admin1

October 12, 2025

Car Lug Bolts vs Lug Nuts Picking the Right Wheel Fastener

As experts in wheel components, we know the key difference is simple. Lug nuts thread onto fixed posts on your car’s hub, which are called wheel studs. In contrast, car lug bolts are single fasteners that screw directly into the hub itself. European cars from brands like BMW and Volkswagen typically use wheel bolts. American and Japanese cars, such as those from Ford and Toyota, often use lug nuts.

Your vehicle’s manufacturer determines which system you have. You cannot choose between them. Understanding this distinction is crucial for safety and proper maintenance.

What Are Lug Nuts? A Closer Look

If your car uses lug nuts, your wheel hub has a set of threaded posts permanently fixed to it. These posts are called wheel studs. You secure your wheel by placing it over these studs and then tightening the lug nuts onto them. This system is common on vehicles from American and Japanese manufacturers.

The Function of a Lug Nut

A lug nut’s primary job is to fasten the wheel securely. To do this correctly, the shape of the nut must match the wheel’s lug hole. This contact point is called the “seat.”

Note: Using a lug nut with the wrong seat style can damage your wheels. It can also cause the wheel to become loose while you drive.

The most common seat designs have specific functions:

- Conical (Tapered) Seat: This nut has a cone-shaped bottom with a 60-degree taper. The design helps perfectly center the wheel on the hub. This precise fit reduces the chances of the nut loosening over time.

- Ball Seat: This design uses a rounded, dome-like shape. It performs the same function as a conical seat but fits wheels designed with a matching rounded lug hole.

The Role of Wheel Studs

Wheel studs are the strong, fixed bolts that stick out from your vehicle’s hub. They provide the threaded posts that lug nuts screw onto. Manufacturers build these studs for immense strength and durability.

- They are typically made from high-strength carbon or alloy steel.

- Most wheel studs meet strict quality standards, such as SAE Grade 8 or ISO Class 10.9, ensuring they can handle the extreme forces of driving.

These high-strength wheel studs are essential for the safety of the entire wheel assembly.

How the System Works Together

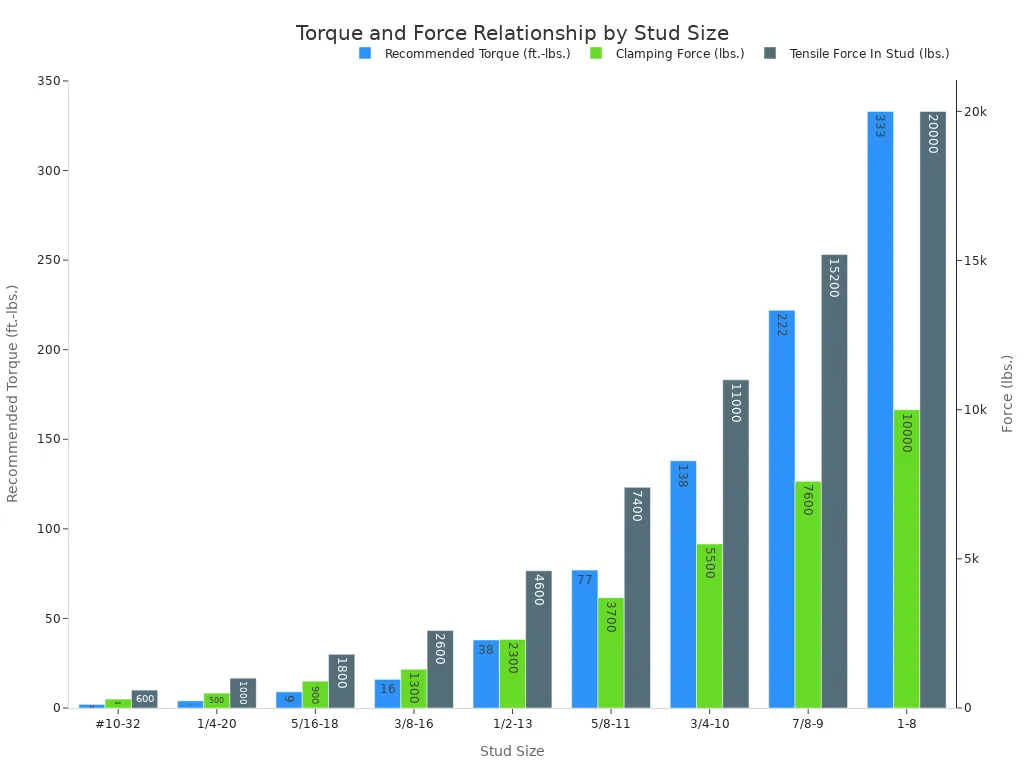

The lug nut and wheel stud system creates a powerful clamping force. When you tighten the lug nuts, you are actually stretching the wheel studs a tiny amount. This stretching action acts like a powerful spring, pulling the wheel tightly against the hub. This immense pressure, or clamping force, generates friction between the wheel and the hub. This friction is what truly holds the wheel in place and supports the vehicle’s weight, not the studs themselves. Applying the correct torque is critical. As you can see below, more torque creates a greater clamping force.

Properly torqued lug nuts ensure the wheel studs are only under tension. If the nuts loosen, the studs are exposed to shearing forces, which can lead to rapid failure.

What Are Car Lug Bolts? The European Standard

If you drive a European car, you likely have car lug bolts instead of nuts. This system uses a single fastener to secure your wheel. Unlike the two-piece stud-and-nut design, a lug bolt is one solid piece with a head on one end and threads on the other. You install it by passing the bolt through the wheel and screwing it directly into threaded holes in the vehicle’s hub.

The All-in-One Fastener

The main reason European manufacturers prefer wheel bolts comes down to design philosophy and manufacturing efficiency. This single-piece fastener simplifies the assembly line process.

- Manufacturing Simplicity: Automakers can skip the step of pressing studs into the wheel hub. This reduces the number of parts and saves manufacturing time and cost across millions of vehicles.

- Engineering for Performance: Some engineers believe wheel bolts provide a more direct and consistent clamping force. This can lead to better wheel balance and stability, which is a key consideration for high-speed driving on roads like the German autobahn.

How Bolts Secure the Wheel

The function of wheel bolts is identical to the lug nut system: creating a strong clamping force. When you tighten the bolts to the correct specification, you are slightly stretching the bolt’s shaft. This tension acts like a powerful spring, pulling the wheel and hub tightly together. This immense pressure is what holds your wheel securely in place. The friction it creates prevents the wheel from shifting or coming loose while you drive.

The Importance of Hub Alignment

The biggest practical difference with car lug bolts appears when you change a tire. Since there are no studs to hang the wheel on, you must support the full weight of the wheel and tire yourself. You have to perfectly align the bolt holes in the wheel with the threaded holes in the hub before you can insert the first bolt.

Heads Up! ⚠️ Holding a heavy wheel in place while trying to start the first of the wheel bolts can be difficult and frustrating. If the wheel is not perfectly flush against the hub, you risk cross-threading the bolt, which can damage the hub itself.

This process requires more patience and physical effort compared to a stud-based system.

Lug Nuts vs. Car Lug Bolts: The Key Differences

When you look at lug nuts and wheel bolts, you see two different ways to do the same job. Both systems are designed to keep your wheels attached safely. However, the key differences between them become very clear during installation, maintenance, and repair.

Installation and Ease of Use

The process for changing a tire highlights the biggest practical difference between the two systems. Your experience will vary greatly depending on which fastener your car uses.

With Lug Nuts: The installation and removal process is generally more straightforward.

- You lift the car and remove the lug nuts.

- You pull the wheel off the studs.

- To put the wheel back on, you simply hang it on the fixed wheel studs. The studs support the wheel’s weight for you.

- You can then use both hands to thread the lug nuts on and tighten them.

This design makes the job much easier for one person to handle, especially with heavy wheel and tire combinations.

With Wheel Bolts: The installation process requires more physical effort and precision.

Heads Up! ⚠️ Since there are no studs to hang the wheel on, you must hold the full weight of the wheel while perfectly aligning its bolt holes with the threaded holes in the hub. This can be very challenging.

This difficult alignment makes the installation and removal of wheels with wheel bolts more frustrating. It also increases the risk of dropping the wheel or incorrectly starting a bolt, which can damage the threads.

Design Strength and Safety

Both systems are engineered to be extremely safe. Manufacturers choose one over the other based on production and design philosophy, not because one is weaker. The strength and durability of your wheel fastener system depend on using high-quality parts and proper torque.

| Feature | Lug Nut & Stud System | Car Lug Bolts System |

|---|---|---|

| Primary Strength | The wheel stud provides the core strength. It is a permanent, high-grade steel post pressed into the hub. | The bolt itself provides the strength. It is also made of high-grade steel. |

| Wear & Tear | The stud remains on the car. The lug nuts are the only part that is repeatedly removed and installed. | The entire fastener (the bolt) is removed and installed each time, experiencing wear on its threads. |

| Safety Factor | Extremely safe. The design separates the load-bearing stud from the tightening nut. | Extremely safe. The design uses a single, robust component to provide clamping force. |

Ultimately, the strength of both systems is more than enough for any driving situation when maintained correctly. The durability of the threads is the main point of comparison.

Repair Costs and Complexity

This is where you will find the most significant key differences in ownership. What happens when a thread gets damaged?

Damaged Lug Nuts and Studs: If you cross-thread one of the lug nuts, you will likely damage the threads on the wheel stud. The fix is simple and affordable. A mechanic can press out the single damaged stud and install a new one, often without even removing the wheel hub from the car. The cost is usually limited to one new stud and a small amount of labor.

Damaged Wheel Bolts and Hubs: If you damage the threads on one of the car lug bolts, you have a bigger problem. The threads are part of the expensive wheel hub assembly itself. Repairing a stripped thread in a hub is a complex and costly job. You may need a special thread repair kit (like a Helicoil), or you might have to replace the entire wheel hub, which can cost hundreds of dollars in parts and labor.

The Bottom Line: A damaged stud is a minor, inexpensive repair. A damaged hub thread is a major, expensive repair. This makes the lug nut system more forgiving of mistakes.

Vehicle Compatibility: Why You Can’t Swap Them

You cannot simply switch from lug bolts to lug nuts, or the other way around. The choice is a core part of your vehicle’s engineering. Your car’s wheel hub is specifically designed for one system. This decision affects everything from the manufacturing process to how you change a flat tire.

Manufacturer Design Philosophy

Car manufacturers make the choice between lug nuts and lug bolts very early in the design process. This decision is not about which one is better, but what fits their production goals and engineering priorities.

The wheel hub is the key component. A hub designed for lug nuts has holes for studs to be pressed in. A hub designed for lug bolts has threaded holes to accept the bolts directly. These two designs are fundamentally different and not interchangeable.

This means the vehicle compatibility of your wheel fasteners is set at the factory. You must use the system your car was built with.

American & Japanese vs. European Cars

You can often guess which system a car uses based on where the manufacturer is from. There is a clear trend among automakers from different parts of the world. This general rule helps you know what to expect from most major brands.

| Region/Country | Common System | Example Brands |

|---|---|---|

| America | Lug Nuts & Studs | Ford, Chevrolet, Dodge |

| Japan | Lug Nuts & Studs | Toyota, Honda, Nissan |

| Europe | Car Lug Bolts | BMW, Volkswagen, Mercedes-Benz |

This difference in regional preference is a major factor in fastener compatibility.

Checking Your Own Vehicle

Not sure which system your car has? You can find out easily with a quick visual check. You do not need any special tools.

- Look at your car’s wheel. If you see nuts threaded onto posts, you have lug nuts.

- If you see only the heads of bolts that sit flush against the wheel, you have car lug bolts.

- If you have a hubcap covering the fasteners, you can often pop it off to look.

- Another easy way is to check your spare tire. The mounting system will be clearly visible.

Knowing this simple fact about your car is the first step to proper wheel maintenance.

The Practical Guide to Changing a Tire

Knowing how to change a tire is a vital skill. The process differs significantly depending on whether your car uses lug nuts or wheel bolts. Understanding these differences prepares you for a roadside emergency.

Changing a Tire with Lug Nuts

The process is much simpler with lug nuts. After you safely jack up the car, the wheel removal is straightforward. The fixed studs on the hub act as a guide and support system.

- You loosen and remove the lug nuts.

- You can simply hang the wheel on the studs while you get a better grip for removal.

- To reinstall the wheel, you lift it onto the studs, which hold it in place. This leaves both of your hands free to start threading the lug nuts.

This design offers great convenience during tire changes, as you do not have to balance the wheel’s weight while aligning it.

The Challenge with Lug Bolts

Changing a tire with wheel bolts requires more effort and care. The main difficulty is aligning the wheel without any studs to guide it. This can be frustrating, especially on the side of the road.

The removal and installation process introduces several risks:

- Incorrect Jack Placement: Before you even touch the wheel bolts, you must know where to place the jack. Check your owner’s manual to find the correct jacking points to avoid damaging your vehicle.

- Alignment and Weight: You must hold the heavy wheel and tire perfectly flush against the hub. At the same time, you have to align the holes and start threading the first of the wheel bolts.

- Improper Tightening: After a difficult removal and installation, it is easy to make a mistake. If you do not fully tighten the bolts, the wheel can become loose and even fall off.

Using Wheel Hanger Pins: A Pro Tip

A wheel hanger pin is a simple tool that makes changing a tire with wheel bolts much easier. These tools are often made from strong, cold-forged metric grade 10.9 carbon steel for durability.

This tool temporarily acts like a wheel stud. You screw one or two hanger pins into the hub’s threaded holes before you mount the wheel. You can then slide the wheel onto the pins, which support its weight and align it perfectly. This allows you to easily insert the remaining wheel bolts without struggling. Once a few bolts are in place, you complete the removal of the hanger pins and install the final bolts.

Common Risks and How to Avoid Them

Proper installation of your wheel fasteners is essential for your safety on the road. You can avoid serious problems by understanding a few common risks. These issues can affect both lug nut and lug bolt systems, but the consequences often differ.

The Danger of Cross-Threading

Cross-threading happens when you force a nut or bolt on at an angle. This damages the threads and prevents the fastener from tightening correctly. A cross-threaded fastener creates a major safety hazard because it cannot provide the necessary clamping force.

You can prevent cross-threading by always starting your lug nuts or bolts by hand. If you feel resistance, stop immediately, back it out, and try again.

Cross-threading usually happens for a few key reasons:

- You use incompatible threads between the fastener and the post.

- You start the fastener at an angle instead of straight on.

- Dirt or debris gets caught in the threads.

Damaged Wheel Studs vs. Damaged Hubs

Checking for damage is a critical part of wheel maintenance. The Tire Industry Association provides guidelines for inspecting your wheel components. You should always check your wheel studs for damage.

- You can remove the lug nuts and clean the wheel studs to get rid of rust and dirt. You should inspect the wheel studs for any signs of wear or stretching.

- You should also examine the wheel itself. Look for damage around the stud holes, such as cracks or distortion.

A damaged wheel stud is a relatively simple and inexpensive fix. However, a damaged thread in the hub is a much more serious and costly repair. This makes the system with wheel studs more forgiving of mistakes.

The Critical Importance of Proper Torque

Torque is the rotational force you apply when tightening a fastener. Using the correct torque is the most important step for wheel safety. Too little torque lets the wheel come loose. Too much torque can stretch and damage the wheel studs or bolts, leading to failure.

Your vehicle’s manufacturer provides an exact torque specification. This number can even change for different generations of the same model. For example, look at the popular Ford F-150:

| Generation | Year Range | Lug Nut Torque Spec |

|---|---|---|

| 1st – 5th | 1975-2003 | 100 ft/lbs |

| 6th – 9th | 2004-Present | 150 ft/lbs |

Always use a torque wrench and follow your owner’s manual. This ensures your wheels are secured safely every time.

Upgrading to a Stud Conversion

If you own a car with lug bolts, you might feel stuck with the difficult process of changing a tire. However, you have an option called a wheel stud conversion. This upgrade replaces your factory lug bolts with permanent wheel studs, giving you the convenience of a lug nut system.

What Is a Wheel Stud Conversion?

A wheel stud conversion kit allows you to change your car’s wheel fastening system. You remove the factory lug bolts and install a set of threaded wheel studs directly into your wheel hub. Once installed, these wheel studs stay on the car permanently. You then use lug nuts to secure your wheels, just like on American and Japanese vehicles. This modification is popular with European car owners who want easier wheel changes.

Benefits for Performance and Convenience

A stud conversion offers significant benefits for both convenience and performance.

- Easier Wheel Changes: The new wheel studs act as hangers, making wheel installation much faster and easier. This is especially helpful for track days where you might change tires frequently.

- Reduced Weight: You can choose titanium wheel studs. These can be up to 60% lighter than steel bolts. For example, a full set of titanium studs can reduce unsprung weight by over 1000g, which helps improve your car’s responsiveness.

- Consistent Torque: Using lug nuts allows for more consistent and accurate torque application. This reduces the risk of mechanical fatigue on the fasteners.

Is a Conversion Right for You?

Deciding on a conversion depends on your needs. If you frequently change your wheels for track use or simply want to make tire changes easier, a stud conversion is a great upgrade. The installation is a job you can do yourself if you are careful.

Pro Tip: Before you begin, always clean the threaded holes in your hub with a tool like a thread chaser or brake cleaner to ensure a secure fit.

The basic installation steps are:

- Apply a thread-locking compound to the hub end of each stud.

- Hand-thread all the new wheel studs into the hub.

- Use a “double-nut method” to tighten the studs to the manufacturer’s specification, often around 50-60 ft-lbs.

- Mount your wheel and secure it with lug nuts, torqued to the stud kit’s specific guidelines.

In summary, the lug nut vs. car lug bolts debate is decided by your car’s manufacturer, not by personal preference. Lug nut systems, which use wheel studs, offer simpler tire changes and more straightforward repairs. In contrast, wheel bolts create a simpler parts list but require more care during installation. From our manufacturing experience, both systems are equally safe when you use high-quality parts and torque them to factory specifications.

Safety First! ⚠️ Always start lug nuts or wheel bolts by hand to prevent damage. Before installation, check that your wheel studs are clean and undamaged. Most importantly, always use a calibrated torque wrench for final tightening to ensure your wheels are secure.

FAQ

Can I switch from lug nuts to lug bolts?

No, you cannot swap them. Your car’s wheel hub is designed for only one system. A hub for lug nuts has holes for studs. A hub for lug bolts has threaded holes. These designs are not interchangeable without major modification.

Are lug nuts safer than lug bolts?

Both systems are equally safe. Manufacturers engineer them to handle extreme forces. Your safety depends on using high-quality parts and applying the correct torque. A properly installed fastener, whether a nut or bolt, will keep your wheel secure.

What happens if I use the wrong torque?

Using the wrong torque is dangerous. Too little torque allows the wheel to loosen. Too much torque can stretch and break the stud or bolt, leading to failure.

Pro Tip: 💡 Always use a calibrated torque wrench and follow your car’s specific torque value found in the owner’s manual.

Why do European cars use lug bolts?

European automakers often choose lug bolts to simplify manufacturing. Using a single fastener saves time and reduces the number of parts on the assembly line. This design choice fits their production philosophy and engineering priorities for high-speed stability.