admin1

October 28, 2025

Secure Your Ride with These Top Wheel Lug Bolts

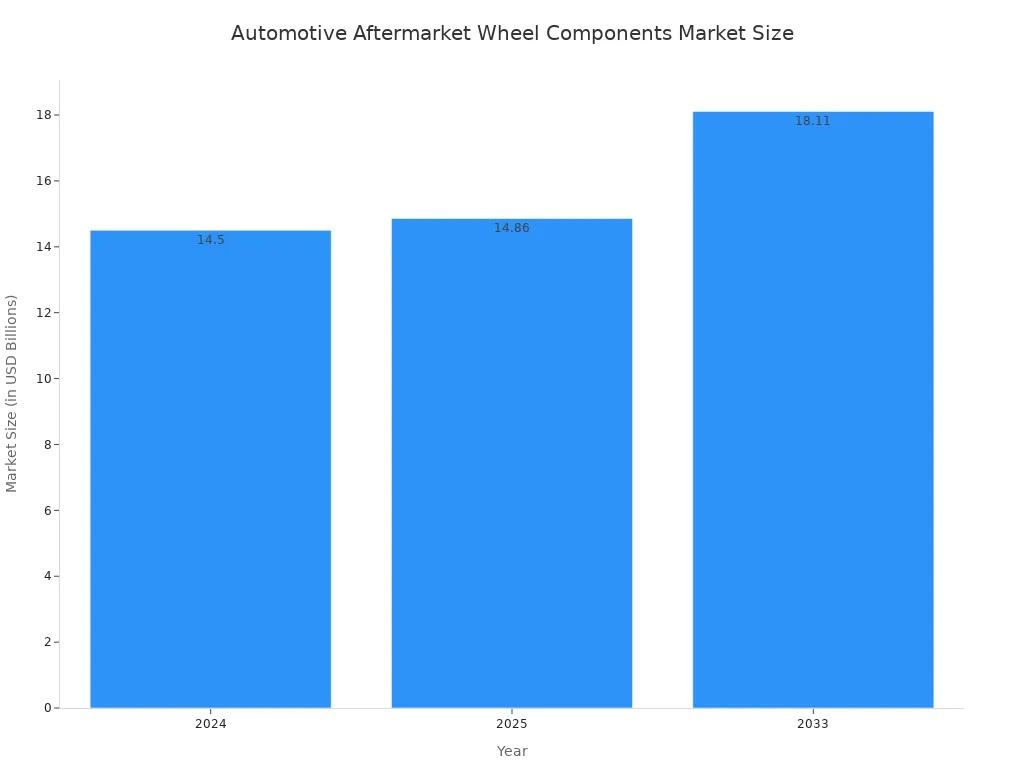

You are part of a massive and growing market. The wheels & tires segment held the largest share of the automotive aftermarket industry in 2024. This industry shows significant projected growth.

Upgrading your wheel lug bolts is a critical safety and performance decision. Here is our lug nuts brand recommendation list to guide your choice.

- ARP Extended Wheel Studs: Best for Overall Strength and Racing Applications.

- Project Kics Monolith T1/06: Best Titanium Option for Weight Reduction.

- MSI Racing Lug Bolts: Top Choice for Professional Motorsport.

- H&R Trak+ Wheel Bolts: Best for European Vehicle Fitment.

- Gorilla Automotive Acorn Lug Bolts: Best Value for Daily Performance.

- Hinuos (Fortune Auto Parts) Lug Bolts: Best for OEM+ Quality and Reliability.

- Bimecc Lug Bolts: Excellent for Corrosion Resistance.

- ACER Racing Titanium Lug Bolts: High-End Aesthetics and Performance.

- World Motorsports TiKORE Titanium Bolts: Best for Custom and Exotic Applications.

- Otis Inc LA European Lug Bolts: Superior Anti-Corrosion Coating.

How We Selected the Best Lug Bolts

Choosing the right hardware for your wheels is a serious decision. Your safety depends on it. We analyzed several key factors to identify the top performers. This guide explains our selection criteria, helping you make an informed choice for your vehicle.

Material Strength and Durability

The strength of your wheel lug bolts is the most critical safety factor. Bolts must withstand immense forces during acceleration, braking, and cornering. We looked at tensile strength, which measures the force required to pull a material apart. Standard OEM bolts typically offer a tensile strength between 120,000 and 150,000 psi. High-performance aftermarket lug nuts, however, use superior materials. For example, 8740 chrome moly steel can be heat-treated to deliver a tensile strength in the 180,000 to 200,000 psi range, offering a significant safety margin.

| Material | Tensile Strength |

|---|---|

| Grade 5 | 120,000 psi |

| 8740 Chrome Moly | 190,000 psi |

| Titanium | 180,000 psi |

Corrosion and Heat Resistance

Your vehicle’s bolts face a constant battle with the elements. Road salt, moisture, and heat can cause corrosion and weaken the metal over time. We prioritized bolts with excellent protective coatings. Manufacturers test these coatings using standardized salt spray tests, such as ASTM B117 and ISO 9227, to simulate harsh conditions. The best brands prove their durability through these rigorous evaluations.

Pro Tip: A quality coating not only prevents rust but also ensures that torque specifications remain accurate over the bolt’s lifespan, preventing loosening or seizing.

Seat Type Compatibility

You must match the bolt’s seat to your wheel’s seat. Using the wrong type creates a dangerous and improper fit. The seat is the area where the bolt makes contact with the wheel. The three main styles are cone (tapered), ball (radius), and mag (shank).

| Lug Type | Shape | Common Use |

|---|---|---|

| Ball (Radius) | Rounded or spherical seat | European vehicles (Audi, VW) and Honda |

| Lug Bolts | Bolt and nut combined | European vehicles (BMW, Mercedes) |

Always verify the correct seat type for your specific wheels. An incorrect match can lead to wheel vibration or, in the worst-case scenario, wheel detachment.

Weight and Rotational Mass

You might not think about the weight of your lug bolts. However, their mass plays a significant role in your car’s performance. Lug bolts are part of the “unsprung mass.” This term refers to any component not supported by your vehicle’s suspension, including your wheels, tires, and brakes. Reducing this weight offers major advantages.

A lighter unsprung mass helps your suspension do its job. It lessens the work required to absorb bumps and imperfections in the road. This allows your suspension to keep the tires in better contact with the pavement. You gain superior traction, which results in sharper handling and increased stability during turns. Your car feels more connected to the road.

Performance materials like titanium make a noticeable difference. A full set of titanium lug nuts can decrease your vehicle’s total unsprung mass by approximately 2-3 kilograms. This reduction directly improves your acceleration and makes the suspension system more responsive. Titanium offers an incredible strength-to-weight ratio compared to traditional steel. Other options, like high-grade lightweight aluminum, also provide weight savings for specific applications.

Lighter wheels are easier to spin and easier to stop. Reducing rotational mass gives you quicker acceleration and more responsive braking, making your car feel more agile.

Ultimately, choosing lighter bolts enhances your vehicle’s overall dynamics. You will notice better handling and quicker acceleration. This simple upgrade even contributes to better fuel efficiency because the engine works less to rotate the wheels. Every gram counts when you want to maximize performance.

In-Depth Reviews: Top 10 High-Performance Wheel Lug Bolts

Choosing the right hardware is one of the most important upgrades you can make for your vehicle’s safety and performance. Below, we dive into the specifics of our top-rated options. You will find detailed information to help you select the perfect set for your needs, from daily driving to professional racing.

1. ARP Extended Wheel Studs

When you demand the absolute best in strength and reliability, you turn to ARP. The company is a legend in the racing world for a reason. Their products are engineered for extreme conditions where failure is not an option.

ARP’s heat-treated 8740 chrome moly wheel studs are a prime example of this commitment. These studs are certified to have a massive tensile strength of 190,000 psi. This provides a huge safety margin over factory hardware. You can push your car on the track with confidence. The trust in their quality is so high that professional NASCAR Cup teams employ ARP ‘Speed Studs’ on their race cars.

Key Features:

- Unmatched Strength: Made from premium 8740 chrome moly steel for superior durability.

- Racing Pedigree: Trusted and used by top-tier motorsport teams worldwide.

- Precision Engineering: Feature thread-rolling after heat treatment, which makes them much stronger than studs with cut threads.

Who is this for? 🏎️

You should choose ARP if you are a serious track day enthusiast, a competitive racer, or simply want the strongest possible connection between your wheels and your car.

2. Project Kics Monolith T1/06

Project Kics offers a brilliant combination of Japanese engineering, lightweight design, and security. The Monolith T1/06 lug nuts are a fantastic choice if you want to reduce unsprung weight without compromising strength.

These lug nuts feature a unique two-piece construction. A durable SCM435 chromoly steel body provides the necessary strength for secure clamping. A free-spinning A7075-T6 aluminum seat protects your expensive aftermarket wheels from scratches during installation. This thoughtful design also ensures more accurate torque readings. The “Monolith” name comes from the single-piece appearance when the inner lug nut is installed, giving your wheels a clean, sleek look.

Key Features:

- Lightweight Design: Reduces rotational mass for improved handling and acceleration.

- Two-Piece Construction: A steel body for strength and an aluminum seat to protect wheels.

- Enhanced Security: The internal-drive design acts as a built-in wheel lock, making theft more difficult.

Note: The T1/06 model uses a special adapter for installation and removal. You should always keep this adapter in your vehicle for emergencies.

3. MSI Racing Lug Bolts

MSI (Motor Sport Industries) is a name you will hear in professional racing paddocks around the globe. They produce hardware for teams in IMSA, WEC, and other premier series. Their wheel lug bolts are built for one purpose: to perform flawlessly under the most intense racing conditions.

MSI engineers its products with incredible attention to detail. For example, their 12mm wheel studs receive a ‘CT10’ dry film lubricant coating. This special treatment helps you achieve proper tension with less torque and prevents the threads from galling or seizing. MSI also applies a durable Manganese phosphate coating to its gray lug nuts. For even more robustness, they use a proprietary Teflon-based material to coat their black and yellow lug nuts. These coatings ensure consistent performance and durability lap after lap.

Key Features:

- Professional Grade: Designed for and used by professional motorsport teams.

- Advanced Coatings: Specialized treatments prevent seizing and ensure accurate torque.

- Extreme Durability: Built to withstand rapid pit stops and high-stress racing environments.

Who is this for? 🏆

You need MSI hardware if you are involved in competitive, wheel-to-wheel racing where pit stop speed and absolute reliability are critical to winning.

4. H&R Trak+ Wheel Bolts

You probably know H&R for their world-class suspension components and wheel spacers. The German company applies that same precision engineering to their Trak+ Wheel Bolts. These bolts are the perfect companions for European vehicles, especially if you are already using H&R’s famous Trak+ wheel spacers.

H&R manufactures all its products in Germany. They operate under strict ISO 9001 quality assurance standards. The company earned its reputation by getting its products, like wheel spacers, certified by the demanding German TÜV. This commitment to quality ensures you get a product designed for perfect fitment and long-term durability. They are available in various lengths, so you can get the exact size you need for your specific wheel and spacer combination.

Who is this for? 🇩🇪

You should choose H&R bolts if you own a European vehicle like a BMW, Mercedes-Benz, or Audi. They are an essential choice when you add wheel spacers to achieve that perfect wheel fitment.

5. Gorilla Automotive Acorn Lug Bolts

Gorilla Automotive offers you one of the best values in the aftermarket. Their Acorn lug bolts provide a significant upgrade over stock hardware without breaking the bank. They are a popular choice for daily drivers and enthusiasts who want a reliable and good-looking product.

Gorilla builds these bolts to last. They feature a hardened steel construction for strength. A triple chrome plating process gives them a brilliant shine and protects them from rust and corrosion. This attention to detail ensures they look great behind your wheels for years. Gorilla Automotive also backs its products with a one-year warranty from the delivery date, giving you confidence in your purchase.

Key Features:

- Excellent Value: A high-quality upgrade at an affordable price point.

- Durable Finish: Triple chrome plating resists corrosion and looks fantastic.

- Wide Application: Available in numerous thread pitches and sizes to fit most vehicles.

Note: Gorilla Automotive is a great starting point if you are new to upgrading your car. You get a dependable product from a trusted brand.

6. Hinuos (Fortune Auto Parts) Lug Bolts

You want hardware that you can install and forget about. Hinuos delivers exactly that with its focus on OEM+ quality and absolute reliability. Operating since 1996, Hinuos (a brand of Fortune Auto Parts) has built a global reputation for manufacturing top-tier components for well-known automotive companies and the aftermarket.

Hinuos adheres to a simple but powerful principle: “customer first, quality first.” This philosophy drives their entire manufacturing process. The company is ISO9001 certified and never uses inferior materials in its products. Their engineering team uses advanced equipment and strict quality control at every stage. In fact, they perform a 100% inspection on their products before they are shipped. This guarantees that the bolts you receive meet the highest standards for safety and performance.

Who is this for? ⚙️

You should select Hinuos bolts if you demand quality that meets or exceeds original factory specifications. They are the ideal choice for a reliable, long-lasting, and safe connection for your daily driver or performance-oriented street car.

7. Bimecc Lug Bolts

You can trust a company that leading car manufacturers trust. Bimecc is an Italian manufacturer with a global reputation for producing high-quality wheel hardware. They are a major supplier to the OEM market. In fact, you will find Bimecc bolts installed from the factory on new vehicles from brands like BMW and MINI. This shows their commitment to meeting strict automotive standards.

Bimecc specializes in creating bolts with exceptional corrosion resistance. Their proprietary coatings are designed to withstand harsh road conditions, including salt and moisture. This focus on durability ensures your bolts will not rust or seize, making wheel changes easier and safer over the life of your car. They offer a huge catalog of bolts, so you can find the perfect fit for almost any vehicle.

Who is this for? 🇮🇹

You should choose Bimecc if you need a reliable, high-quality replacement that meets or exceeds factory specifications. They are an excellent choice for European car owners who value long-lasting corrosion protection.

8. ACER Racing Titanium Lug Bolts

You want an upgrade that looks as good as it performs. ACER Racing delivers on both fronts with their stunning titanium lug bolts. These bolts are crafted for enthusiasts who appreciate fine details and want to reduce the unsprung weight of their vehicle.

ACER Racing uses aerospace-grade 6AL4V Titanium for its bolts. This premium material has a tensile strength of 1000 MPa (145,000 psi), providing excellent strength for street performance use. Titanium is also naturally resistant to rust and corrosion, so your bolts will maintain their integrity and appearance. A key benefit is the significant weight savings. A set of ACER Racing titanium bolts can be up to 50% lighter than steel bolts, which helps improve your car’s handling and acceleration.

You can choose a finish that perfectly matches your style:

- Natural Finish: This option shows off the raw, beautiful look of the machined titanium. It provides a clean and technical appearance.

- BLACK PVD Titanium: This deep black finish uses a Physical Vapor Deposition (PVD) process. This method is far more durable than paint or powder coating and is the same type of finish you find on high-end luxury watches.

Who is this for? 💎

You should select ACER Racing bolts if you want to combine lightweight performance with high-end aesthetics. They are perfect for show cars and performance street cars where every detail matters.

9. World Motorsports TiKORE Titanium Bolts

You own a special vehicle, and it deserves specialized hardware. World Motorsports TiKORE is the premier choice for custom and exotic applications. They engineer and manufacture bespoke titanium lug bolts for some of the world’s most exclusive cars. When an off-the-shelf solution is not good enough, you turn to TiKORE.

TiKORE’s expertise lies in creating hardware for unique fitments. Whether you have custom wheels or a high-performance exotic, they can produce bolts to your exact specifications. They use certified aerospace-grade titanium to ensure the highest level of quality and strength. Their client list demonstrates their standing in the high-performance world. You will find TiKORE bolts on vehicles such as:

- Porsche 911, 997.1 Turbo, and 991 models

- BMW F80 M3 performance sedans

- High-performance EVs like the Tesla P85+

Their two-piece lug bolt design, featuring a separate shank and seat, is another mark of quality. This design prevents the bolt from scratching your valuable wheels during installation and ensures a more accurate and secure fit.

Who is this for? 🏎️💨

You need TiKORE bolts if you own a high-end exotic or have a custom wheel setup that requires a non-standard bolt length. They are for the owner who accepts no compromises on safety, performance, or quality.

10. Otis Inc LA European Lug Bolts

You need wheel bolts that can survive the harshest conditions. Otis Inc LA specializes in creating hardware with some of the best corrosion protection available. They are a leading OEM supplier for many European car manufacturers. This means their bolts meet the same strict quality and durability standards as the ones that came on your car from the factory.

The key advantage of Otis Inc LA bolts is their advanced coating technology. Many of their bolts feature a Dacromet coating. This is not a simple paint or chrome plate. Dacromet is a water-based coating containing zinc and aluminum flakes. The application process involves multiple layers and a special heat-curing process. This creates a thin, hard, and incredibly durable barrier against rust and corrosion.

- Superior Protection: The Dacromet coating provides over 500 hours of salt spray resistance, far exceeding the performance of standard zinc plating.

- Consistent Torque: The coating has a built-in lubricant. This ensures you get accurate torque readings during installation and prevents the bolts from seizing to your wheel hub over time.

- OEM Quality: As an original equipment supplier, their products are engineered for a perfect fit and long-term reliability on European vehicles.

Who is this for? 🛡️

You should choose Otis Inc LA bolts if you live in an area with harsh winters where roads are heavily salted. They are the ultimate choice for any European car owner who demands maximum corrosion resistance and OEM-level quality for long-lasting safety.

Essential Guide to Choosing and Installing Your Bolts

You have chosen your new bolts. Now you must install them correctly. Proper installation is just as important as the quality of the hardware itself. This guide will walk you through the essential steps for a safe and secure fit.

Measuring for Correct Thread and Length

You must use bolts with the correct thread pitch and length. An incorrect fit can lead to serious problems. Bolts that are too long can cause significant damage.

- Long bolts can hit your car’s e-brake parts inside the wheel hub.

- They might also rub against other internal components as the wheel spins.

- The ends can get damaged, which strips the threads in your hub when you try to remove them.

You can use a thread checker to easily find your bolt’s size. These tools help you identify the exact measurements you need.

- JoblikeBrez Thread Checker: A wall-mountable tool with 30 gauges for standard and metric sizes.

- Manalete Thread Checker: A 49-piece set that also includes drill bit gauges.

- Nut and Bolt Thread Checker (55-piece): A comprehensive kit for identifying nearly any thread or screw size.

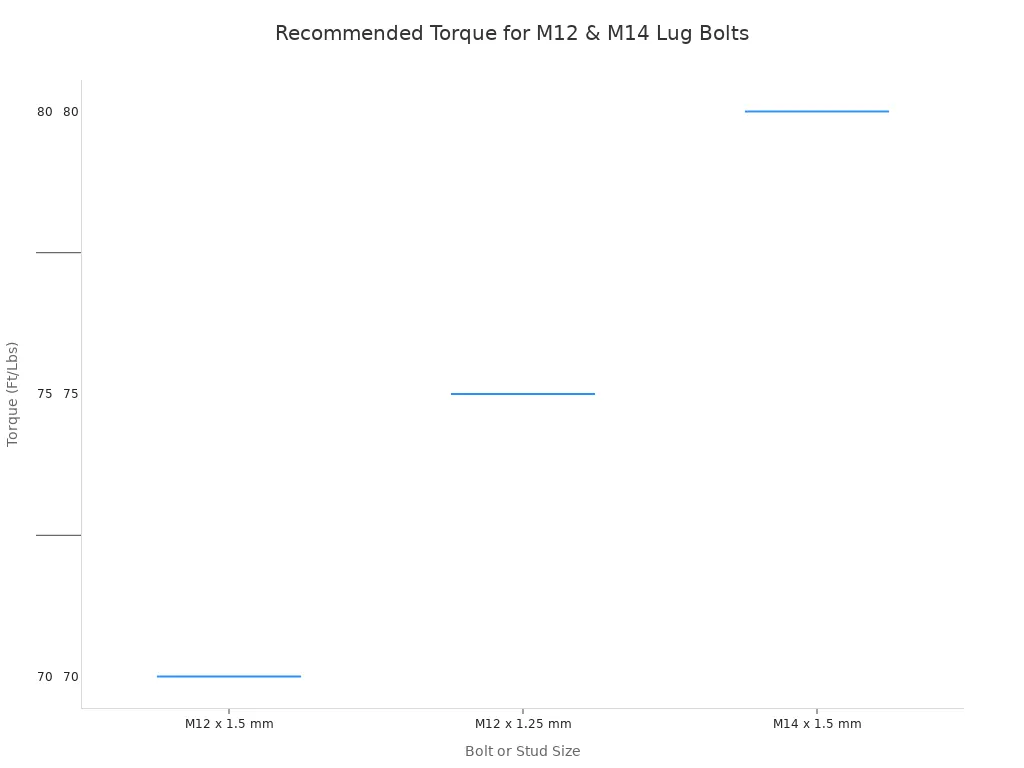

Proper Torque Specs and Installation

You need to tighten your bolts to the manufacturer’s specification. This is called “torque.” Using the right torque ensures your wheels are secure. Always use a torque wrench for this job. Below are typical torque ranges for common bolt sizes.

| Hardware Bolt or Stud Size | Typical Torque Range in Ft/Lbs |

|---|---|

| M12 x 1.5 mm | 70 – 80 |

| M12 x 1.25 mm | 70 – 80 |

| M14 x 1.5 mm | 85 – 90 |

| M14 x 1.25 mm | 85 – 90 |

Installation Tip: Tighten your bolts in a star pattern to ensure the wheel sits flat against the hub. Install any locking lug nuts last. Drive about 50 miles, then re-check the torque on all bolts.

Understanding Seat Types

The “seat” is where the bolt touches the wheel. You must match the bolt’s seat to the wheel’s seat. The most common types are cone (tapered), ball (rounded), and mag (flat with a shank). Using the wrong seat type creates a tiny contact point. This can cause the wheel lug bolts to loosen over time. It is a major safety risk. Always confirm the seat type for your specific wheels, especially when buying aftermarket lug nuts.

You now have the information to make a smart choice. Your selection depends on your specific needs.

- For Track Use: You should choose ARP or MSI for ultimate strength. 🏎️

- For Lightweight Value: You will find a great balance with Project Kics.

- For Daily Reliability: You can trust Hinuos and Gorilla for OEM-level quality. ⚙️

Your investment in high-quality wheel lug bolts is a critical safety decision for any vehicle. It ensures your wheels stay securely attached, giving you peace of mind on the road or track.

FAQ

Can you reuse old lug bolts?

You should inspect your old bolts carefully. Replace them if you see any signs of rust, thread damage, or stretching. Worn bolts can fail under stress. For maximum safety, especially with new wheels, you should always consider installing a fresh set of high-quality bolts.

What is the difference between lug bolts and lug nuts?

You can easily tell them apart. A lug bolt is a single piece of hardware with a threaded shaft that screws directly into your wheel hub. A lug nut is a fastener that threads onto a wheel stud, which is a post that sticks out from the hub.

Should you put anti-seize on lug bolts?

No, you should never apply anti-seize or any lubricant to the threads of your lug bolts. Lubricants reduce friction. This causes you to apply much more clamping force than intended when using a torque wrench. This can stretch the bolts or damage your wheel hub.

Important Safety Tip: Always install lug bolts clean and dry to ensure accurate torque readings.

How often should you check your lug bolt torque?

You must re-check the torque on your lug bolts after driving about 50 miles on a new set. After that initial check, you should inspect the torque during your vehicle’s regular maintenance, such as every tire rotation or oil change, to ensure they remain secure.