admin1

October 14, 2025

Choosing the Right Acorn Lug Nuts for Your Aluminum Rims

Your vehicle’s safety depends on the correct hardware. Choosing the right acorn lug nuts is a critical task. You must match three key factors: seat type, thread size, and material. Improperly secured wheels are a serious hazard. The NTSB reported that tire-related issues caused 612 fatalities in a single year. The right parts provide the necessary strength for a secure connection. This prevents wheel damage and keeps you safe on the road.

Note: Selecting the correct lug nuts acorn style is not just for looks; it is a crucial safety measure for your vehicle.

Why Acorn Lug Nuts Are Essential for Aluminum Wheels

Your aluminum wheels require specific hardware for a safe connection. The design of the lug nut is just as important as the wheel itself. Understanding why acorn lug nuts are the standard for most aftermarket wheels is the first step toward a secure installation.

The 60-Degree Conical Seat Explained

The “seat” is the surface of the lug nut that makes direct contact with the wheel. Acorn lug nuts feature a tapered, cone-shaped bottom. This design has a 60-degree angle. Most aftermarket aluminum wheels have matching 60-degree conical seats in their lug holes. This cone-in-cone fit creates the maximum possible surface contact between the nut and the wheel. A larger contact area distributes the clamping force evenly. This even pressure is essential for holding your wheel securely against the hub.

Risks of Using the Wrong Lug Nut Type

Using the wrong lug nut is a serious safety hazard. Your vehicle’s original hardware, or OEM lug nuts, might use a different seat style, such as a flat “mag” seat or a rounded “ball” seat. You must never use these on a wheel designed for a conical seat.

Warning: A mismatched seat creates a tiny, high-pressure contact point. This can cause the lug nuts to loosen over time, damage the wheel, or even break the wheel stud.

An incorrect fit compromises the hardware’s clamping strength. This can lead to several dangerous problems:

- Vibrations while driving.

- Damage to the lug holes on your expensive aluminum rims.

- Lug nuts backing off and becoming loose.

- Catastrophic failure, where the wheel separates from the vehicle.

Always verify that you are using the correct lug nuts acorn style to match your wheels. Your safety depends on it.

How to Find Your Perfect Fit: 3 Key Specifications

Finding the perfect lug nuts for your aluminum rims is easier than you think. You just need to verify three key specifications. Getting these details right ensures your wheels are mounted safely and securely. Let’s walk through each step to find the correct hardware for your vehicle.

Step 1: Determine Your Thread Size and Pitch

The first step is identifying your vehicle’s thread size and pitch. This measurement is usually written as Diameter x Pitch, like 12mm x 1.5.

- Diameter: This is the diameter of the wheel stud.

- Pitch: This is the distance between the threads. For metric studs, it’s measured in millimeters (e.g., 1.5mm). For imperial studs, it’s threads per inch.

You can find this information in your vehicle’s owner’s manual or by searching online. However, the most accurate method is to measure it yourself. You have a few simple options:

- Use a Thread Pitch Gauge: This tool has several toothed blades, each marked with a pitch number. You can find the correct pitch by matching a blade to your wheel stud’s threads until it fits perfectly with no gaps.

- Visit a Hardware Store: Take one of your existing lug nuts to a local hardware or auto parts store. They can help you match it to bolts or use a thread checker board.

- Use a Lug Nut Thread Checker: This convenient tool has male and female ends for most common sizes, allowing you to quickly identify the threads on both your studs and nuts.

Common vehicles like the Toyota RAV4 and many Honda models use a 12mm x 1.5 thread. Knowing your specific size is critical. Using the wrong size can strip the threads on your studs or nuts, leading to a dangerous failure. You must also ensure you have sufficient thread engagement. Some OEM lug nuts may only catch a few threads on aftermarket wheels, which is not enough for a secure fit.

Step 2: Confirm the Acorn Seat Requirement

Next, you need to confirm your wheels require a 60-degree acorn seat. Most aftermarket aluminum wheels use this design. You can verify this by looking inside the lug holes on your wheel.

Tip: Look for a tapered, cone-shaped surface inside each lug hole. This beveled edge is the visual sign of a 60-degree conical seat, which perfectly matches the shape of acorn lug nuts.

It is vital not to confuse seat types. Your vehicle’s original hardware might use a different style. Using the wrong seat creates an unsafe connection. Here is how to tell the difference:

| Seat Type | Visual Description |

|---|---|

| Acorn (Conical) | Features a beveled, 60-degree angled surface. |

| Ball | Has a rounded, bowl-shaped surface. |

| Mag | Is completely flat and uses a separate washer. |

A mismatch between the lug nut and the wheel seat is a common problem. It can prevent the nut from seating properly, reduce the contact area, and cause the hardware to loosen over time. Always match your lug nuts acorn style to your wheel’s seat design.

Step 3: Select the Right Material and Finish

Finally, you must choose the right material and finish for your new lug nut set. This choice affects strength, durability, and appearance.

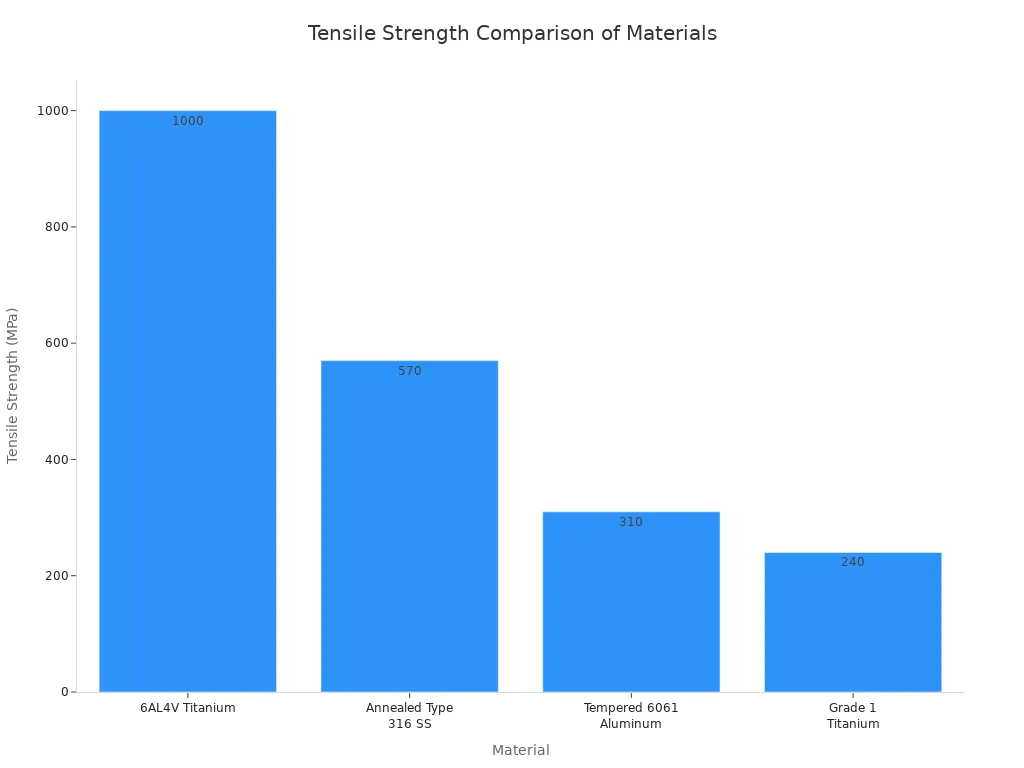

Material: The material determines the lug nut’s overall strength and ability to handle torque. Steel is the most common and reliable choice for daily driving and performance applications. While materials like titanium are known for being lightweight, high-quality forged steel often provides superior tensile strength, which is critical for wheel hardware.

Finish: The finish protects the lug nut from corrosion and adds to your vehicle’s style.

- Chrome: A multi-layer chrome finish offers a classic, bright look and good durability.

- Zinc: Zinc plating is a cost-effective way to achieve high corrosion resistance. It is a common choice in the automotive industry to protect fasteners from harsh elements.

- PVD and Advanced Coatings: Modern coatings like Physical Vapor Deposition (PVD) and zinc flake offer superior corrosion resistance and come in various colors, like black or neo-chrome, for a custom look.

Choosing a quality material and a durable finish ensures your lug nuts will perform safely and look great for years to come.

Key Features to Look for in Lug Nuts Acorn Style

Once you know your thread size and seat type, you can explore different styles. The design of your lug nuts acorn impacts both appearance and function. Understanding these key features helps you choose the perfect hardware for your specific needs.

Bulge Acorn vs. Standard Acorn

You will often see two types of acorn nuts: standard and bulge. A bulge acorn lug nut has a wider, extended seating surface compared to a standard one. This design is not just for looks; it is a critical safety feature for aluminum wheels.

For most aftermarket aluminum rims, you should choose a bulge acorn style. This ensures a secure fit that protects your wheels from damage.

Open-End vs. Closed-End Designs

You also have a choice between open-end and closed-end designs.

- Closed-End: These nuts are capped at the end. They protect your wheel studs from dirt, moisture, and rust. This is the most common choice for daily driving.

- Open-End: These nuts are open on both ends, allowing the wheel stud to pass through.

You should use open-ended lug nuts if you have extended wheel studs, which are common in racing. Many race tracks require open-ended lug nuts because they allow for a quick visual safety check. You can easily see if the stud has enough thread engagement. Using open-ended lug nuts also saves you from having to trim studs that are too long. For safety, many racing series require steel open-ended lug nuts.

Choosing the Correct Overall Length

The final feature to consider is the overall length of the lug nut. This choice affects both the look of your wheels and the ease of installation. Longer lug nuts can create a more aggressive, performance-oriented style. They also provide more surface area for your socket to grip. Shorter lug nuts offer a more subtle, OEM look.

When selecting your new lug nut set, make sure the length is compatible with your wheel design. A nut that is too long might bottom out on the hub before it fully tightens the wheel, creating a dangerous situation. Choose a length that fits your wheels correctly and matches your personal style.

A Guide to the Best Lug Nuts Materials

The material of your lug nuts determines their strength, durability, and appearance. You should choose a material that provides safety and matches your style. Let’s explore the best options for your wheels.

The Strength and Value of Steel

Steel is the top choice for lug nuts because of its exceptional strength. It can handle the high torque needed to secure your wheels safely. High-grade steel, like Grade 10.9 or 12.9, offers superior performance. These numbers indicate the material’s tensile strength, which is its ability to resist being pulled apart. A higher grade means a stronger bolt.

Fact: Manufacturers like Fortune Auto Parts use certified processes, such as ISO9001, to produce high-quality steel hardware that meets strict safety standards.

You can see the difference in strength between these common grades:

| Property | 10.9 Grade Steel | 12.9 Grade Steel |

|---|---|---|

| Hardness | 36-38 HRC | 39-42 HRC |

| Tensile Strength | ≥ 1140 MPa | ≥ 1320 MPa |

This data shows that Grade 12.9 steel is harder and stronger, making it an excellent choice for performance applications.

Chrome Finishes for Durability and Shine

Chrome provides a classic look and a tough, corrosion-resistant finish. A quality chrome plating is not just a single layer. It is a multi-step process that creates a durable shield for the steel underneath.

A superior chrome finish involves a ‘duplex nickel plating‘ system. This process uses two different nickel layers before the final chrome is applied.

- The steel is cleaned and prepared.

- A layer of semi-bright nickel is applied.

- A layer of bright nickel is added on top.

- The final chrome plating creates the shine.

This multi-layer method creates a powerful corrosion-resistant finish. The bright nickel layer sacrificially protects the semi-bright layer, preventing rust from reaching the steel.

Black and Colored Finishes for Style

You can customize your vehicle’s look with black or colored lug nuts. For these styles, the type of coating is very important. While paint and powder coating are common, Physical Vapor Deposition (PVD) offers the best durability. PVD is a modern process that bonds a thin metallic layer to the lug nut in a vacuum. This creates a finish that is much more scratch-resistant and long-lasting than paint. When you buy a new lug nut set, choosing one with a PVD coating ensures your custom color will not chip or fade easily.

Top Aftermarket Acorn Lug Nuts Brands to Consider

When you shop for aftermarket lug nuts, you will find many brands. Choosing a reputable manufacturer is key to your safety. The best lug nuts come from companies that follow strict quality control. These brands often hold an ISO 9001 certification. They also test their products to meet high standards for material strength and corrosion resistance. This ensures you get hardware that performs better than generic or some OEM lug nuts. Let’s look at some top brands.

Gorilla Automotive: The Overall Leader

Gorilla Automotive is a leader in the wheel accessory market. They are famous for their innovative security designs. Many consider their products to be the best lug nuts for theft prevention.

Gorilla’s “The System” is a popular choice. With this set, every single lug nut is a wheel lock. Each one has a unique, narrow-groove key pattern. This design makes them almost impossible to remove without the special matching key.

These locks are made from case-hardened steel. This material provides excellent strength and durability. Gorilla offers a secure and reliable option for protecting your wheels.

DPAccessories: Best Value and Finish Options

DPAccessories gives you great quality at an affordable price. This brand is an excellent choice if you want a stylish look without a high cost. They offer some of the best lug nuts for drivers seeking both value and appearance. You can find their products in popular finishes like chrome and black. They also provide common thread sizes, such as M12x1.50, which fit many vehicles. DPAccessories makes it easy to find a reliable set of aftermarket lug nuts that matches your style and budget.

Other Reputable Brands: Muteki and McGuard

You have other great options besides Gorilla and DPAccessories. Two more reputable brands are Muteki and McGuard.

- Muteki: This brand is popular in the import and sport compact scene. They are known for their high-strength, lightweight acorn lug nuts. Muteki offers a wide range of colors for a custom look.

- McGuard: McGuard is a trusted name in wheel security. They produce high-quality wheel locks and lug nuts. Their products are known for their precise engineering and durable finishes.

Safe Installation and Maintenance Tips

Properly installing and maintaining your lug nuts is just as important as choosing the right ones. You must follow the correct procedures to ensure your wheels are secure. These tips will help you install your hardware safely and keep your vehicle on the road.

The Importance of Hand-Tightening First

You should always start the installation process by hand. Never use an impact wrench to start threading your lug nuts. This can cause cross-threading, which damages the threads on both the nut and the wheel stud.

Follow these simple steps for a safe start:

- Place the wheel onto the hub.

- Thread each acorn lug nut on by hand.

- Continue turning until each nut is snug against the wheel.

This process ensures the nuts are seated correctly in the wheel’s conical seats. It prevents damage and prepares the wheel for final tightening.

Using a Torque Wrench for Final Tightening

After hand-tightening, you must use a torque wrench for the final step. A torque wrench applies a specific amount of rotational force. This ensures each lug nut is tightened to the manufacturer’s specification. Using the correct torque optimizes the hardware’s clamping strength and prevents dangerous issues.

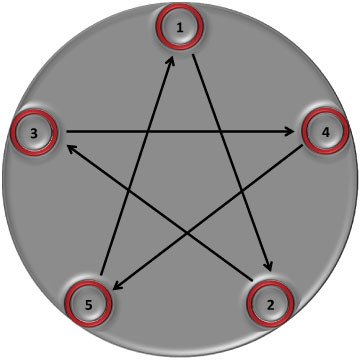

For a 5-lug wheel, you must tighten the nuts in a star pattern. This industry-standard method centers the wheel and distributes pressure evenly. You should repeat the sequence to confirm all lugs are secure.

You can find the correct torque value in your vehicle’s owner’s manual. Do not guess or use an impact gun for final tightening.

When to Re-Torque Your Lug Nuts

Your work is not finished after the initial installation. Lug nuts can loosen slightly as they settle into place. You must re-check the torque after driving a short distance.

Reminder: Tire fitting services recommend that wheel torque settings MUST be checked within 50 miles of the wheels being fitted. Some auto shops suggest returning for a re-torque within 50–100 miles.

Here is a simple schedule for re-torquing your lug nuts:

- Initial Re-Torque: Check the torque after driving 50-100 miles. This is the most critical step.

- Regular Re-Torque: Check the torque every 5,000 miles or during your regular tire rotations.

- Post-Service Re-Torque: Always re-torque your lug nuts after any service that involves removing the wheels, such as brake or suspension work.

You make a critical safety choice when selecting acorn lug nuts for your aluminum wheels. You must always verify three key specs: the 60-degree acorn seat, correct thread size, and material strength. This guide helps you confidently choose the right lug nuts acorn style for both safety and appearance. You can trust manufacturers like Fortune Auto Parts. Their ISO9001 certified processes and rigorous testing guarantee you receive premium, reliable products for your vehicle.

FAQ

Can I reuse my old lug nuts on new aluminum wheels?

You should only reuse old lug nuts if they match your new wheels perfectly. Your old hardware must have the correct 60-degree acorn seat. Using the wrong seat type creates an unsafe connection and can damage your new rims. Always verify the seat type before installation.

What happens if I overtighten my lug nuts?

Overtightening your lug nuts is very dangerous. Too much force can stretch the wheel studs, which weakens them and can cause them to break. It can also damage the lug seats on your aluminum wheels. Always use a torque wrench for the correct tightness.

Are steel lug nuts safe for aluminum wheels?

Yes, high-quality steel lug nuts are the safest choice for aluminum wheels. Steel provides the necessary strength to handle the high clamping force required. Reputable manufacturers design steel lug nuts specifically for safe use with aluminum rims, ensuring a secure and reliable fit.

How do I know if I need bulge acorn lug nuts?

You likely need bulge acorn nuts for your aftermarket aluminum wheels. The wider “bulge” seat distributes clamping force over a larger area. This design protects the softer aluminum from damage and ensures the lug nuts stay tight. Check your wheel manufacturer’s recommendation to be certain.