admin1

December 8, 2025

Bolts on Wheels Explained A Guide for Every Car Owner

The bolts on wheels are crucial fasteners. They secure a vehicle’s wheel to its hub. Proper bolt installation is a critical safety measure. Incorrect tightening can lead to a dangerous wheel detachment.

UK research shows improper maintenance causes about 72% of wheel loss cases. These preventable events result in hundreds of accidents annually.

This guide provides car owners with essential knowledge. It helps ensure every wheel is attached securely for a safe journey.

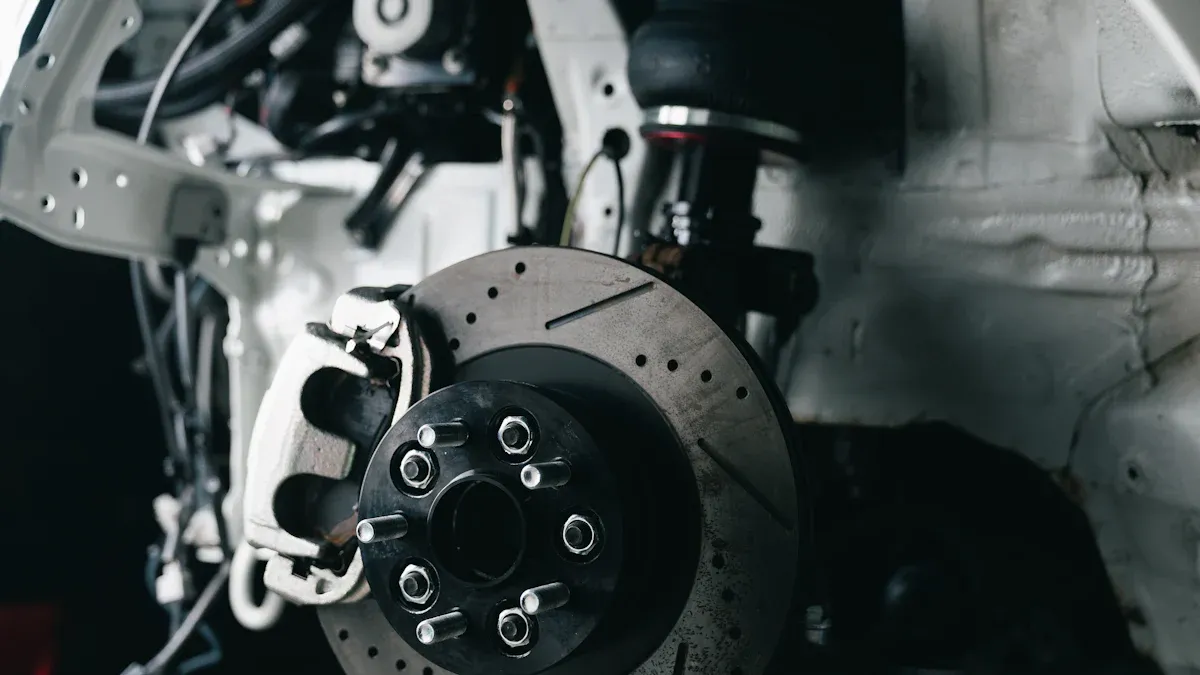

Understanding the Basics of Bolts on Wheels

Understanding the hardware that holds your wheel in place is the first step toward vehicle safety. The two main types of fasteners are wheel bolts and the wheel nuts and bolts system. Each has a distinct design and is common in different regions.

Wheel Bolts vs. Wheel Nuts and Bolts

Automakers use two primary systems to attach a wheel. European brands often prefer wheel bolts. American manufacturers typically use wheel nuts and bolts. The main difference lies in their design and installation. A wheel nuts and bolts system uses studs that are fixed to the hub. The wheel slides over these studs and is secured with lug nuts. In contrast, a wheel bolt passes through the wheel and screws directly into threaded holes in the hub.

The choice between these systems affects wheel installation and maintenance.

| Feature | Wheel Nuts and Bolts System | Wheel Bolt System |

|---|---|---|

| Design | Studs are fixed in the hub. A separate nut secures the wheel. | A single bolt passes through the wheel into the hub. |

| Installation | The wheel hangs on the studs, simplifying alignment. | The wheel and hub holes must be aligned manually. |

| Common Usage | Popular with American and Japanese manufacturers. | Popular with European brands like Audi, BMW, and Mercedes. |

| Maintenance | A damaged stud can be replaced individually. | Stripped hub threads may require replacing the entire hub. |

Knowing which system your car uses is essential for any wheel-related task. The wheel nuts and bolts approach can make changing a tire easier. The bolts on wheels design offers a simpler parts list.

Why the Right Bolts Are a Safety Priority

Correct bolts on wheels create a powerful clamping force. This force is a critical safety feature. It presses the wheel firmly against the hub. This pressure generates immense friction between the two surfaces. The friction prevents the wheel from shifting or sliding during acceleration, braking, and cornering. The bolts establish a preload, an internal tension that external forces must overcome before the joint can fail. This ensures the wheel remains securely attached, preventing dangerous wheel separation incidents. Using the wrong hardware compromises this essential clamping force.

The Role of High-Strength Materials

Wheel bolts are made from high-strength steel alloys to withstand extreme forces. Manufacturers follow strict industry standards from organizations like SAE (Society of Automotive Engineers) and ISO (International Organization for Standardization). These standards, such as ISO 898-1 and SAE J429, define the material, dimensions, and strength requirements.

Note: Common steel grades include Class 8.8 and Class 10.9. Higher class numbers indicate greater tensile strength, meaning the bolt can handle more stress before breaking.

These certified materials ensure that the wheel nuts and bolts can endure constant vibration and stress. Using inferior or non-certified wheel nuts and bolts risks fastener failure and a potential accident. Always choose high-quality wheel nuts and bolts that meet or exceed manufacturer specifications for your vehicle’s wheel. This guarantees the wheel nuts and bolts provide the necessary strength.

The Ultimate Wheel Bolts Guide to Selection

Selecting the correct hardware is not just about making a wheel fit; it is about ensuring safety on the road. Using the wrong bolts can lead to vibration, damage, and even wheel detachment. This ultimate wheel bolts guide breaks down the three critical factors for choosing the correct parts: seat type, thread dimensions, and length. Getting these wheel bolt specifications right is essential for any car owner.

Matching the Bolt Seat to the Wheel

The bolt “seat” is the surface of the bolt head that makes direct contact with the wheel. The wheel’s bolt holes are machined with a matching seat design. A perfect match between the bolt seat and the wheel seat ensures the bolt centers correctly and applies clamping force evenly. There are three main types of bolt seats.

| Seat Type | Description | Common Use |

|---|---|---|

| Cone (Tapered) | The most common type, with a 60-degree tapered surface. | Used on many factory and aftermarket wheels. |

| Ball (Radius) | Features a rounded, spherical seating surface. | Primarily used by European brands like Volkswagen and Mercedes-Benz. |

| Flat (Mag) | A flat surface that requires a washer for even pressure distribution. | Often found on some older vehicles and specific aftermarket wheels. |

Using a bolt with a seat that does not match the wheel is extremely dangerous. A mismatch creates a tiny contact point instead of a large, stable surface. This concentrates all the clamping force on a small area, leading to severe problems.

⚠️ Safety Alert: Never use a cone seat bolt on a wheel designed for a ball seat, or vice versa. The incorrect fit will fail to secure the wheel properly.

Consequences of a mismatched seat include:

- Bent wheel bolts from uneven stress.

- Damage to the bolt holes on the wheel.

- The bolt loosening over time due to vibration.

- The wheel becoming insecure and potentially detaching from the vehicle.

Decoding Thread Size and Pitch

Every bolt has a specific thread size and pitch. These measurements must match the threaded holes in your vehicle’s hub.

- Thread Size: This is the diameter of the bolt. Common metric sizes are M12 and M14 (the “M” stands for metric, and the number is the diameter in millimeters).

- Thread Pitch: This measures the distance between threads.

The method for measuring thread pitch differs for metric and US standard bolts. Metric pitch is the distance in millimeters between two adjacent threads; a 1.5 pitch means threads are 1.5mm apart. US standard pitch is measured in threads per inch (TPI); a pitch of 20 means there are 20 threads in one inch. A complete specification looks like M12x1.5, indicating a 12mm diameter and a 1.5mm pitch. To find the best wheel bolts, you must know this specification.

A car owner can identify the correct thread size and pitch in a couple of ways:

- Use a thread pitch gauge, an inexpensive tool found at auto parts stores.

- Take an existing bolt to a hardware or auto parts store to test it against nuts or other bolts.

Determining the Correct Bolt Length

The bolt’s length, or shank length, is the measurement from the base of the seat to the end of the bolt. This dimension is crucial for safety. Using wheel bolts that are too long or too short prevents them from properly securing the wheel.

A bolt that is too short will not have enough thread engagement in the hub. The general rule is that the bolt should engage the hub by a length equal to its diameter. For an M12 bolt, this means at least 12mm of thread must screw into the hub. Anything less risks stripping the threads and losing clamping force.

Conversely, a bolt that is too long can “bottom out.” It may hit the back of the hub or interfere with brake components before it fully tightens the wheel. This gives a false sense of tightness. The wheel will remain loose even though the bolt feels secure, leading to a catastrophic failure of the wheel assembly. Always confirm the correct length, especially when installing thicker aftermarket wheels or wheel spacers.

Choosing the Right Material and Grade

The wheel bolt composition is a critical factor in its strength and reliability. Bolts are not all created equal. Their material and strength grade directly impact vehicle safety and performance. Choosing the correct grade ensures the fastener can handle the immense forces a wheel endures.

Manufacturers stamp a property class, or grade, directly onto the head of high-quality bolts. These numbers, like 10.9 or 12.9, are not random. They are a standardized code defined by the International Standards Organization (ISO) that reveals the bolt’s strength. The first number (10) multiplied by 100 gives the minimum tensile strength in megapascals (MPa). The second number (9) indicates the yield strength is 90% of the tensile strength.

- Class 10.9: These are high-strength bolts with a minimum tensile strength of 1040 MPa.

- Class 12.9: These are ultra-high-strength bolts with a minimum tensile strength of 1220 MPa, among the strongest available.

Note: Always use bolts that meet or exceed the vehicle manufacturer’s specified grade. Using a lower-grade bolt can lead to fastener failure.

The most common materials for wheel bolts are steel, titanium, and stainless steel. Each offers a different balance of strength, weight, and cost. Steel is the industry standard for its excellent strength-to-cost ratio. However, performance enthusiasts often consider titanium for its unique advantages.

| Feature | High-Grade Steel | Grade 5 Titanium |

|---|---|---|

| Weight | Heavier | Approximately 50% lighter than steel |

| Strength | Very strong (e.g., 800+ MPa) | Extremely strong (e.g., 950+ MPa) |

| Corrosion | Can rust without a protective coating | Naturally resistant to rust and corrosion |

| Heat | May weaken under extreme heat cycles | Maintains strength at high temperatures |

| Cost | Lower | Significantly higher |

Titanium’s low weight reduces unsprung mass, which can improve handling and acceleration. Its superior corrosion resistance also makes it ideal for vehicles in harsh weather conditions. Stainless steel is another option, offering good corrosion resistance but typically lower tensile strength than high-grade alloy steel or titanium. The best wheel bolts for a specific vehicle depend on the owner’s priorities, whether they are daily driving reliability or maximum track performance.

Safe Installation and Tightening Procedures

Correctly installing a wheel is a task that demands precision and care. Safety organizations like the Occupational Safety and Health Administration (OSHA) emphasize that demonstrated proficiency in wheel installation and removal is a core skill for professionals. Car owners can adopt these same high standards by using the right tools and following proper installation techniques. A methodical approach to installation ensures the wheel is secure and the vehicle is safe to drive.

Essential Tools for the Job

Having the correct equipment is the first step toward a successful and safe wheel installation. A basic toolkit for this job should include a jack, jack stands, a lug wrench or socket set, and a wheel chock. However, the single most important tool is a calibrated torque wrench.

A quality torque wrench is not a luxury; it is a necessity for achieving the correct clamping force. When selecting one, car owners should look for several key features:

- Drive Size: The wrench should have a drive size (e.g., ⅜-inch or ½-inch) that matches the sockets needed for the vehicle’s bolts.

- Torque Range: Its range must cover the manufacturer’s specified torque for the wheel.

- Accuracy: A good wrench offers an accuracy of +/- 4% or better to ensure precision.

- Ease of Use: Features like a comfortable handle, a flexible head, and a clear display make the job easier and more accurate.

Modern digital torque wrenches often include helpful functions like memory storage for common settings and multiple measurement units (ft-lbs, Nm), adding versatility to the tool.

Step-by-Step Installation Process

Following a consistent, step-by-step process eliminates guesswork and prevents common mistakes. This procedure ensures each bolt is tightened correctly, securing the entire wheel assembly.

- Prepare the Vehicle: Park the car on a flat, level surface. Engage the parking brake and place a wheel chock behind a wheel that will remain on the ground.

- Clean Mating Surfaces: Before mounting the wheel, clean any rust, dirt, or debris from the hub surface, the back of the wheel, and the bolt threads. A clean connection is vital for proper seating.

- Mount the Wheel: Carefully lift the wheel and align the bolt holes with the threaded holes in the hub. For bolt systems, this may require holding the wheel in place while starting the first bolt.

- Hand-Tighten the Bolts: Screw in all the bolts by hand until they are snug. This prevents cross-threading and ensures the wheel is seated flat against the hub.

- Lower the Vehicle: Use the jack to lower the vehicle until the tire just touches the ground. The weight of the car will prevent the wheel from turning during the final tightening.

- Torque in Sequence: Use a torque wrench to tighten the bolts to the manufacturer’s specification. Always tighten them in a star or cross pattern. This pattern distributes pressure evenly across the hub.

- For a 5-bolt wheel, tighten every other bolt in a star shape.

- For a 6-bolt wheel, tighten bolts in a cross pattern, moving from one bolt to the one directly opposite.

- Tighten in Stages: Do not apply full torque on the first pass. Tighten the bolts in two or three stages. For example, first tighten all bolts to 45 ft-lbs, then to 65 ft-lbs, and finally to the final specification of 85 ft-lbs. This gradual installation process ensures an even clamp.

- Final Check: Once all bolts are torqued to the final value, perform one last check by moving around the wheel in a clockwise circle to ensure none were missed.

The Importance of Torque Specifications

Torque is the rotational force applied to a fastener. Every vehicle manufacturer provides a specific torque value for its wheel bolts. Adhering to this specification is not optional; it is critical for safety. Applying the wrong amount of torque—either too much or too little—can lead to component damage and dangerous failures.

⚠️ Warning: Over-torquing or under-torquing bolts compromises the integrity of the wheel connection and can lead to a catastrophic wheel detachment while driving.

The Dangers of Over-Torquing Applying too much force can be just as dangerous as not applying enough. Over-tightening stretches the bolt beyond its designed limit, which permanently weakens it and reduces its ability to hold the wheel securely. This can cause several problems:

- Stripped Threads: Excessive force can strip the threads on the bolt or inside the hub, requiring costly repairs.

- Stretched Bolts: A stretched bolt loses its tensile strength and may shear off under driving stress.

- Warped Brake Rotors: Uneven and excessive clamping force can deform the brake rotor, leading to a pulsating brake pedal and reduced braking performance.

The Dangers of Under-Torquing Insufficient torque is a direct cause of wheel loss incidents. When bolts are too loose, they cannot create the necessary clamping force to hold the wheel against the hub. Vibrations from normal driving will cause the bolts to loosen further over time. The consequences include:

- Vibrations: A loose wheel will often cause a noticeable vibration in the steering wheel.

- Component Damage: Movement between the wheel and hub can elongate the bolt holes and damage the mounting surfaces.

- Wheel Detachment: In the worst-case scenario, the bolts will back out completely, allowing the wheel to separate from the vehicle.

Proper installation is the final, critical step in ensuring road safety.

When to Re-Check Your Torque

A proper wheel installation does not end after the final turn of the torque wrench. The connection between the wheel and the hub is a dynamic joint. It settles and adjusts after the vehicle begins to move. Re-checking the torque is a critical safety step that confirms the clamping force remains at the correct level.

Technicians advise that a re-torque is necessary after driving a short distance. It is particularly crucial to check wheel torque after driving approximately 50 to 100 miles on newly replaced tires for optimal safety. This initial period allows the hardware to settle into place. Small movements or compression of materials can slightly reduce the initial clamping force applied during the installation.

Several factors can cause bolts to loosen over time. One significant cause is thermal cycling. The wheel and bolts expand and contract with temperature changes from driving and braking.

Differential Thermal Expansion. If the material of the bolt and the joint are different, large differences in temperature due to rapid environmental changes or cycling industrial processes can cause bolt material to expand or contract rapidly, possibly loosening the bolt.

This constant expansion and contraction can gradually reduce the bolt’s preload. A re-torque check ensures the bolts are tight and secure. Car owners should plan to re-check torque in these situations:

- After Initial Installation: Always re-check the torque within 50 to 100 miles of any wheel service. This includes tire rotations, new tire installations, or brake work.

- After Hard Driving: Aggressive driving or track days place extreme stress on the wheel assembly. A torque check after such events is a wise precaution.

- Seasonal Changes: Significant shifts in ambient temperature can affect the hardware. Checking torque when switching between summer and winter tires is a good practice.

Ignoring this simple follow-up procedure can undermine an otherwise perfect installation. A few minutes with a torque wrench provides peace of mind and reinforces the safety of the vehicle.

Advanced Topics and Common Mistakes

Beyond basic installation, car owners should understand advanced topics to avoid common but dangerous mistakes. Proper knowledge of specialty hardware and wheel differences ensures long-term safety and performance.

Securing Your Wheels with Locking Bolts

Wheel theft is a persistent concern for many vehicle owners. Locking wheel bolts offer an effective layer of security. These special fasteners replace one standard bolt on each wheel. Locking bolts feature a unique, irregular pattern on the head. This design requires a matching key for removal. An ordinary wrench or socket will not fit, which deters thieves from stealing a valuable wheel. Each set of locking bolts has a distinct pattern, making it very difficult to remove the wheel without the specific key.

Bolts for Factory vs. Aftermarket Wheels

Switching to aftermarket wheels is a popular vehicle upgrade. However, owners often overlook the need for new hardware. Factory and aftermarket wheels are not always interchangeable. An aftermarket wheel may require different bolts for a safe fit.

Key differences to check include:

- Seat Type: A new wheel may use a cone seat, while the factory wheel used a ball seat. The bolt seat must match the wheel.

- Bolt Length: Aftermarket wheels can have a thicker mounting pad, which requires longer bolts to achieve proper thread engagement in the hub.

- Bolt Pattern: The bolt pattern, or Pitch Circle Diameter (PCD), must match the vehicle’s hub. A

5x114.3pattern means the wheel has 5 holes on a 114.3mm circle.

Using the original bolts on a new wheel without confirming these specifications is a serious safety risk.

The Risk of Using Anti-Seize on Threads

Some people apply anti-seize compound to bolt threads to prevent rust. This is a dangerous mistake for bolts on wheels. Torque specifications from manufacturers are for clean, dry threads. Anti-seize is a lubricant that dramatically reduces friction.

Approximately 90% of the torque applied to a bolt overcomes friction. Only 10% creates the clamping force.

When a lubricant is present, the same amount of torque creates a much higher clamping force. This over-tightens the bolt, stretching it beyond its design limits. This can lead to stripped threads, a damaged wheel, or bolt failure while driving. Always install wheel bolts dry unless the vehicle manufacturer explicitly states otherwise. There are different types of fasteners, but this rule applies broadly.

Securing a vehicle’s wheel is a critical safety task. Car owners must select the correct parts for a safe installation. Following a few key rules ensures every wheel is attached properly.

- Always match the bolt’s seat type (cone, ball, or flat) to the wheel design.

- Confirm all wheel bolt specifications, including the thread size, pitch, and length.

- Use a calibrated torque wrench to tighten bolts to the manufacturer’s value.

- Consult a professional mechanic for guidance when in doubt.

FAQ

Can a car owner reuse old wheel bolts?

Experts generally advise against reusing wheel bolts, especially torque-to-yield types. These bolts can stretch during their first installation. Reusing them compromises their strength and clamping force. For maximum safety, a car owner should always install new bolts when replacing critical components.

What happens if someone loses their locking bolt key?

Losing the key prevents wheel removal. The owner can contact the locking bolt manufacturer with the key’s code, often found in the original packaging. A professional mechanic also has special tools that can remove locking bolts without the key, though this may damage the bolt.

How often should a person check wheel bolt torque?

A torque re-check is a critical safety step. A car owner must check the torque after driving 50 to 100 miles on newly installed wheels. This allows the hardware to settle. Periodic checks during tire rotations also ensure long-term safety.

💡 Tip: Seasonal temperature shifts can affect bolt tension. Checking torque when swapping between summer and winter tires is a good practice.

Do titanium bolts really make a car faster?

Titanium bolts reduce a car’s unsprung weight. This is the mass not supported by the suspension. Lighter wheels can slightly improve acceleration, braking, and handling response. While the effect is small for daily driving, performance enthusiasts value every advantage on the track.