admin1

October 18, 2025

Never Ignore Your Wheels Again With These Long Lug Nuts

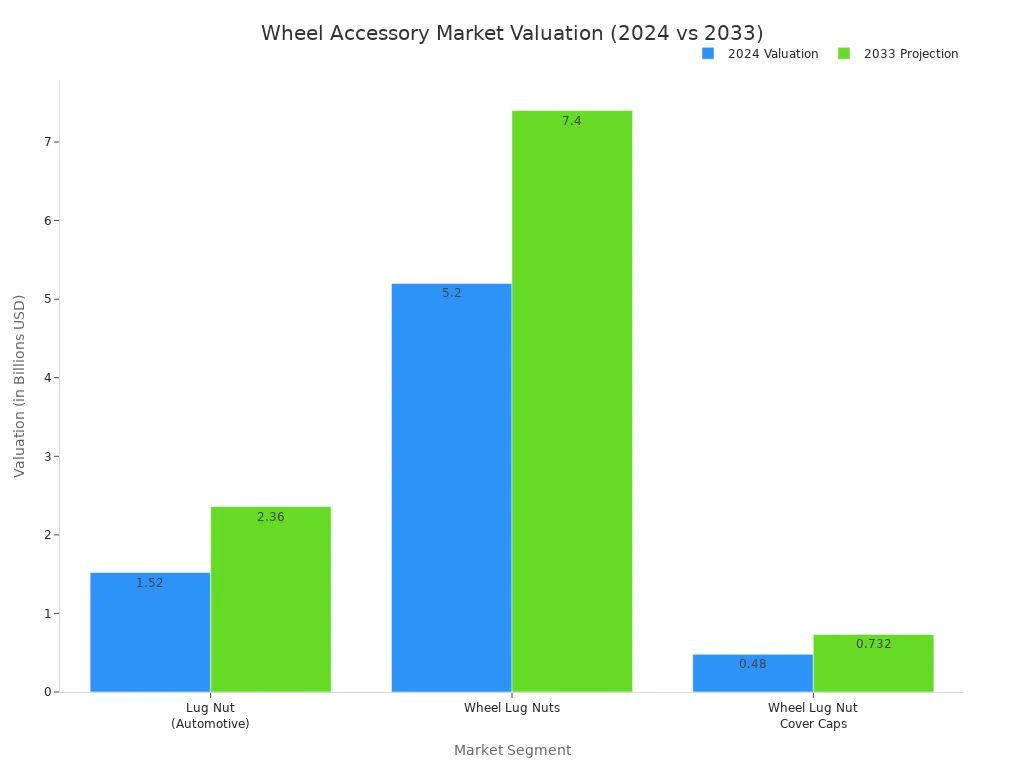

Choosing the right wheel hardware is more important than ever. The market for wheel accessories is growing fast, driven by a focus on safety and vehicle customization.

| Market Segment | 2024 Valuation (USD) | 2033 Projection (USD) | CAGR (2025-2033) |

|---|---|---|---|

| Wheel Lug Nuts | 5.2 billion | 7.4 billion | 4.1% |

For most drivers, the best overall long lug nuts are the Muteki SR48. They deliver an ideal balance of forged steel strength for security, a precise fit for aftermarket wheels, and a sleek look. Other excellent choices include the Project Kics R40 Iconix for racing and McGard Tough Nuts for durability.

Why Long Lug Nuts Are a Smart Upgrade

Upgrading your vehicle’s hardware might seem small, but it makes a big difference in safety and performance. Long lug nuts offer clear advantages over standard-sized ones. They provide a more secure connection and improve your car’s overall reliability. Let’s explore why this upgrade is a smart choice for any driver.

Improved Thread Engagement

Proper thread engagement is critical for keeping your wheels attached to your car. It refers to how many threads on the lug nut connect with the threads on the wheel stud. A longer nut allows for more threads to make contact. This creates a much stronger and more secure hold.

Think of it this way: Screwing a bottle cap on with just one turn is risky. Screwing it on with several full turns makes it secure. More thread engagement on your lug nuts works the same way, giving you peace of mind on the road.

This is especially important if you use aftermarket wheels or wheel spacers. These parts are often thicker than factory equipment, leaving fewer threads available for a standard nut.

Enhanced Heat Dissipation

Your brakes generate intense heat during use. This heat transfers from the brake rotors to the wheel hub, studs, and lug nuts. Overheating can cause metal parts to expand and, in extreme cases, fail.

Longer lug nuts have more surface area than shorter ones. This increased area helps them release heat into the surrounding air more effectively.

- Benefit: Better heat dissipation keeps the wheel studs cooler.

- Result: This reduces the risk of the studs stretching or weakening under high-stress conditions like track days or spirited driving.

Easier and Safer Wheel Swaps

Working on your car should be as simple and safe as possible. The extra length of these nuts makes them easier to handle and install. You can easily start threading them by hand, which is the best way to prevent cross-threading. Cross-threading damages both the nut and the stud, leading to costly repairs.

| Task | Standard Lug Nut | Long Lug Nut |

|---|---|---|

| Handling | Can be clumsy | Easy to grip |

| Starting Thread | Harder to align | Simple to start by hand |

| Tool Access | Can be tight | Easy to access with a wrench |

The added length also gives your lug wrench more clearance from the wheel face. This helps you avoid scratching your expensive rims while tightening or loosening the nuts.

The Best Long Lug Nuts for 2024

Finding the right lug nuts can feel overwhelming with so many options available. We have analyzed the top products on the market to help you make a confident choice. This guide breaks down the best options based on your specific needs, from daily driving to competitive racing.

Best Overall: Muteki SR48

The Muteki SR48 lug nuts earn our top spot as the best overall choice for most drivers. They provide an excellent combination of strength, appearance, and value. You get high-end features without the premium price tag. These nuts are perfect for daily drivers and enthusiasts who use aftermarket wheels.

Their construction from cold-forged 50BV30 steel makes them incredibly strong and durable. The open-ended design is a key feature. It works with standard factory studs and longer aftermarket studs, giving you flexibility for future upgrades.

Drivers who use the Muteki SR48s often praise their lasting quality. Many reviews highlight how the color and finish hold up over time, unlike cheaper alternatives. Users report they look and feel like a high-quality product, offering great value and preventing common issues like corrosion or cross-threading. They are seen as a crucial and durable upgrade for any aftermarket wheel setup.

| Feature | Benefit for You |

|---|---|

| Forged Steel | Provides superior strength and security for your wheels. |

| Open-End Design | Fits both standard and extended wheel studs. |

| 60-Degree Seat | Ensures a perfect fit for most aftermarket wheels. |

| Multiple Colors | Lets you customize your car’s look. |

Best for Racing: Project Kics R40 Iconix

When every second and every ounce matters, you need hardware built for the track. The Project Kics R40 Iconix are the ultimate choice for racing and high-performance applications. These long lug nuts are engineered with advanced features to handle extreme conditions.

The R40 Iconix uses a special two-piece design. The main body secures the wheel, while a rotating seat makes contact with the wheel face. This clever design allows for a more accurate torque setting and prevents scratches on your expensive rims during installation.

Here is what makes them ideal for the track:

- Superb Material: They are made from forged SCM435 Chromium Molybdenum. This material offers incredible strength to resist the stresses of racing.

- Lightweight Construction: The entire set weighs less than two pounds. Reducing unsprung weight helps improve your car’s handling and acceleration.

- Smart Design: The two-piece construction ensures a precise hold, and the open end fits extended race studs.

- Durable: You can use an impact gun on them, which saves valuable time in the pits.

Best Budget-Friendly: 1320 Performance Steel Nuts

Upgrading your wheel hardware does not have to be expensive. The 1320 Performance Steel Nuts offer a safe and reliable option for drivers on a budget. They deliver the most important safety benefit of an upgrade—proper thread engagement—at a very accessible price.

These nuts are a no-frills, function-first choice.

- They are made from steel for dependable strength.

- They feature the standard 60-degree conical seat for aftermarket wheels.

- Their extended length makes them easy to install by hand, reducing the risk of thread damage.

If you just installed new aftermarket wheels and need a safe, affordable hardware solution, these nuts are an excellent choice. They provide peace of mind without straining your wallet.

Most Durable: McGard Tough Nuts

When your top priority is long-term reliability, you need hardware that can withstand anything. McGard Tough Nuts are the ultimate choice for durability. They are engineered to resist rust, corrosion, and wear better than almost any other nut on the market. This makes them perfect if you live in areas with harsh winters or simply want a set-it-and-forget-it solution.

McGard’s incredible durability comes from a precise and advanced manufacturing process. They do not cut corners. Every aspect of their design focuses on strength and longevity.

- Through-Hardened Steel: Each nut is hardened all the way through. This is different from cheaper nuts that are only hardened on the surface. This deep hardness provides unmatched safety and strength.

- Specialized Steel: McGard uses a specific type of steel made just for them. This “restricted chemistry” steel ensures every nut has the same high level of structural integrity.

- Triple-Nickel Chrome Plating: A unique plating process creates a powerful shield against the elements. It involves three layers of nickel for corrosion resistance and shine, plus a final layer of microporous chrome to fight rust.

This multi-layer plating is proven to work. McGard uses a tough corrosion test called CASS to simulate years of exposure to bad weather. Their lug nuts pass these tests with flying colors, proving they will look great and stay rust-free for years.

If you need a set of long lug nuts that you can install with total confidence, McGard is the answer. They are built to last the life of your vehicle, protecting your investment and keeping your wheels secure no matter the conditions. You can find warranty information directly on the McGard website.

Understanding Long Lug Nut Materials

The material of your lug nuts directly impacts their strength, weight, and lifespan. Choosing the right one is key to getting the performance and safety you need. You have three main options: forged steel, lightweight aluminum, and premium titanium.

Forged Steel

Forged steel is the most popular and trusted material for lug nuts. The forging process compresses the steel, creating an incredibly dense and strong part. This method removes tiny internal flaws that can weaken other types of metal.

Forged steel offers you superior safety and durability. Its continuous internal grain structure makes it much stronger than cast metal parts.

Here is why forged steel is a top choice:

- Exceptional Strength: Forging creates a uniform structure that resists impact and stress extremely well.

- Increased Durability: The dense metal can handle over-tightening and frequent use without failing.

- Proven Safety: Studies show forged parts withstand impacts that can cause cast parts to break.

Lightweight Aluminum

Aluminum lug nuts attract drivers because they are very light. Reducing weight on your wheels can slightly improve handling. However, you must understand the significant risks associated with this material. Aluminum is much softer than steel.

This softness creates serious problems:

- The threads can easily strip or gall, especially after you remove and install them a few times.

- Using an aluminum nut on a steel stud can cause corrosion, which weakens the connection.

- The metal can expand and contract with heat, potentially causing the nuts to loosen while you drive.

For daily driving, the small weight savings do not justify the safety risks.

Premium Titanium

Titanium is the ultimate material for lug nuts. It combines the best qualities of steel and aluminum. You get incredible strength with very low weight.

Titanium offers a fantastic strength-to-weight ratio. It is about 50% lighter than steel but often exceeds its strength. This makes it perfect for high-performance and racing applications. Titanium is also extremely resistant to rust and corrosion. Your lug nuts will maintain their integrity and appearance even in harsh winter weather or coastal areas. The only downside is the cost, as titanium is significantly more expensive than steel or aluminum.

How to Choose the Right Long Lug Nuts

Choosing the correct hardware is simple when you follow a few key steps. You need to match the lug nuts to your car’s specifications and your driving style. This ensures a perfect fit for maximum safety and performance.

Step 1: Identify Your Thread Pitch

Your vehicle’s wheel studs have a specific thread size, called thread pitch. Your new lug nuts must match this size exactly. An incorrect thread pitch will damage the studs and prevent a secure fit. You can find your car’s thread pitch in several ways:

- Check your vehicle owner’s manual.

- Use a thread pitch gauge to measure the studs.

- Take an old lug nut to a hardware store for comparison.

- Search for your car’s specifications in online guides.

Thread pitch varies between manufacturers. The table below shows some examples.

| Make | Model | Thread Pitch |

|---|---|---|

| Honda | All Manual | 10mm x 1.50 |

| Ford | Mustang Boss 302 | 12mm x 1.25 |

| BMW | All Manual | Non-Threaded Adapter |

Step 2: Determine the Correct Seat Type

The “seat” is the part of the lug nut that touches the wheel. This contact point is very important for safety. Most aftermarket wheels use a conical seat, which has a tapered 60-degree cone shape. Factory wheels often use a ball seat with a rounded end or a mag seat with a flat washer. You must match the nut’s seat to the wheel’s lug hole.

Using the wrong seat type is a common cause of loose lug nuts. A mismatch can lead to the wheel shifting, snapping the studs, and even complete wheel separation. This creates an extremely dangerous situation on the road.

Step 3: Match Material to Your Driving Needs

The right material depends on how you use your vehicle. Your choice balances strength, weight, and cost. For most people, forged steel is the best option. For competitive racers, titanium offers unique advantages. The table below helps you decide.

| Use Case | Steel Lug Nuts | Titanium Lug Nuts |

|---|---|---|

| Best For | Daily Commuting | Competitive Racing |

| Strength | High durability for everyday use | High strength at a lower weight |

| Weight | Heavier | Much lighter for better performance |

| Corrosion | Excellent resistance | Extraordinary resistance |

This simple guide helps you select the perfect hardware for your car.

Proper Installation for Maximum Safety

Installing your lug nuts correctly is the most important step for wheel safety. Proper installation prevents wheels from loosening and protects your hardware from damage. You can do this job yourself with the right tools and a careful approach.

Essential Tools for the Job

Having the correct tools makes the installation process safe and easy. You do not need many tools, but each one has an important role.

- Torque Wrench: This is the most critical tool. It allows you to tighten the nuts to the exact specification.

- Socket Set: You need the correct size socket to fit your new lug nuts.

- Jack and Jack Stands: These are essential for safely lifting your vehicle and keeping it secure while you work.

Step-by-Step Installation Guide

Follow these steps carefully to ensure your wheels are secure. Always work on a flat, level surface.

- Start by Hand: Screw each lug nut onto the wheel stud by hand. This prevents cross-threading, which can ruin both the nut and the stud.

- Snug the Nuts: Use a wrench to gently tighten the nuts in a star pattern. This helps the wheel sit evenly against the hub. Do not apply full force yet.

- Lower and Torque: Lower the vehicle so the tire is firmly on the ground. Now, use your torque wrench to tighten each nut to the manufacturer’s recommended specification. Always follow the star pattern.

- Re-Check Your Work: Drive for about 50 to 100 miles. Then, re-torque the lug nuts to ensure they are still tight.

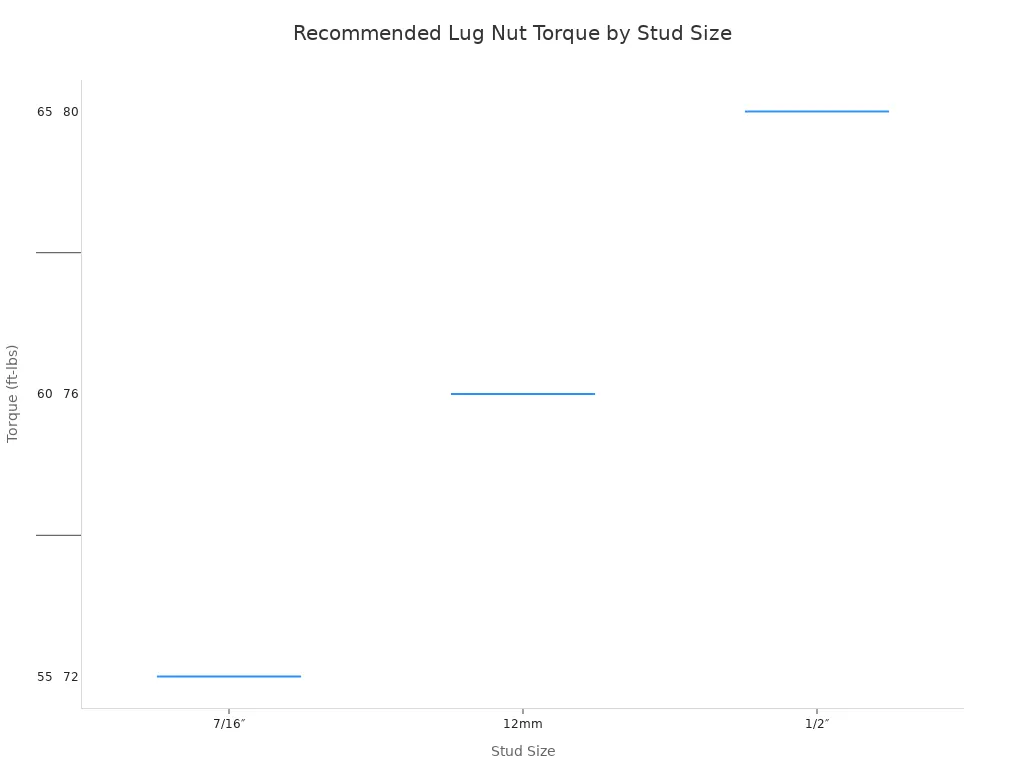

Your vehicle’s owner’s manual has the correct torque value. If you cannot find it, you can use this general guide based on your wheel stud size.

| Stud Size | Torque Spec (ft.-lbs.) |

|---|---|

| 12mm | 72 to 80 |

| 14mm | 85 to 95 |

| 7/16″ | 55 to 65 |

| 1/2″ | 75 to 85 |

Safety Tip: Always use torque specifications on clean, dry threads. Do not put oil or lubricant on the studs. This can cause you to over-tighten the nuts and damage the hardware.

Upgrading your hardware is a critical investment. You improve your vehicle’s safety, performance, and appearance. High-quality long lug nuts provide a secure connection for your wheels.

The Muteki SR48 stands out as the best all-around choice. It offers exceptional strength, reliability, and value. This makes it ideal for daily drivers and car enthusiasts.

Secure your wheels with confidence. Choose the right long lug nuts for your vehicle today. Your safety on the road depends on it.

FAQ

### Can I use an impact wrench on my new lug nuts?

You should only use an impact wrench to snug the nuts lightly. For final tightening, you must use a torque wrench. This ensures you apply the correct force and prevents damage to the studs, nuts, and wheels.

### Why are my new long lug nuts rusting?

Rust often points to low-quality steel or poor protective plating. Premium nuts use advanced coatings to prevent this. For example, McGard uses a special triple-nickel chrome plating process. This guarantees long-term corrosion resistance and keeps your wheels looking great.

### Do I need a wheel alignment after changing lug nuts?

No, you do not need an alignment. Changing your lug nuts does not affect your vehicle’s suspension angles. You only need to ensure the wheels are torqued correctly to the hub for safety.

### What happens if I use the wrong seat type?

Using the wrong seat type is extremely dangerous. The nut will not make proper contact with the wheel. This mismatch can cause the lug nuts to loosen while you drive, potentially leading to wheel damage or separation.