

Regular Inspection and Maintenance Tips

You keep your tire valve in top shape by following a regular inspection schedule. Industry guidelines recommend these practices:

- Inspect high pressure tire valves every six months. Look for leaks, cracks, or corrosion.

- Perform an annual pressure test to verify the valve’s set pressure.

- After any discharge event, check the valve for leaks and proper operation.

- Lift the test lever once a year to make sure the valve works.

- Clean, lubricate, and inspect the valve stem, packing, seals, and actuators.

- Follow local rules for disassembly, repair, and testing, which may require action every five years.

Regular tire maintenance and checking tire pressure help you spot issues early. This keeps your tires safe and extends their life.

Identifying Signs of Wear or Failure

You need to know when to replace valve stems to prevent tire problems. Watch for these signs of wear or failure:

- Fluid leaks from the tire valve or nearby hoses.

- Slower tire inflation or reduced system performance.

- Unusual noises like banging, hissing, or whining.

- Overheating, burnt smells, or discolored fluid near the valve.

- Water hammer or pressure surges when closing the valve.

- Loss of sealing ability, shown by leaks through the valve seat or shell.

- Inconsistent or disrupted air flow during inflating tires.

- Fragments or debris in the fluid, which may signal internal damage.

- Pipe leaks near valve joints.

If you notice any of these issues, replace valve stems right away. Good tire maintenance and maintaining proper tire pressure help you avoid sudden failures and keep your vehicle safe.

Ensuring Proper Fit and Avoiding Common Mistakes

Mistakes to Avoid in Valve Stem Selection

You want to make sure you choose the right valve stem for your tires. Picking the wrong type can lead to leaks, sensor problems, or even tire failures. Here are some mistakes you should avoid:

- Selecting a valve stem that does not match your tire’s pressure rating. This can cause the stem to fail under high pressure.

- Ignoring compatibility with your tire pressure monitoring system (TPMS). Some stems do not work with certain sensors.

- Overlooking the material. Using a stem made from the wrong material can lead to corrosion or early wear.

- Not checking the size. A stem that does not fit your wheel can cause air leaks.

- Forgetting to consider the environment. If you drive in harsh weather, you need a stem that resists corrosion.

Tip: Always check your vehicle manual and talk to a tire professional to ensure a proper fit for your needs.

Installation Errors and How to Prevent Them

Installing a valve stem the wrong way can cause leaks and shorten its life. You can prevent most problems by following best practices. Common installation errors include:

- Inadequate valve alignment, which strains the stem and causes leaks. Align the valve carefully with the wheel.

- Incorrect valve seat installation, leading to leaks and early wear. Make sure the seat is clean and installed with the right materials.

- Over-tightening or under-tightening connections. Use a torque wrench and follow the manufacturer’s specs.

- Failing to seal the valve properly. Use the correct sealing materials and check for a tight fit.

- Ignoring stem packing or lubrication. Replace worn packing and lubricate as recommended.

- Using the wrong direction or not checking seals. Always follow the flow direction and inspect seals for damage.

| Common Error | What Happens | How to Prevent |

|---|---|---|

| Over-tightening | Damages valve or wheel | Use correct torque |

| Under-tightening | Causes leaks | Tighten as recommended |

| Misalignment | Leads to leaks and wear | Align stem during installation |

| Ignoring temperature/pressure limits | Causes damage or safety risks | Check valve ratings |

Regular inspection and careful installation help you avoid these issues.

Preventing Air Loss and Tire Damage

You can keep your tires safe by taking a few simple steps. Regularly check your valve stems for cracks, corrosion, or missing caps. Replace any stem that looks damaged. Tighten the valve core if it feels loose, but do not overtighten. Always use a valve cap to keep out dirt and moisture. Schedule regular tire maintenance and ask a professional to inspect your valves. Monitor your tire pressure often to catch leaks early. Avoid using temporary fixes like sealants for long-term repairs.

Note: These habits help you prevent air loss and protect your tires from damage, reducing the risk of sudden tire failures on the road.

High pressure valve stems play a vital role in your vehicle’s safety and tire performance. When you choose the right stem, you help regulate tire pressure and prevent leaks or blowouts. To keep your tires reliable, follow these steps:

- Select stems rated for your tire’s pressure and match the material to your driving conditions.

- Use proper tools during installation and check for a secure fit.

- Inspect, clean, and lubricate valve stems regularly. Replace worn parts before leaks start.

By following these habits, you support long-term tire durability and safer driving.

FAQ

What is the main difference between high pressure and standard valve stems?

High pressure valve stems use stronger materials like brass or steel. These stems handle higher PSI levels, often up to 200 PSI. Standard stems usually support lower pressures and use more rubber. You need high pressure stems for trucks, trailers, or vehicles with heavy loads.

How often should you replace high pressure valve stems?

You should inspect valve stems every six months. Replace them if you see cracks, corrosion, or leaks. Most experts recommend changing valve stems whenever you replace your tires. This helps prevent air loss and keeps your tires safe.

Can you use high pressure valve stems on regular passenger cars?

You can use high pressure valve stems on passenger cars. These stems offer extra durability and better air retention. However, most passenger cars do not require them. Always check your vehicle’s tire pressure rating before making a switch.

Do high pressure valve stems work with tire pressure monitoring systems (TPMS)?

Many high pressure valve stems work with TPMS sensors. You must check for compatibility before installation. Using the wrong stem can damage the sensor or cause false readings. Always follow your vehicle manufacturer’s recommendations for TPMS and valve stem selection.

What are signs that a valve stem needs replacement?

Look for these signs:

- Cracks or splits in the rubber

- Corrosion on metal parts

- Air leaks around the base

- Loose or missing valve caps

Tip: Replace damaged valve stems right away to avoid sudden air loss and tire damage.